coolant level NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 110 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression NISSAN X-TRAIL 2001 Service Repair Manual EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression](/img/5/57405/w960_57405-109.png)

EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

●If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug

hole of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, the valves may be

malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

●If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, the gaskets are leaking. In such a case, replace the cylinder

head gaskets.

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS00KNQ

REMOVAL

1. Release fuel pressure. Refer to EC-775, "FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO-OBD)], EC-42, "FUEL PRES-

SURE RELEASE" [QR25DE (WITH EURO-OBD)] or EC-452, "FUEL PRESSURE RELEASE" [QR25DE

(WITHOUT EURO-OBD)].

2. Drain engine coolant and engine oil.

3. Remove the following components and related parts.

●Engine hood and engine undercover.

●Air cleaner case and air duct assembly; Refer to EM-14, "AIR CLEANER AND AIR DUCT" .

●Ignition coils; Refer to EM-29, "IGNITION COIL" .

●Rocker cover; Refer to EM-35, "ROCKER COVER" .

●Engine coolant reservoir tank

●Drive belt; Refer to EM-12, "REMOVAL" .

●Alternator

●Drive belt auto-tensioner; Refer to EM-13, "REMOVAL" .

●Exhaust front tube; Refer to EX-2, "Removal and Installation" .

●Exhaust manifold; Refer to EM-24, "EXHAUST MANIFOLD AND THREE WAY CATALYST" .

KBIA0250E

1. Cylinder head assembly 2. Cylinder head gasket 3. Cylinder head bolt

Page 121 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simul NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simul](/img/5/57405/w960_57405-120.png)

ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or something similar as the support-

ing surface, secure a completely stable condition.

23. Remove RH engine mounting insulator.

24. Pull LH engine mounting through-bolt out.

25. Remove mounting bolts at front end of center member.

26. Remove front suspension member mounting bolts and nuts.

27. Remove engine, transaxle and transfer assembly with suspen-

sion member from vehicle downward by carefully operating sup-

porting tools.

CAUTION:

●During the operation, make sure that no part interferes

with body side.

●Before and during this lifting, always check if any har-

nesses are left connected.

●During the removal operation, always be careful to pre-

vent vehicle from falling off the lift due to changes in the center of gravity.

●If necessary, support vehicle by setting a jack or equivalent tool at the rear.

28. Remove power steering pump with piping connected from engine. Move it aside on suspension member.

29. Remove front engine mounting and rear engine mounting through-bolts to remove suspension member.

30. Remove starter motor.

31. Separate engine and transaxle. Refer to MT-15, "

TRANSAXLE ASSEMBLY" (M/T models) or AT- 4 1 8 ,

"REMOVAL AND INSTALLATION" (A/T models)

INSTALLATION

Install in the reverse order of removal.

●Do not allow engine oil to get on mounting insulator. Be careful not to damage mounting insulator.

●When installation directions are specified, install parts according to the direction marks on them referring

to components illustration.

●Make sure that each mounting insulator is seated properly, and tighten mounting bolts and nuts.

INSPECTION AFTER INSTALLATION

●Before starting engine, check the levels of engine coolant, lubrications and working engine oils. If less

than required quantity, fill to the specified level.

●Run engine to check for unusual noise and vibration.

●Warm up engine thoroughly to make sure there is no leakage of engine coolant, lubricants, working

engine oil, fuel and exhaust gas.

KBIA0256E

KBIA0257E

KBIA0270E

Page 246 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill NISSAN X-TRAIL 2001 Service Repair Manual EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill](/img/5/57405/w960_57405-245.png)

EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill to the specified level.

●Before starting engine, bleed air from fuel piping. Refer to FL-16, "Air Bleeding" .

●Run engine to check for unusual noise and vibration.

●Warm up engine thoroughly to make sure there is no leakage of engine coolant, lubricants, working

engine oil, fuel and exhaust gas.

●Bleed air from passages in pipes and tubes of applicable lines.

Page 287 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE OIL

LU-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS00KO3

ENGINE OIL LEVEL

●Before starting the engine, put vehicle horizontally then check

the engine oil leve NISSAN X-TRAIL 2001 Service Repair Manual ENGINE OIL

LU-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS00KO3

ENGINE OIL LEVEL

●Before starting the engine, put vehicle horizontally then check

the engine oil leve](/img/5/57405/w960_57405-286.png)

ENGINE OIL

LU-7

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS00KO3

ENGINE OIL LEVEL

●Before starting the engine, put vehicle horizontally then check

the engine oil level. If the engine is already started, stop it and

allow 10 minutes before checking.

●Check that the engine oil level is within the range shown in the

figure.

●If it is out of range, adjust it.

ENGINE OIL APPEARANCE

●Check the engine oil for white turbidity or remarkable contamination.

●If the engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Find the cause and repair.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

●Oil pan

●Oil pan drain plug

●Oil pressure switch

●Oil filter

●Oil cooler

●Intake valve timing control cover and intake valve timing control solenoid valve

●Front cover

●Mating surface between cylinder block and cylinder head

●Mating surface between cylinder head and rocker cover

●Crankshaft oil seal.

OIL PRESSURE CHECK

WARNING:

●Be careful not to burn yourself, as the engine oil is hot.

●Engine oil pressure check should be done in “ Parking

position” (A/T model) or “Neutral position” (M/T model).

1. Check engine oil level. Refer to LU-7, "

ENGINE OIL LEVEL" .

2. Remove the undercover.

3. Remove the oil pressure switch to connect the oil pressure

gauge.

4. After warming up the engine, check that oil pressure corre-

sponding to the engine speed is produced.

Engine oil pressure [Engine oil temperature at 80 °C (176 °F)]

5. After checking, install the oil pressure switch as follows.

a. Remove old sealant adhering to the switch and engine.

b. Apply thread sealant.

Use Genuine Liquid Gasket or equivalent.

PBIC0249E

KBIA0275E

Engine speed (rpm) Idle speed 2,000 6,000

Engine pressure

kPa (bar, kg/cm

2 , psi)Approx. 98 (0.98, 1.0, 14) or more Approx. 294 (2.9, 3.0, 43) or more Approx. 392 (3.9, 4.0, 57) or more

Page 293 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual OIL COOLER

LU-13

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00KO8

WARNING:

Be careful not to get burned when the engine and engine oil are hot.

CAUTION:

●When remo NISSAN X-TRAIL 2001 Service Repair Manual OIL COOLER

LU-13

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00KO8

WARNING:

Be careful not to get burned when the engine and engine oil are hot.

CAUTION:

●When remo](/img/5/57405/w960_57405-292.png)

OIL COOLER

LU-13

[QR]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00KO8

WARNING:

Be careful not to get burned when the engine and engine oil are hot.

CAUTION:

●When removing oil cooler, prepare a shop cloth to absorb any engine oil leakage or spillage.

●Completely wipe off any engine oil that adhere to the engine and the vehicle.

REMOVAL

1. Remove front RH wheel and engine room right side cover.

2. Drain engine coolant by removing cylinder block drain plug and radiator drain cock. Refer to CO-9,

"Changing Engine Coolant" .

3. Paint a mating mark at the oil cooler and oil cooler bracket.

INSPECTION

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler assembly.

Oil Pressure Relief Valve

Inspect oil pressure relief valve for movement, cracks and breaks by pushing the ball. If replacement is neces-

sary, remove valve by prying it out with a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Installation is in the reverse order of removal.

●After warming up the engine, check for engine oil and engine coolant leakage and for engine oil level.

Refer to LU-7, "

ENGINE OIL" .

PBIC0278E

1. Oil pressure switch 2. Oil cooler bracket 3. Oil cooler

4. Gasket

Page 298 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

ENGINE OIL LEVEL AND MUDDINESS

●Before starting the engine, put vehicle horizontally then check

the engine oil level. If t NISSAN X-TRAIL 2001 Service Repair Manual LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

ENGINE OIL LEVEL AND MUDDINESS

●Before starting the engine, put vehicle horizontally then check

the engine oil level. If t](/img/5/57405/w960_57405-297.png)

LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

ENGINE OIL LEVEL AND MUDDINESS

●Before starting the engine, put vehicle horizontally then check

the engine oil level. If the engine is already started, stop it and

allow 10 minutes before checking.

●Check that the engine oil level is within the range shown in the

figure.

●If it is out of range, adjust it.

●Check the engine oil for white turbidity or remarkable contamina-

tion.

●If the engine oil becomes turbid and white, it is highly probable

that it is contaminated with engine coolant. Find the cause and

repair.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

●Oil pan

●Oil pan drain plug

●Oil pressure switch

●Oil filter bracket

●Oil cooler.

●Oil pump housing

●Vacuum pump

●Cylinder head rear cover assembly

●Chain case

●Mating surface between cylinder block and cylinder head

●Mating surface between cylinder head and rocker cover

●Crankshaft oil seal. Refer to LU-18, "ENGINE OIL LEVEL AND MUDDINESS" .

ENGINE OIL PRESSURE CHECK

WARNING:

●Be careful not to burn yourself, as the engine oil is hot.

●Oil pressure check should be done in “ Neutral position”.

1. Check the engine oil level. Refer to LU-18, "

ENGINE OIL LEVEL

AND MUDDINESS" .

2. Remove the undercover.

3. Remove the oil pressure switch to connect the oil pressure

gauge.

4. After warming up the engine, check that oil pressure corre-

sponding to the engine speed is produced.

Engine oil pressure [Engine oil temperature at 80 °C (176 °F)]

5. After checking, install the oil pressure switch as follows.

a. Remove old sealant adhering to the switch and engine.

b. Apply thread sealant.

Use Genuine Liquid Gasket or equivalent.

SBIA0122E

SBIA0123E

Engine speed (rpm) Idle speed 2,000 4,000

Engine pressure

kPa (bar, kg/cm

2 , psi)Approx. 140 (1.40, 1.43, 20.3) or

moreApprox. 270 (2.69, 2.75, 39.1) or

moreApprox. 430 (4.29, 4.38, 62.3) or

more

Page 305 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual OIL COOLER

LU-25

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00OE8

CAUTION:

●Be careful not to get burned when the engine and engine oil are hot.

●When remo NISSAN X-TRAIL 2001 Service Repair Manual OIL COOLER

LU-25

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00OE8

CAUTION:

●Be careful not to get burned when the engine and engine oil are hot.

●When remo](/img/5/57405/w960_57405-304.png)

OIL COOLER

LU-25

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

OIL COOLERPFP:21305

Removal and InstallationEBS00OE8

CAUTION:

●Be careful not to get burned when the engine and engine oil are hot.

●When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

●Completely wipe off any engine oil that adhere to the engine and the vehicle.

REMOVAL

1. Remove front RH wheel and engine side cover.

2. Remove the exhaust front tube. Refer to EX-2, "

EXHAUST SYSTEM" .

3. Drain coolant by removing cylinder block drain plug and radiator drain cock.

INSPECTION

Oil Cooler

Check oil cooler for cracks. check oil cooler for clogging by blowing through coolant inlet. If necessary, replace

oil cooler assembly.

INSTALLATION

Installation is in reverse order of removal.

●Confirm that no foreign objects are adhering to the installation

planes of the oil cooler or cylinder block.

●Tighten the connecting bolt after aligning the stopper on the cyl-

inder block side with protrusion of the oil cooler.

●After for warming up the engine, check for engine oil and engine

coolant leakage and for engine oil level. Refer to LU-18,

"ENGINE OIL" .

PBIC1231E

1. Oil cooler 2. O-ring 3. Water hose

4. Gasket 5. Water hose connector 6. Connecting bolt

SBIA0126E

Page 307 of 3833

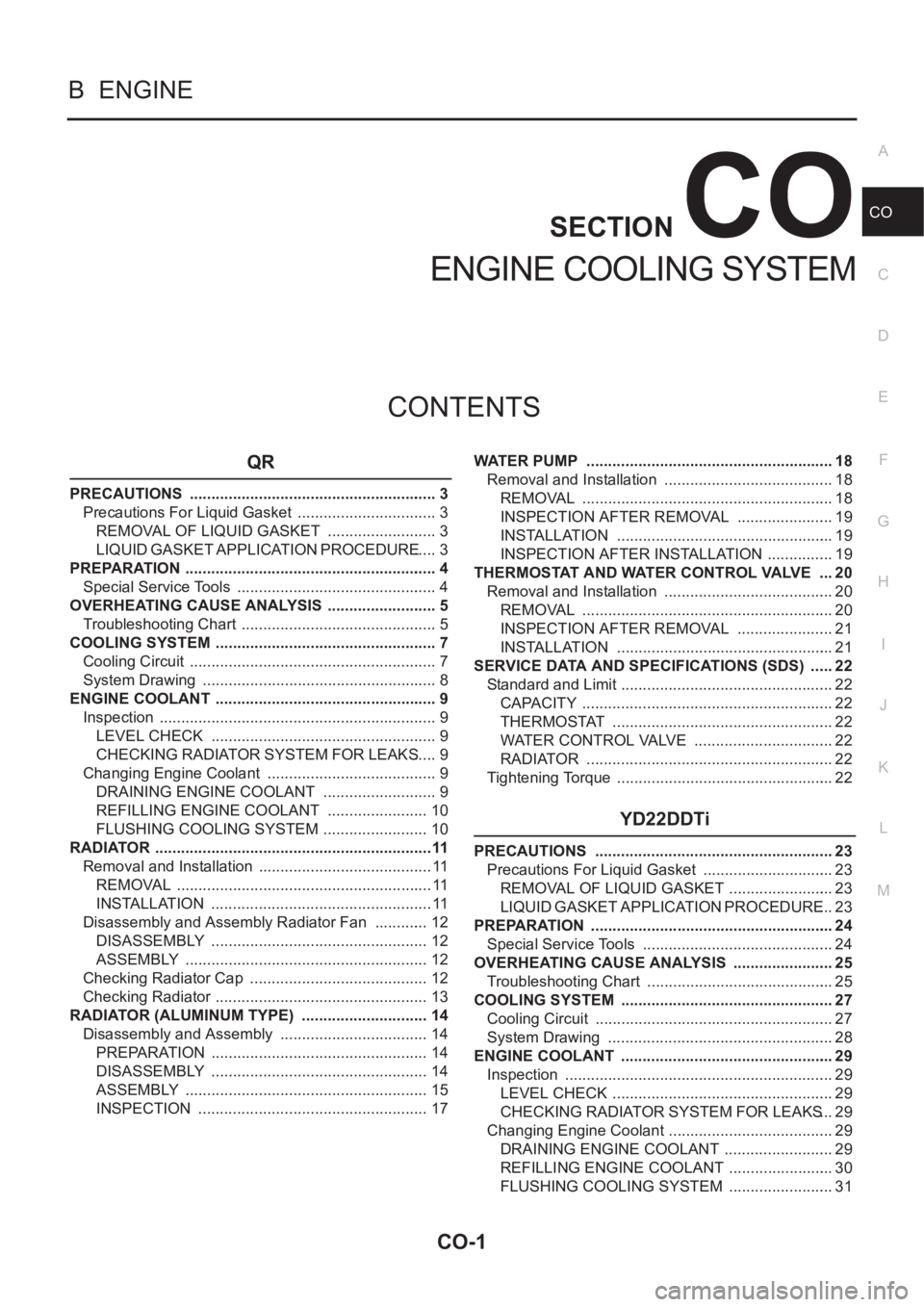

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE ..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

System Drawing ....................................................... 8

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

CHECKING RADIATOR SYSTEM FOR LEAKS ..... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR .................................................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

Disassembly and Assembly Radiator Fan ............. 12

DISASSEMBLY ................................................... 12

ASSEMBLY ......................................................... 12

Checking Radiator Cap .......................................... 12

Checking Radiator .................................................. 13

RADIATOR (ALUMINUM TYPE) .............................. 14

Disassembly and Assembly ................................... 14

PREPARATION ................................................... 14

DISASSEMBLY ................................................... 14

ASSEMBLY ......................................................... 15

INSPECTION ...................................................... 17WATER PUMP .......................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 19

THERMOSTAT AND WATER CONTROL VALVE .... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................

... 21

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 22

Standard and Limit .................................................. 22

CAPACITY ........................................................... 22

THERMOSTAT .................................................... 22

WATER CONTROL VALVE ................................. 22

RADIATOR ....................................................... ... 22

Tightening Torque ................................................... 22

YD22DDTi

PRECAUTIONS ........................................................ 23

Precautions For Liquid Gasket ............................... 23

REMOVAL OF LIQUID GASKET ......................... 23

LIQUID GASKET APPLICATION PROCEDURE ... 23

PREPARATION ......................................................... 24

Special Service Tools ............................................. 24

OVERHEATING CAUSE ANALYSIS ........................ 25

Troubleshooting Chart ............................................ 25

COOLING SYSTEM .................................................. 27

Cooling Circuit ........................................................ 27

System Drawing ..................................................... 28

ENGINE COOLANT .................................................. 29

Inspection ............................................................... 29

LEVEL CHECK .................................................... 29

CHECKING RADIATOR SYSTEM FOR LEAKS ... 29

Changing Engine Coolant ....................................... 29

DRAINING ENGINE COOLANT .......................... 29

REFILLING ENGINE COOLANT ......................... 30

FLUSHING COOLING SYSTEM ......................... 31

Page 315 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE COOLANT

CO-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS00KOG

LEVEL CHECK

●Check if the reservoir tank engine coolant level within MIN to

MAX when engine is NISSAN X-TRAIL 2001 Service Repair Manual ENGINE COOLANT

CO-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS00KOG

LEVEL CHECK

●Check if the reservoir tank engine coolant level within MIN to

MAX when engine is](/img/5/57405/w960_57405-314.png)

ENGINE COOLANT

CO-9

[QR]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS00KOG

LEVEL CHECK

●Check if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

●Adjust engine coolant if too much or too little.

CHECKING RADIATOR SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a

tester.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure engine coolant escaping

from the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS00KOH

WARNING:

●To avoid being scalded, never change the engine coolant when the engine is hot.

●Wrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

●Be careful not to allow engine coolant to contact drive belts.

2. Open drain plug on cylinder block.

3. Remove reservoir tank and drain engine coolant.

4. Check drained engine coolant for contaminants such as rust,

corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to CO-10,

"FLUSHING COOLING SYSTEM" .

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2 , 23 psi)

SLC134B

PBIC0236E

KBIA0163E

Page 316 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui](/img/5/57405/w960_57405-315.png)

CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

●Use genuine Nissan engine coolant or equivalent in its

quality. Refer to MA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

●Pour engine coolant slowly of less than 2 (1-3/4 lmp qt)

a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

6. Refill reservoir tank to MAX level line with engine coolant.

7. Repeat steps 4 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

●Sound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 4 through 6 until engine coolant level

no longer drops.

●Clean excess engine coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator. Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank: 0.6 (1/2 lmp qt)

SMA412B