troubleshooting NISSAN X-TRAIL 2005 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2005Pages: 4555, PDF Size: 88.09 MB

Page 1413 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS

EC-1009

[YD (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine co NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS

EC-1009

[YD (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine co](/img/5/57403/w960_57403-1412.png)

TROUBLE DIAGNOSIS

EC-1009

[YD (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

EC-1009, "

DIAGNOSTIC WORK SHEET" .

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st/2nd trip) DTC and

the freeze frame data (When 1st/2nd trip DTC is detected, Freeze Frame Data is not recorded.), then erase the DTC

and the data. (Refer to EC-999

.) The (1st/2nd trip) DTC and the freeze frame data can be used when duplicating the

incident at STEP III & IV.

If the incident cannot be verified, perform EC-1045, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

Study the relationship between the cause, specified by (1st/2nd trip) DTC, and the symptom described by the cus-

tomer. (The Symptom Matrix Chart will be useful. See EC-1016

.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The DIAGNOSTIC WORK SHEET and the freeze frame data are useful to verify the incident. Connect CONSULT-II

to the vehicle in “DATA MONITOR (AUTO TRIG)” mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-1045, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st/2nd trip) DTC by driving in (or performing) the DTC Confirmation Procedure. Check and read

the (1st/2nd trip) DTC and freeze frame data by using CONSULT-II or GST.

During the (1st/2nd trip) DTC verification, be sure to connect CONSULT-II to the vehicle in “DATA MONITOR (AUTO

TRIG)” mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-1045, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

In case the DTC Confirmation Procedure is not available, perform the Overall Function Check instead. The (1st/2nd

trip) DTC cannot be displayed by this check, however, this simplified check is an effective alternative.

The NG result of the Overall Function Check is the same as the (1st/2nd trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-1012

.)Then perform inspections

according to the Symptom Matrix Chart. (Refer to EC-1016

.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect the

system for mechanical binding, loose connectors or wiring damage using (tracing) Harness Layouts.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR

(AUTO TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CONSULT-II.

Refer to EC-1027

, EC-1042 .

The Diagnostic Procedure in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in

GI-23, "

How to Perform Efficient Diagnosis for an Electrical Incident" .

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform EC-1045, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT" .

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions and

circumstances which resulted in the customer's initial complaint.

Perform the DTC Confirmation Procedure and confirm the normal code [DTC No. P0000] is detected. If the incident is

still detected in the final check, perform STEP VI by using a method different from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st/2nd trip) DTC in

ECM. (Refer to EC-999, "

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION" .)

SEF907L

Page 1756 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual EC-1352

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.FUEL TEMP SEN/CIRC P0183 0183 —EC-1462 NISSAN X-TRAIL 2005 Service Owners Manual EC-1352

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.FUEL TEMP SEN/CIRC P0183 0183 —EC-1462](/img/5/57403/w960_57403-1755.png)

EC-1352

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.FUEL TEMP SEN/CIRC P0183 0183 —EC-1462

HIGH FUEL PRESS P0088 0088×EC-1430

IAT SEN/CIRCUIT P0112 0112 —EC-1443

IAT SEN/CIRCUIT P0113 0113 —EC-1443

INJ ADJ RES/CIRC1 P1260 1260 —EC-1590

INJ ADJ RES/CIRC1 P1261 1261 —EC-1590

INJ ADJ RES/CIRC2 P1262 1262 —EC-1590

INJ ADJ RES/CIRC2 P1263 1263 —EC-1590

INJ ADJ RES/CIRC3 P1264 1264 —EC-1590

INJ ADJ RES/CIRC3 P1265 1265 —EC-1590

INJ ADJ RES/CIRC4 P1266 1266 —EC-1590

INJ ADJ RES/CIRC4 P1267 1267 —EC-1590

INJ PWR/CIRC P2146 2146×EC-1631

INJ PWR/CIRC P2149 2149×EC-1631

INJECTOR P0200 0200×EC-1472

INJECTOR/CIRC P2147 2147×EC-1635

INJECTOR/CIRC P2148 2148×EC-1635

INJECTOR 1 P1268 1268 —EC-1596

INJECTOR 2 P1269 1269 —EC-1596

INJECTOR 3 P1270 1270 —EC-1596

INJECTOR 4 P1271 1271 —EC-1596

MAF SEN/CIRCUIT P0102 0102 —EC-1438

MAF SEN/CIRCUIT P0103 0103 —EC-1438

NATS MALFUNCTION P1610 - P1617 1610 - 1617 —EC-1373

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P00000000 — —

SENSOR PWR/CIRC1 P0642 0642 —EC-1575

SENSOR PWR/CIRC1 P0643 0643 —EC-1575

SENSOR PWR/CIRC2 P0652 0652 —EC-1579

SENSOR PWR/CIRC2 P0653 0653 —EC-1579

STRG SW/CIRC P0580 0580 —EC-1557

STRG SW/CIRC P0581 0581 —EC-1557

TC BOOST SEN/CIRC P0237 0237 —EC-1506

TC BOOST SEN/CIRC P0238 0238 —EC-1506

TC SYSTEM P0234 0234 —EC-1500

TCS/CIRC P1212 1212×EC-1589

TCS C/U FUNCTN P1211 1211×EC-1588

VEHICLE SPEED P0501 0501 —EC-1538

VEHICLE SPEED P0502 0502 —EC-1540

VEHICLE SPEED P0503 0503 —EC-1542

Items

(CONSULT-II screen terms) DTC

MI lighting

up Reference page

CONSULT-II

ECM*

1

Page 1758 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual EC-1354

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.P0504 0504 BRAKE SW/CIRCUIT —EC-1544

P NISSAN X-TRAIL 2005 Service Owners Manual EC-1354

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.P0504 0504 BRAKE SW/CIRCUIT —EC-1544

P](/img/5/57403/w960_57403-1757.png)

EC-1354

[YD (WITHOUT EURO-OBD)]

INDEX FOR DTC

*1: In Diagnostic Test Mode II (Self-diagnostic results).

*2: The troubleshooting for this DTC needs CONSULT-II.P0504 0504 BRAKE SW/CIRCUIT —EC-1544

P0563 0563 BATTERY VOLTAGE —EC-1554

P0580 0580 STRG SW/CIRC —EC-1557

P0581 0581 STRG SW/CIRC —EC-1557

P0605 0605 ECM×EC-1566

P0606 0606 ECM×EC-1568

P0628 0628 FUEL PUMP/CIRC×EC-1570

P0629 0629 FUEL PUMP/CIRC×EC-1570

P0642 0642 SENSOR PWR/CIRC1 —EC-1575

P0643 0643 SENSOR PWR/CIRC1 —EC-1575

P0652 0652 SENSOR PWR/CIRC2 —EC-1579

P0653 0653 SENSOR PWR/CIRC2 —EC-1579

P0686 0686 ECM RELAY —EC-1584

P1211 1211 TCS C/U FUNCTN —EC-1588

P1212 1212 TCS/CIRC —EC-1589

P1260 1260 INJ ADJ RES/CIRC1 —EC-1590

P1261 1261 INJ ADJ RES/CIRC1 —EC-1590

P1262 1262 INJ ADJ RES/CIRC2 —EC-1590

P1263 1263 INJ ADJ RES/CIRC2 —EC-1590

P1264 1264 INJ ADJ RES/CIRC3 —EC-1590

P1265 1265 INJ ADJ RES/CIRC3 —EC-1590

P1266 1266 INJ ADJ RES/CIRC4 —EC-1590

P1267 1267 INJ ADJ RES/CIRC4 —EC-1590

P1268 1268 INJECTOR 1 —EC-1596

P1269 1269 INJECTOR 2 —EC-1596

P1270 1270 INJECTOR 3 —EC-1596

P1271 1271 INJECTOR 4 —EC-1596

P1272 1272 FRP RELIEF VALVE —EC-1602

P1273 1273 FUEL PUMP —EC-1609

P1274 1274 FUEL PUMP×EC-1614

P1275 1275 FUEL PUMP×EC-1619

P1610 - P1617 1610 - 1617 NATS MALFUNTION —EC-1373

P2135 2135 APP SENSOR —EC-1624

P2146 2146 INJ PWR/CIRC×EC-1631

P2147 2147 INJECTOR/CIRC×EC-1635

P2148 2148 INJECTOR/CIRC×EC-1635

P2149 2149 INJ PWR/CIRC×EC-1631

P2228 2228 BARO SEN/CIRC —EC-1641

P2229 2229 BARO SEN/CIRC —EC-1641

DTC

Items

(CONSULT-II screen item) MI lighting up Reference page

CONSULT-II

ECM*

1

Page 1784 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual EC-1380

[YD (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine components. A good grasp NISSAN X-TRAIL 2005 Service Owners Manual EC-1380

[YD (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine components. A good grasp](/img/5/57403/w960_57403-1783.png)

EC-1380

[YD (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

DIAGNOSTIC WORK SHEET

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

EC-1380, "

DIAGNOSTIC WORK SHEET" .

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the DTC and the freeze frame

data, then erase the DTC. The DTC and the freeze frame data can be used when duplicating the incident at STEP III

& IV. Refer to EC-1373

.

If the incident cannot be verified, perform EC-1414, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

Symptom Matrix Chart will be useful. Refer toEC-1387

) Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The DIAGNOSTIC WORK SHEET and the freeze frame data are useful to verify the incident. Connect CONSULT-II to

the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-1414, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the DTC by driving in (or performing) the DTC Confirmation Procedure. Check and read the DTC and the

freeze frame data by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode

and check real time diagnosis results.

If the incident cannot be verified, perform EC-1414, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

In case the DTC Confirmation Procedure is not available, perform the Overall Function Check instead. The DTC can-

not be displayed by this check, however, this simplified check is an effective alternative.

The “NG” result of the Overall Function Check is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to Trouble Diagnosis for DTC PXXXX.

If the normal code is indicated, proceed to the Basic Inspection, EC-1382

. Then perform inspections according to the

Symptom Matrix Chart. Refer to EC-1387

.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect the

system for mechanical binding, loose connectors or wiring damage using (tracing) Harness Layouts.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR (AUTO

TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CONSULT-II.

Refer to EC-1398

or EC-1411 .

The Diagnostic Procedure in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI-23, "

How to Per-

form Efficient Diagnosis for an Electrical Incident" , “Circuit Inspection”.

Repair or replace the malfunction parts.

If the malfunctioning part cannot be detected, perform EC-1414, "

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT" .

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions and

circumstances which resulted in the customer's initial complaint.

Perform the DTC Confirmation Procedure and confirm the normal code (DTC P0000) is detected. If the incident is still

detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM. (Refer to

EC-1372

.)

SEF907L

Page 2137 of 4555

CL-1

CLUTCH

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION CL

A

B

CL

CLUTCH

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

CLUTCH PEDAL ........................................................ 5

On-Vehicle Inspection and Adjustment .................... 5

Removal and Installation .......................................... 6

COMPONENTS .................................................... 6

REMOVAL ............................................................. 6

INSPECTION AFTER REMOVAL ......................... 7

INSTALLATION ..................................................... 7

CLUTCH FLUID .......................................................... 8

Air Bleeding Procedure ............................................ 8

CLUTCH MASTER CYLINDER .................................. 9

Components ............................................................. 9

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ................................................... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY .......................................................... 11

OPERATING CYLINDER .......................................... 12

Components ........................................................... 12Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly .................................... 12

DISASSEMBLY ................................................... 12

INSPECTION AFTER DISASSEMBLY ................ 12

ASSEMBLY ......................................................... 12

CLUTCH PIPING ....................................................... 13

Removal and Installation ........................................ 13

CLUTCH RELEASE MECHANISM ........................... 14

Removal and Installation ........................................ 14

COMPONENTS ................................................... 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL ... 16

Removal and Installation ........................................ 16

COMPONENTS ................................................... 16

REMOVAL ........................................................... 16

INSPECTION AND ADJUSTMENT AFTER

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 19

Clutch Control System ............................................ 19

Clutch Master Cylinder ........................................... 19

Clutch Operating Cylinder ...................................... 19

Clutch Disc ............................................................. 19

Clutch Cover ........................................................... 19

Page 2140 of 4555

CL-4

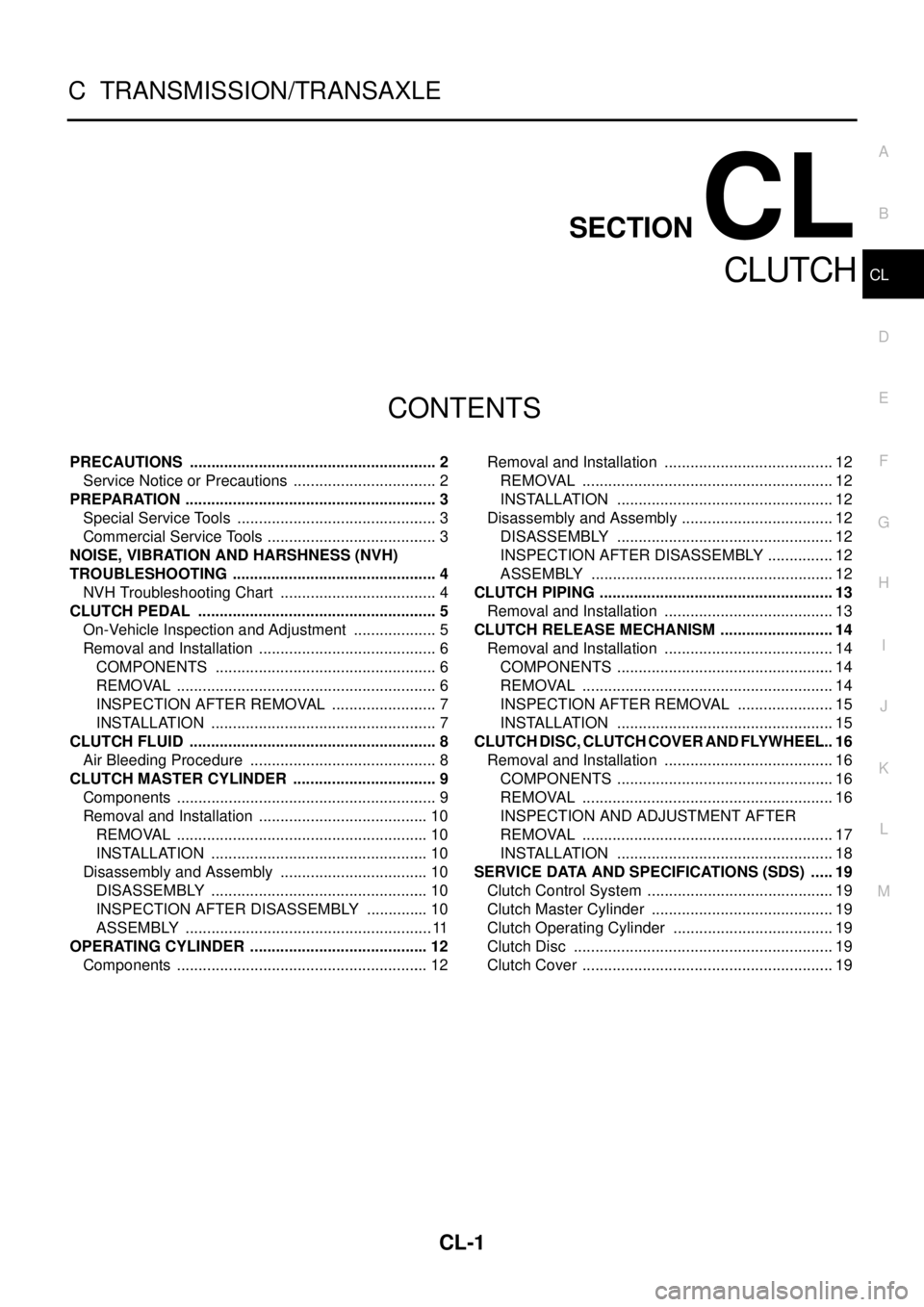

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartECS008B8

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageCL-5CL-8CL-9CL-12

EM-81

(QR engine models), EM-222

(YD engine models)

CL-14

CL-16

EM-116

(QR engine models),EM-255

(YD engine models)

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

Page 2157 of 4555

MT-1

MANUAL TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION MT

A

B

MT

MANUAL TRANSAXLE

PRECAUTIONS .......................................................... 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 8

NVH Troubleshooting Chart ..................................... 8

DESCRIPTION ............................................................ 9

Cross-Sectional View ............................................... 9

DOUBLE-CONE SYNCHRONIZER ..................... 11

TRIPLE-CONE SYNCHRONIZER ....................... 11

REVERSE GEAR NOISE PREVENTION FUNC-

TION (SYNCHRONIZING METHOD) .................. 11

M/T OIL ..................................................................... 12

Changing M/T Oil ................................................... 12

DRAINING ........................................................... 12

FILLING ............................................................... 12

Checking M/T Oil .................................................... 12

OIL LEAKAGE AND OIL LEVEL ......................... 12

SIDE OIL SEAL ........................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

POSITION SWITCH .................................................. 15

Checking ................................................................ 15

BACK-UP LAMP SWITCH .................................. 15

PARK/NEUTRAL POSITION SWITCH ............... 15

CONTROL LINKAGE ............................................... 16

Components of Control Device and Cable ............. 16

Removal and Installation ........................................ 17

AIR BREATHER HOSE ............................................ 18

Removal and Installation ........................................ 18

TRANSAXLE ASSEMBLY ........................................ 19

Removal and Installation ........................................ 19

COMPONENTS .................................................. 19

REMOVAL ........................................................... 20

INSTALLATION ................................................... 21

Disassembly and Assembly (RS5F51A) ................ 22

COMPONENTS .................................................. 22DISASSEMBLY ................................................... 26

ASSEMBLY ......................................................... 30

ADJUSTMENT .................................................... 36

Disassembly and Assembly (RS6F51A) ................. 40

COMPONENTS ................................................... 40

DISASSEMBLY ................................................... 44

ASSEMBLY ......................................................... 48

ADJUSTMENT .................................................... 54

INPUT SHAFT AND GEARS .................................... 58

Disassembly and Assembly (RS5F51A) ................. 58

DISASSEMBLY ................................................... 58

INSPECTION AFTER DISASSEMBLY ................ 59

ASSEMBLY ......................................................... 62

Disassembly and Assembly (RS6F51A) ................. 66

DISASSEMBLY ................................................... 66

INSPECTION AFTER DISASSEMBLY ................ 67

ASSEMBLY ......................................................... 69

MAINSHAFT AND GEARS ....................................... 73

Disassembly and Assembly (RS5F51A) ................. 73

DISASSEMBLY ................................................... 73

INSPECTION AFTER DISASSEMBLY ................ 74

ASSEMBLY ......................................................... 76

Disassembly and Assembly (RS6F51A) ................. 80

DISASSEMBLY ................................................... 80

INSPECTION AFTER DISASSEMBLY ................ 81

ASSEMBLY ......................................................... 83

REVERSE IDLER SHAFT AND GEARS .................. 89

Disassembly and Assembly (RS5F51A) ................. 89

DISASSEMBLY ................................................... 89

INSPECTION AFTER DISASSEMBLY ................ 89

ASSEMBLY ......................................................... 90

Disassembly and Assembly (RS6F51A) ................. 90

DISASSEMBLY ................................................... 90

INSPECTION AFTER DISASSEMBLY ................ 91

ASSEMBLY ......................................................... 91

FINAL DRIVE ............................................................ 93

Disassembly and Assembly (RS5F51A) ................. 93

PRE-INSPECTION .............................................. 93

DISASSEMBLY ................................................... 93

INSPECTION AFTER DISASSEMBLY ................ 94

Page 2164 of 4555

MT-8

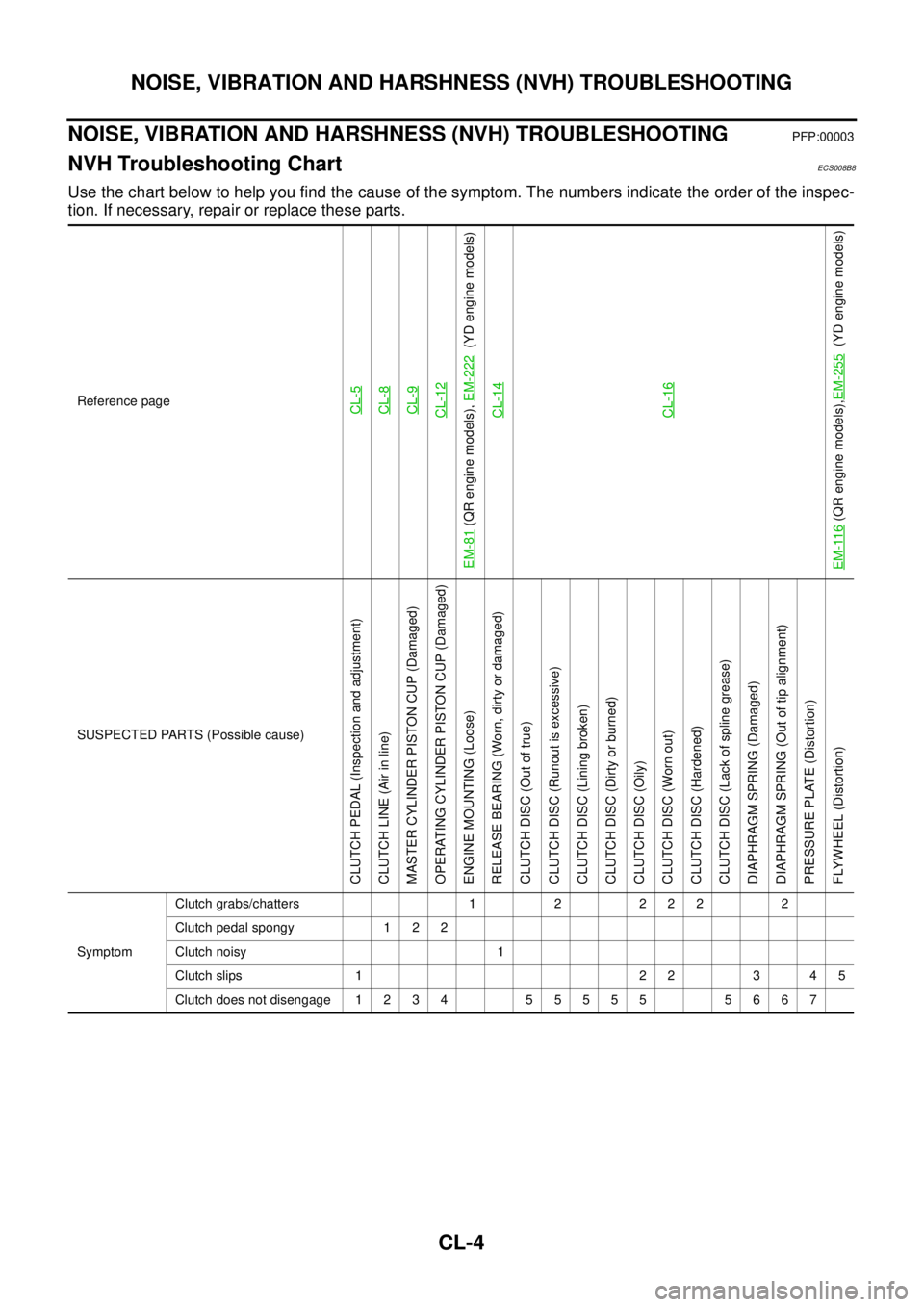

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartECS008BP

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageMA-39

MT-22

(RS5F51A), MT-40

(RS6F51A)

MT-16

MT-25

(RS5F51A), MT-43

(RS6F51A)

MT-23

(RS5F51A), MT-41

(RS6F51A)

SUSPECTED PARTS

(Possible cause)

OIL (Oil level is low.)

OIL (Wrong oil.)

OIL (Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL LINKAGE (Worn)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomsNoise 1 2 3 3

Oil leakage 31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1 2 3 3

Page 2325 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-61

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004QP

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-61

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004QP

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction](/img/5/57403/w960_57403-2324.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-61

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004QP

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, “INFORMATION FROM CUSTOMER” (AT- 5 8 , "

Information from

Customer" ) and “DIAGNOSTIC WORKSHEET” (AT- 5 9 , "Diagnostic Worksheet" ), to perform the best trouble-

shooting possible.

Page 2519 of 4555

![NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-255

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004TG

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malf NISSAN X-TRAIL 2005 Service Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-255

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004TG

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malf](/img/5/57403/w960_57403-2518.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-255

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Work FlowECS004TG

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, “INFORMATION FROM CUSTOMER” (AT- 2 5 2

) and “DIAGNOS-

TIC WORKSHEET” (AT- 2 5 3

), to perform the best troubleshooting possible.

WORK FLOW CHART

*1AT-252*2AT- 2 5 3*3AT- 1 0

*4AT-256*5AT- 2 5 7*6AT-260

*7AT-262*8AT- 2 4 6*9AT-242

*10AT-242*11AT- 3 3 2*12AT-329

*13AT-291*14AT- 3 2 2:15AT-277

*16AT-245*17AT- 2 5 0*18AT-332

*19AT-329

SAT097KC