parking brake NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

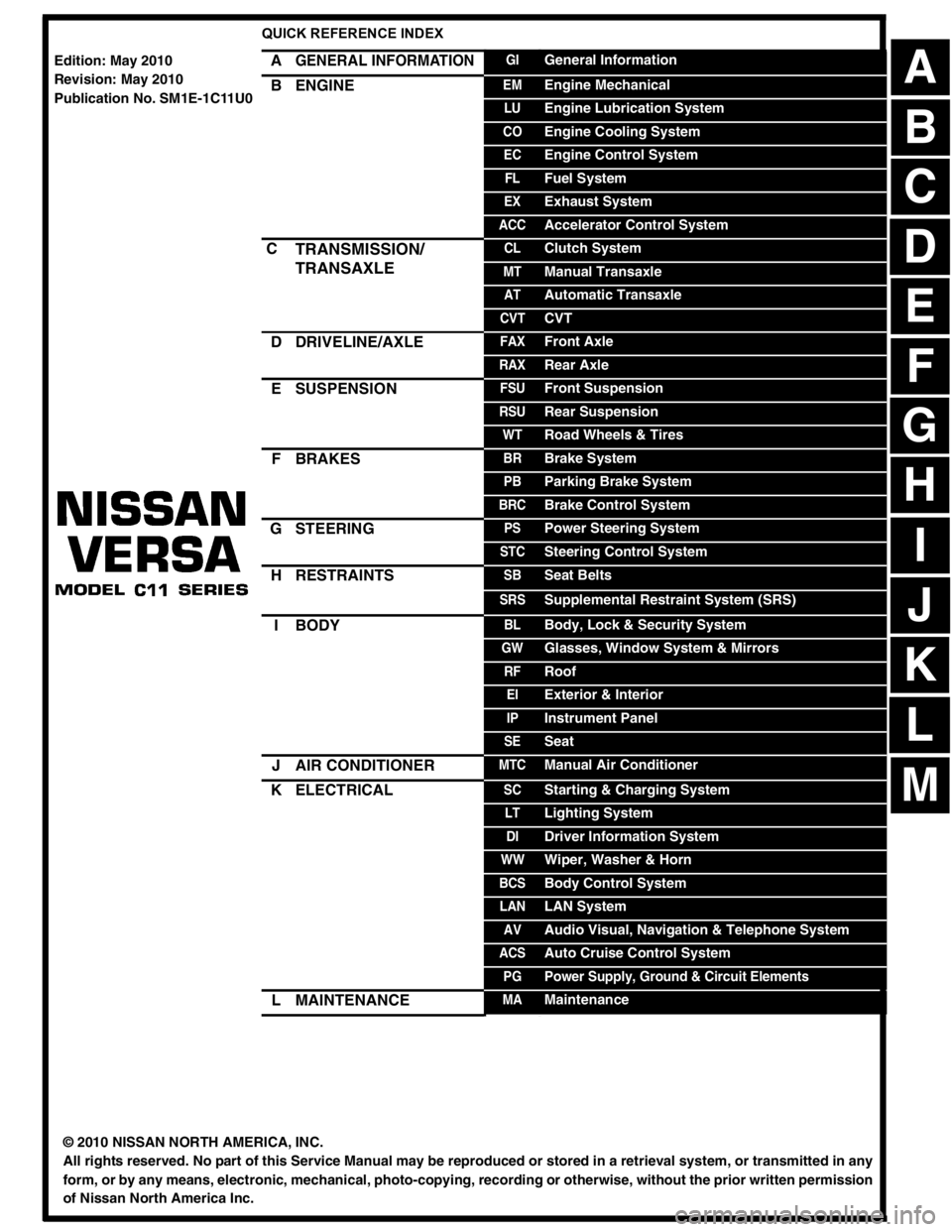

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 34 of 3787

A/T FLUIDAT-17

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

A/T FLUID

Checking A/T FluidINFOID:0000000005928070

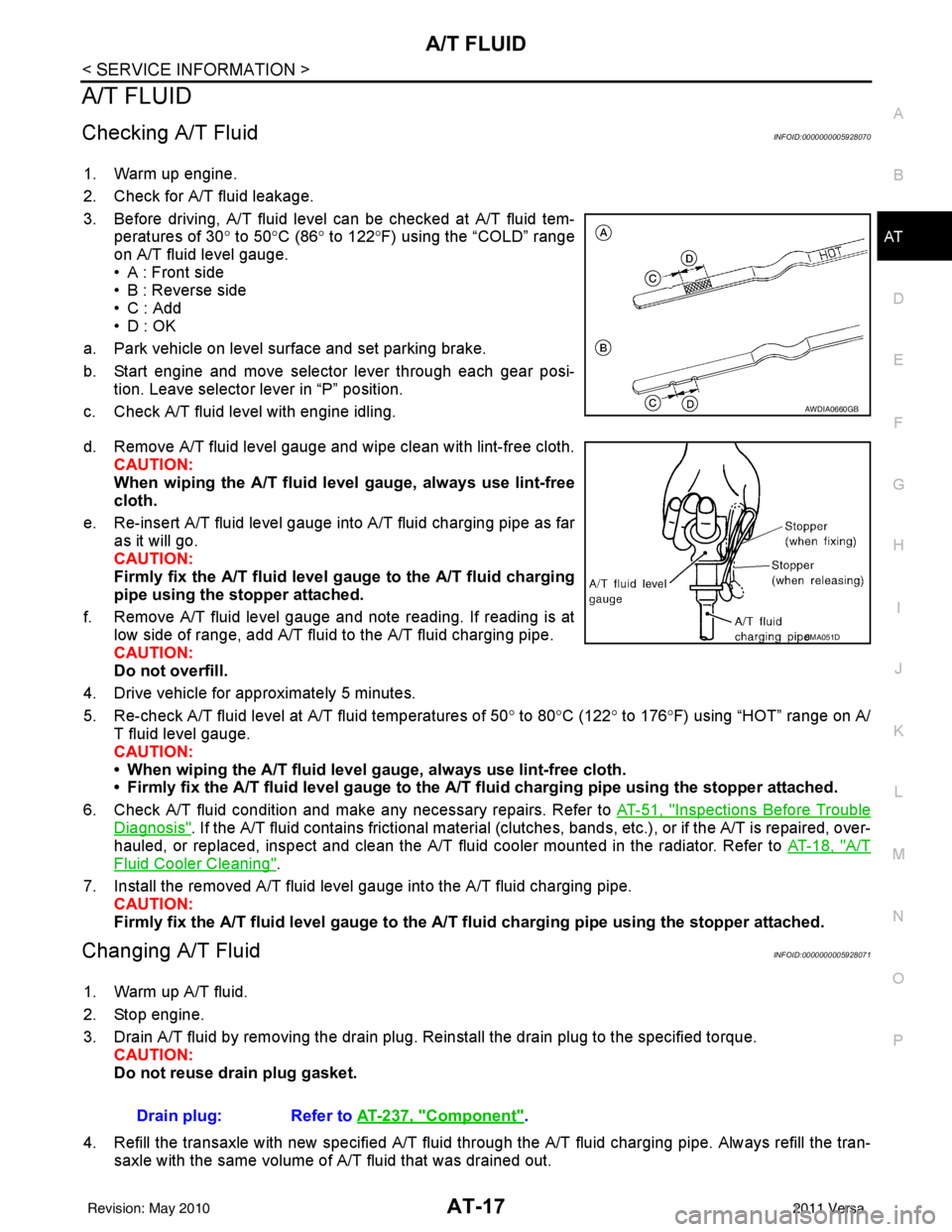

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid tem- peratures of 30° to 50°C (86° to 122° F) using the “COLD” range

on A/T fluid level gauge.

• A : Front side

• B : Reverse side

•C : Add

• D : OK

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi- tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth. CAUTION:

When wiping the A/T fluid l evel gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

Firmly fix the A/T fluid level ga uge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50° to 80 °C (122° to 176°F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level ga uge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-51, "

Inspections Before Trouble

Diagnosis". If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired, over-

hauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-18, "

A/T

Fluid Cooler Cleaning".

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe. CAUTION:

Firmly fix the A/T fluid level gaug e to the A/T fluid charging pipe using the stopper attached.

Changing A/T FluidINFOID:0000000005928071

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Re install the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran- saxle with the same volume of A/T fluid that was drained out.

AWDIA0660GB

SMA051D

Drain plug: Refer to AT-237, "Component".

Revision: May 2010 2011 Versa

Page 40 of 3787

A/T CONTROL SYSTEMAT-23

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

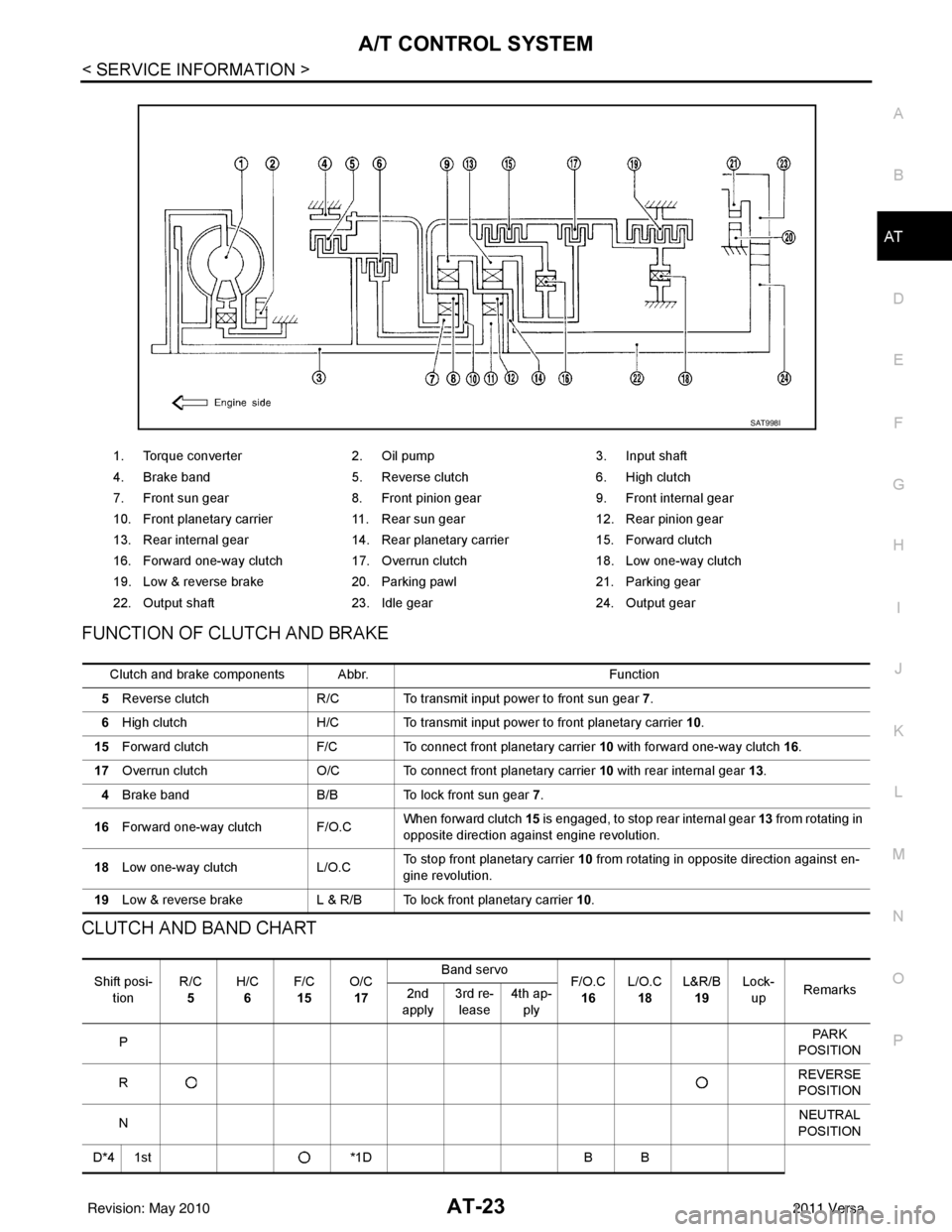

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5 Reverse clutch R/C To transmit input power to front sun gear 7 .

6 High clutch H/C To transmit input power to front planetary carrier 10.

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13 .

4 Brake band B/B To lock front sun gear 7.

16 Forward one-way clutch F/O.C When forward clutch 15

is engaged, to stop rear internal gear 13 from rotating in

opposite direction against engine revolution.

18 Low one-way clutch L/O.CTo stop front planetary carrier

10 from rotating in opposite direction against en-

gine revolution.

19 Low & reverse brake L & R/B To lock front planetary carrier 10.

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

P PA R K

POSITION

R REVERSE

POSITION

N NEUTRAL

POSITION

D*4 1st *1DB B

Revision: May 2010 2011 Versa

Page 41 of 3787

AT-24

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

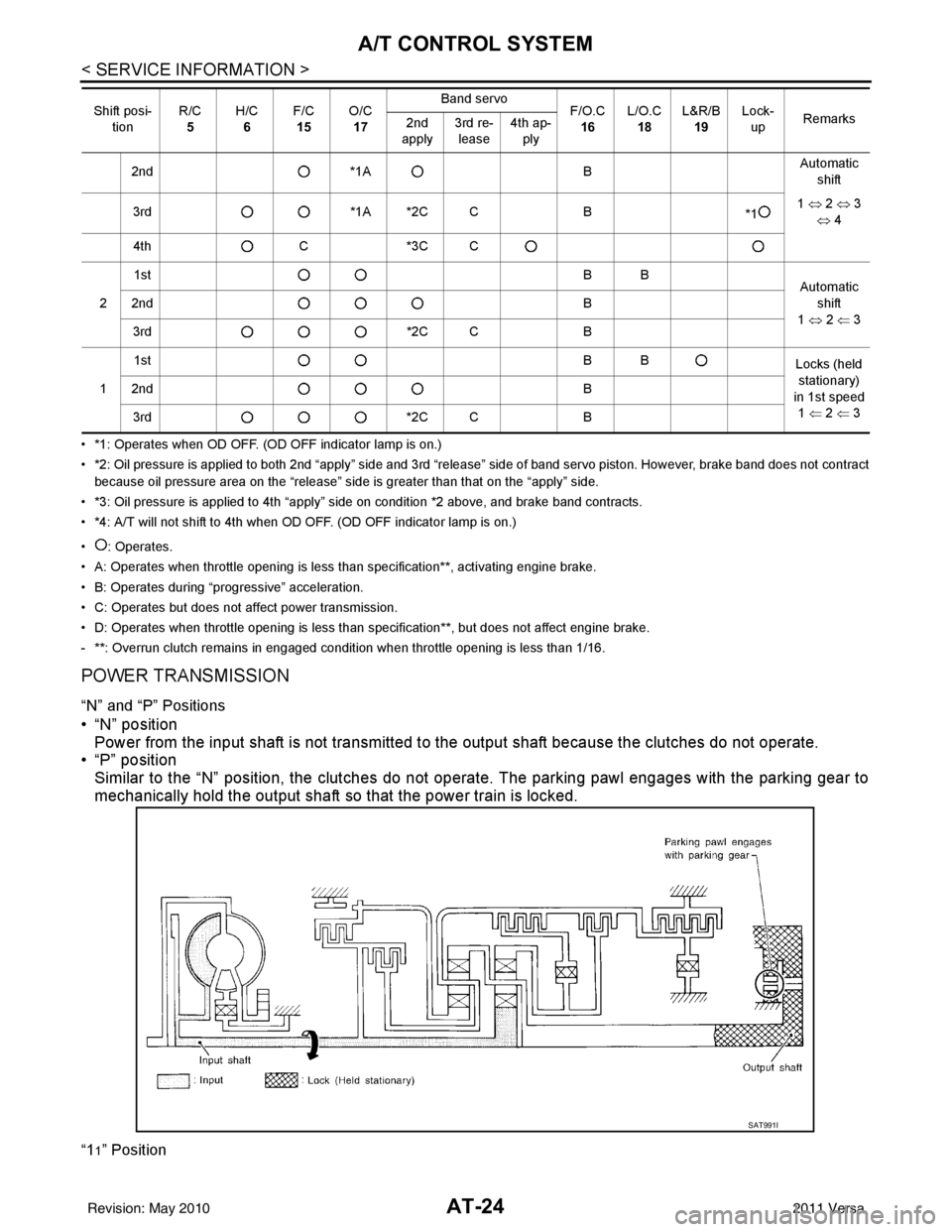

• *1: Operates when OD OFF. (OD OFF indicator lamp is on.)

• *2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

• *3: Oil pressure is applied to 4th “apply” side on condition *2 above, and brake band contracts.

• *4: A/T will not shift to 4th when OD OFF. (OD OFF indicator lamp is on.)

• : Operates.

• A: Operates when throttle opening is less than specification**, activating engine brake.

• B: Operates during “pro gressive” acceleration.

• C: Operates but does not affect power transmission.

• D: Operates when throttle opening is less than specification**, but does not affect engine brake.

- **: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

POWER TRANSMISSION

“N” and “P” Positions

• “N” position Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

• “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power train is locked.

“11” Position

2nd *1A BAutomatic

shift

3rd *1A *2C C B

*11

⇔ 2 ⇔ 3

⇔ 4

4th C*3C C

2 1st

BB

Automatic

shift

1 ⇔ 2 ⇐ 3

2nd

B

3rd *2C CB

1 1st

BB

Locks (held

stationary)

in 1st speed 1 ⇐ 2 ⇐ 3

2nd

B

3rd *2C CB

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

SAT991I

Revision: May 2010 2011 Versa

Page 68 of 3787

TROUBLE DIAGNOSISAT-51

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Inspections Before Trouble DiagnosisINFOID:0000000005928094

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

Check fluid leakage and check the fluid level. Refer to AT-17, "Checking A/T Fluid".

Fluid Condition Check

Check the A/T fluid condition.

STALL TEST

Stall Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF and engine oil.

2. Drive vehicle for approximately 10 minutes or until ATF and engine oil reach operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test. •It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D” position.

Fluid status Conceivable Cause Required Operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudy Water in the ATFReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

A/T

Replace the ATF and check for im-

proper operation of the A/T.

SAT638A

ATF operating temperature: 50 - 80

°C (122 - 176 °F)

SAT647B

SAT513G

SAT775B

Revision: May 2010 2011 Versa

Page 71 of 3787

AT-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

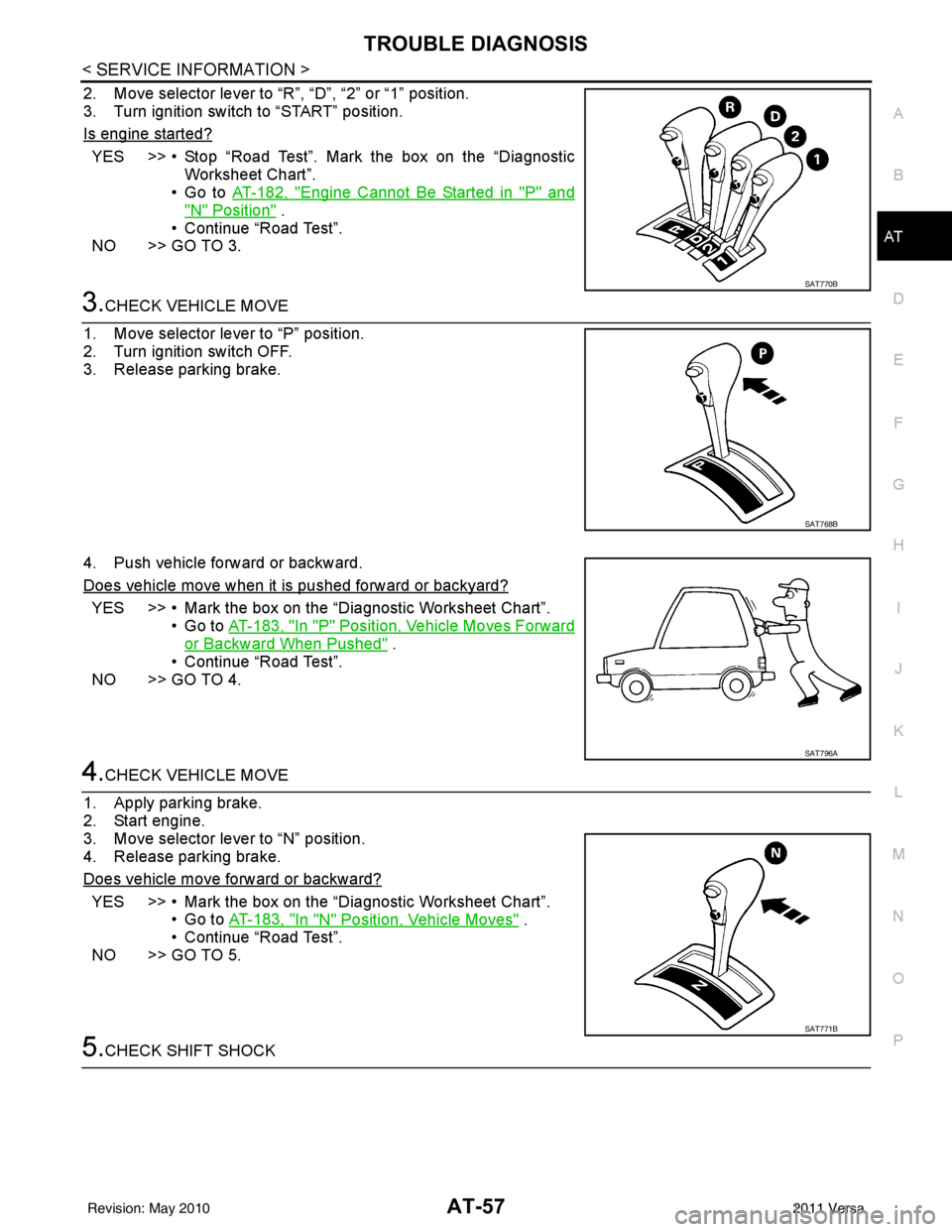

Location of line pressure test ports are shown in the figure.

•Always replace pressure plugs as they are self-sealing bolts.

Line Pressure Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF or

engine oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF reach operating temperature.

3. Install oil pressure gauge to corresponding line pressure test port.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed. CAUTION:

• Keep the brake pedal pressed all the way down duringmeasurement.

• When measuring the line pressure at the stall speed, refer to "STALL TEST".

SCIA7187E

ATF operating temperature: 50 - 80° C (122 -176°F)

SAT647B

SCIA6528J

SAT513G

SAT493G

Revision: May 2010 2011 Versa

Page 74 of 3787

TROUBLE DIAGNOSISAT-57

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2. Move selector lever to “R”, “D”, “2” or “1” position.

3. Turn ignition switch to “START” position.

Is engine started?

YES >> • Stop “Road Test”. Mark the box on the “Diagnostic Worksheet Chart”.

•Go to AT-182, "

Engine Cannot Be Started in "P" and

"N" Position" .

• Continue “Road Test”.

NO >> GO TO 3.

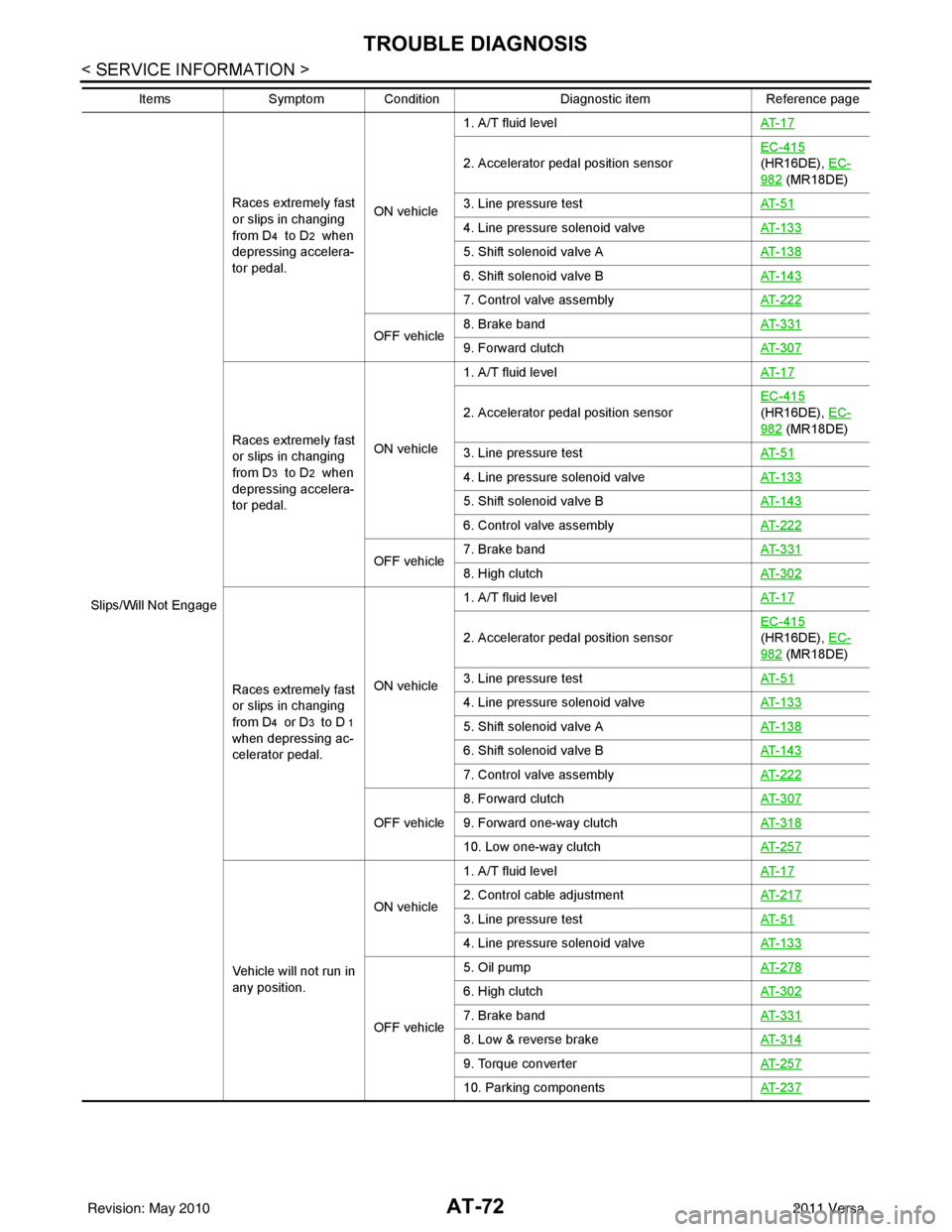

3.CHECK VEHICLE MOVE

1. Move selector lever to “P” position.

2. Turn ignition switch OFF.

3. Release parking brake.

4. Push vehicle forward or backward.

Does vehicle move when it is pushed forward or backyard?

YES >> • Mark the box on the “D iagnostic Worksheet Chart”.

•Go to AT-183, "

In "P" Position, Vehicle Moves Forward

or Backward When Pushed" .

• Continue “Road Test”.

NO >> GO TO 4.

4.CHECK VEHICLE MOVE

1. Apply parking brake.

2. Start engine.

3. Move selector lever to “N” position.

4. Release parking brake.

Does vehicle move forward or backward?

YES >> • Mark the box on the “D iagnostic Worksheet Chart”.

•Go to AT-183, "

In "N" Position, Vehicle Moves" .

• Continue “Road Test”.

NO >> GO TO 5.

5.CHECK SHIFT SHOCK

SAT770B

SAT768B

SAT796A

SAT771B

Revision: May 2010 2011 Versa

Page 89 of 3787

AT-72

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Slips/Will Not EngageRaces extremely fast

or slips in changing

from D

4 to D2 when

depressing accelera-

tor pedal. ON vehicle1. A/T fluid level

AT- 1 7

2. Accelerator pedal position sensorEC-415

(HR16DE), EC-

982 (MR18DE)

3. Line pressure test AT- 5 1

4. Line pressure solenoid valveAT- 1 3 3

5. Shift solenoid valve AAT- 1 3 8

6. Shift solenoid valve BAT- 1 4 3

7. Control valve assemblyAT- 2 2 2

OFF vehicle8. Brake band

AT- 3 3 19. Forward clutchAT- 3 0 7

Races extremely fast

or slips in changing

from D

3 to D2 when

depressing accelera-

tor pedal. ON vehicle1. A/T fluid level

AT- 1 7

2. Accelerator pedal position sensor EC-415

(HR16DE), EC-

982 (MR18DE)

3. Line pressure test AT- 5 1

4. Line pressure solenoid valveAT- 1 3 3

5. Shift solenoid valve BAT- 1 4 3

6. Control valve assemblyAT- 2 2 2

OFF vehicle7. Brake band

AT- 3 3 18. High clutchAT- 3 0 2

Races extremely fast

or slips in changing

from D

4 or D3 to D 1

when depressing ac-

celerator pedal. ON vehicle1. A/T fluid level

AT- 1 7

2. Accelerator pedal position sensorEC-415

(HR16DE), EC-

982 (MR18DE)

3. Line pressure test AT- 5 1

4. Line pressure solenoid valveAT- 1 3 3

5. Shift solenoid valve AAT- 1 3 8

6. Shift solenoid valve BAT- 1 4 3

7. Control valve assemblyAT- 2 2 2

OFF vehicle8. Forward clutch

AT- 3 0 79. Forward one-way clutchAT- 3 1 8

10. Low one-way clutchAT- 2 5 7

Vehicle will not run in

any position.ON vehicle

1. A/T fluid level

AT- 1 7

2. Control cable adjustmentAT- 2 1 7

3. Line pressure testAT- 5 1

4. Line pressure solenoid valveAT- 1 3 3

OFF vehicle5. Oil pump

AT- 2 7 8

6. High clutchAT- 3 0 2

7. Brake bandAT- 3 3 1

8. Low & reverse brakeAT- 3 1 4

9. Torque converterAT- 2 5 7

10. Parking componentsAT- 2 3 7

ItemsSymptom Condition Diagnostic itemReference page

Revision: May 2010 2011 Versa

Page 90 of 3787

TROUBLE DIAGNOSISAT-73

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

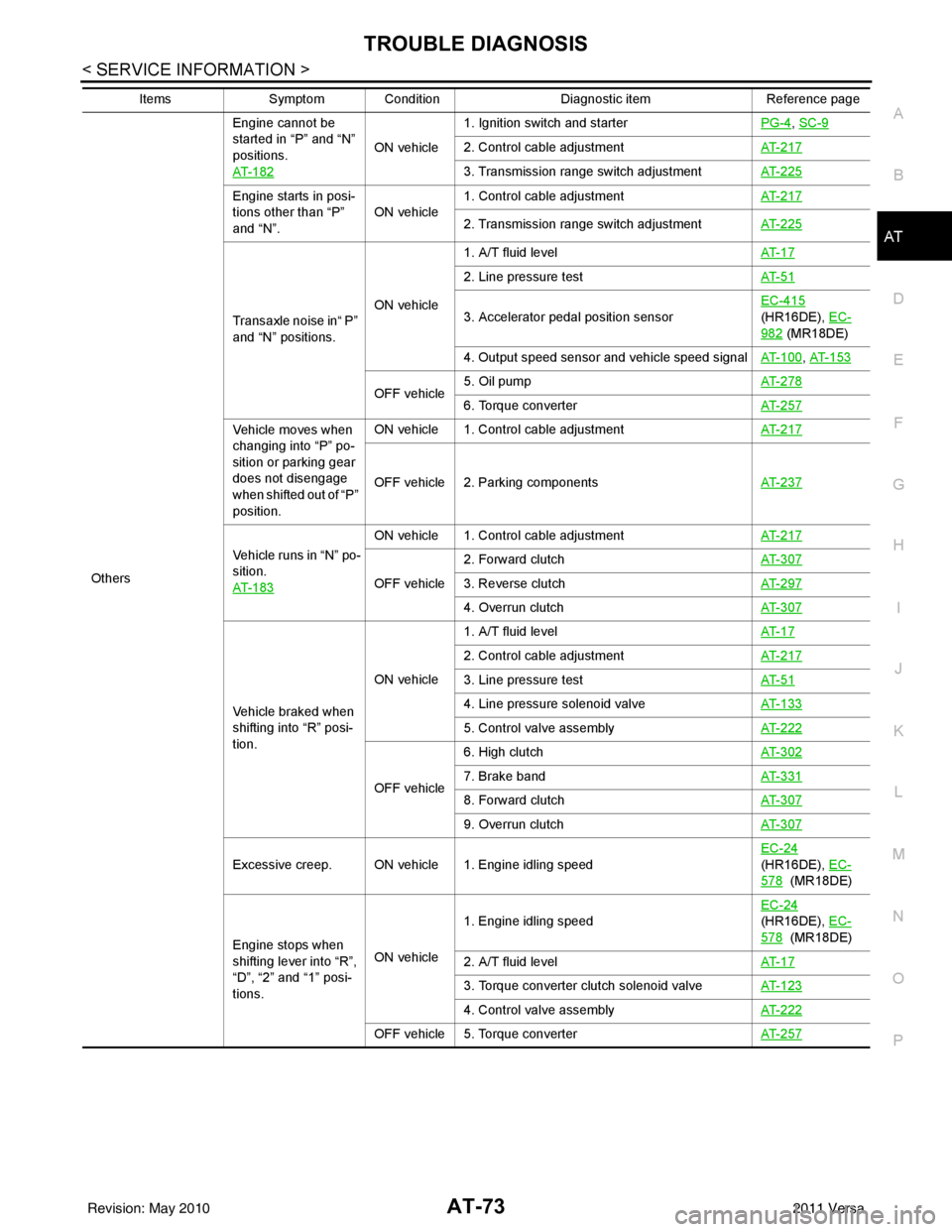

Others Engine cannot be

started in “P” and “N”

positions.

AT- 1 8 2

ON vehicle

1. Ignition switch and starter

PG-4

, SC-9

2. Control cable adjustmentAT- 2 1 7

3. Transmission range switch adjustmentAT- 2 2 5

Engine starts in posi-

tions other than “P”

and “N”.ON vehicle

1. Control cable adjustment

AT- 2 1 7

2. Transmission range switch adjustmentAT- 2 2 5

Transaxle noise in“ P”

and “N” positions.ON vehicle1. A/T fluid level

AT- 1 7

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorEC-415

(HR16DE), EC-

982 (MR18DE)

4. Output speed sensor and vehicle speed signal AT- 1 0 0

, AT- 1 5 3

OFF vehicle5. Oil pump

AT- 2 7 86. Torque converterAT- 2 5 7

Vehicle moves when

changing into “P” po-

sition or parking gear

does not disengage

when shifted out of “P”

position.ON vehicle 1. Control cable adjustment

AT- 2 1 7

OFF vehicle 2. Parking componentsAT- 2 3 7

Vehicle runs in “N” po-

sition.

AT- 1 8 3

ON vehicle 1. Control cable adjustmentAT- 2 1 7

OFF vehicle2. Forward clutch

AT- 3 0 73. Reverse clutchAT- 2 9 7

4. Overrun clutchAT- 3 0 7

Vehicle braked when

shifting into “R” posi-

tion.ON vehicle

1. A/T fluid level

AT- 1 7

2. Control cable adjustmentAT- 2 1 7

3. Line pressure testAT- 5 1

4. Line pressure solenoid valveAT- 1 3 3

5. Control valve assemblyAT- 2 2 2

OFF vehicle6. High clutch

AT- 3 0 27. Brake band AT- 3 3 1

8. Forward clutchAT- 3 0 7

9. Overrun clutchAT- 3 0 7

Excessive creep. ON vehicle 1. Engine idling speed EC-24

(HR16DE), EC-

578 (MR18DE)

Engine stops when

shifting lever into “R”,

“D”, “2” and “1” posi-

tions. ON vehicle

1. Engine idling speed

EC-24

(HR16DE), EC-

578 (MR18DE)

2. A/T fluid level AT- 1 7

3. Torque converter clutch solenoid valveAT- 1 2 3

4. Control valve assemblyAT- 2 2 2

OFF vehicle 5. Torque converter AT- 2 5 7

ItemsSymptom Condition Diagnostic itemReference page

Revision: May 2010 2011 Versa

Page 231 of 3787

AT-214

< SERVICE INFORMATION >

SHIFT CONTROL SYSTEM

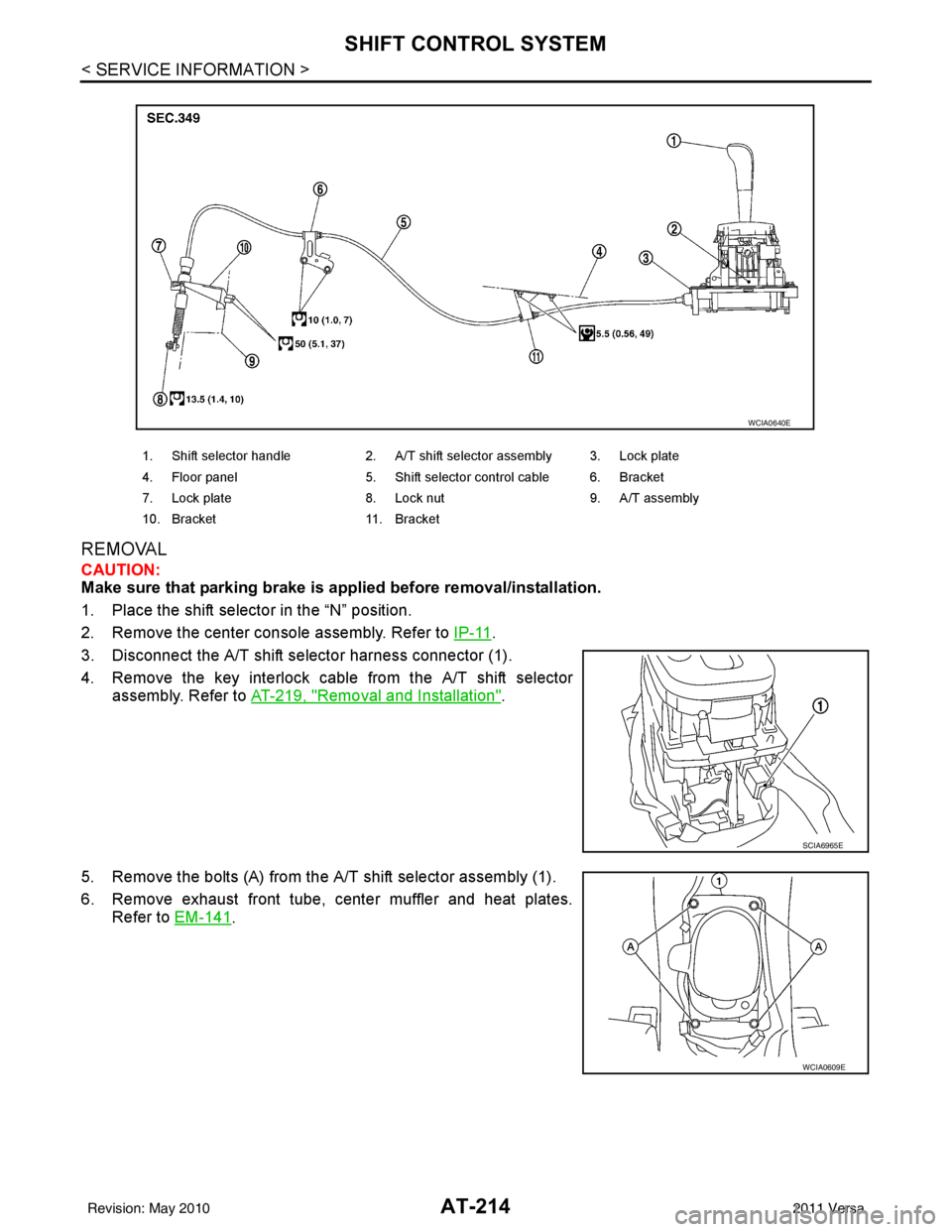

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation.

1. Place the shift selector in the “N” position.

2. Remove the center console assembly. Refer to IP-11

.

3. Disconnect the A/T shift selector harness connector (1).

4. Remove the key interlock cable from the A/T shift selector assembly. Refer to AT-219, "

Removal and Installation".

5. Remove the bolts (A) from the A/T shift selector assembly (1).

6. Remove exhaust front tube, center muffler and heat plates. Refer to EM-141

.

1. Shift selector handle 2. A/T shift selector assembly 3. Lock plate

4. Floor panel 5. Shift selector control cable 6. Bracket

7. Lock plate 8. Lock nut 9. A/T assembly

10. Bracket 11. Bracket

WCIA0640E

SCIA6965E

WCIA0609E

Revision: May 2010 2011 Versa