display NISSAN TITAN 2022 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2022, Model line: TITAN, Model: NISSAN TITAN 2022Pages: 635, PDF Size: 7.78 MB

Page 450 of 635

When the vehicle is stopped on a hill, the hill

start assist system automatically keeps

the brakes applied. This helps prevents the

vehicle from rolling backward in the time it

takes the driver to release the brake pedal

and apply the accelerator when the vehicle

is stopped on a hill.

Hill start assist will operate automatically

under the following conditions:

• The shif t lever is shif ted to a forward orreverse gear.

• The vehicle is stopped completely on a hill by applying the brake.

The maximum holding time is 2 seconds.

Af ter 2 seconds the vehicle will begin to roll

back and hill start assist will stop operating

completely.

Hill start assist will not operate when the

shif t lever is shif ted into N (Neutral) or P

(Park) or on a flat and level road. When the

indicator light illuminates in the meter,

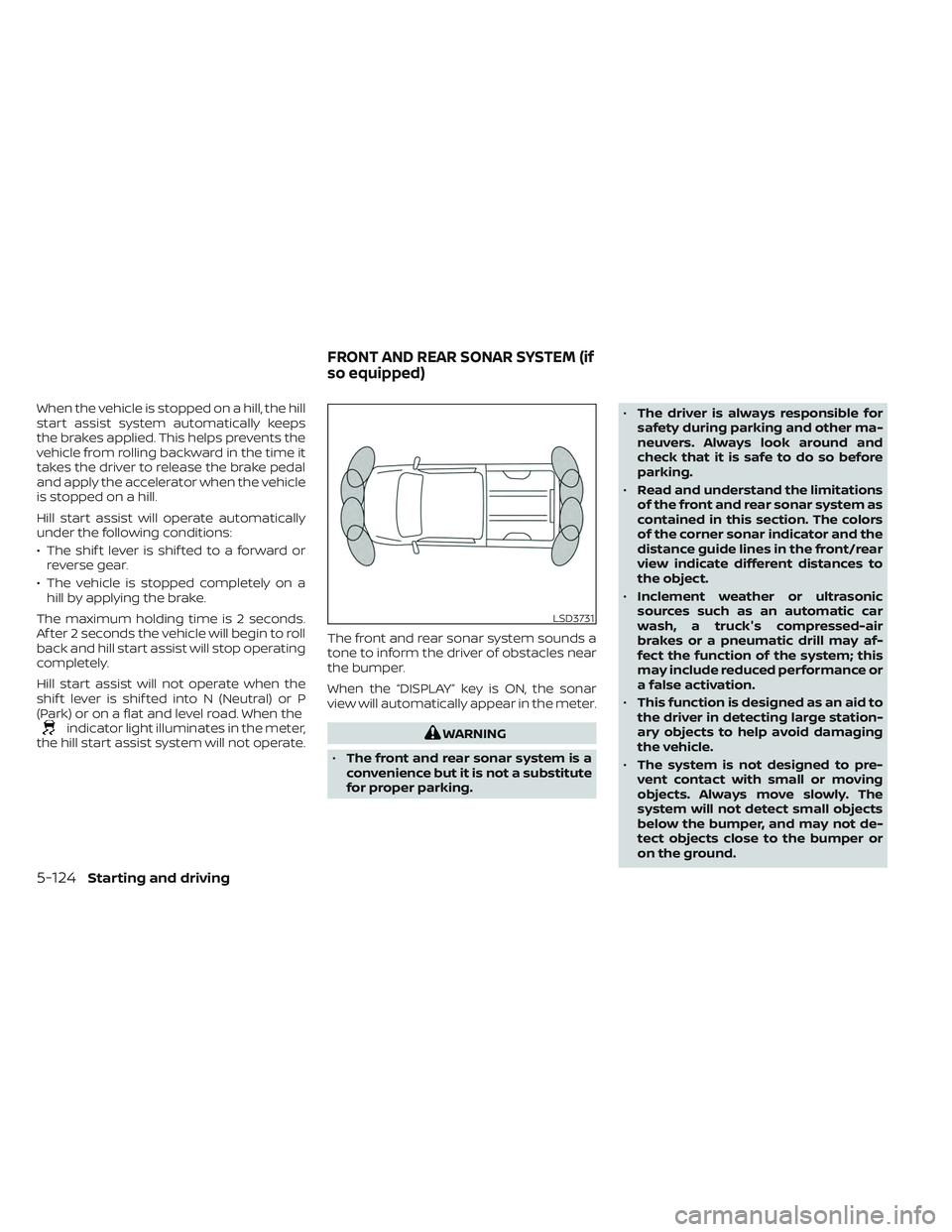

the hill start assist system will not operate. The front and rear sonar system sounds a

tone to inform the driver of obstacles near

the bumper.

When the “DISPLAY” key is ON, the sonar

view will automatically appear in the meter.WARNING

• The front and rear sonar system is a

convenience but it is not a substitute

for proper parking. •

The driver is always responsible for

safety during parking and other ma-

neuvers. Always look around and

check that it is safe to do so before

parking.

• Read and understand the limitations

of the front and rear sonar system as

contained in this section. The colors

of the corner sonar indicator and the

distance guide lines in the front/rear

view indicate different distances to

the object.

• Inclement weather or ultrasonic

sources such as an automatic car

wash, a truck's compressed-air

brakes or a pneumatic drill may af-

fect the function of the system; this

may include reduced performance or

a false activation.

• This function is designed as an aid to

the driver in detecting large station-

ary objects to help avoid damaging

the vehicle.

• The system is not designed to pre-

vent contact with small or moving

objects. Always move slowly. The

system will not detect small objects

below the bumper, and may not de-

tect objects close to the bumper or

on the ground.

LSD3731

FRONT AND REAR SONAR SYSTEM (if

so equipped)

5-124Starting and driving

Page 451 of 635

•The system may not detect the fol-

lowing objects: fluff y objects such as

snow, cloth, cotton, glass, wool, etc.;

thin objects such as rope, wire and

chain, etc.; or wedge-shaped objects.

If your vehicle sustains damage to the

bumper fascia, leaving it misaligned or

bent, the sensing zone may be altered

causing inaccurate measurement of ob-

stacles or false alarms.

CAUTION

• Excessive noise (such as audio sys-

tem volume or an open vehicle win-

dow) will interfere with the tone and

it may not be heard.

• Keep the sonar sensors (located on

the bumper fascia) free from snow,

ice and large accumulations of dirt.

Do not clean the sensors with sharp

objects. If the sensors are covered,

the accuracy of the sonar function

will be diminished.

SYSTEM OPERATION

The system informs with a visual and au-

dible alert of front obstacles when the shif t

lever is in the D (Drive) position and both

front and rear obstacles when the shif t le-

ver is in the R (Reverse) position.

Sonar Operation Table

FR Sensor RR Sensor

Range Sound Display Sound Dis- play

Px†x†

Roooo

Nx†x† Do o x †

o – Display/Beep when detect

† – Display on camera view

x – No Display and Beep

The system is deactivated at speeds above

6 mph (10 km/h). It is reactivated at lower

speeds.

The intermittent tone will stop af ter 3 sec-

onds when an obstacle is detected by only

the corner sensor and the distance does

not change. The tone will stop when the

obstacle gets away from the vehicle. When the object is detected, the indicator

(green) appears and blinks and the tone

sounds intermittently. When the vehicle

moves closer to the object, the color of the

indicator turns yellow and the rate of the

blinking increases. When the vehicle is very

close to the object, the indicator stops

blinking and turns red, and the tone

sounds continuously.

Starting and driving5-125

Page 453 of 635

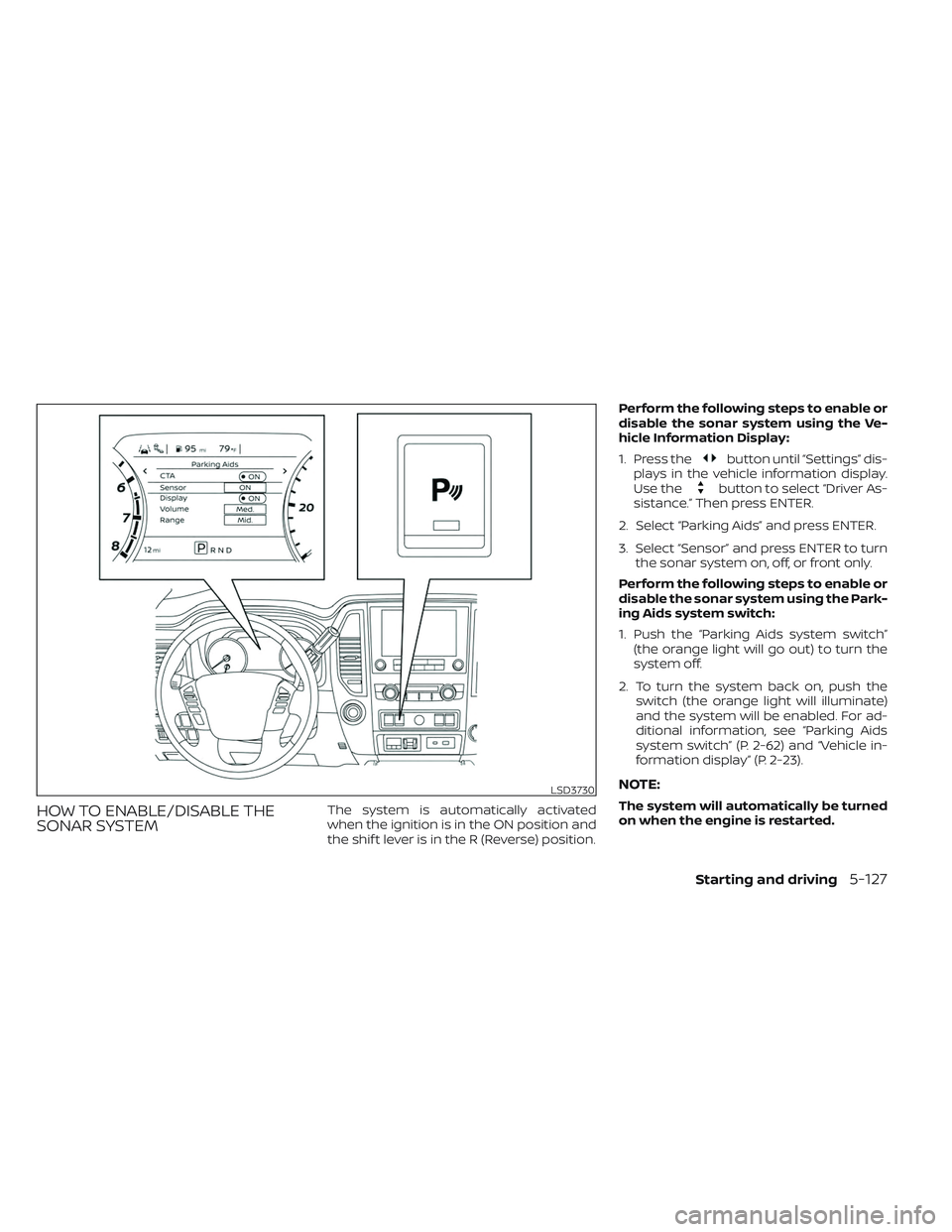

HOW TO ENABLE/DISABLE THE

SONAR SYSTEMThe system is automatically activated

when the ignition is in the ON position and

the shif t lever is in the R (Reverse) position.Perform the following steps to enable or

disable the sonar system using the Ve-

hicle Information Display:

1. Press the

button until “Settings” dis-

plays in the vehicle information display.

Use the

button to select “Driver As-

sistance.” Then press ENTER.

2. Select “Parking Aids” and press ENTER.

3. Select “Sensor” and press ENTER to turn the sonar system on, off, or front only.

Perform the following steps to enable or

disable the sonar system using the Park-

ing Aids system switch:

1. Push the “Parking Aids system switch” (the orange light will go out) to turn the

system off.

2. To turn the system back on, push the switch (the orange light will illuminate)

and the system will be enabled. For ad-

ditional information, see “Parking Aids

system switch” (P. 2-62) and “Vehicle in-

formation display” (P. 2-23).

NOTE:

The system will automatically be turned

on when the engine is restarted.

LSD3730

Starting and driving5-127

Page 459 of 635

TIRE PRESSURE MONITORING

SYSTEM (TPMS)

This vehicle is equipped with TPMS. It moni-

tors tire pressure of all tires except the

spare. When the low tire pressure warning

light is lit, and the Tire Pressure Low — Add

Air warning appears in the vehicle informa-

tion display, one or more of your tires is

significantly under-inflated. If equipped, the

system also displays pressure of all tires

(except the spare tire) on the display screen

by sending a signal from a sensor that is

installed in each wheel. If the vehicle is be-

ing driven with low tire pressure, the TPMS

will activate and warn you of it by the low

tire pressure warning light. This system will

activate only when the vehicle is driven at

speeds above 16 mph (25 km/h). For addi-

tional information, see “Warning lights, indi-

cator lights and audible reminders” (P. 2-12)

and “Tire Pressure Monitoring System

(TPMS)” (P. 5-5).

WARNING

• Radio waves could adversely affect

electric medical equipment. Those

who use a pacemaker should contact

the electric medical equipment

manufacturer for the possible influ-

ences before use. •

If the low tire pressure warning light

illuminates while driving, avoid sud-

den steering maneuvers or abrupt

braking, reduce vehicle speed, pull

off the road to a safe location and

stop the vehicle as soon as possible.

Driving with under-inflated tires may

permanently damage the tires and

increase the likelihood of tire failure.

Serious vehicle damage could occur

and may lead to an accident and

could result in serious personal in-

jury. Check the tire pressure for all

four tires. Adjust the tire pressure to

the recommended COLD tire pres-

sure shown on the Tire and Loading

Information label to turn the low tire

pressure warning light OFF. If the

light still illuminates while driving af-

ter adjusting the tire pressure, a tire

may be flat or the TPMS may be mal-

functioning. If you have a flat tire, re-

place it with a spare tire as soon as

possible, If no tire is flat and all tires

are properly inflated, have the ve-

hicle checked. It is recom-

mended that you visit a NISSAN

dealer for this service •

When using a wheel without the

TPMS such as the spare tire, the TPMS

will not function and the low tire

pressure warning light will flash for

approximately one minute. The light

will remain on af ter one minute. Have

your tires replaced and/or TPMS sys-

tem reset as soon as possible. It is

recommended that you visit a

NISSAN dealer for these services.

• Replacing tires with those not origi-

nally specified by NISSAN could af-

fect the proper operation of the

TPMS.

• Do not inject any tire liquid or aerosol

tire sealant into the tires, as this may

cause a malfunction of the tire pres-

sure sensors.

CHANGING A FLAT TIRE

If you have a flat tire, follow the instructions

below:

Stopping the vehicle

1. Safely move the vehicle off the road and away from traffic.

2. Turn on the hazard warning flashers.

FLAT TIRE

In case of emergency6-3

Page 465 of 635

4. Lower the vehicle slowly until the tiretouches the ground. Then, with the

wheel nut wrench, tighten the wheel

nuts securely in the sequence illustrated

(

O1,O2,O3,O4,O5,O6). Lower the vehicle

completely.

WARNING

• Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

• Do not use oil or grease on the wheel

studs or nuts. This could cause the

nuts to become loose.

• Retighten the wheel nuts when the

vehicle has been driven for 600 miles

(1,000 km) (also in cases of a flat tire,

etc.).

As soon as possible, tighten the wheel

nuts to the specified torque with a

torque wrench.

Wheel nut tightening torque:

Non-XD models: 98 f t-lb (133 N·m)

XD models: 131 f t-lb (177 N·m) The wheel nuts must be kept tightened

to specification at all times. It is recom-

mended that wheel nuts be tightened to

specifications at each lubrication

interval.

Adjust tire pressure to the COLD

pressure.

COLD pressure: Af ter vehicle has been

parked for 3 hours or more or driven less

than 1 mi. (1.6 km).

COLD tire pressures are shown on the

Tire and Loading Information label af-

fixed to the driver side center pillar.

Af ter adjusting tire pressure to the COLD

tire pressure, the display (if so equipped)

of the tire pressure information may

show higher pressure than the COLD tire

pressure af ter the vehicle has been

driven more than 1 mi. (1.6 km). This is

because the tire pressure increases as

the tire temperature rises. This does not

indicate a system malfunction.

5. Securely store the tools and jacking

equipment in the vehicle. For additional

information, see the “Getting the spare

tire and tools (Crew and King Cab® mod-

els)” (P. 6-4).

WARNING

• Always make sure that the spare tire

and jacking equipment are properly

secured af ter use. Such items can be-

come dangerous projectiles in an ac-

cident or sudden stop.

• The spare tire is designed for emer-

gency use. For additional informa-

tion, see “Wheels and tires” (P. 8-33).

In case of emergency6-9

Page 492 of 635

WARNING

• Prolonged and repeated contact

with used engine oil may cause skin

cancer.

• Try to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand

cleaner as soon as possible.

• Keep used engine oil out of reach of

children.

4. Loosen the oil filter with an oil filter wrench by turning it counterclockwise.

Remove the oil filter by turning it by

hand.

5. Wipe the engine oil filter mounting sur- face with a clean rag.

CAUTION

Be sure to remove any old gasket ma-

terial remaining on the sealing surface

of the engine. Failure to do so could

lead to an oil leak and engine damage.

• The dipstick must be inserted in

place to prevent oil spillage from the

dipstick hole when filling the engine

with oil. 6. Coat the gasket on the new filter with

clean engine oil.

7. Screw in the oil filter clockwise until a slight resistance is felt, then tighten addi-

tionally more than 2/3 turn.

Oil filter tightening torque: 11 to 15 f t-lb (15.0 to 21.0 N·m)

8. Clean and re-install the drain plug with a new washer. Securely tighten the drain

plug with a wrench. Do not use exces-

sive force.

Drain plug tightening torque: 22 to 29 f t-lb (29.4 to 39.2 N·m)

9. Refill the engine with the recommended oil through the oil filler opening, and in-

stall the oil filler cap securely.

For additional information about drain and

refill capacity, see “Recommended fluids/

lubricants and capacities” (P. 10-2). The

drain and refill capacity depends on the oil

temperature and drain time. Use these

specifications for reference only. Always

use the dipstick to determine the proper

amount of oil in the engine. 10. Start the engine and check for leakage

around the drain plug and the oil filter.

Correct as required. Turn the engine off

and wait more than 15 minutes. Check

the oil level with the dipstick. Add en-

gine oil if necessary.

Af ter the operation

1. Reinstall plate in reverse order ofremoval.

2. Lower the vehicle carefully to the ground.

3. Reset oil and oil filter maintenance re- minder. For additional information, see

“Vehicle information display” (P. 2-23).

• Dispose of waste oil and filter properly.

• Check your local regulations.

8-12Do-it-yourself

Page 495 of 635

WINDSHIELD-WASHER FLUID

RESERVOIR

Fill the windshield-washer fluid reservoir

periodically. Add windshield-washer fluid

when the “Low Washer Fluid” warning mes-

sage shows on the vehicle information

display.

To fill the windshield-washer fluid reservoir,

lif t the cap off the reservoir and pour the

windshield-washer fluid into the reservoir

opening.Add a washer solvent to the washer for

better cleaning. In the winter season, add a

windshield washer antifreeze. Follow the

manufacturer's instructions for the mix-

ture ratio.

Refill the reservoir more frequently when

driving conditions require an increased

amount of windshield-washer fluid.

Recommended fluid is Genuine NISSAN

Windshield Washer Concentrate Cleaner &

Antifreeze or equivalent.

CAUTION

• Do not substitute engine antifreeze

coolant for windshield-washer fluid.

This may result in damage to the

paint.

• Do not fill the windshield-washer

fluid reservoir with washer fluid con-

centrates at full strength. Some

methyl alcohol based washer fluid

concentrates may permanently stain

the grille if spilled while filling the

windshield-washer fluid reservoir. •

Pre-mix washer fluid concentrates

with water to the manufacturer's

recommended levels before pouring

the fluid into the windshield-washer

fluid reservoir. Do not use the

windshield-washer fluid reservoir to

mix the washer fluid concentrate and

water.

LDI2879

WINDSHIELD-WASHER FLUID

Do-it-yourself8-15

Page 513 of 635

Reverse steps to install bulbs and rear

combination light.If you have a flat tire, see “Flat tire”

(P. 6-3).

TIRE PRESSURE

Tire Pressure Monitoring System

(TPMS)

WARNING

Radio waves could adversely af-

fect electric medical equipment.

Those who use a pacemaker

should contact the electric medi-

cal equipment manufacturer for

the possible influences before

use.

This vehicle is equipped with the Tire

Pressure Monitoring System (TPMS).

It monitors tire pressure of all four

tires except the spare. When the low

tire pressure warning light is lit and

the “Tire Pressure Low - Add Air”

warning appears in the vehicle infor-

mation display, one or more of your

tires is significantly under-inflated. If equipped, the system also displays

pressure of all tires (except the spare

tire) on the display screen by send-

ing a signal from a sensor that is

installed in each wheel.

The TPMS will activate only when the

vehicle is driven at speeds above

16 mph (25 km/h). Also, this system

may not detect a sudden drop in tire

pressure (for example a flat tire while

driving).

For additional information, see

“Warning lights, indicator lights and

audible reminders” (P. 2-12), “Tire

Pressure Monitoring System (TPMS)”

(P. 5-5), and “Flat tire” (P. 6-3).

Tire inflation pressure

Check the tire pressures (including

the spare) of ten and always prior to

long distance trips. The recom-

mended tire pressure specifications

are shown on the F.M.V.S.S. certifica-

tion label or the Tire and Loading

WHEELS AND TIRES

Do-it-yourself8-33

Page 610 of 635

Trailer brake controller unit (if so

equipped)

The Trailer Brake Controller Unit (TBCU), lo-

cated on the lower instrument panel, is a

device that assists the vehicle in having

effective and smooth braking while towing

a trailer.

Operating modes:

•Automatic mode: This is the normal op-

eration of the TBCU depending on the

gain and boost settings adjusted by the

customer. This mode will activate when

vehicle brake pedal is pressed.

• Manual mode: This mode is initiated by

adjusting the manual control lever from

resting position. This mode will provide

output power to trailer brakes without

applying the vehicle brake pedal. To determine the output operation of the

system:

•

Gain + and Gain - : Used to increase or

decrease the braking force supplied to

the trailer brakes. To adjust the gain, press

Gain + or Gain - to the desired point (0-10).

For example: gain setting 6.0 is a typical

starting point for heavy loads.

• Boost: Used to adjust the feel of the au-

tomatic brake event that occurs when

the vehicle brake pedal is applied. To set

up boost, press Boost button once to dis-

play for current boost setting (display for

3 seconds). Keep pressing to increase

boost level until the desired level (0-3) is

achieved.

• Manual Control Lever: Provides brake

output power to trailer brakes without

applying the vehicle brake pedal. The

amount of brake output supplied corre-

sponds to the amount of pinch pressure

applied to the manual control lever.

10-48Technical and consumer information

Page 624 of 635

Top tether strap anchor point

locations...................1-32Child safety rear door lock..........3-9Cleaning exterior and interior......7-2,7-4Climate control seat switch.........2-53Cold weather driving............5-129Console light..................2-89Controls

Heater and air conditioner controls. .4-38Heater and air conditioner controls

(manual)...................4-28CoolantCapacities and recommended

fuel/lubricants

...............10-2Changing engine coolant.........8-6Checking engine coolant level......8-6Engine coolant temperature gauge. . .2-8Corrosion protection..............7-7Cruise control................ .5-49Cup holders...................2-77Curtain side-impact and rollover

air bag......................1-79

D

Daytime Running Light System......2-50Digital video disc DVD............4-43Dimensions and weights..........10-11Dimmer switch for instrument panel. . .2-51Display

Information display............2-23Door locks................... .3-4Drive belt....................8-20

Driving

Cold weather driving...........5-129Driving with automatic

transmission................5-19Precautions when starting

and driving...............5-4, 5-11Driving the vehicle...............5-18Dual power moonroof............2-86

E

Eco Drive Report...............5-114Economy - fuel................5-107Electronic locking rear differential

(E-Lock) system................5-113Electronic locking rear differential

(E-Lock) system switch...........2-60Emergency call (SOS) button........2-63Emergency engine shutoff.......5-15,6-2Emission control information label. . . .10-17Emission control system warranty. . . .10-56EngineBefore starting the engine........5-16Capacities and recommended

fuel/lubricants...............10-2Changing engine coolant.........8-6Changing engine oil.............8-7Changing engine oil filter.........8-7Checking engine coolant level......8-6Checking engine oil level..........8-7Engine compartment check

locations.................. .8-3Engine coolant temperature gauge. . .2-8

Engine cooling system...........8-5Engine oil...................8-7Engine oil and oil filter

recommendation.............10-7Engine oil pressure gauge........2-10Engine oil pressure warning light. . . .2-15Engine oil viscosity.............10-7Engine serial number..........10-16Engine specifications...........10-9Starting the engine............5-17Engine coolant temperature gauge. . . .2-8Engine oil pressure gauge..........2-10Event Data recorders............10-59Exhaust gas (Carbon monoxide)......5-4Explanation of maintenance items.....9-2Explanation of scheduled maintenance

items...................... .9-5Extended storage switch..........2-69Eyeglass case.................2-76

F

F.M.V.S.S. certification label.........10-16Flashers (See hazard warning flasher

switch)......................6-2Flat tire......................6-3Floor mat positioning aid...........7-6Fluid

Brake fluid..................8-14Capacities and recommended

fuel/lubricants...............10-2Engine coolant................8-5Engine oil...................8-7

11-2