radiator cap Oldsmobile Aurora 1998 Owner's Manuals

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 1998, Model line: Aurora, Model: Oldsmobile Aurora 1998Pages: 380, PDF Size: 19.75 MB

Page 237 of 380

I NOTICE:

In cold weather, water can freeze and crack the

engine, radiator, heater core and other parts.

So

use the recommended coolant.

I A CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol

and it will burn if the engine parts are hot

enough. Don’t spill coolant on

a hot engine.

1. You can remove the coolant surge tank pressure cap

when the cooling system, including the coolant surge

tank pressure cap and upper radiator hose, is no

longer hot. Turn the pressure cap slowly about

one-quarter turn to the left and then stop.

If you hear a hiss, wait for that to stop. A hiss means

there is still some pressure

left.

5-21

Page 239 of 380

4. With the coolant surge tank pressure cap off, start the

engine and let

it run until you can feel the upper

radiator hose getting hot. Watch out for the engine

cooling fans.

5. Then replace the pressure cap. Be sure the pressure

cap is tight.

By this time, the coolant level inside the coolant

surge tank may be lower.

If the level is lower, add

more of the proper mixture to the coolant surge tank

until the level reaches

FULL COLD.

5-23

Page 275 of 380

Checking Coolant

The engine coolant surge tank is located on the driver’s

side

of the engine compartment.

A CAUTION:

Turning the surge tank pressure cap when the

engine and radiator are hot can allow steam and

scalding liquids to blow out and burn

you badly.

Never turn the surge tank pressure cap

-- even a

little

-- when the engine and radiator are hot.

Page 277 of 380

A CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol,

and it

will burn if the engine parts are hot

enough. Don’t spill coolant on a hot engine.

11

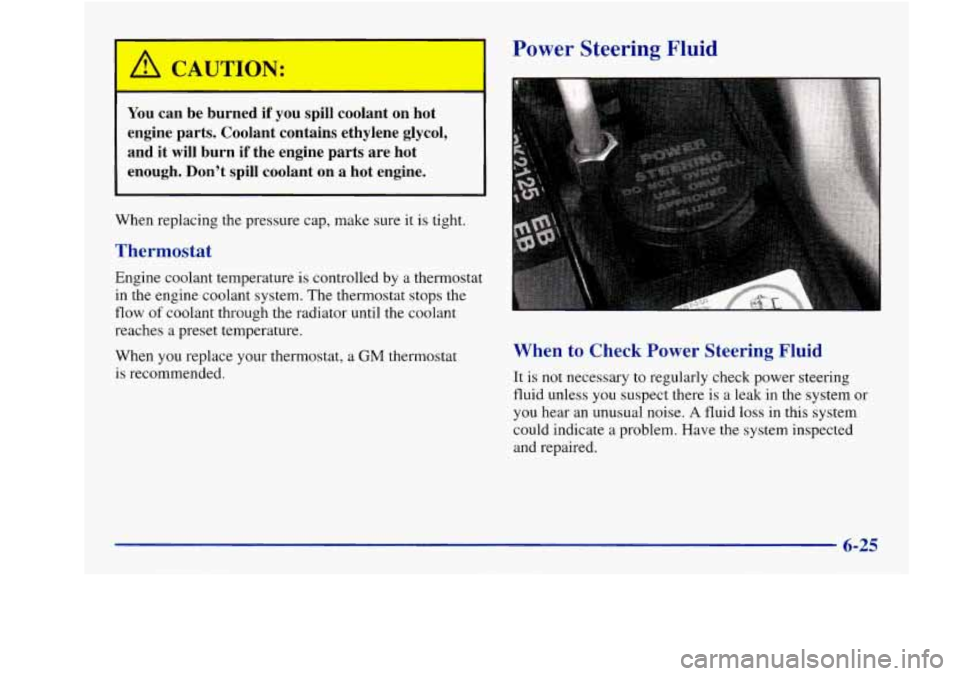

Power Steering Fluid

I I I

When replacing the pressure cap, make sure it is tight.

Thermostat

Engine coolant temperature is controlled by a thermostat

in the engine coolant system. The thermostat stops the

flow

of coolant through the radiator until the coolant

reaches a preset temperature.

When you replace your thermostat, a GM thermostat

is recommended.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering

fluid unless you suspect there is a leak

in the system or

you hear an unusual noise.

A fluid loss in this system

could indicate a problem. Have the system inspected

and repaired.

6-25

Page 339 of 380

I Maintenance Schedule I

100,000 Miles (166 000 km)

0 Inspect spark plug wires.

Replace spark plugs.

0 Change automatic transaxle fluid and bottom screens if the vehicle is mainly

An Emission Control Service.

An Emission Control Service.

driven under one or more of these conditions:

I DATE 1

I MILEAGE ACTUAL I SERVICEDBY I

- In heavy city traffic where the outside temperature regularly reaches

90°F (32°C) or higher.

- In hilly or mountainous terrain.

- When doing frequent trailer towing.

- Uses such as found in taxi, police or delivery service.

If you do not use your veh.icle under any of these conditions, th.e jluid and

filter do not require changing.

150,000 Miles (240 000 km)

17 Drain, flush and refill cooling system (or every 60 months since last service,

MILEAGE whichever occurs first). See “Engine Coolant” in the Index for what to use.

Inspect hoses. Clean radiator, condenser, pressure cap and neck. Pressure test

the cooling system and pressure cap.

An Emission Control Service.

7-13

Page 344 of 380

Part C: Periodic

Maintenance Inspections

Listed below are inspections and services which should

be performed at least twice a year (for instance, each

spring and fall). You should let your retailer’s service

department or other qualified service center do these

jobs. Make sure any necessary repairs are completed

at once.

Proper procedures to perform these services may be

found

in a service manual. See “Service and Owner

Publications” in the Index.

Steering, Suspension and Front Drive

Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the floor pan or could let

exhaust fumes into the vehicle. See “Engine Exhaust”

in the Index.

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they are

cracked, swollen or deteriorated. Inspect all pipes,

fittings and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of the

cooling system and pressure cap is recommended at

least once a year.

7-18