wheel torque NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3 of 3833

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

General Precautions ................................................ 4

Precautions for All Mode 4 × 4 System .................... 5

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 5

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 7

Precautions for Air Conditioning ............................... 7

HOW TO USE THIS MANUAL ................................... 8

Description ............................................................... 8

Terms ....................................................................... 8

Units ......................................................................... 8

Contents ................................................................... 8

Components ............................................................. 8

SYMBOLS ............................................................. 9

How to Follow Trouble Diagnoses ............................ 9

DESCRIPTION ...................................................... 9

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 10

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ........................................ 11

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 12

How to Read Wiring Diagrams ............................... 14CONNECTOR SYMBOLS ................................... 14

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 15

DESCRIPTION .................................................... 16

Abbreviations .......................................................... 22

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 23

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 23

WORK FLOW ...................................................... 23

INCIDENT SIMULATION TESTS ........................ 23

CIRCUIT INSPECTION ....................................... 26

Control Units and Electrical Parts ........................

... 31

PRECAUTIONS .................................................. 31

CONSULT-II CHECKING SYSTEM .......................... 33

Description .............................................................. 33

Function and System Application ........................... 33

Nickel Metal Hydride Battery Replacement ............ 33

Checking Equipment .............................................. 34

CONSULT-II Data Link Connector (DLC) Circuit .... 34

INSPECTION PROCEDURE .............................. 34

LIFTING POINT ......................................................... 35

Special Service Tools ............................................. 35

Garage Jack and Safety Stand ............................... 35

2-pole Lift ................................................................ 36

Board-on Lift ........................................................... 37

TOW TRUCK TOWING ............................................. 38

Tow Truck Towing ................................................... 38

TOWING AN AUTOMATIC TRANSAXLE

MODEL WITH FOUR WHEELS ON GROUND ... 38

T O W I N G T H E V E H I C L E W I T H R E A R W H E E L S

R A I S E D ( W I T H F R O N T W H E E L S O N G R O U N D )

OR FRONT WHEELS RAISED ........................... 39

Vehicle Recovery (Freeing a stuck vehicle) ............ 39

TIGHTENING TORQUE OF STANDARD BOLTS .... 40

Tightening Torque Table ......................................... 40

IDENTIFICATION INFORMATION ............................ 41

Model Variation ....................................................... 41

IDENTIFICATION NUMBER ................................ 42

IDENTIFICATION PLATE .................................... 43

ENGINE SERIAL NUMBER ................................ 43

Page 52 of 3833

EM-2

TIMING CHAIN .......................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSPECTION AFTER REMOVAL ........................ 41

INSTALLATION .................................................... 41

CAMSHAFT ............................................................... 46

Removal and Installation ........................................ 46

REMOVAL ........................................................... 46

INSTALLATION .................................................... 48

INSPECTION AFTER REMOVAL ........................ 51

Valve Clearance ...................................................... 53

INSPECTION ....................................................... 53

ADJUSTMENT .................................................... 54

OIL SEAL .................................................................. 56

Removal and Installation of Valve Oil Seal ............. 56

REMOVAL ........................................................... 56

INSTALLATION .................................................... 56

Removal and Installation of Front Oil Seal ............. 56

REMOVAL ........................................................... 56

INSTALLATION .................................................... 57

Removal and Installation of Rear Oil Seal .............. 57

REMOVAL ........................................................... 57

INSTALLATION .................................................... 57

CYLINDER HEAD .................................................. ... 59

On-Vehicle Service ................................................. 59

CHECKING COMPRESSION PRESSURE ......... 59

Removal and Installation ........................................ 60

REMOVAL ........................................................... 60

INSPECTION AFTER REMOVAL ........................ 61

INSTALLATION .................................................... 61

Disassembly and Assembly .................................... 62

DISASSEMBLY ................................................... 63

ASSEMBLY ......................................................... 63

Inspection After Disassembly ................................. 64

CYLINDER HEAD DISTORTION ........................ 64

VALVE DIMENSIONS .......................................... 64

VALVE GUIDE CLEARANCE .............................. 65

VALVE GUIDE REPLACEMENT ......................... 65

VALVE SEAT CONTACT ..................................... 66

VALVE SEAT REPLACEMENT ........................... 66

VALVE SPRING SQUARENESS ......................... 67

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD ............................... 68

ENGINE ASSEMBLY ................................................ 69

Removal and Installation ........................................ 69

REMOVAL .......................................................

.... 69

INSTALLATION .................................................... 71

INSPECTION AFTER INSTALLATION ................ 71

CYLINDER BLOCK ................................................... 73

Disassembly and Assembly .................................... 73

DISASSEMBLY ................................................... 74

ASSEMBLY ......................................................... 78

How to Select Piston and Bearing .......................... 82

DESCRIPTION .................................................... 82

HOW TO SELECT PISTON ................................. 83

HOW TO SELECT CONNECTING ROD BEAR-

ING ...................................................................... 83HOW TO SELECT MAIN BEARING .................... 85

Inspection After Disassembly .................................. 88

CRANKSHAFT END PLAY .................................. 88

CONNECTING ROD SIDE CLEARANCE ........... 89

PISTON AND PISTON PIN CLEARANCE ........... 89

PISTON RING SIDE CLEARANCE ..................... 90

PISTON RING END GAP .................................... 90

CONNECTING ROD BEND AND TORSION ....... 91

CONNECTING ROD BEARING (BIG END) ........ 91

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) ........................................... 91

CYLINDER BLOCK DISTORTION ...................... 92

INNER DIAMETER OF MAIN BEARING HOUS-

ING ....................................................................... 93

PISTON TO CYLINDER BORE CLEARANCE .... 93

OUTER DIAMETER OF CRANKSHAFT JOUR-

NAL ...................................................................... 94

OUTER DIAMETER OF CRANKSHAFT PIN ...... 94

OUT-OF-ROUND AND TAPER OF CRANK-

SHAFT ................................................................. 94

CRANKSHAFT RUNOUT .................................... 95

CONNECTING ROD BEARING OIL CLEAR-

ANCE ................................................................... 95

MAIN BEARING OIL CLEARANCE ..................... 95

MAIN BEARING CRUSH HEIGHT ...................... 96

OUTER DIAMETER OF LOWER CYLINDER

BLOCK MOUNTING BOLT .................................. 96

OUTER DIAMETER OF CONNECTING ROD

BOLT .................................................................... 96

MOVEMENT AMOUNT OF FLYWHEEL (M/T

MODELS) ............................................................. 97

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 98

Standard and Limit .................................................. 98

GENERAL SPECIFICATIONS ............................. 98

DRIVE BELTS ...................................................... 98

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD ................................................................... 98

SPARK PLUG ...................................................... 98

CYLINDER HEAD ................................................ 98

VALVE .................................................................. 99

CAMSHAFT AND CAMSHAFT BEARING .........102

CYLINDER BLOCK ............................................102

PISTON, PISTON RING AND PISTON PIN .....

.103

CONNECTING ROD ..........................................104

CRANKSHAFT ...................................................105

MAIN BEARING .................................................106

CONNECTING ROD BEARING .........................107

Tightening Torque .................................................108

YD22DDTi

PRECAUTIONS .......................................................110

Precautions for Drain Engine Coolant ...................110

Precautions for Disconnecting Fuel Piping ...........110

Precautions for Removal and Disassembly ..........110

Precautions for Inspection, Repair and Replace-

ment ......................................................................110

Precautions for Assembly and Installation ............110

Page 54 of 3833

EM-4

INSPECTION AFTER REMOVAL ......................184

INSTALLATION ..................................................185

Disassembly and Assembly ..................................187

DISASSEMBLY .................................................187

ASSEMBLY .......................................................188

INSPECTION AFTER DISASSEMBLY ..............188

ENGINE ASSEMBLY ..............................................193

Removal and Installation ......................................193

REMOVAL .........................................................194

INSTALLATION ..................................................195

INSPECTION AFTER INSTALLATION ..............196

CYLINDER BLOCK .................................................197

Disassembly and Assembly ..................................197

DISASSEMBLY .................................................198

ASSEMBLY .......................................................202

How to Select Piston and Bearing ........................206

DESCRIPTION ..................................................206

HOW TO SELECT PISTON ...............................206

HOW TO SELECT CONNECTING ROD BEAR-

ING ....................................................................207

HOW TO SELECT MAIN BEARING ..................208

Inspection After Disassembly ...............................210

CRANKSHAFT END PLAY ................................210

CONNECTING ROD SIDE CLEARANCE .........210

PISTON TO PISTON PIN CLEARANCE ...........210

PISTON RING SIDE CLEARANCE ...................211

PISTON RING END GAP ..................................211

CONNECTING ROD BEND AND TORSION .....212

CONNECTING ROD BIG END INNER DIAME-

TER ...................................................................212

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) .........................................212

CYLINDER BLOCK TOP SURFACE DISTOR-TION ..................................................................213

MAIN BEARING HOUSING INNER DIAMETER .213

PISTON TO CYLINDER BORE CLEARANCE ..214

CRANKSHAFT JOURNAL OUTER DIAMETER .215

CRANKSHAFT PIN OUTER DIAMETER ..........215

CRANKSHAFT OUT-OF-ROUND AND TAPER .215

CRANKSHAFT RUNOUT ..................................216

CONNECTING ROD BEARING OIL CLEAR-

ANCE .................................................................216

MAIN BEARING OIL CLEARANCE ...................216

MAIN BEARING CRUSH HEIGHT ....................217

MAIN BEARING CAP BOLT DEFORMATION ...217

CONNECTING ROD BOLT DEFORMATION ....217

OIL JET ..............................................................218

OIL JET RELIEF VALVE ....................................218

MOVEMENT AMOUNT OF FLYWHEEL ...........218

SERVICE DATA AND SPECIFICATIONS (SDS) ....220

Standard and Limit ...............................................

.220

GENERAL SPECIFICATIONS ...........................220

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD .................................................................220

DRIVE BELTS ....................................................220

CYLINDER HEAD ..............................................221

VALVE ................................................................221

CAMSHAFT AND CAMSHAFT BEARING .........225

CYLINDER BLOCK ............................................225

PISTON, PISTON RING AND PISTON PIN ......226

CONNECTING ROD ..........................................227

CRANKSHAFT ...................................................227

AVAILABLE MAIN BEARING .............................228

AVAILABLE CONNECTING ROD BEARING .....228

MISCELLANEOUS COMPONENTS ..................228

Tightening Torque .................................................229

Page 147 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-97

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

MOVEMENT AMOUNT OF FLYWHEEL (M/T MODELS)

NOTE:

●Inspection for double mass flywheel only.

●Do not disassembly double mass flywheel.

Flywheel Def NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-97

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

MOVEMENT AMOUNT OF FLYWHEEL (M/T MODELS)

NOTE:

●Inspection for double mass flywheel only.

●Do not disassembly double mass flywheel.

Flywheel Def](/img/5/57405/w960_57405-146.png)

CYLINDER BLOCK

EM-97

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

MOVEMENT AMOUNT OF FLYWHEEL (M/T MODELS)

NOTE:

●Inspection for double mass flywheel only.

●Do not disassembly double mass flywheel.

Flywheel Deflection

●Measure deflection of flywheel contact surface to the clutch with a dial gauge.

●Measure deflection at 210 mm (8.27 in) dia.

●When measured value exceeds the limit, replace it with a new

one.

Movement Amount in Radial (rotation) Direction

Check the movement amount in the following procedure.

1. Install a bolt to clutch cover mounting hole, and place a torque wrench on the extended line of the flywheel

center line.

●Tighten bolt at a force of 9.8 N·m (1.0 kg-m, 87 in-lb) to keep it from loosening.

2. Put a mating mark on circumferences of the two flywheel

masses without applying any load (Measurement standard

points).

3. Apply a force of 9.8 N·m (1.0 kg-m, 87 in-lb) in each direction,

and mark the movement amount on the mass on the transaxle

side.

4. Measure dimensions of movement amounts A and B on circum-

ference of the flywheel on the transaxle side.

●When measured value is outside the standard, replace fly-

wheel.Standard : 0.45 mm (0.0177 in) or less.

Limit : 1.3 mm (0.051 in) or less.

SBIA0287E

Standard: 28.3 mm (1.114 in) or less.

PBIC1263E

Page 268 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-218

[YD22DDTi]

CYLINDER BLOCK

OIL JET

●Check nozzle for deformation and damage.

●Blow compressed air from nozzle, and check for clogs.

●If it out of the standard, replace oil jet.

OIL JET REL NISSAN X-TRAIL 2001 Service Repair Manual EM-218

[YD22DDTi]

CYLINDER BLOCK

OIL JET

●Check nozzle for deformation and damage.

●Blow compressed air from nozzle, and check for clogs.

●If it out of the standard, replace oil jet.

OIL JET REL](/img/5/57405/w960_57405-267.png)

EM-218

[YD22DDTi]

CYLINDER BLOCK

OIL JET

●Check nozzle for deformation and damage.

●Blow compressed air from nozzle, and check for clogs.

●If it out of the standard, replace oil jet.

OIL JET RELIEF VALVE

●Using a clean plastic stick, press check valve in oil jet relief

valve. Make sure that valve moves smoothly with proper reac-

tion force.

●If it is out of the standard, replace oil jet relief valve.

MOVEMENT AMOUNT OF FLYWHEEL

NOTE:

●Inspection for double mass flywheel only.

●Do not disassembly double mass flywheel.

Flywheel Deflection

●Measure deflection of flywheel contact surface to the clutch with a dial gauge.

●Measure deflection at 210 mm (8.27 in) dia.

●When measured value exceeds the limit, replace flywheel with a

new one.

Movement Amount in Radial (rotation) Direction

Check the movement amount in the following procedure.

1. Install a bolt to clutch cover mounting hole, and place a torque wrench on the extended line of the flywheel

center line.

●Tighten bolt at a force of 9.8 N·m (1 kg-m, 87 in-lb) to keep it from loosening. Standard : Deformation and damage.

JEM221G

Standard:

Valve moves smoothly with proper reaction force.

JEM222G

Standard : 0.45 mm (0.0177 in) or less

Limit : 1.3 mm (0.051 in)

PBIC0683E

Page 475 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P0011 IVT CONTROL

EC-125

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00M1K

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases NISSAN X-TRAIL 2001 Service Repair Manual DTC P0011 IVT CONTROL

EC-125

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00M1K

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases](/img/5/57405/w960_57405-474.png)

DTC P0011 IVT CONTROL

EC-125

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00M1K

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing control solenoid

valve depending on driving status. This makes it possible to control the shut/open timing of the intake valve to

increase engine torque in low/mid speed range and output in high-speed range.

CONSULT-II Reference Value in Data Monitor ModeEBS00M1L

Specification data are reference values.

ECM Terminals and Reference ValueEBS00M1M

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Sensor Input signal to ECM function ECM Actuator

Crankshaft position sensor (POS) Engine speed

Intake valve

timing controlIntake valve timing control

solenoid valve Camshaft position sensor (PHASE) Engine speed and piston position

Engine coolant temperature sensor Engine coolant temperature

Wheel sensor Vehicle speed

PBIB0540E

MONITOR ITEM CONDITION SPECIFICATION

INT/V TIM (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle−5° - 5°CA

When revving engine up to 2,000 rpm

quicklyApprox. 0° - 20°CA

INT/V SOL (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle 0% - 2%

When revving engine up to 2,000 rpm

quicklyApprox. 0% - 50%

Page 1049 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual IVT CONTROL SOLENOID VALVE

EC-699

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00ND9

SYSTEM DESCRIPTION

This mechanism hydraulically controls NISSAN X-TRAIL 2001 Service Repair Manual IVT CONTROL SOLENOID VALVE

EC-699

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00ND9

SYSTEM DESCRIPTION

This mechanism hydraulically controls](/img/5/57405/w960_57405-1048.png)

IVT CONTROL SOLENOID VALVE

EC-699

[QR25(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00ND9

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing control solenoid

valve depending on driving status. This makes it possible to control the shut/open timing of the intake valve to

increase engine torque in low/mid speed range and output in high-speed range.

COMPONENT DESCRIPTION

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

CONSULT-II Reference Value in Data Monitor ModeEBS00NDA

Specification data are reference values.

Sensor Input signal to ECM function ECM Actuator

Crankshaft position sensor (POS) Engine speed

Intake valve

timing controlIntake valve timing control

solenoid valve Camshaft position sensor (PHASE) Engine speed and piston position

Engine coolant temperature sensor Engine coolant temperature

Wheel sensor Vehicle speed

PBIB0540E

PBIB0195E

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle 0% - 2%

When revving engine up to 2,000 rpm

quicklyApprox. 0% - 50%

Page 1207 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P0011 IVT CONTROL

EC-857

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00MTJ

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases NISSAN X-TRAIL 2001 Service Repair Manual DTC P0011 IVT CONTROL

EC-857

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00MTJ

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases](/img/5/57405/w960_57405-1206.png)

DTC P0011 IVT CONTROL

EC-857

[QR20(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0011 IVT CONTROLPFP:23796

DescriptionEBS00MTJ

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing control solenoid

valve depending on driving status. This makes it possible to control the shut/open timing of the intake valve to

increase engine torque in low/mid speed range and output in high-speed range.

CONSULT-II Reference Value in Data Monitor ModeEBS00MTK

Specification data are reference values.

ECM Terminals and Reference ValueEBS00MTL

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Sensor Input signal to ECM function ECM Actuator

Crankshaft position sensor (POS) Engine speed

Intake valve

timing controlIntake valve timing control

solenoid valve Camshaft position sensor (PHASE) Engine speed and piston position

Engine coolant temperature sensor Engine coolant temperature

Wheel sensor Vehicle speed

PBIB0540E

MONITOR ITEM CONDITION SPECIFICATION

INT/V TIM (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle−5° - 5°CA

When revving engine up to 2,000 rpm

quicklyApprox. 0° - 20°CA

INT/V SOL (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle 0% - 2%

When revving engine up to 2,000 rpm

quicklyApprox. 0% - 50%

Page 1697 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual IVT CONTROL SOLENOID VALVE

EC-1347

[QR20(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00N9S

SYSTEM DESCRIPTION

This mechanism hydraulically control NISSAN X-TRAIL 2001 Service Repair Manual IVT CONTROL SOLENOID VALVE

EC-1347

[QR20(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00N9S

SYSTEM DESCRIPTION

This mechanism hydraulically control](/img/5/57405/w960_57405-1696.png)

IVT CONTROL SOLENOID VALVE

EC-1347

[QR20(WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

IVT CONTROL SOLENOID VALVEPFP:23796

DescriptionEBS00N9S

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing control solenoid

valve depending on driving status. This makes it possible to control the shut/open timing of the intake valve to

increase engine torque in low/mid speed range and output in high-speed range.

COMPONENT DESCRIPTION

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

CONSULT-II Reference Value in Data Monitor ModeEBS00N9T

Specification data are reference values.

Sensor Input signal to ECM function ECM Actuator

Crankshaft position sensor (POS) Engine speed

Intake valve

timing controlIntake valve timing control

solenoid valve Camshaft position sensor (PHASE) Engine speed and piston position

Engine coolant temperature sensor Engine coolant temperature

Wheel sensor Vehicle speed

PBIB0540E

PBIB0195E

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL (B1)

●Engine: After warming up

●Shift lever: N

●Air conditioner switch: OFF

●No-loadIdle 0% - 2%

When revving engine up to 2,000 rpm

quicklyApprox. 0% - 50%

Page 2110 of 3833

AT-32

OVERALL SYSTEM

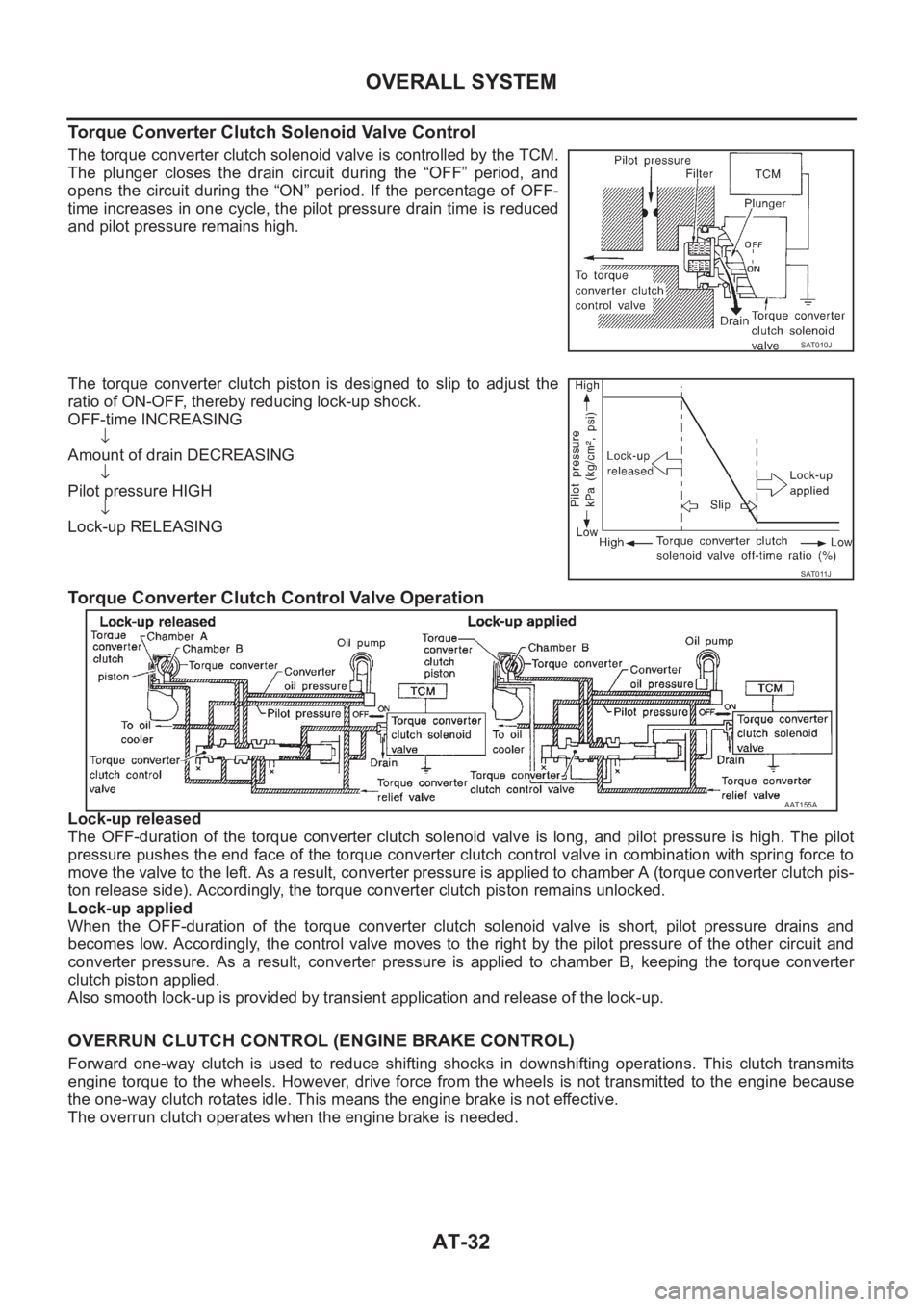

Torque Converter Clutch Solenoid Valve Control

The torque converter clutch solenoid valve is controlled by the TCM.

The plunger closes the drain circuit during the “OFF” period, and

opens the circuit during the “ON” period. If the percentage of OFF-

time increases in one cycle, the pilot pressure drain time is reduced

and pilot pressure remains high.

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

OFF-time INCREASING

↓

Amount of drain DECREASING

↓

Pilot pressure HIGH

↓

Lock-up RELEASING

Torque Converter Clutch Control Valve Operation

Lock-up released

The OFF-duration of the torque converter clutch solenoid valve is long, and pilot pressure is high. The pilot

pressure pushes the end face of the torque converter clutch control valve in combination with spring force to

move the valve to the left. As a result, converter pressure is applied to chamber A (torque converter clutch pis-

ton release side). Accordingly, the torque converter clutch piston remains unlocked.

Lock-up applied

When the OFF-duration of the torque converter clutch solenoid valve is short, pilot pressure drains and

becomes low. Accordingly, the control valve moves to the right by the pilot pressure of the other circuit and

converter pressure. As a result, converter pressure is applied to chamber B, keeping the torque converter

clutch piston applied.

Also smooth lock-up is provided by transient application and release of the lock-up.

OVERRUN CLUTCH CONTROL (ENGINE BRAKE CONTROL)

Forward one-way clutch is used to reduce shifting shocks in downshifting operations. This clutch transmits

engine torque to the wheels. However, drive force from the wheels is not transmitted to the engine because

the one-way clutch rotates idle. This means the engine brake is not effective.

The overrun clutch operates when the engine brake is needed.

SAT010J

SAT011J

AAT155A