rear NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 8 of 3787

2011

QUICK REFERENCE INDEX: VERSA

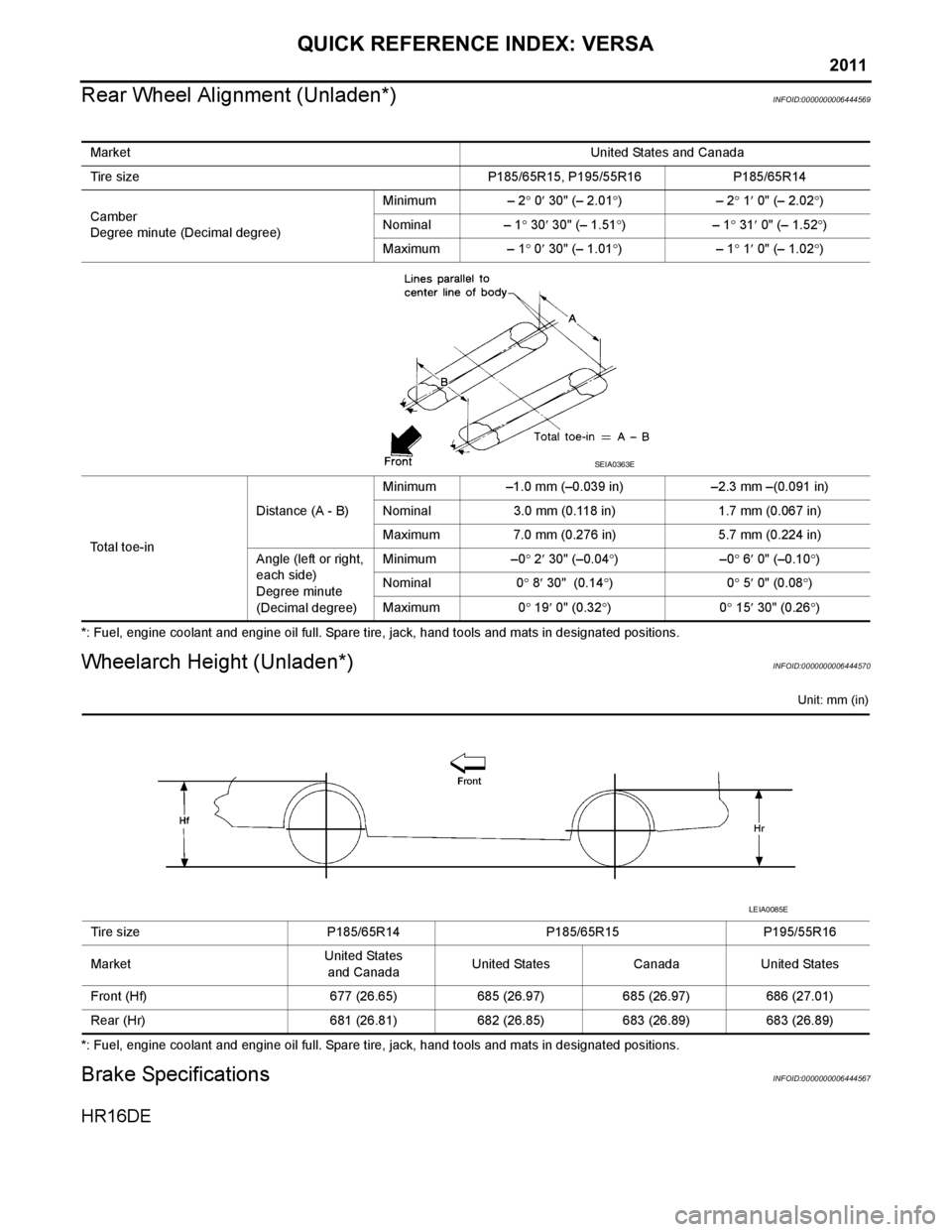

Rear Wheel Alignment (Unladen*)

INFOID:0000000006444569

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000006444570

Unit: mm (in)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

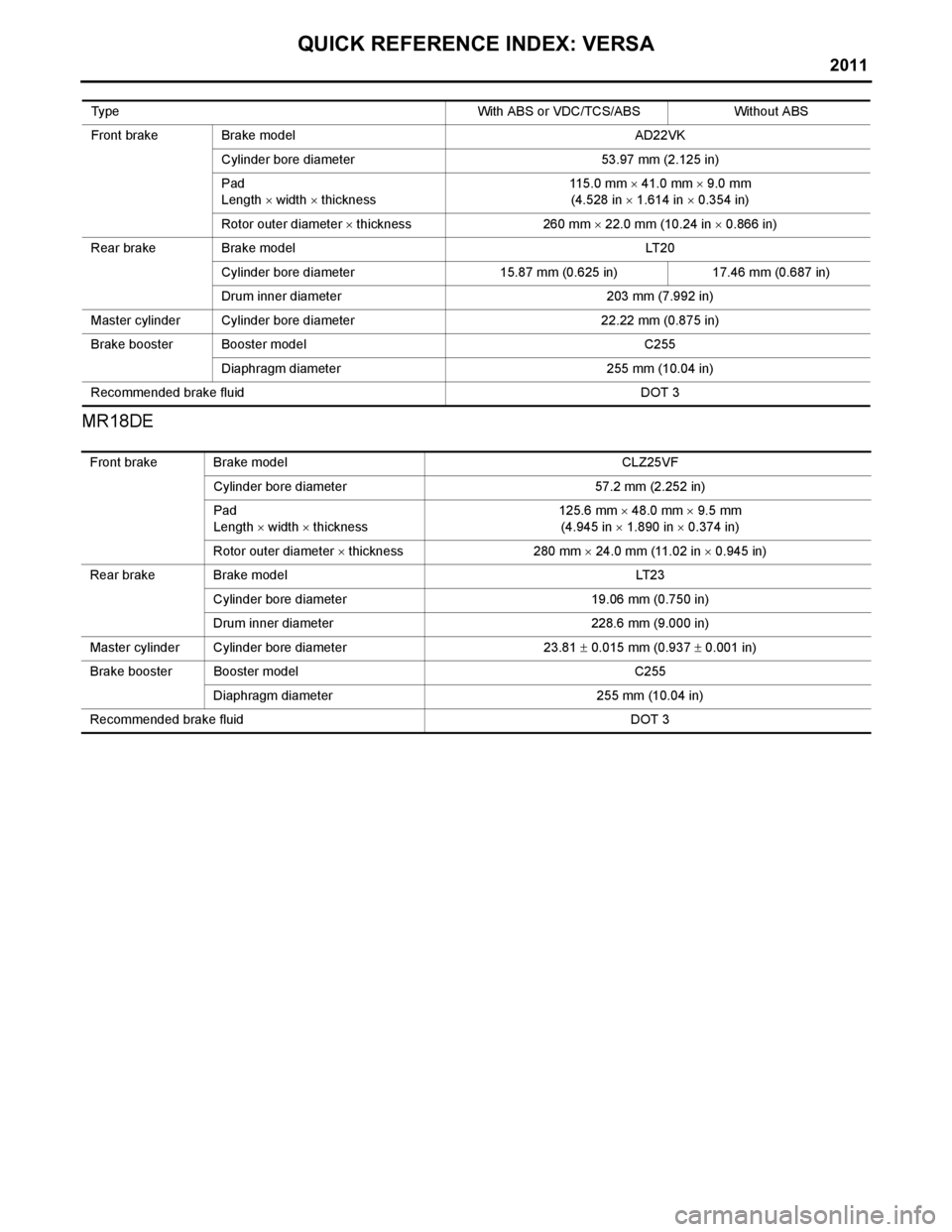

Brake SpecificationsINFOID:0000000006444567

HR16DE

Market United States and Canada

Tire size P185/65R15, P195/55R16P185/65R14

Camber

Degree minute (Decimal degree) Minimum

– 2° 0 ′ 30" (– 2.01 °)– 2° 1 ′ 0" (– 2.02 °)

Nominal – 1° 30 ′ 30" (– 1.51 °)– 1° 31 ′ 0" (– 1.52 °)

Maximum – 1° 0 ′ 30" (– 1.01 °)– 1° 1 ′ 0" (– 1.02 °)

Total toe-in Distance (A - B)

Minimum

–1.0 mm (–0.039 in) –2.3 mm –(0.091 in)

Nominal 3.0 mm (0.118 in) 1.7 mm (0.067 in)

Maximum 7.0 mm (0.276 in) 5.7 mm (0.224 in)

Angle (left or right,

each side)

Degree minute

(Decimal degree) Minimum

–0° 2 ′ 30" (–0.04 °)– 0° 6 ′ 0" (–0.10 °)

Nominal 0° 8 ′ 30" (0.14 °)0 ° 5 ′ 0" (0.08 °)

Maximum 0° 19 ′ 0" (0.32 °)0 ° 15 ′ 30" (0.26 °)

SEIA0363E

Tire size P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65)685 (26.97)685 (26.97)686 (27.01)

Rear (Hr) 681 (26.81)682 (26.85)683 (26.89)683 (26.89)

LEIA0085E

Page 9 of 3787

QUICK REFERENCE INDEX: VERSA

2011

MR18DE

TypeWith ABS or VDC/TCS/ABSWithout ABS

Front brake Brake model AD22VK

Cylinder bore diameter 53.97 mm (2.125 in)

Pad

Length × width × thickness 11 5 . 0 m m

× 41.0 mm × 9.0 mm

(4.528 in × 1.614 in × 0.354 in)

Rotor outer diameter × thickness 260 mm × 22.0 mm (10.24 in × 0.866 in)

Rear brake Brake model LT20

Cylinder bore diameter 15.87 mm (0.625 in)17.46 mm (0.687 in)

Drum inner diameter 203 mm (7.992 in)

Master cylinder Cylinder bore diameter 22.22 mm (0.875 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Front brake Brake modelCLZ25VF

Cylinder bore diameter 57.2 mm (2.252 in)

Pad

Length × width × thickness 125.6 mm

× 48.0 mm × 9.5 mm

(4.945 in × 1.890 in × 0.374 in)

Rotor outer diameter × thickness 280 mm × 24.0 mm (11.02 in × 0.945 in)

Rear brake Brake model LT23

Cylinder bore diameter 19.06 mm (0.750 in)

Drum inner diameter 228.6 mm (9.000 in)

Master cylinder Cylinder bore diameter 23.81 ± 0.015 mm (0.937 ± 0.001 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Page 11 of 3787

QUICK REFERENCE INDEX: VERSA

2011

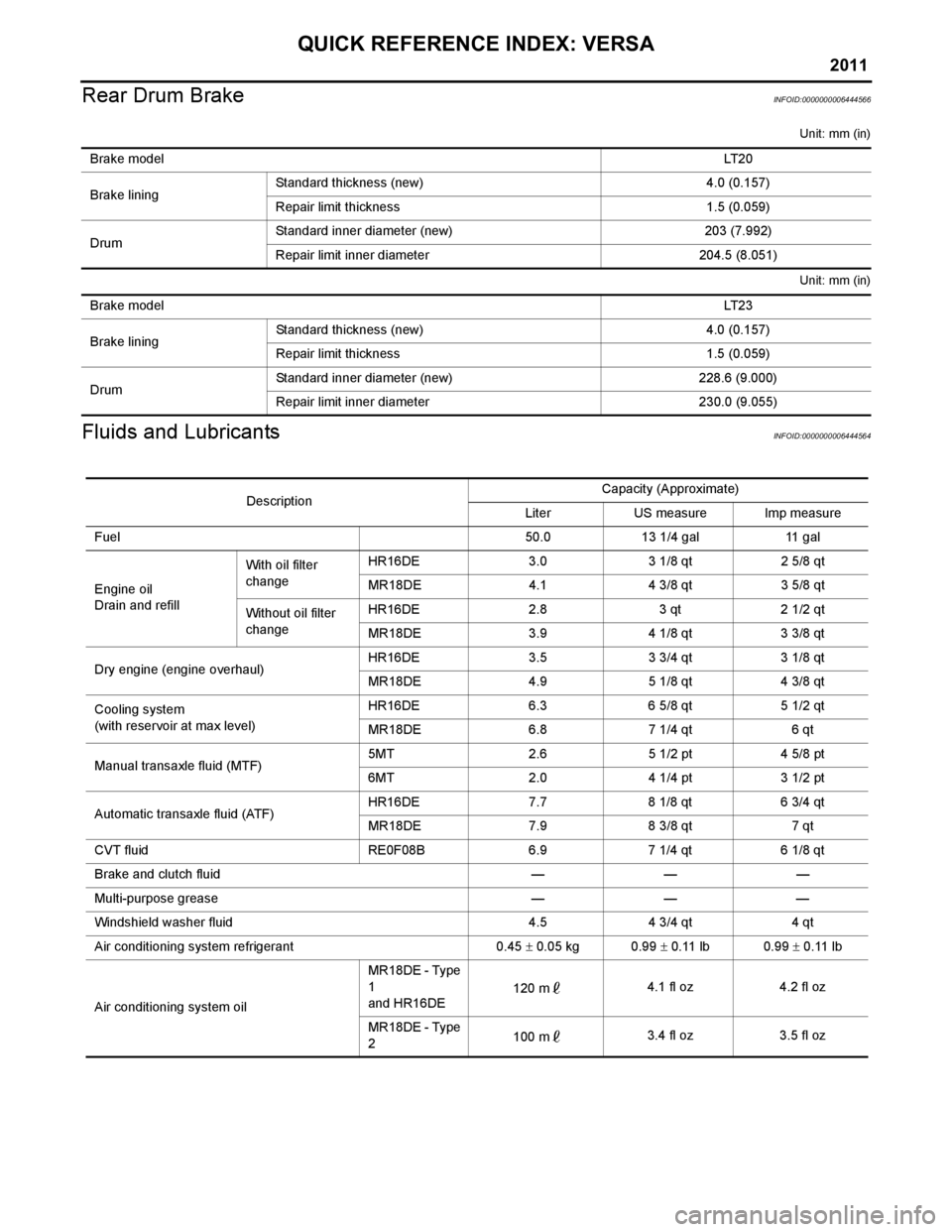

Rear Drum BrakeINFOID:0000000006444566

Unit: mm (in)

Unit: mm (in)

Fluids and LubricantsINFOID:0000000006444564

Brake modelLT 2 0

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

DescriptionCapacity (Approximate)

Liter US measure Imp measure

Fuel 50.013 1/4 gal 11 gal

Engine oil

Drain and refill With oil filter

change

HR16DE

3.03 1/8 qt 2 5/8 qt

MR18DE 4.14 3/8 qt 3 5/8 qt

Without oil filter

change HR16DE

2.83 qt2 1/2 qt

MR18DE 3.94 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE

3.53 3/4 qt 3 1/8 qt

MR18DE 4.95 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE

6.36 5/8 qt 5 1/2 qt

MR18DE 6.87 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT

2.65 1/2 pt 4 5/8 pt

6MT 2.04 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) HR16DE

7.78 1/8 qt 6 3/4 qt

MR18DE 7.98 3/8 qt 7 qt

CVT fluid RE0F08B6.97 1/4 qt 6 1/8 qt

Brake and clutch fluid —— —

Multi-purpose grease —— —

Windshield washer fluid 4.54 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil MR18DE - Type

1

and HR16DE

120 m

4.1 fl oz

4.2 fl oz

MR18DE - Type

2 100 m

3.4 fl oz

3.5 fl oz

Page 21 of 3787

AT-4

Transmission Range Switch ..................................225

Output Speed Sensor ............................................227

Input Speed Sensor ...............................................228

Differential Side Oil Seal ........................................229

AIR BREATHER HOSE ...................................232

Removal and Installation ..................................... ..232

TRANSAXLE ASSEMBLY ..............................233

Removal and Installation ..................................... ..233

OVERHAUL .................................................... .237

Component .......................................................... ..237

Oil Channel ............................................................250

Location of Adjusting Shims, Needle Bearings and

Thrust Washers .....................................................

253

Location of Snap Rings .........................................255

DISASSEMBLY .............................................. .257

Disassembly ........................................................ ..257

REPAIR FOR COMPONENT PARTS ..............275

Manual Shaft ....................................................... ..275

Oil Pump ................................................................278

Control Valve Assembly ........................................281

Control Valve Upper Body .....................................290

Control Valve Lower Body ................................... ..294

Reverse Clutch ......................................................297

High Clutch ............................................................302

Forward and Overrun Clutches .............................307

Low & Reverse Brake ............................................314

Rear Internal Gear and Forward Clutch Hub .........318

Output Shaft, Output Gear, Idler Gear, Reduction

Pinion Gear and Bearing Retainer .........................

322

Band Servo Piston Assembly ................................331

Final Drive .............................................................337

ASSEMBLY .....................................................344

Assembly (1) ........................................................ ..344

Adjustment (1) (For HR16DE Engine Models) ..... .345

Adjustment (1) (For MR18DE Engine Models) .....349

Assembly (2) .........................................................355

Adjustment (2) .......................................................360

Assembly (3) .........................................................363

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

373

General Specification ........................................... .373

Vehicle Speed at Which Gear Shifting Occurs .....373

Vehicle Speed at When Lock-up Occurs/Releases

.

373

Stall Speed ............................................................374

Line Pressure ........................................................374

Adjusting shims, Needle Bearings, Thrust Wash-

ers and Snap Rings ..............................................

374

Control Valves .......................................................375

Accumulator ..........................................................376

Clutches and Brakes .............................................376

Final Drive .............................................................378

Planetary Carrier ...................................................378

Oil Pump ...............................................................378

Input Shaft .............................................................378

Reduction Pinion Gear ..........................................378

Band Servo ...........................................................378

Output Shaft ..........................................................379

Bearing Retainer ...................................................379

Total End Play ...................................................... .379

Reverse Clutch End Play ......................................379

Removal and Installation .......................................379

Shift Solenoid Valves ........................................... .379

Solenoid Valves ....................................................380

A/T Fluid Temperature Sensor ..............................380

Output Speed Sensor ...........................................380

Dropping Resistor .................................................380

Input Speed Sensor ..............................................380

Revision: May 2010 2011 Versa

Page 38 of 3787

A/T CONTROL SYSTEMAT-21

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

A/T CONTROL SYSTEM

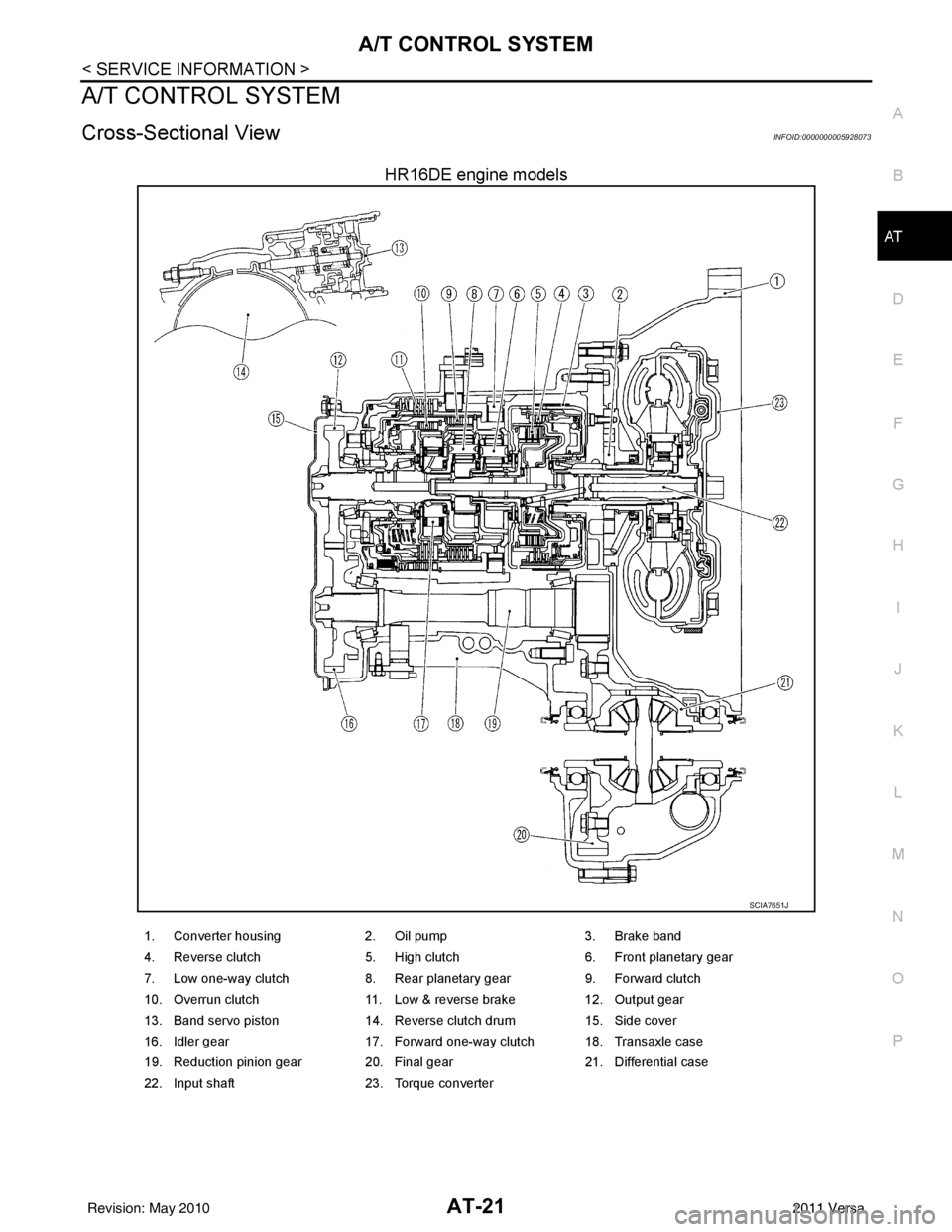

Cross-Sectional ViewINFOID:0000000005928073

HR16DE engine models

SCIA7651J

1. Converter housing 2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear 21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 39 of 3787

AT-22

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

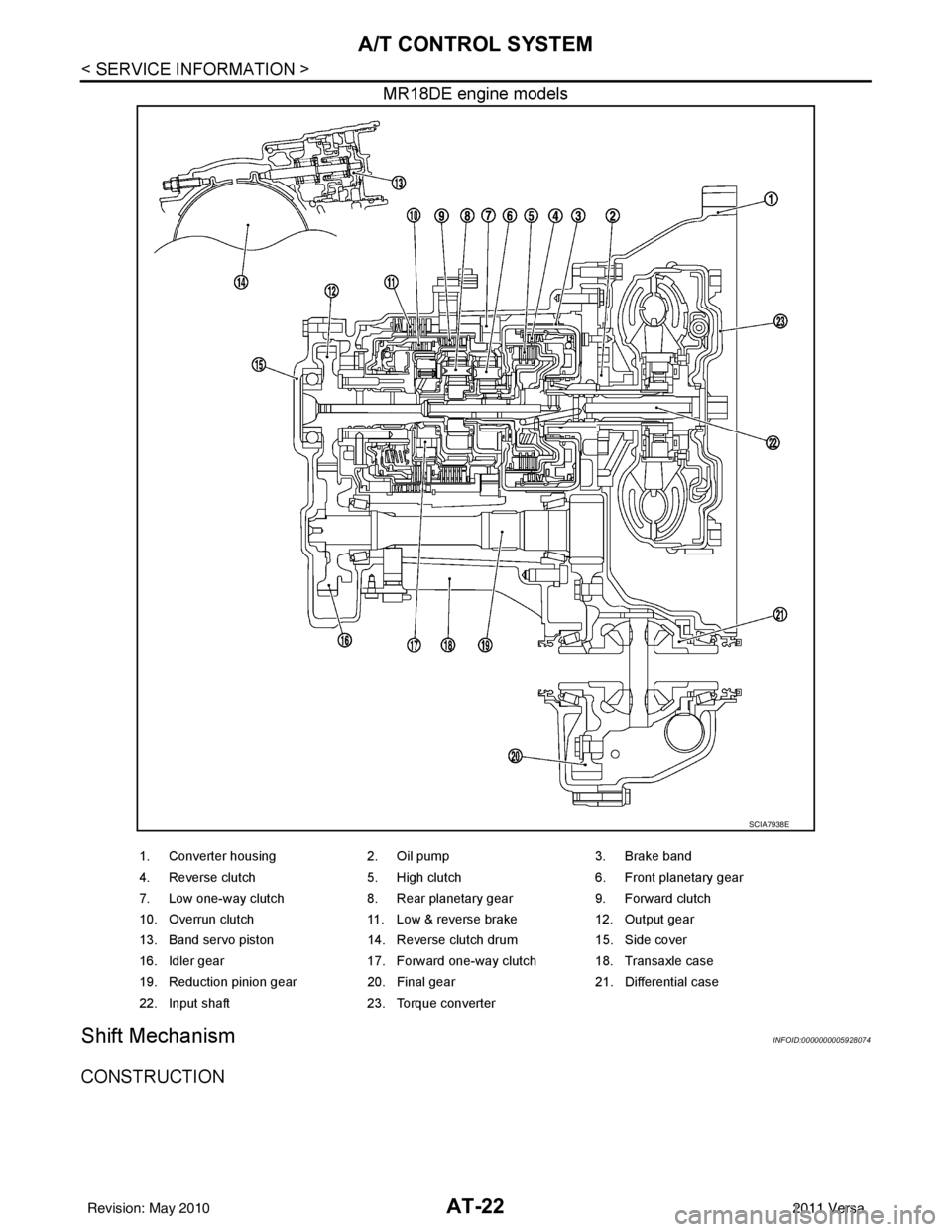

MR18DE engine models

Shift MechanismINFOID:0000000005928074

CONSTRUCTION

SCIA7938E

1. Converter housing2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 40 of 3787

A/T CONTROL SYSTEMAT-23

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

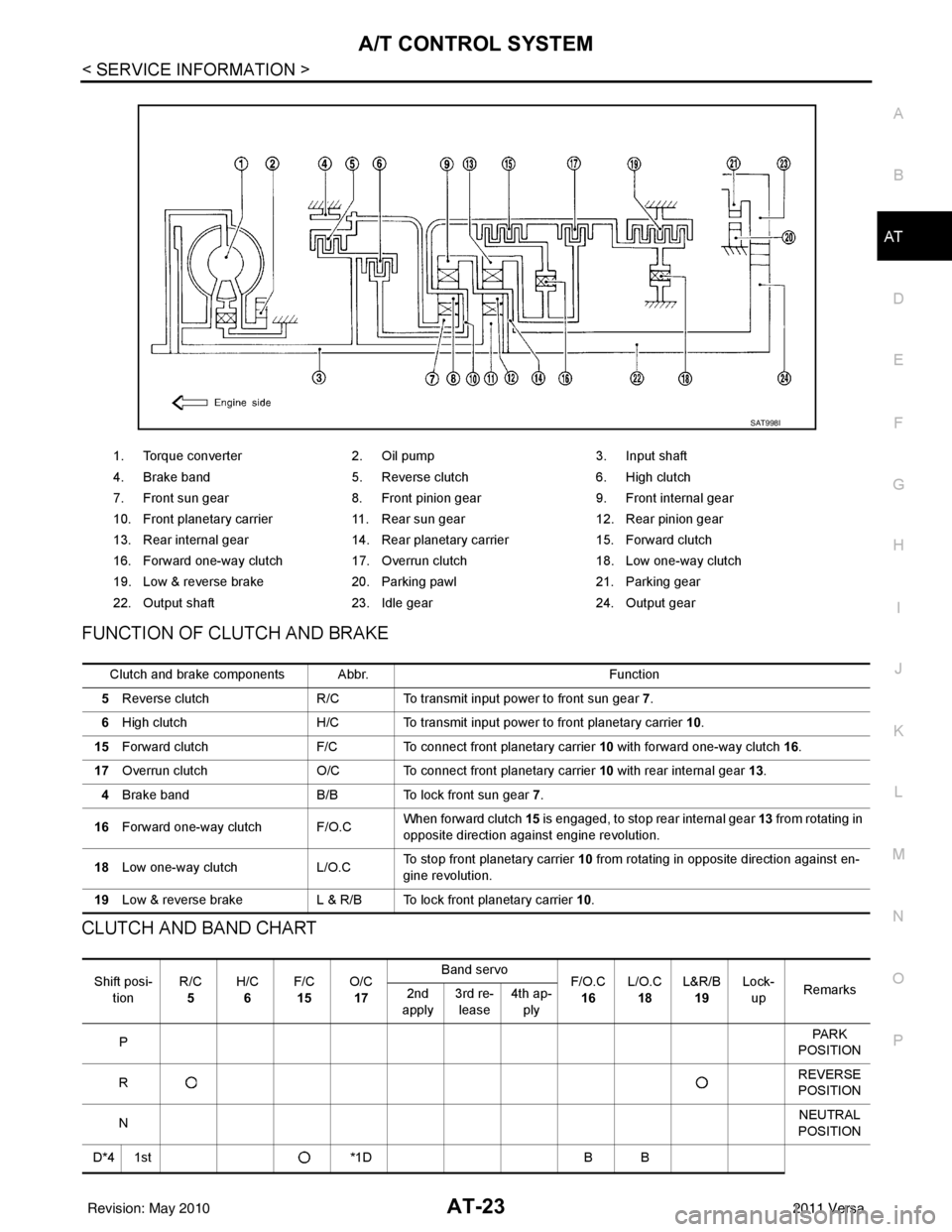

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5 Reverse clutch R/C To transmit input power to front sun gear 7 .

6 High clutch H/C To transmit input power to front planetary carrier 10.

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13 .

4 Brake band B/B To lock front sun gear 7.

16 Forward one-way clutch F/O.C When forward clutch 15

is engaged, to stop rear internal gear 13 from rotating in

opposite direction against engine revolution.

18 Low one-way clutch L/O.CTo stop front planetary carrier

10 from rotating in opposite direction against en-

gine revolution.

19 Low & reverse brake L & R/B To lock front planetary carrier 10.

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

P PA R K

POSITION

R REVERSE

POSITION

N NEUTRAL

POSITION

D*4 1st *1DB B

Revision: May 2010 2011 Versa

Page 42 of 3787

A/T CONTROL SYSTEMAT-25

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

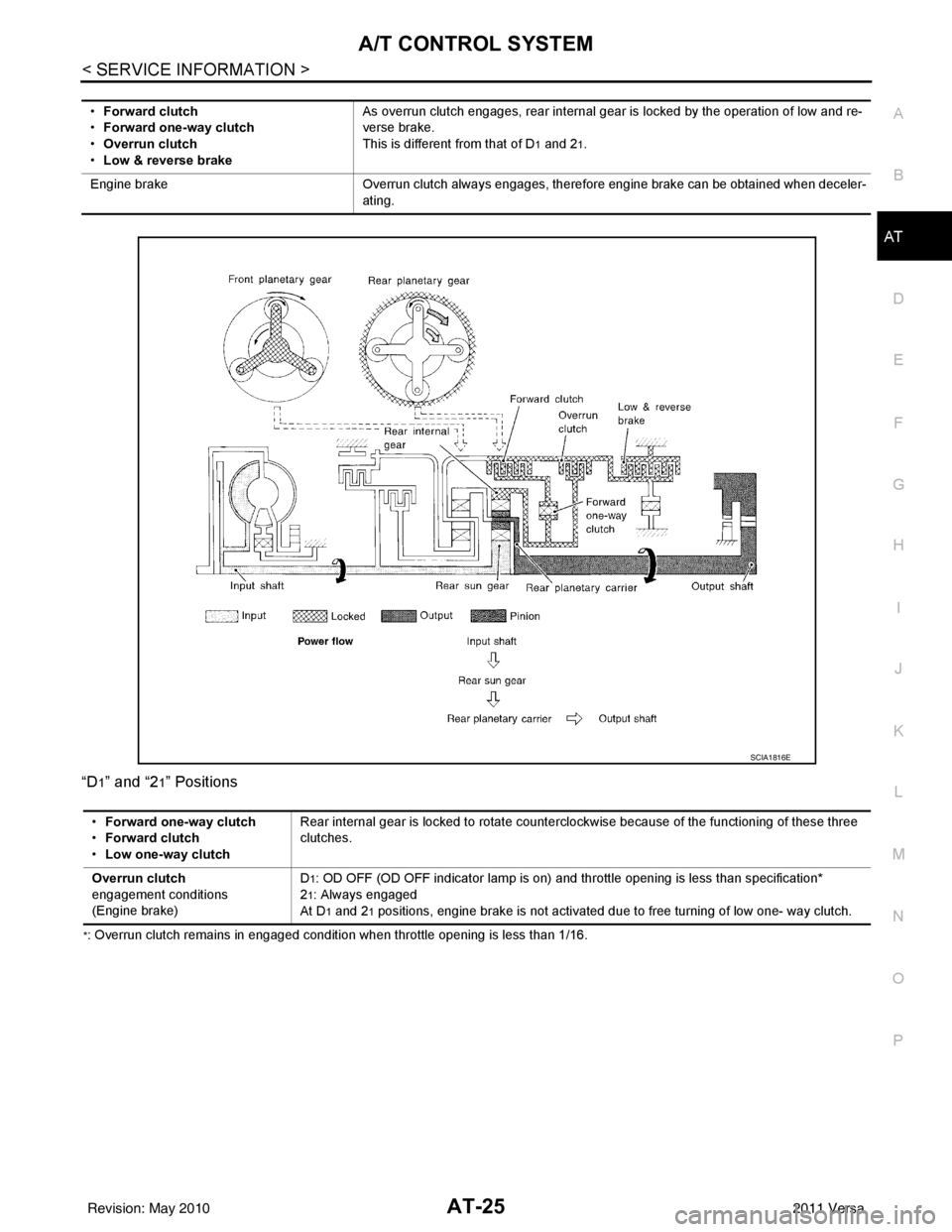

“D

1” and “21” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16. •

Forward clutch

• Forward one-way clutch

• Overrun clutch

• Low & reverse brake As overrun clutch engages, rear internal gear is locked by the operation of low and re-

verse brake.

This is different from that of D

1 and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SCIA1816E

• Forward one-way clutch

• Forward clutch

• Low one-way clutch Rear internal gear is locked to rotate counterclockwise because of the functioning of these three

clutches.

Overrun clutch

engagement conditions

(Engine brake) D

1: OD OFF (OD OFF indicator lamp is on) and th

rottle opening is less than specification*

2

1: Always engaged

At D

1 and 21 positions, engine brake is not activated due to free turning of low one- way clutch.

Revision: May 2010 2011 Versa

Page 43 of 3787

AT-26

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

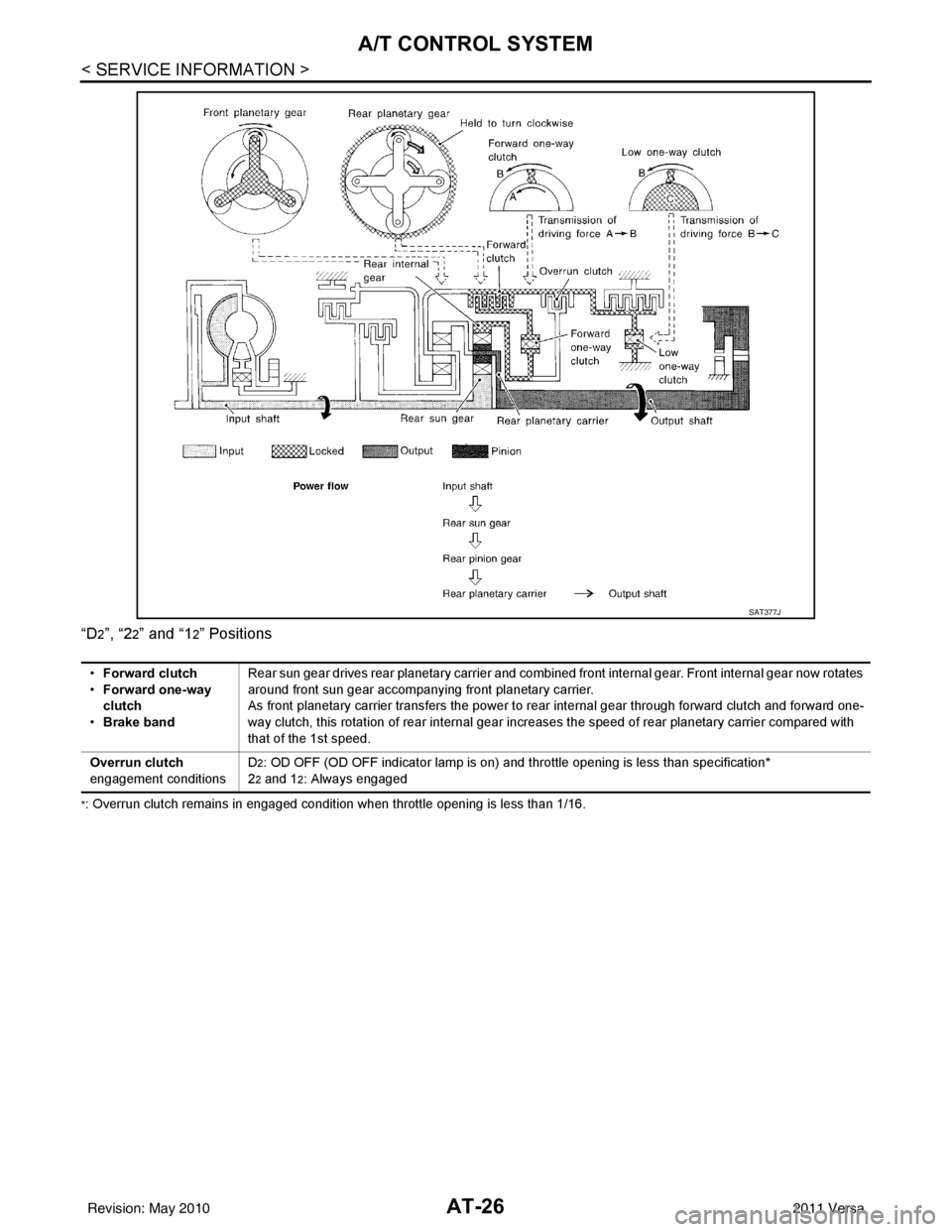

“D2”, “22” and “12” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

SAT377J

•Forward clutch

• Forward one-way

clutch

• Brake band Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates

around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward one-

way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with

that of the 1st speed.

Overrun clutch

engagement conditions D

2: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

2 and 12: Always engaged

Revision: May 2010 2011 Versa