ignition NISSAN TITAN 2020 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2020, Model line: TITAN, Model: NISSAN TITAN 2020Pages: 657, PDF Size: 5.1 MB

Page 504 of 657

CAUTION

• Do not ground accessories directly to

the battery terminal. Doing so will

bypass the variable voltage control

system and the vehicle battery may

not charge completely.

• Use electrical accessories with the

engine running to avoid discharging

the vehicle battery.

NOTE:

If the battery is dead the transmission

will not manually shif t into another

position.

Your vehicle is equipped with a variable

voltage control system. This system mea-

sures the amount of electrical discharge

from the battery and controls voltage gen-

erated by the generator.

The current sensor is located near the bat-

tery along the negative battery cable. If you

add electrical accessories to your vehicle,

be sure to ground them to a suitable body

ground such as the frame or engine block

area.

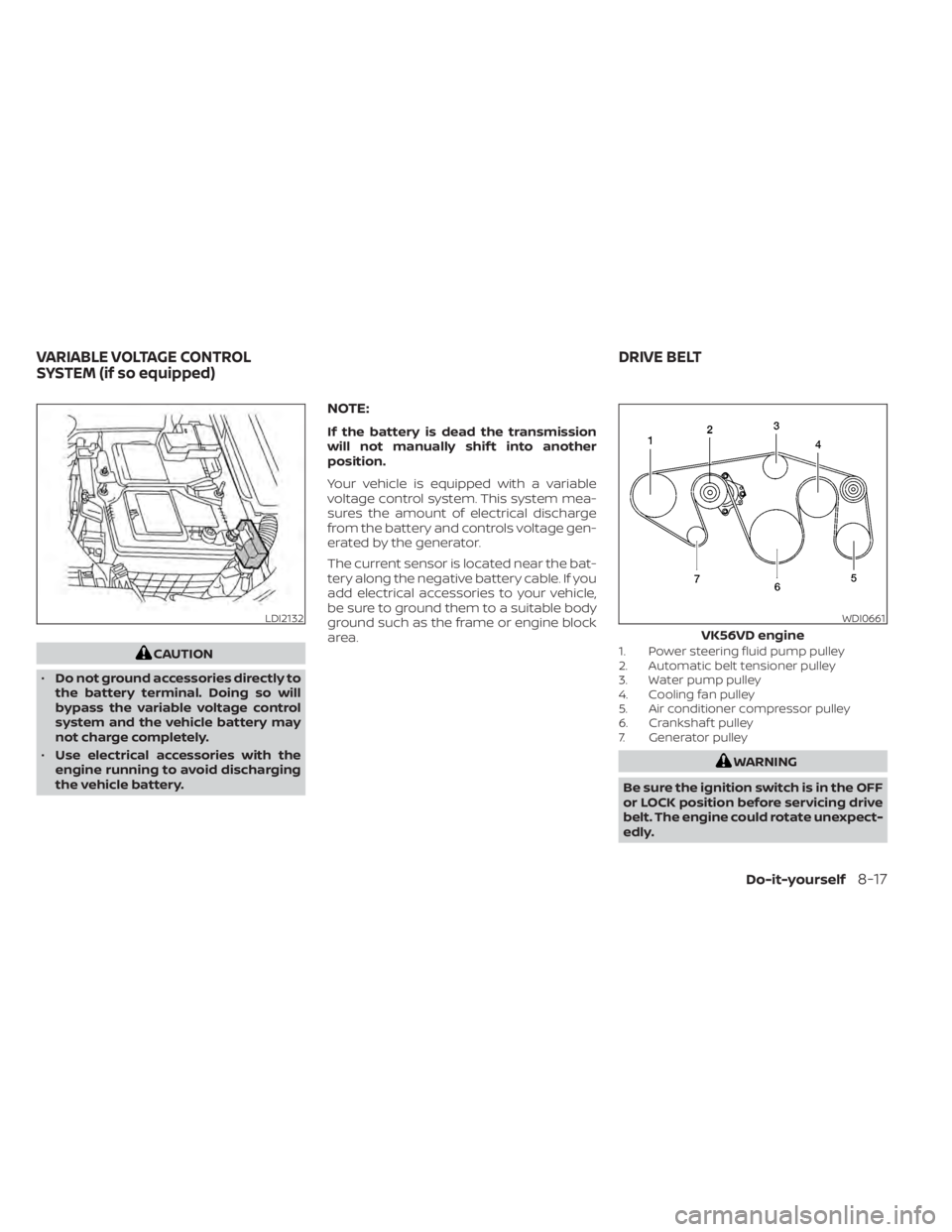

1. Power steering fluid pump pulley

2. Automatic belt tensioner pulley

3. Water pump pulley

4. Cooling fan pulley

5. Air conditioner compressor pulley

6. Crankshaf t pulley

7. Generator pulley

WARNING

Be sure the ignition switch is in the OFF

or LOCK position before servicing drive

belt. The engine could rotate unexpect-

edly.

LDI2132WDI0661

VK56VD engine

VARIABLE VOLTAGE CONTROL

SYSTEM (if so equipped) DRIVE BELT

Do-it-yourself8-17

Page 505 of 657

1. Visually inspect the belt for signs of un-usual wear, cuts, fraying or looseness. If

the belt is in poor condition or is loose,

have it replaced or adjusted. It is recom-

mended that you visit a NISSAN dealer

for this service.

2. Have the belt checked regularly for con- dition and tension in accordance with

the maintenance schedule. For addi-

tional information, refer to the "Mainte-

nance and schedules" section of this

manual.

REPLACING SPARK PLUGS

Iridium-tipped spark plugs

It is not necessary to replace iridium-

tipped spark plugs as frequently as con-

ventional type spark plugs because they

last much longer. Follow the maintenance

log shown in the “Maintenance and sched-

ules” section of this manual. Do not service

iridium-tipped spark plugs by cleaning or

regapping.

•Always replace spark plugs with rec-

ommended or equivalent ones.

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to re-

move the spark plugs. An incorrect

socket can damage the spark plugs.

If replacement is required, it is recom-

mended that you visit a NISSAN dealer for

this service.

LDI2972

SPARK PLUGS

8-18Do-it-yourself

Page 510 of 657

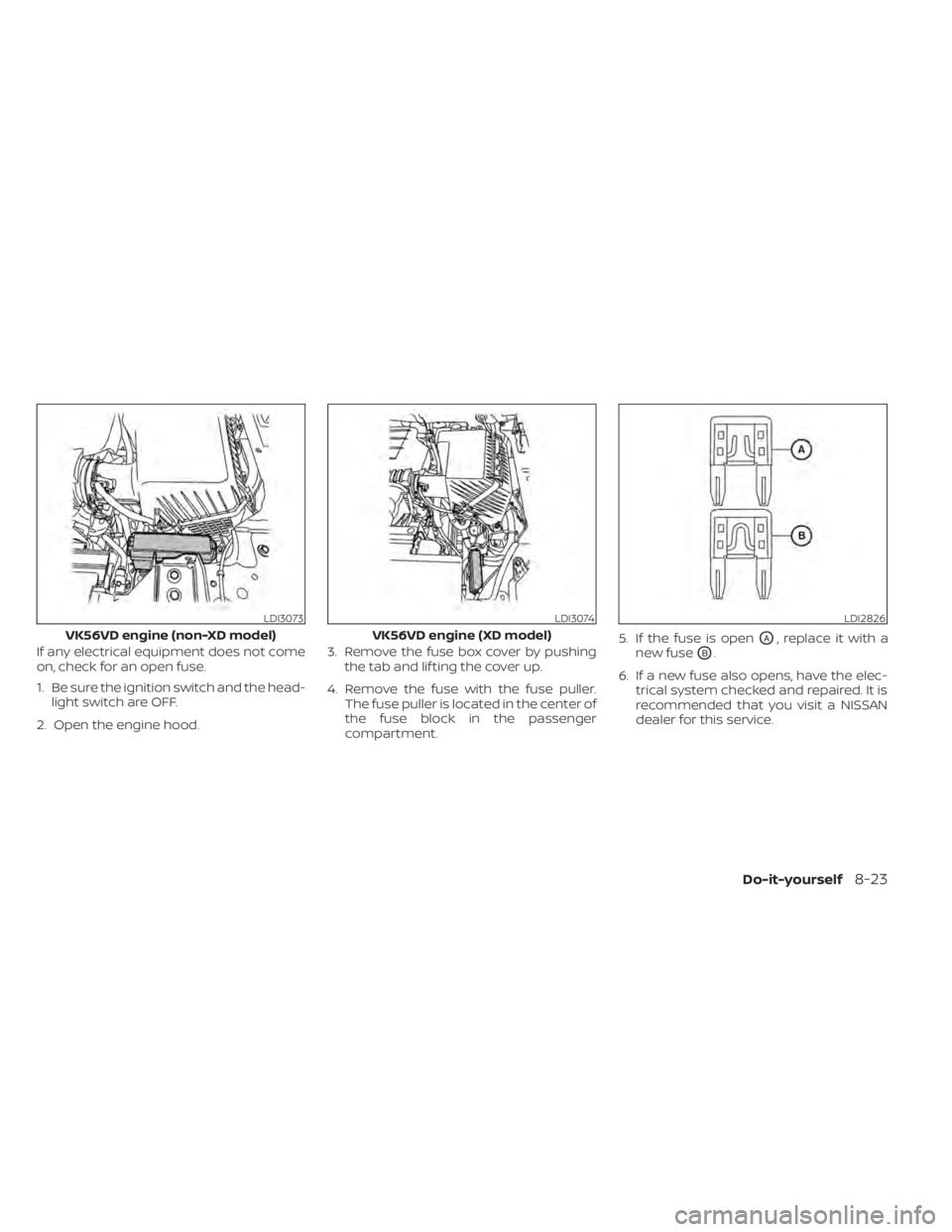

If any electrical equipment does not come

on, check for an open fuse.

1. Be sure the ignition switch and the head-light switch are OFF.

2. Open the engine hood. 3. Remove the fuse box cover by pushing

the tab and lif ting the cover up.

4. Remove the fuse with the fuse puller. The fuse puller is located in the center of

the fuse block in the passenger

compartment. 5. If the fuse is openOA, replace it with a

new fuse

OB.

6. If a new fuse also opens, have the elec- trical system checked and repaired. It is

recommended that you visit a NISSAN

dealer for this service.

LDI3073

VK56VD engine (non-XD model)

LDI3074

VK56VD engine (XD model)

LDI2826

Do-it-yourself8-23

Page 511 of 657

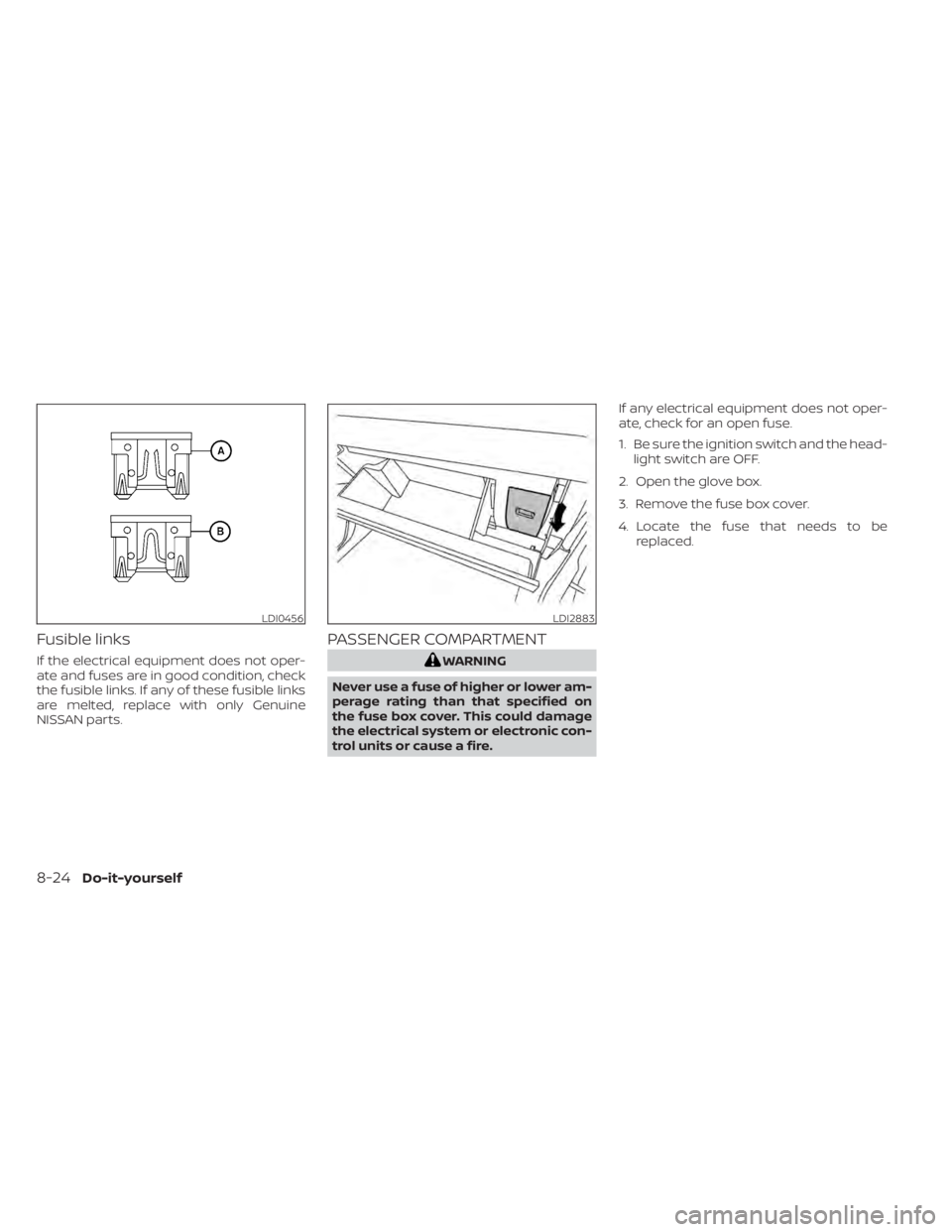

Fusible links

If the electrical equipment does not oper-

ate and fuses are in good condition, check

the fusible links. If any of these fusible links

are melted, replace with only Genuine

NISSAN parts.

PASSENGER COMPARTMENT

WARNING

Never use a fuse of higher or lower am-

perage rating than that specified on

the fuse box cover. This could damage

the electrical system or electronic con-

trol units or cause a fire. If any electrical equipment does not oper-

ate, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the glove box.

3. Remove the fuse box cover.

4. Locate the fuse that needs to be replaced.

LDI0456LDI2883

8-24Do-it-yourself

Page 516 of 657

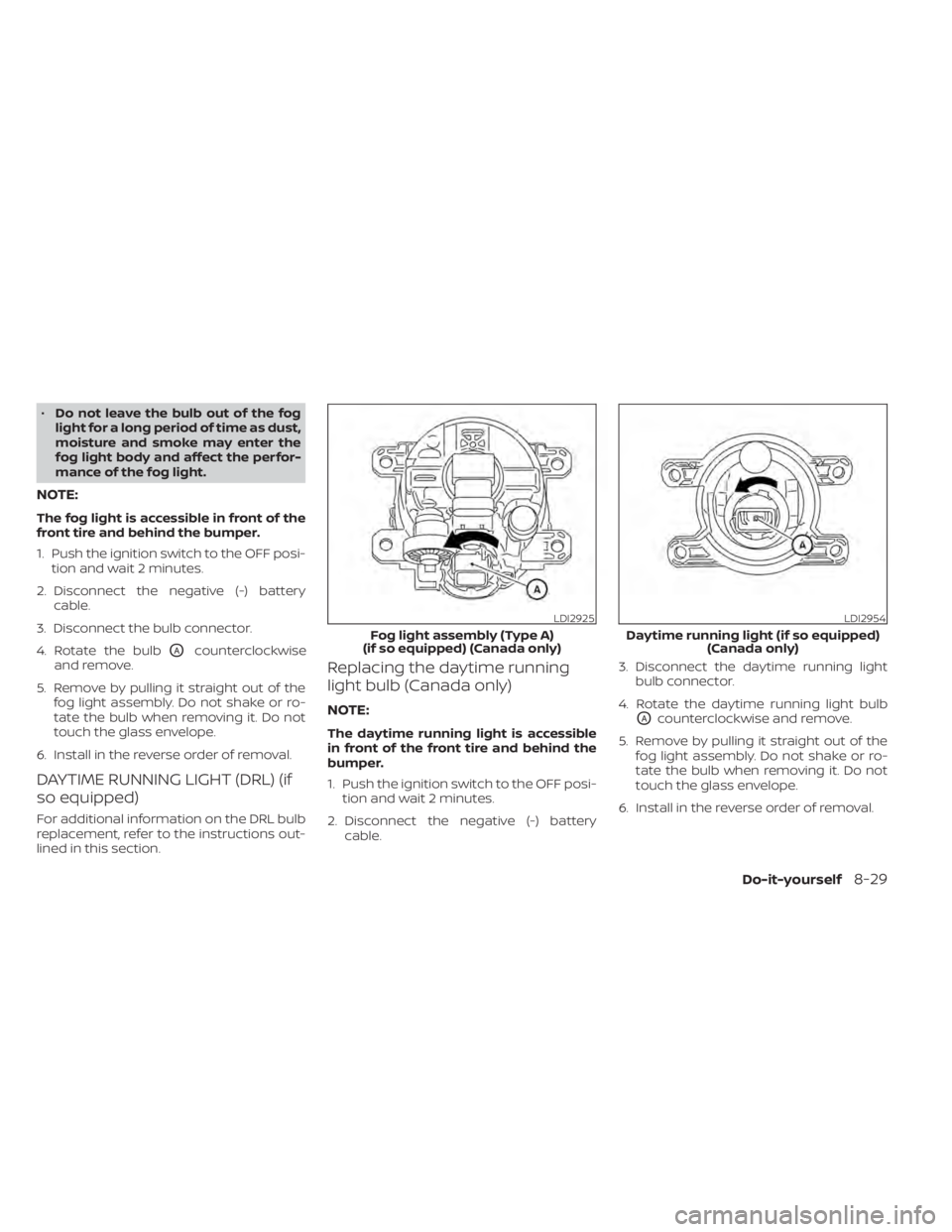

•Do not leave the bulb out of the fog

light for a long period of time as dust,

moisture and smoke may enter the

fog light body and affect the perfor-

mance of the fog light.

NOTE:

The fog light is accessible in front of the

front tire and behind the bumper.

1. Push the ignition switch to the OFF posi- tion and wait 2 minutes.

2. Disconnect the negative (-) battery cable.

3. Disconnect the bulb connector.

4. Rotate the bulb

OAcounterclockwise

and remove.

5. Remove by pulling it straight out of the fog light assembly. Do not shake or ro-

tate the bulb when removing it. Do not

touch the glass envelope.

6. Install in the reverse order of removal.

DAYTIME RUNNING LIGHT (DRL) (if

so equipped)

For additional information on the DRL bulb

replacement, refer to the instructions out-

lined in this section.

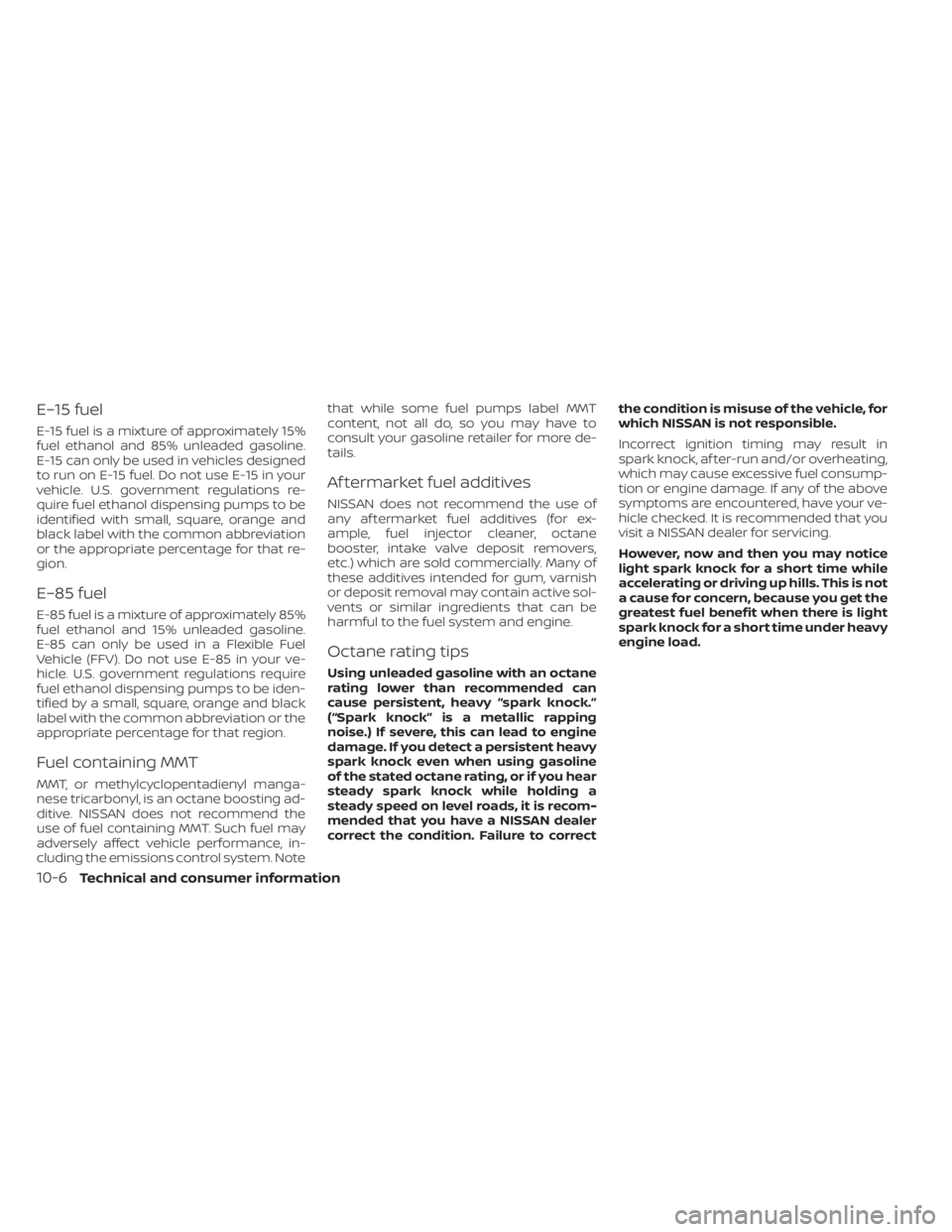

Replacing the daytime running

light bulb (Canada only)

NOTE:

The daytime running light is accessible

in front of the front tire and behind the

bumper.

1. Push the ignition switch to the OFF posi- tion and wait 2 minutes.

2. Disconnect the negative (-) battery cable. 3. Disconnect the daytime running light

bulb connector.

4. Rotate the daytime running light bulbOAcounterclockwise and remove.

5. Remove by pulling it straight out of the fog light assembly. Do not shake or ro-

tate the bulb when removing it. Do not

touch the glass envelope.

6. Install in the reverse order of removal.

LDI2925

Fog light assembly (Type A)

(if so equipped) (Canada only)

LDI2954

Daytime running light (if so equipped) (Canada only)

Do-it-yourself8-29

Page 555 of 657

E–15 fuel

E-15 fuel is a mixture of approximately 15%

fuel ethanol and 85% unleaded gasoline.

E-15 can only be used in vehicles designed

to run on E-15 fuel. Do not use E-15 in your

vehicle. U.S. government regulations re-

quire fuel ethanol dispensing pumps to be

identified with small, square, orange and

black label with the common abbreviation

or the appropriate percentage for that re-

gion.

E–85 fuel

E-85 fuel is a mixture of approximately 85%

fuel ethanol and 15% unleaded gasoline.

E-85 can only be used in a Flexible Fuel

Vehicle (FFV). Do not use E-85 in your ve-

hicle. U.S. government regulations require

fuel ethanol dispensing pumps to be iden-

tified by a small, square, orange and black

label with the common abbreviation or the

appropriate percentage for that region.

Fuel containing MMT

MMT, or methylcyclopentadienyl manga-

nese tricarbonyl, is an octane boosting ad-

ditive. NISSAN does not recommend the

use of fuel containing MMT. Such fuel may

adversely affect vehicle performance, in-

cluding the emissions control system. Notethat while some fuel pumps label MMT

content, not all do, so you may have to

consult your gasoline retailer for more de-

tails.

Af termarket fuel additives

NISSAN does not recommend the use of

any af termarket fuel additives (for ex-

ample, fuel injector cleaner, octane

booster, intake valve deposit removers,

etc.) which are sold commercially. Many of

these additives intended for gum, varnish

or deposit removal may contain active sol-

vents or similar ingredients that can be

harmful to the fuel system and engine.

Octane rating tips

Using unleaded gasoline with an octane

rating lower than recommended can

cause persistent, heavy “spark knock.”

(“Spark knock” is a metallic rapping

noise.) If severe, this can lead to engine

damage. If you detect a persistent heavy

spark knock even when using gasoline

of the stated octane rating, or if you hear

steady spark knock while holding a

steady speed on level roads, it is recom-

mended that you have a NISSAN dealer

correct the condition. Failure to correct

the condition is misuse of the vehicle, for

which NISSAN is not responsible.

Incorrect ignition timing may result in

spark knock, af ter-run and/or overheating,

which may cause excessive fuel consump-

tion or engine damage. If any of the above

symptoms are encountered, have your ve-

hicle checked. It is recommended that you

visit a NISSAN dealer for servicing.

However, now and then you may notice

light spark knock for a short time while

accelerating or driving up hills. This is not

a cause for concern, because you get the

greatest fuel benefit when there is light

spark knock for a short time under heavy

engine load.

10-6Technical and consumer information

Page 558 of 657

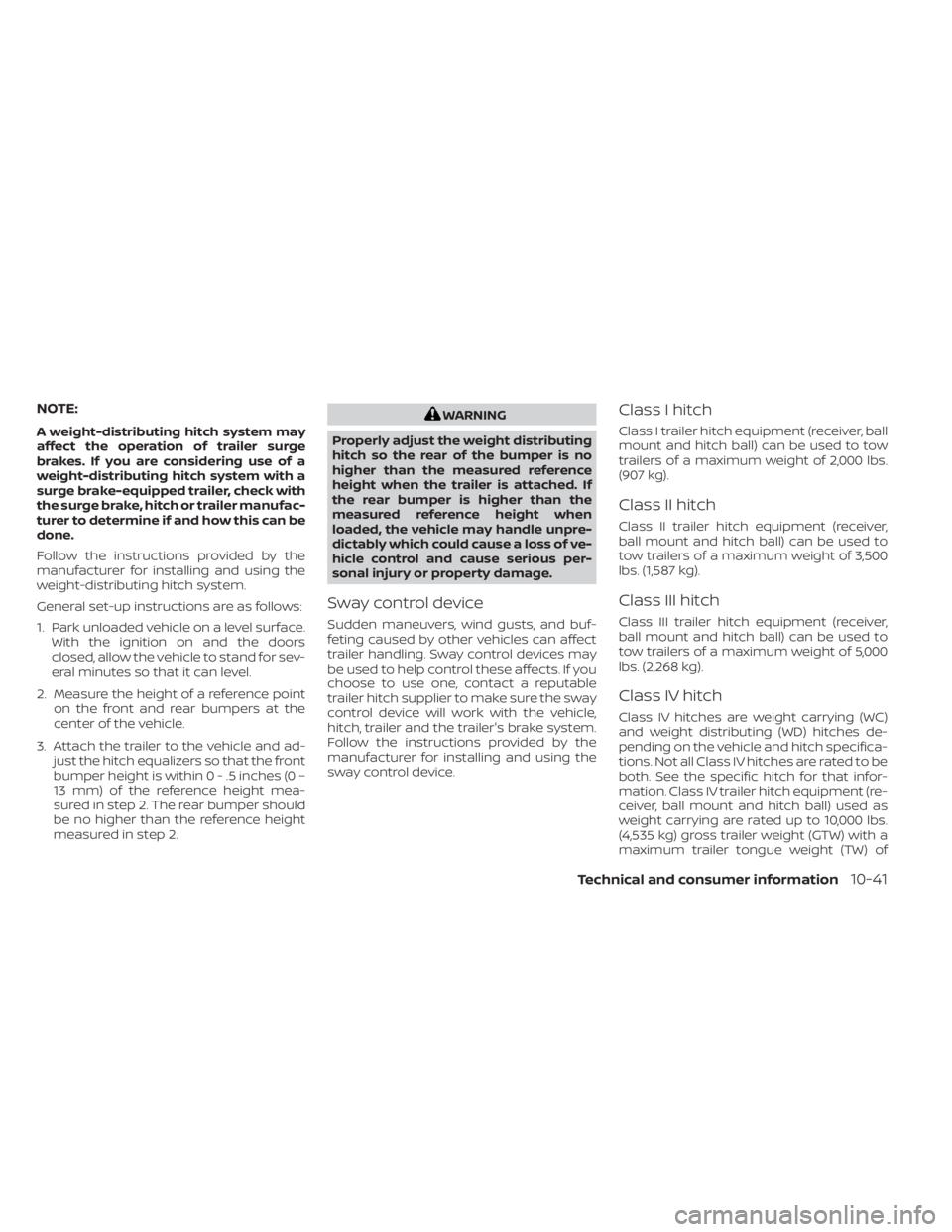

ENGINE

ModelVK56VD

Type Gasoline, 4-cycle, DOHC

Cylinder arrangement 8-cylinder, V-block, Slanted at 90°

Bore x Stroke in (mm) 3.858 x 3.622 (98 x 92)

Displacement cu in (cm

3) 338.78 (5,552)

Firing order 1–8–7–3–6–5–4–2

Idle speed

No adjustment is necessary.

A/T (in “N” position)

Ignition timing (degree B.T.D.C. at idle

speed)

CO%atidle

Spark plug

DILKAR7B11

Spark plug gap (Nominal) in (mm) 0.043 (1.1)

Camshaf t operation Timing chain

This spark ignition system complies with the Canadian standard ICES-002.

SPECIFICATIONS

Technical and consumer information10-9

Page 590 of 657

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check with

the surge brake, hitch or trailer manufac-

turer to determine if and how this can be

done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level surface.With the ignition on and the doors

closed, allow the vehicle to stand for sev-

eral minutes so that it can level.

2. Measure the height of a reference point on the front and rear bumpers at the

center of the vehicle.

3. Attach the trailer to the vehicle and ad- just the hitch equalizers so that the front

bumper height is within0-.5inches (0 –

13 mm) of the reference height mea-

sured in step 2. The rear bumper should

be no higher than the reference height

measured in step 2.

WARNING

Properly adjust the weight distributing

hitch so the rear of the bumper is no

higher than the measured reference

height when the trailer is attached. If

the rear bumper is higher than the

measured reference height when

loaded, the vehicle may handle unpre-

dictably which could cause a loss of ve-

hicle control and cause serious per-

sonal injury or property damage.

Sway control device

Sudden maneuvers, wind gusts, and buf-

feting caused by other vehicles can affect

trailer handling. Sway control devices may

be used to help control these affects. If you

choose to use one, contact a reputable

trailer hitch supplier to make sure the sway

control device will work with the vehicle,

hitch, trailer and the trailer's brake system.

Follow the instructions provided by the

manufacturer for installing and using the

sway control device.

Class I hitch

Class I trailer hitch equipment (receiver, ball

mount and hitch ball) can be used to tow

trailers of a maximum weight of 2,000 lbs.

(907 kg).

Class II hitch

Class II trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of 3,500

lbs. (1,587 kg).

Class III hitch

Class III trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of 5,000

lbs. (2,268 kg).

Class IV hitch

Class IV hitches are weight carrying (WC)

and weight distributing (WD) hitches de-

pending on the vehicle and hitch specifica-

tions. Not all Class IV hitches are rated to be

both. See the specific hitch for that infor-

mation. Class IV trailer hitch equipment (re-

ceiver, ball mount and hitch ball) used as

weight carrying are rated up to 10,000 lbs.

(4,535 kg) gross trailer weight (GTW) with a

maximum trailer tongue weight (TW) of

Technical and consumer information10-41

Page 603 of 657

• Be careful when passing other vehicles.Passing while towing a trailer requires

considerably more distance than normal

passing. Remember, the length of the

trailer must also pass the other vehicle

before you can safely change lanes.

• Use the Tow Mode or downshif t the transmission to a lower gear for engine

braking when driving down steep or long

hills. This will help slow the vehicle without

applying the brakes.

• Avoid holding the brake pedal down too long or too frequently. This could cause

the brakes to overheat, resulting in re-

duced braking efficiency.

• Increase your following distance to allow for greater stopping distances while tow-

ing a trailer. Anticipate stops and brake

gradually.

• NISSAN recommends that the cruise control (if so equipped) not be used while

towing a trailer.

• While towing a trailer, do not use the fol- lowing systems (if so equipped):–– the Lane Departure Warning (LDW) sys- tem

–– the Blind Spot Warning (BSW) system

– – the Intelligent Cruise Control (ICC) sys-

tem –

– the Automatic Emergency Braking

(AEB) system

– – the Intelligent Forward Collision Warn-

ing (I-FCW) system

– – the Rear Automatic Braking (RAB) sys-

tem

– – the Moving Object Detection (MOD)

system

– – the Cross Traffic Alert system

–– the Rear Sonar system

• Some states or provinces have specific regulations and speed limits for vehicles

that are towing trailers. Obey the local

speed limits.

• Check your hitch, trailer wiring harness connections, and trailer wheel lug nuts

af ter 50 miles (80 km) of travel and at

every break.

• When launching a boat, don't allow the water level to go over the exhaust tail

pipe or rear bumper.

• Make sure you disconnect the trailer lights before backing the trailer into the

water or the trailer lights may burn out.

When towing a trailer, final drive gear oil

should be replaced and transmission oil/

fluid should be changed more fre-

quently. For additional information, refer

to the “Do-it-yourself ” section in this

manual.Tow mode

Using tow mode is recommended when

pulling a heavy trailer or hauling a heavy

load. Press the TOW MODE switch to acti-

vate tow mode. The indicator light on the

TOW MODE switch illuminates when tow

mode is selected. Press the TOW MODE

switch again to turn tow mode off. Tow

mode is automatically canceled when the

ignition switch is turned off.

Tow mode includes the following features:

• Grade logic — Adjusts transmission shif ts when pulling a trailer or hauling a load up

a grade.

• Downhill Speed Control (DSC) — auto- matically downshif ts when driving down

a grade with a trailer or heavy load to help

control vehicle speed.

Driving the vehicle in the tow mode with no

trailer/load or light trailer/light load will not

cause any damage. However, fuel

economy may be reduced and the

transmission/engine driving characteris-

tics may feel unusual.

When towing a trailer, final drive gear oil

should be replaced and transmission oil/

fluid should be changed more frequently.

For additional information, refer to the

“Do-it-yourself ” section of this manual.

10-54Technical and consumer information

Page 608 of 657

WARNING

A vehicle equipped with 4-Wheel Drive

(4WD) should never be tested using a

two wheel dynamometer (such as the

dynamometers used by some states

for emissions testing), or similar equip-

ment. Make sure you inform the test

facility personnel that your vehicle is

equipped with 4WD before it is placed

on a dynamometer. Using the wrong

test equipment may result in transmis-

sion damage or unexpected vehicle

movement which could result in seri-

ous vehicle damage or personal injury.

Due to legal requirements in some states

and Canadian Provinces, your vehicle may

be required to be in what is called the

“ready condition” for an Inspection/

Maintenance (I/M) test of the emission

control system.

The vehicle is set to the “ready condition”

when it is driven through certain driving

patterns. Usually, the ready condition can

be obtained by ordinary usage of the ve-

hicle. If a powertrain system component is re-

paired or the battery is disconnected, the

vehicle may be reset to a “not ready ” condi-

tion. Before taking the I/M test, check the

vehicle's inspection/maintenance test

readiness condition. Place the ignition

switch in the ON position without starting

the engine. If the Malfunction Indicator

Light (MIL) comes on steady for 20 seconds

and then blinks for 10 seconds, the I/M test

condition is “not ready”. If the MIL does not

blink af ter 20 seconds, the I/M test condi-

tion is “ready ”. It is recommended that you

visit a NISSAN dealer to set the “ready con-

dition” or to prepare the vehicle for testing.

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an

EDR is to record, in certain crash or near

crash-like situations, such as an air bag

deployment or hitting a road obstacle, data

that will assist in understanding how a ve-

hicle's systems performed. The EDR is de-

signed to record data related to vehicle dy-

namics and safety systems for a short

period of time, typically 30 seconds or less.

The EDR in this vehicle is designed to re-

cord such data as:

• How various systems in your vehicle were

operating;

• Whether or not the driver and passenger safety belts were buckled/fastened;

• How far (if at all) the driver was depress- ing the accelerator and/or brake pedal;

and,

• How fast the vehicle was traveling.

• Sounds are not recorded.

READINESS FOR INSPECTION/

MAINTENANCE (I/M) TEST EVENT DATA RECORDERS (EDR)

Technical and consumer information10-59