service schedule NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 398 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-48

[QR25(WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

If a 1st trip DTC is stored in the ECM, the time data will be “[1t]”.

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records NISSAN X-TRAIL 2001 Service Repair Manual EC-48

[QR25(WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

If a 1st trip DTC is stored in the ECM, the time data will be “[1t]”.

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records](/img/5/57405/w960_57405-397.png)

EC-48

[QR25(WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

If a 1st trip DTC is stored in the ECM, the time data will be “[1t]”.

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short term fuel trim, long term fuel trim, engine speed, vehicle speed, base fuel schedule and intake

air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II or

GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

details, see EC-97

.

Only one set of freeze frame data (either 1st trip freeze frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in EC-56, "

HOW TO ERASE EMIS-

SION-RELATED DIAGNOSTIC INFORMATION" .

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Mode 1 of ISO 15031-5.

As part of an enhanced emissions test for Inspection & Maintenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has completed self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

PBIB0911E

Priority Items

1Freeze frame data Misfire — DTC: P0300 - P0304

Fuel Injection System Function — DTC: P0171, P0172

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 423 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-73

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00M0V

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a relat NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-73

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00M0V

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a relat](/img/5/57405/w960_57405-422.png)

TROUBLE DIAGNOSIS

EC-73

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00M0V

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3

SEF983U

SEF976U

SEF977U

Page 815 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-465

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00NEC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a r NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-465

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00NEC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a r](/img/5/57405/w960_57405-814.png)

TROUBLE DIAGNOSIS

EC-465

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00NEC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3.

P1229 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2122

P2123

P2127

P2128

P2138Accelerator pedal position

sensorThe ECM controls the electric throttle control actuator in regulating the throttle opening

in order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the nor-

mal condition.

So, the acceleration will be poor. DTC No. Detected items Engine operating condition in fail-safe mode

SEF983U

SEF976U

SEF977U

Page 1155 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-805

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00MSU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a rela NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-805

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00MSU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a rela](/img/5/57405/w960_57405-1154.png)

TROUBLE DIAGNOSIS

EC-805

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00MSU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3

SEF983U

SEF976U

SEF977U

Page 1179 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-829

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items o NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-829

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items o](/img/5/57405/w960_57405-1178.png)

TROUBLE DIAGNOSIS

EC-829

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of “DTC and 1st trip DTC”, refer to EC-753, "INDEX FOR DTC" .)

Freeze Frame Data and 1st Trip Freeze Frame Data

*1: The items are the same as those of 1st trip freeze frame data. SELF-LEARNING CONT

●THE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT.When releasing fuel pressure

from fuel line

TARGET IDLE RPM ADJ*

●IDLE CONDITION When setting target idle speed

TARGET IGNITION TIMING ADJ*

●IDLE CONDITION When adjusting target ignition tim-

ing WORK ITEM CONDITION USAGE

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]

●The engine control component part/control system has a trouble code, it is displayed as “PXXXX”. (Refer

to EC-753, "

INDEX FOR DTC" .)

FUEL SYS-B1

●“Fuel injection system status” at the moment a malfunction is detected is displayed.

●One mode in the following is displayed.

“MODE 2”: Open loop due to detected system malfunction

“MODE 3”: Open loop due to driving conditions (power enrichment, deceleration enrichment)

“MODE 4”: Closed loop - using oxygen sensor(s) as feedback for fuel control

“MODE 5”: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%]

●The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP [°C]

or [°F]

●The engine coolant temperature at the moment a malfunction is detected is displayed.

S-FUEL TRIM-B1 [%]

●“Short-term fuel trim” at the moment a malfunction is detected is displayed.

●The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

L-FUEL TRIM-B1 [%]

●“Long-term fuel trim” at the moment a malfunction is detected is displayed.

●The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule

than short-term fuel trim.

ENGINE SPEED

[rpm]

●The engine speed at the moment a malfunction is detected is displayed.

VHCL SPEED [km/h]

or [mph]

●The vehicle speed at the moment a malfunction is detected is displayed.

B/FUEL SCHDL

[msec]

●The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [°C]

or [°F]

●The intake air temperature at the moment a malfunction is detected is displayed.

Page 1502 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-1152

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Basic Inspection

EBS00N3Z

1. INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or NISSAN X-TRAIL 2001 Service Repair Manual EC-1152

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Basic Inspection

EBS00N3Z

1. INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or](/img/5/57405/w960_57405-1501.png)

EC-1152

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Basic Inspection

EBS00N3Z

1. INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2. REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3.

SEF983U

SEF976U

SEF977U

Page 1526 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-1176

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of “DTC and 1st trip NISSAN X-TRAIL 2001 Service Repair Manual EC-1176

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of “DTC and 1st trip](/img/5/57405/w960_57405-1525.png)

EC-1176

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of “DTC and 1st trip DTC”, refer to E C - 111 9 , "INDEX FOR DTC" .)

Freeze Frame Data and 1st Trip Freeze Frame Data

*1: The items are the same as those of 1st trip freeze frame data. SELF-LEARNING CONT

●THE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT.When releasing fuel pressure

from fuel line

TARGET IDLE RPM ADJ*

●IDLE CONDITION When setting target idle speed

TARGET IGNITION TIMING ADJ*

●IDLE CONDITION When adjusting target ignition tim-

ing WORK ITEM CONDITION USAGE

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]

●The engine control component part/control system has a trouble code, it is displayed as “PXXXX”. (Refer

to E C - 111 9 , "

INDEX FOR DTC" .)

FUEL SYS-B1

●“Fuel injection system status” at the moment a malfunction is detected is displayed.

●One mode in the following is displayed.

“MODE 2”: Open loop due to detected system malfunction

“MODE 3”: Open loop due to driving conditions (power enrichment, deceleration enrichment)

“MODE 4”: Closed loop - using oxygen sensor(s) as feedback for fuel control

“MODE 5”: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%]

●The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP [°C]

or [°F]

●The engine coolant temperature at the moment a malfunction is detected is displayed.

S-FUEL TRIM-B1 [%]

●“Short-term fuel trim” at the moment a malfunction is detected is displayed.

●The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

L-FUEL TRIM-B1 [%]

●“Long-term fuel trim” at the moment a malfunction is detected is displayed.

●The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule

than short-term fuel trim.

ENGINE SPEED

[rpm]

●The engine speed at the moment a malfunction is detected is displayed.

VHCL SPEED [km/h]

or [mph]

●The vehicle speed at the moment a malfunction is detected is displayed.

B/FUEL SCHDL

[msec]

●The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [°C]

or [°F]

●The intake air temperature at the moment a malfunction is detected is displayed.

Page 1763 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-1413

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident.

2. Check the current need for schedule NISSAN X-TRAIL 2001 Service Repair Manual TROUBLE DIAGNOSIS

EC-1413

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident.

2. Check the current need for schedule](/img/5/57405/w960_57405-1762.png)

TROUBLE DIAGNOSIS

EC-1413

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to

MA-7, "

PERIODIC MAINTENANCE" .

3. Open engine hood and check the following:

–Harness connectors for improper connections

–Vacuum hoses for splits, kinks, or improper connections

–Wiring for improper connections, pinches, or cuts

4. Start engine and warm it up to the normal operating tempera-

ture.

>> GO TO 2.

2.PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

>> GO TO 3.

3.CHECK IDLE SPEED

With CONSULT-II

1. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

2. Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace.

SEF142I

725±25 rpm

SEF817Y

Page 2082 of 3833

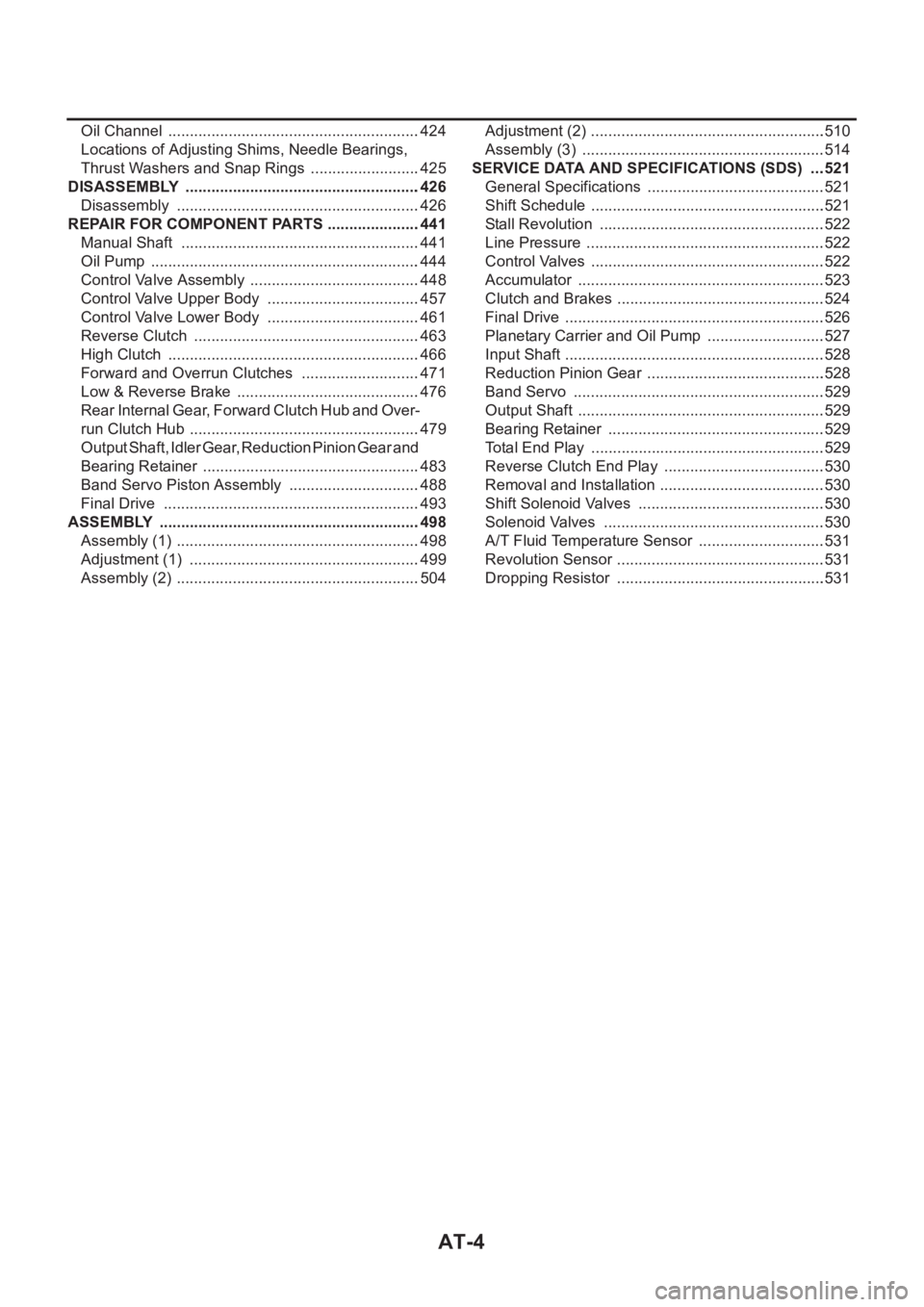

AT-4

Oil Channel ...........................................................424

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................425

DISASSEMBLY .......................................................426

Disassembly .........................................................426

REPAIR FOR COMPONENT PARTS ......................441

Manual Shaft ........................................................441

Oil Pump ...............................................................444

Control Valve Assembly ........................................448

Control Valve Upper Body ....................................457

Control Valve Lower Body ....................................461

Reverse Clutch .....................................................463

High Clutch ...........................................................466

Forward and Overrun Clutches ............................471

Low & Reverse Brake ...........................................476

Rear Internal Gear, Forward Clutch Hub and Over-

run Clutch Hub ......................................................479

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................483

Band Servo Piston Assembly ...............................488

Final Drive ............................................................493

ASSEMBLY .............................................................498

Assembly (1) .........................................................498

Adjustment (1) ......................................................499

Assembly (2) .........................................................504Adjustment (2) .......................................................510

Assembly (3) .........................................................514

SERVICE DATA AND SPECIFICATIONS (SDS) ....521

General Specifications ......................................... .521

Shift Schedule .......................................................521

Stall Revolution .....................................................522

Line Pressure ........................................................522

Control Valves .......................................................522

Accumulator ..........................................................523

Clutch and Brakes .................................................524

Final Drive .............................................................526

Planetary Carrier and Oil Pump ............................527

Input Shaft .............................................................528

Reduction Pinion Gear ..........................................528

Band Servo ...........................................................529

Output Shaft ..................................................

........529

Bearing Retainer ...................................................529

Total End Play .......................................................529

Reverse Clutch End Play ......................................530

Removal and Installation .......................................530

Shift Solenoid Valves ............................................530

Solenoid Valves ....................................................530

A/T Fluid Temperature Sensor ..............................531

Revolution Sensor .................................................531

Dropping Resistor .................................................531

Page 2119 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

sw NISSAN X-TRAIL 2001 Service Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

sw](/img/5/57405/w960_57405-2118.png)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is for

checking the lamp.

●If the malfunction indicator does not light up, refer to DI-43,

"Schematic" .

(Or see MIL & CONSULT-II in EC section. Refer to EC-58,

"Malfunction Indicator (MI)" (QR25DE) or EC-790, "Malfunc-

tion Indicator (MI)" (QR20DE), EC-94, "CONSULT-II Func-

tion" (QR25DE) or EC-826, "CONSULT-II Function"

(QR20DE).

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has detected an emission-related (EURO-OBD)

malfunction. For detail, refer to EC-44, "

ON BOARD DIAGNOSTIC (OBD) SYSTEM" (QR25DE) or EC-

777, "ON BOARD DIAGNOSTIC (OBD) SYSTEM" (QR20DE).

CONSULT-IIECS004QM

After performing “SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)” AT- 4 1 , place check marks for

results on the “DIAGNOSTIC WORKSHEET”, AT- 5 7

. Reference pages are provided following the items.

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

–Actual shift schedule has more or less tolerance or allowance,

–Shift schedule indicated in Service Manual refers to the point where shifts start, and

–Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSULT-II at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)

1. Turn on CONSULT-II and touch “ENGINE” for EURO-OBD

detected items or touch “A/T” for TCM self-diagnosis.

If A/T is not displayed, check TCM power supply and ground cir-

cuit. Refer to AT- 1 0 6 , "

TCM Terminals and Reference Value" . If

result is NG, refer to PG-2, "

POWER SUPPLY ROUTING" .

SAT652J

SAT014K