wheel bolts NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 71 of 3787

AT-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

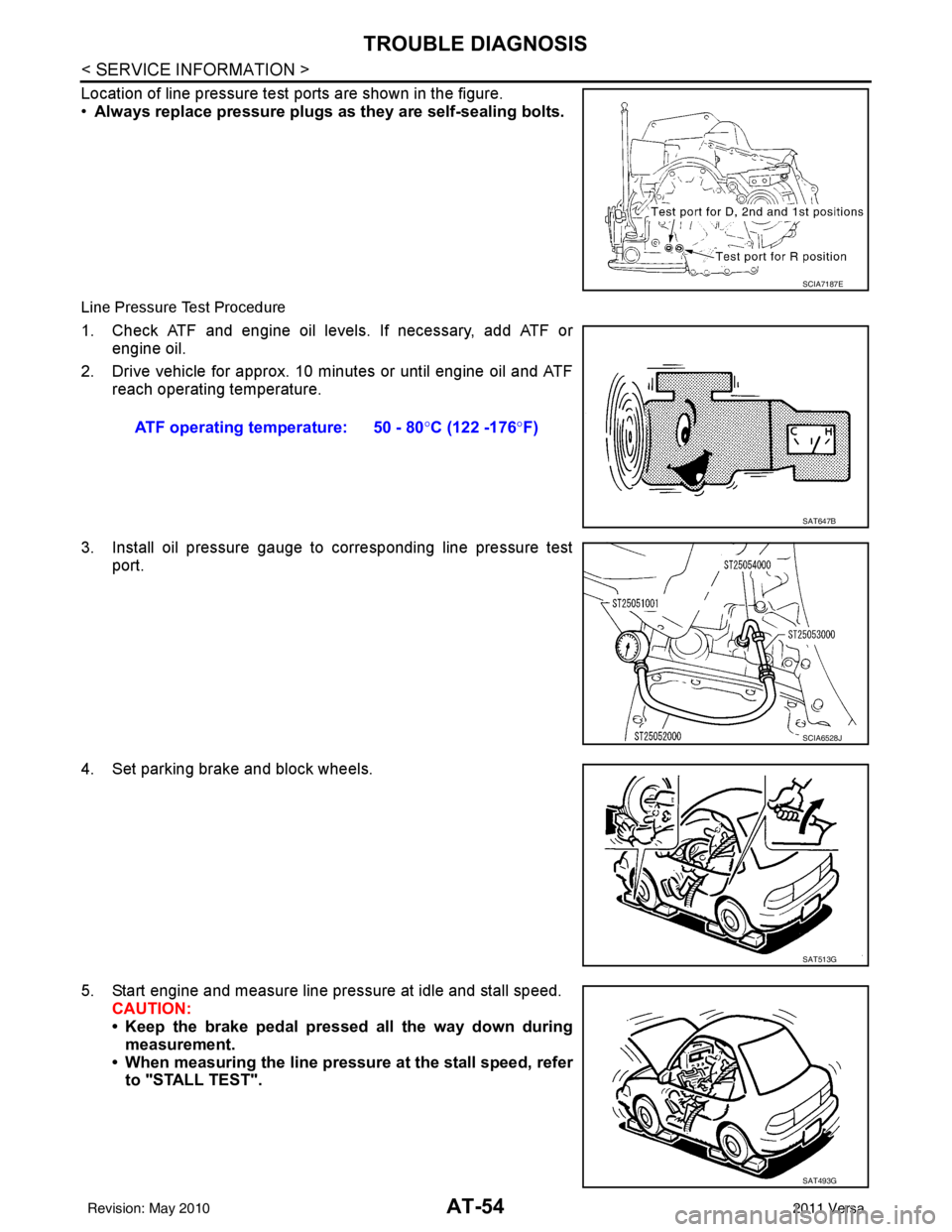

Location of line pressure test ports are shown in the figure.

•Always replace pressure plugs as they are self-sealing bolts.

Line Pressure Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF or

engine oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF reach operating temperature.

3. Install oil pressure gauge to corresponding line pressure test port.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed. CAUTION:

• Keep the brake pedal pressed all the way down duringmeasurement.

• When measuring the line pressure at the stall speed, refer to "STALL TEST".

SCIA7187E

ATF operating temperature: 50 - 80° C (122 -176°F)

SAT647B

SCIA6528J

SAT513G

SAT493G

Revision: May 2010 2011 Versa

Page 873 of 3787

BR-26

< SERVICE INFORMATION >

FRONT DISC BRAKE

CLZ25VF

CAUTION:

• Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

• While removing brake pad or cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to remove torque member mounting bolts and brake hose except for disassembly

or replacement of caliper assembly. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Keep rotor free from brake fluid.

• When replacing brake pad, replace shim with a new one.

Removal and Installation of Brake PadINFOID:0000000005928412

AD22VK

Removal

1. Partially drain brake fluid reservoir. Refer to BR-9, "Drain and Refill".

2. Remove front wheel and tire using power tools.

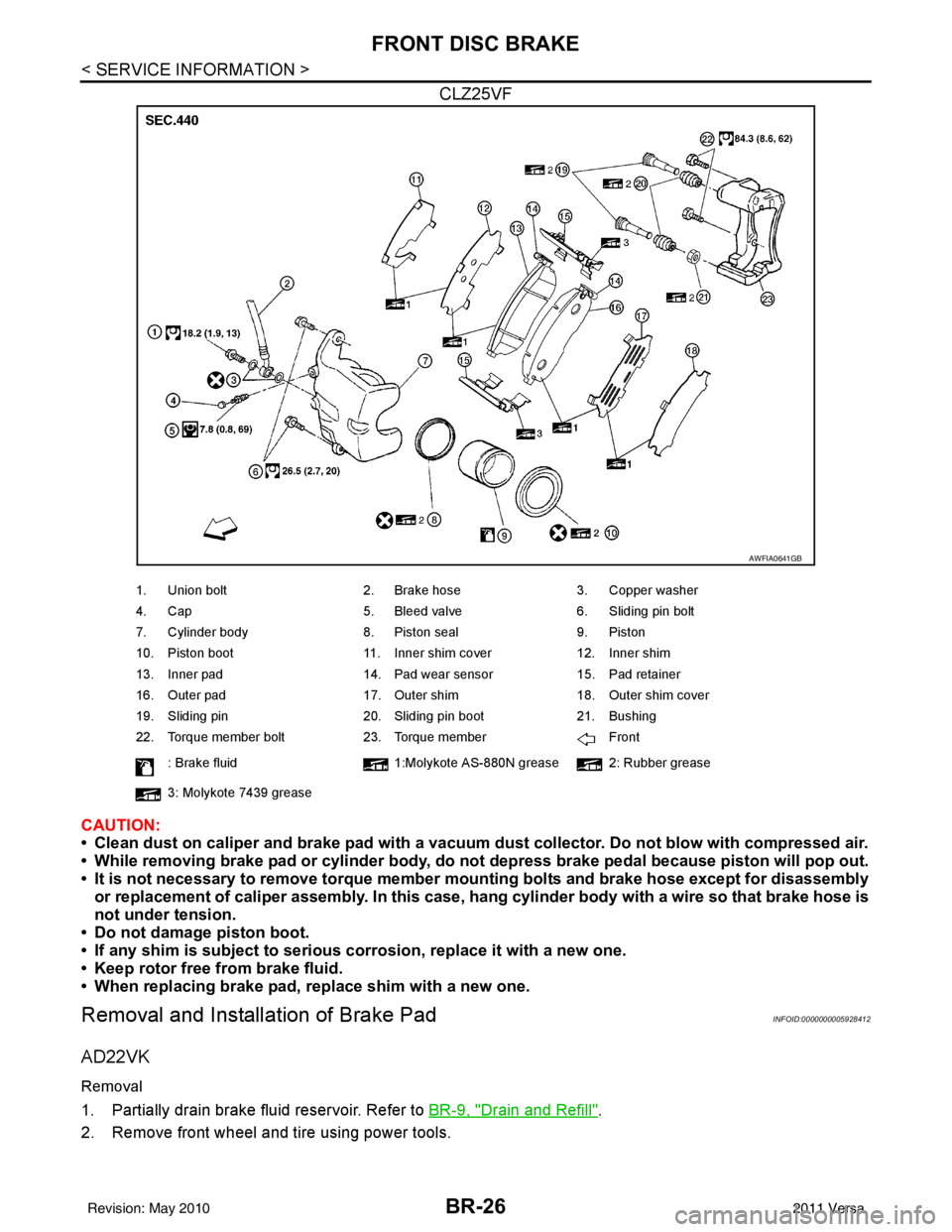

AWFIA0641GB

1. Union bolt 2. Brake hose3. Copper washer

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Cylinder body 8. Piston seal9. Piston

10. Piston boot 11. Inner shim cover12. Inner shim

13. Inner pad 14. Pad wear sensor15. Pad retainer

16. Outer pad 17. Outer shim18. Outer shim cover

19. Sliding pin 20. Sliding pin boot21. Bushing

22. Torque member bolt 23. Torque member Front

: Brake fluid 1:Molykote AS-880N grease 2: Rubber grease

3: Molykote 7439 grease

Revision: May 2010 2011 Versa

Page 877 of 3787

BR-30

< SERVICE INFORMATION >

FRONT DISC BRAKE

Removal and Installation of Brake Caliper Assembly

INFOID:0000000005928413

REMOVAL

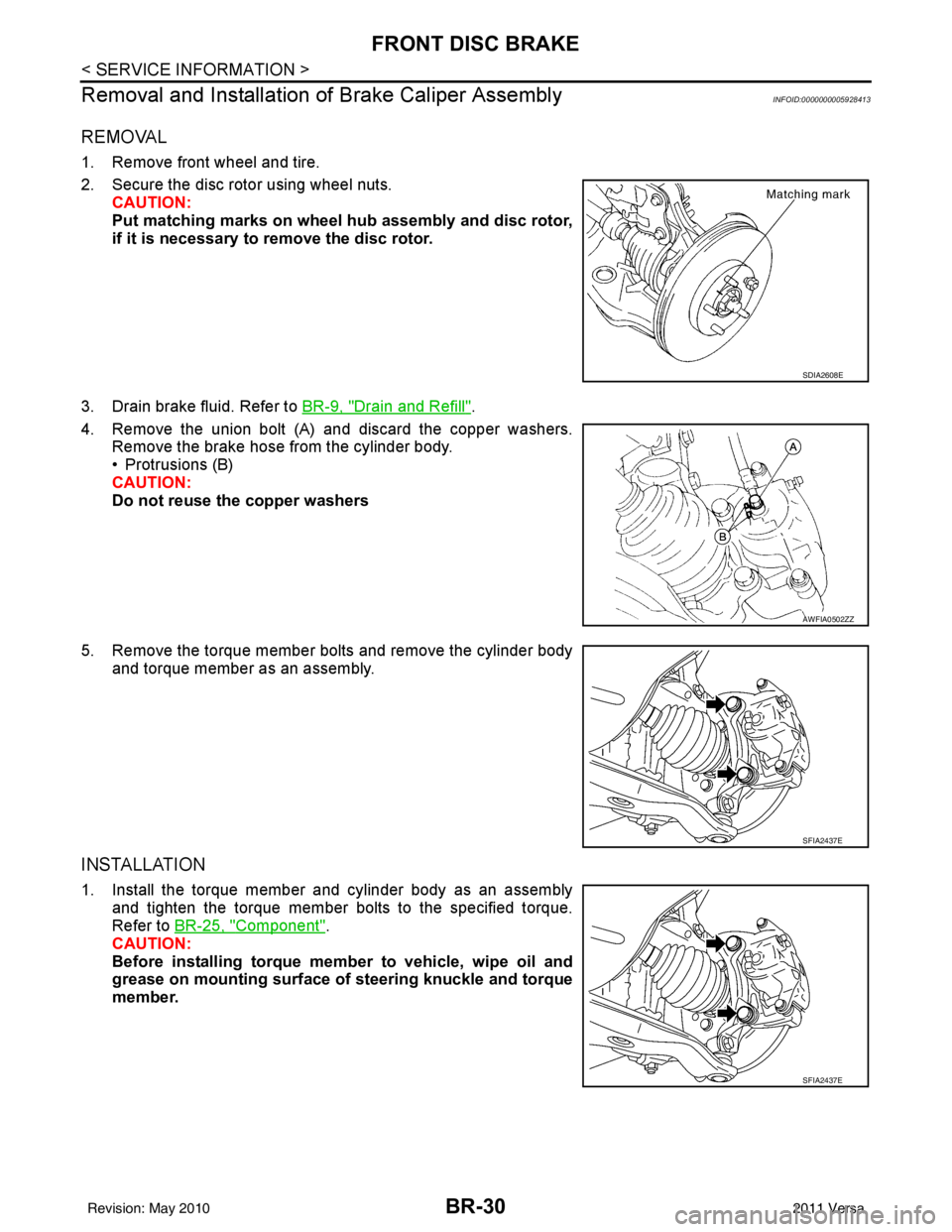

1. Remove front wheel and tire.

2. Secure the disc rotor using wheel nuts.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor,

if it is necessary to remove the disc rotor.

3. Drain brake fluid. Refer to BR-9, "

Drain and Refill".

4. Remove the union bolt (A) and discard the copper washers. Remove the brake hose from the cylinder body.

• Protrusions (B)

CAUTION:

Do not reuse the copper washers

5. Remove the torque member bolts and remove the cylinder body and torque member as an assembly.

INSTALLATION

1. Install the torque member and cylinder body as an assemblyand tighten the torque member bolts to the specified torque.

Refer to BR-25, "

Component".

CAUTION:

Before installing torque member to vehicle, wipe oil and

grease on mounting surface of steering knuckle and torque

member.

SDIA2608E

AWFIA0502ZZ

SFIA2437E

SFIA2437E

Revision: May 2010 2011 Versa

Page 878 of 3787

FRONT DISC BRAKEBR-31

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

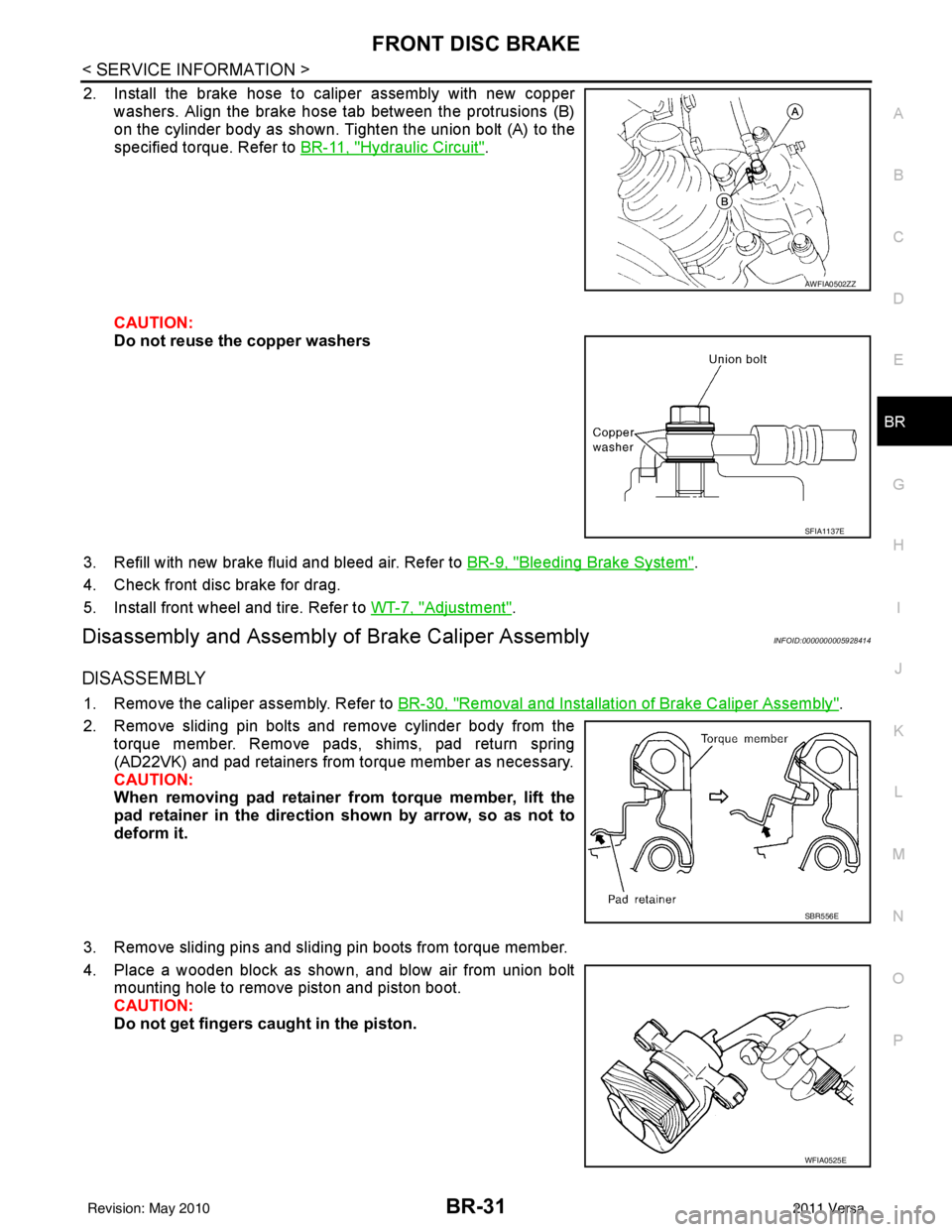

2. Install the brake hose to caliper assembly with new copper washers. Align the brake hose tab between the protrusions (B)

on the cylinder body as shown. Tighten the union bolt (A) to the

specified torque. Refer to BR-11, "

Hydraulic Circuit".

CAUTION:

Do not reuse the copper washers

3. Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

4. Check front disc brake for drag.

5. Install front wheel and tire. Refer to WT-7, "

Adjustment".

Disassembly and Assembly of Brake Caliper AssemblyINFOID:0000000005928414

DISASSEMBLY

1. Remove the caliper assembly. Refer to BR-30, "Removal and Installation of Brake Caliper Assembly".

2. Remove sliding pin bolts and remove cylinder body from the torque member. Remove pads, shims, pad return spring

(AD22VK) and pad retainers from torque member as necessary.

CAUTION:

When removing pad retainer from torque member, lift the

pad retainer in the direction shown by arrow, so as not to

deform it.

3. Remove sliding pins and sliding pin boots from torque member.

4. Place a wooden block as shown, and blow air from union bolt mounting hole to remove piston and piston boot.

CAUTION:

Do not get fingers caught in the piston.

AWFIA0502ZZ

SFIA1137E

SBR556E

WFIA0525E

Revision: May 2010 2011 Versa

Page 879 of 3787

BR-32

< SERVICE INFORMATION >

FRONT DISC BRAKE

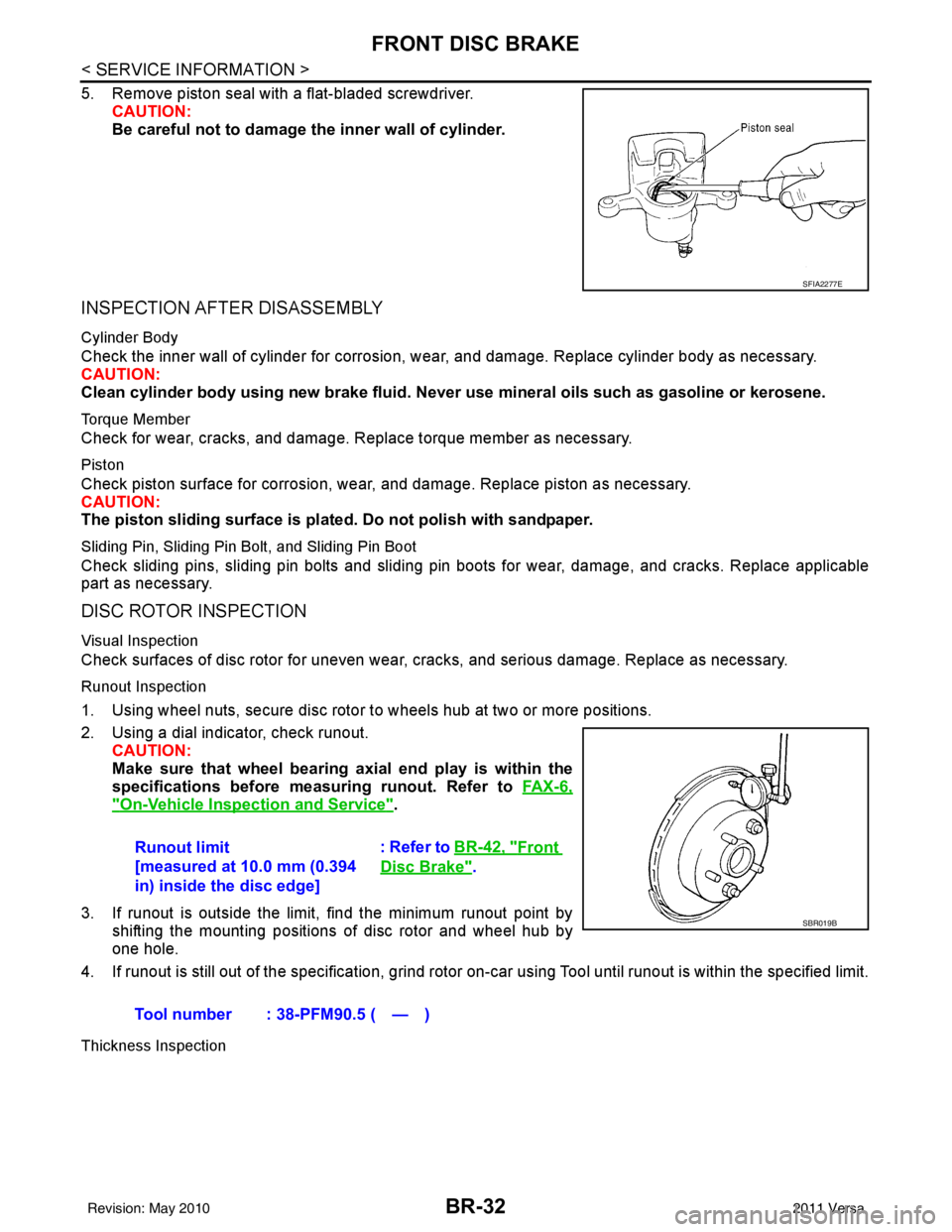

5. Remove piston seal with a flat-bladed screwdriver.CAUTION:

Be careful not to damage the inner wall of cylinder.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, w ear, and damage. Replace cylinder body as necessary.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. R eplace torque member as necessary.

Piston

Check piston surface for corrosion, wear, and damage. Replace piston as necessary.

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check sliding pins, sliding pin bolts and sliding pin boots for wear, damage, and cracks. Replace applicable

part as necessary.

DISC ROTOR INSPECTION

Visual Inspection

Check surfaces of disc rotor for uneven wear, cr acks, and serious damage. Replace as necessary.

Runout Inspection

1. Using wheel nuts, secure disc rotor to wheels hub at two or more positions.

2. Using a dial indicator, check runout.

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer to FA X - 6 ,

"On-Vehicle Inspection and Service".

3. If runout is outside the limit, find the minimum runout point by shifting the mounting positions of disc rotor and wheel hub by

one hole.

4. If runout is still out of the specification, grind rotor on-car using Tool until runout is within the specified limit.

Thickness Inspection

SFIA2277E

Runout limit

[measured at 10.0 mm (0.394

in) inside the disc edge] : Refer to BR-42, "Front

Disc Brake".

Tool number : 38-PFM90.5 ( — )

SBR019B

Revision: May 2010 2011 Versa

Page 886 of 3787

REAR DRUM BRAKEBR-39

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. Connect the parking brake rear cable to the operating lever.

6. Install the shoe assembly. After assembly, be sure that each part is installed properly. CAUTION:

Do not damage the wheel cylinder piston boot.

7. Install the brake drum.

8. Depress brake pedal for several times (approximately 2 or 3 times).

9. Adjust clearance of brake shoe. Refer to PB-5, "

On-Vehicle Service".

10. Install rear wheel and tire. Refer to WT-7, "

Adjustment".

Removal and Installati on of Wheel CylinderINFOID:0000000005928418

REMOVAL

1. Drain the brake fluid. Refer to BR-9, "Drain and Refill".

2. Remove the rear brake shoe assembly. Refer to BR-36, "

Removal and Installation of Drum Brake Assem-

bly".

3. Remove the bleed valve.

4. Disconnect the brake tube from the wheel cylinder.

5. Remove the wheel cylinder bolts and then remove the wheel cylinder from the back plate.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten bolts and bleed valve to the specified torque. Refer to BR-35, "

Component".

• Refill with new brake fluid and bleed the air. Refer to BR-9, "

Bleeding Brake System".

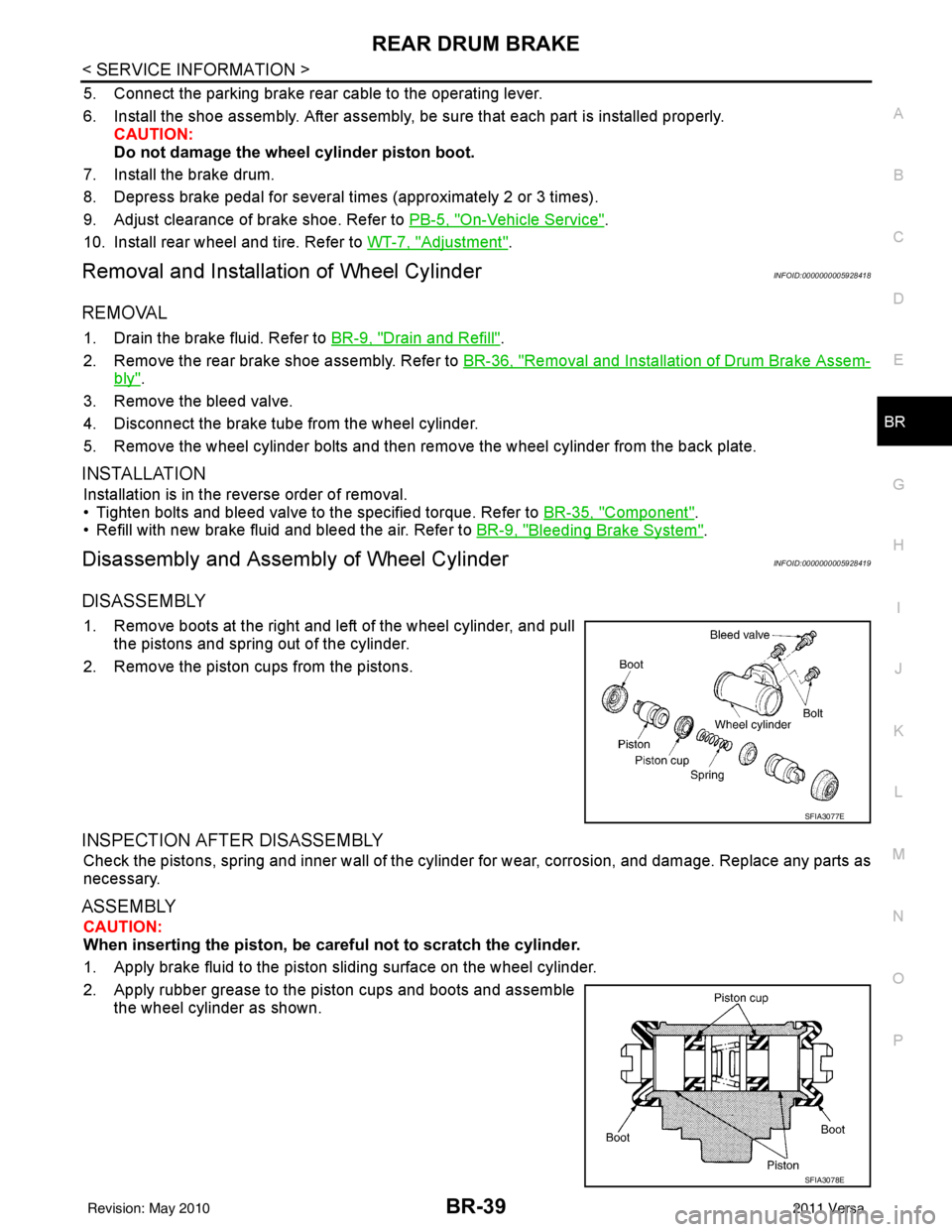

Disassembly and Assembly of Wheel CylinderINFOID:0000000005928419

DISASSEMBLY

1. Remove boots at the right and left of the wheel cylinder, and pull

the pistons and spring out of the cylinder.

2. Remove the piston cups from the pistons.

INSPECTION AFTER DISASSEMBLY

Check the pistons, spring and inner wall of the cylinder for wear, corrosion, and damage. Replace any parts as

necessary.

ASSEMBLY

CAUTION:

When inserting the piston, be caref ul not to scratch the cylinder.

1. Apply brake fluid to the piston sliding surface on the wheel cylinder.

2. Apply rubber grease to the piston cups and boots and assemble the wheel cylinder as shown.

SFIA3077E

SFIA3078E

Revision: May 2010 2011 Versa

Page 925 of 3787

![NISSAN TIIDA 2011 Service Repair Manual BRC-36

< SERVICE INFORMATION >[ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005928459

CAUTION:

• Before servicing, disconnec NISSAN TIIDA 2011 Service Repair Manual BRC-36

< SERVICE INFORMATION >[ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005928459

CAUTION:

• Before servicing, disconnec](/img/5/57396/w960_57396-924.png)

BRC-36

< SERVICE INFORMATION >[ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005928459

CAUTION:

• Before servicing, disconnect battery negative terminal.

• To remove brake tube, use flare nut wrench to pr

event flare nuts and brake tube from being dam-

aged. To install, use flare nut torque wrench, tighten flare nut to the specified torque. Refer to BR-11,

"Hydraulic Circuit".

• Do not apply excessive impact to ABS actuator and electric unit (control unit), such as dropping it.

• Do not remove and install actuator by holding harness.

• After work is completed, bleed the ai r from the brake hydraulic system. Refer to BR-9, "

Bleeding

Brake System".

REMOVAL

1. Disconnect the battery negative terminal.

2. Remove the cowl top. Refer to EI-24, "

Removal and Installation".

3. Disconnect ABS actuator and electric unit (control unit) connector.

4. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

5. Remove brake booster hose from engine. Refer to BR-23, "

Removal and Installation".

6. Remove ABS actuator and electric unit (control unit) bracket bolts.

7. Remove ABS actuator and electric unit (control unit).

1. To front right caliper 2. To rear left wheel cylinder 3. To rear right wheel cylinder

4. To front left caliper 5. From master cylinder primary side 6. From master cylinder secondary side

7. ABS actuator and electric unit (control unit) 8. Harness connector

Front

AWFIA0532GB

Revision: May 2010 2011 Versa

Page 978 of 3787

![NISSAN TIIDA 2011 Service Repair Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-89

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:000000000592850 NISSAN TIIDA 2011 Service Repair Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-89

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:000000000592850](/img/5/57396/w960_57396-977.png)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-89

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005928509

CAUTION:

• Before servicing, disconnect battery negative terminal.

• To remove brake tube, use flare nut wrench to pr event flare nuts and brake tube from being dam-

aged. To install, use flare nut torque wrench, ti ghten flare nut to the specified torque. Refer to BR-11,

"Hydraulic Circuit".

• Do not apply excessive impact to ABS actuator and elect ric unit (control unit), such as dropping it.

• Do not remove and install actuator by holding harness.

• After work is completed, bleed the air from the brake hydraulic system. Refer to BR-9, "

Bleeding

Brake System".

REMOVAL

1. Disconnect the battery negative terminal.

2. Remove the cowl top. Refer to EI-24, "

Removal and Installation".

3. Disconnect ABS actuator and electric unit (control unit) connector.

4. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

5. Remove brake booster hose from engine. Refer to BR-23, "

Removal and Installation".

6. Remove ABS actuator and electric unit (control unit) bracket bolts.

7. Remove ABS actuator and electric unit (control unit).

1. To front right caliper 2. To rear left wheel cylinder 3. To rear right wheel cylinder

4. To front left caliper 5. From master cylinder primary side 6. From master cylinder secondary side

7. ABS actuator and electric unit (control unit) 8. Harness connector

Front

AWFIA0532GB

Revision: May 2010 2011 Versa

Page 997 of 3787

CL-16

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

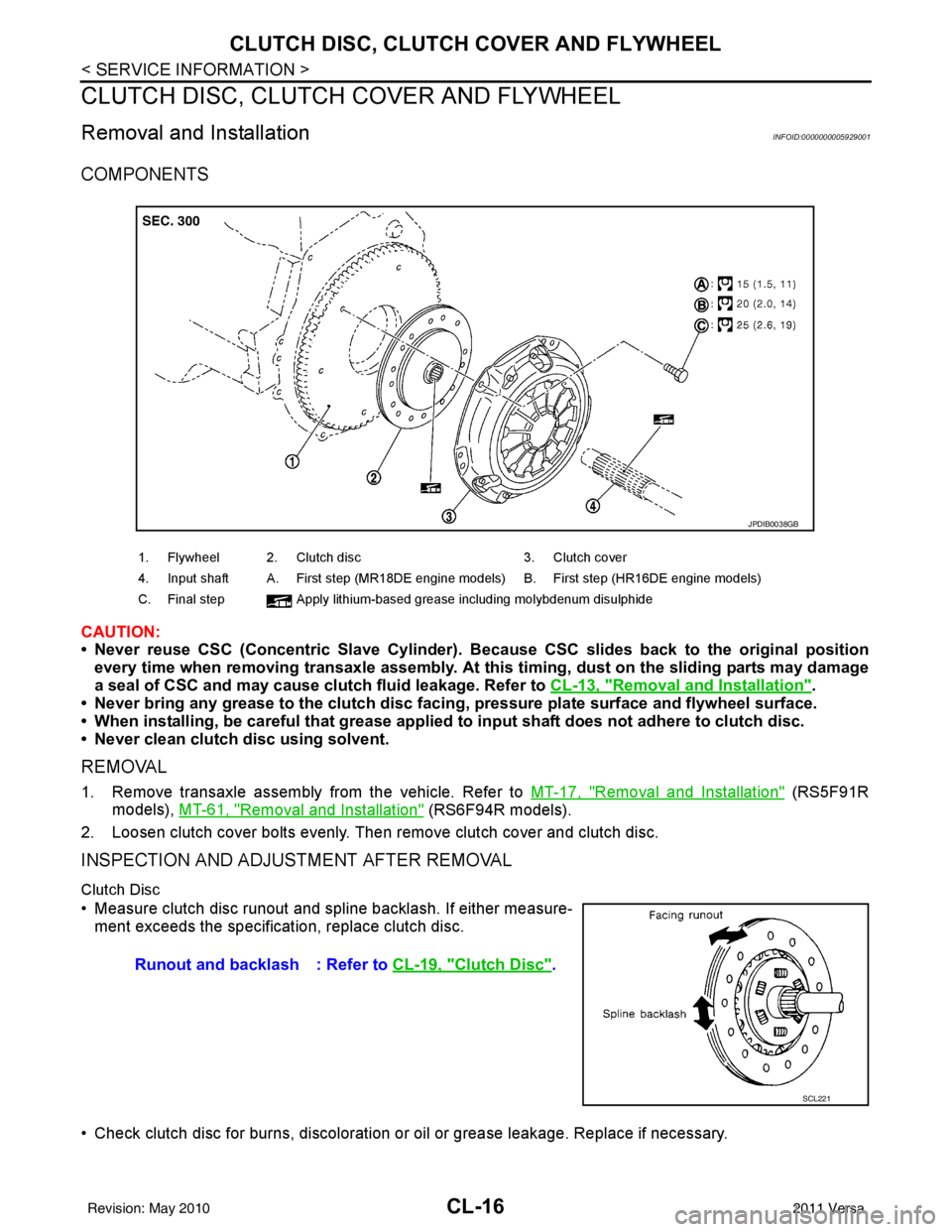

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Removal and InstallationINFOID:0000000005929001

COMPONENTS

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the original position

every time when removing transaxle assembly. At this timing, dust on the sliding parts may damage

a seal of CSC and may cause clutch fluid leakage. Refer to CL-13, "

Removal and Installation".

• Never bring any grease to the clutch disc faci ng, pressure plate surface and flywheel surface.

• When installing, be careful that grease applied to input shaft does not adhere to clutch disc.

• Never clean clutch disc using solvent.

REMOVAL

1. Remove transaxle assembly from the vehicle. Refer to MT-17, "Removal and Installation" (RS5F91R

models), MT-61, "

Removal and Installation" (RS6F94R models).

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

INSPECTION AND ADJUSTMENT AFTER REMOVAL

Clutch Disc

• Measure clutch disc runout and spline backlash. If either measure- ment exceeds the specificat ion, replace clutch disc.

• Check clutch disc for burns, discoloration or oil or grease leakage. Replace if necessary.

1. Flywheel 2. Clutch disc 3. Clutch cover

4. Input shaft A. First step (MR18DE engine models) B. First step (HR16DE engine models)

C. Final step Apply lithium-based grease including molybdenum disulphide

JPDIB0038GB

Runout and backlash : Refer to CL-19, "Clutch Disc".

SCL221

Revision: May 2010 2011 Versa

Page 999 of 3787

CL-18

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

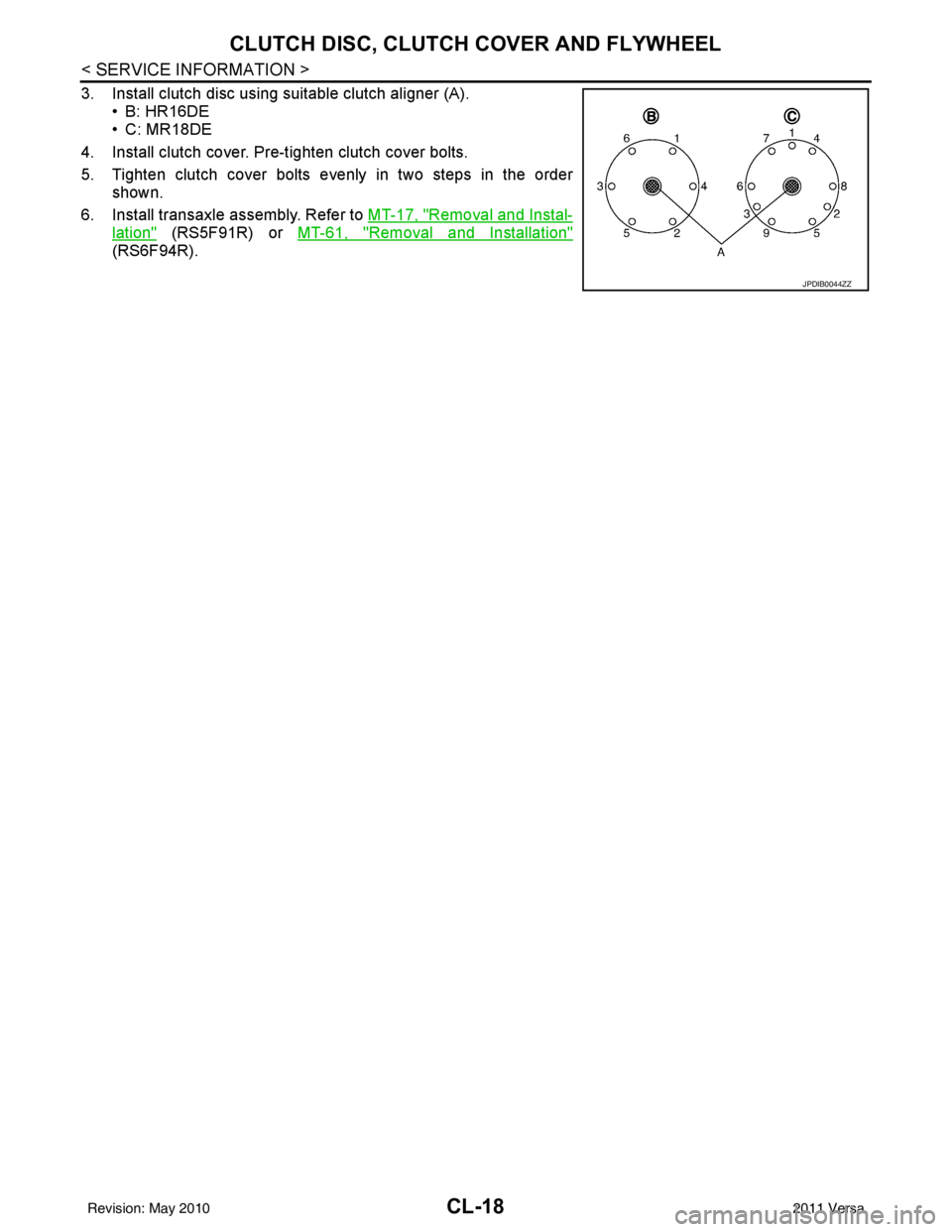

3. Install clutch disc using suitable clutch aligner (A).• B: HR16DE

• C: MR18DE

4. Install clutch cover. Pre-tighten clutch cover bolts.

5. Tighten clutch cover bolts evenly in two steps in the order shown.

6. Install transaxle assembly. Refer to MT-17, "

Removal and Instal-

lation" (RS5F91R) or MT-61, "Removal and Installation"

(RS6F94R).

JPDIB0044ZZ

Revision: May 2010 2011 Versa