air suspension OLDSMOBILE SILHOUETTE 1994 Owners Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 1994, Model line: SILHOUETTE, Model: OLDSMOBILE SILHOUETTE 1994Pages: 276, PDF Size: 15.82 MB

Page 240 of 276

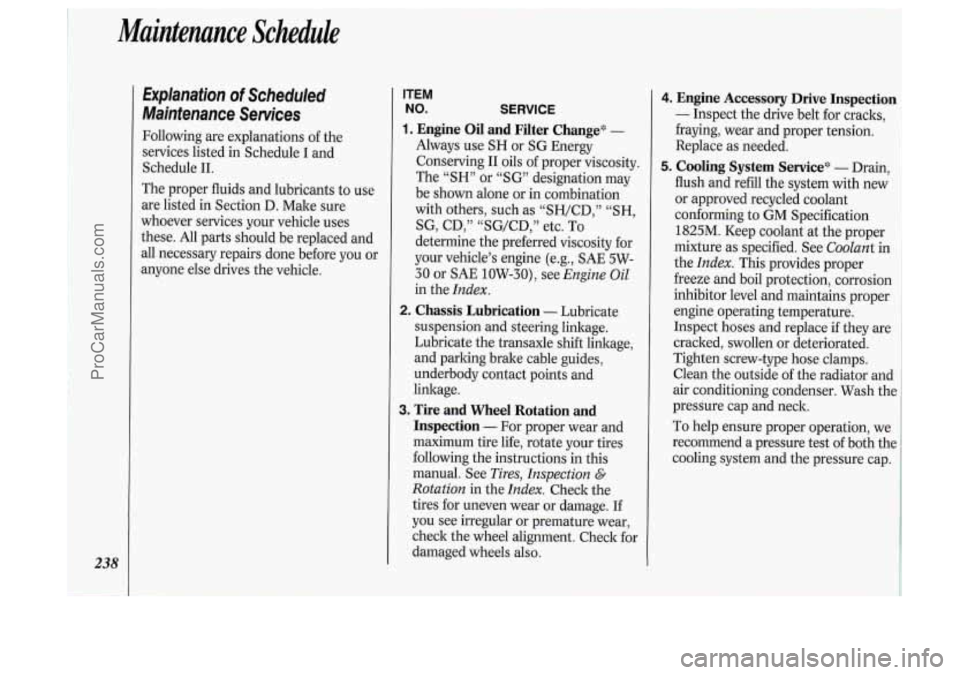

Maintenance Schedule

238

Explanation of Scheduled

Maintenance Services

Following are explanations of the

services listed in Schedule I and

Schedule 11.

The proper fluids and lubricants to use

are listed in Section D. Make sure

whoever services your vehicle uses

these. All parts should be replaced and

all necessary repairs done before you or

anyone else drives the vehicle.

ITEM

NO. SERVICE

1. Engine Oil and Filter Change* -

Always use SH or SG Energy

Conserving

I1 oils of proper viscosity.

The

“SH” or “SG” designation may

be shown alone

or in combination

with others, such as “SH/CD,”

“SH,

SG, CD,” “SG/CD,” etc. To

determine the preferred viscosity for

your vehicle’s engine (e.g.,

SAE 5W-

30 or SAE 10W-30), see

Engine Oil

in the Index.

2. Chassis Lubrication - Lubricate

suspension and steering linkage.

Lubricate the transaxle shift linkage,

and parking brake cable guides,

underbody contact points and

linkage.

3. Tire and Wheel Rotation and

Inspection

- For proper wear and

maximum tire life, rotate your tires

following the instructions in this

manual. See

Tires, Inspection E.

Rotation in the Index. Check the

tires for uneven wear

or damage. If

you see irregular or premature wear,

check the wheel alignment. Check for

damaged wheels also.

Engine Accessory Drive Inspection

- Inspect the drive belt for cracks,

fraying, wear and proper tension.

Replace as needed.

I

Cooling System Servicee - Drain,

flush and refill the system with new

or approved recycled coolant

conforming to GM Specification

I

1825M. Keep coolant at the proper 1

mixture as specified. See Coolant in

the

Index. This provides proper

freeze and boil protection, corrosion

I

inhibitor level and maintains proper ’

engine operating temperature.

Inspect hoses

and replace if they are

cracked, swollen or deteriorated.

Tighten screw-type hose clamps.

Clean the outside of the radiator and

air conditioning condenser. Wash tht

pressure cap and neck.

To help ensure proper operation, we

recommend

a pressure test of both the

cooling system and the pressure cap.

ProCarManuals.com

Page 245 of 276

Section C: Periodic Maintenance Inspections fall). You should let your GM dealer’s service department or

other qualified service center do these jobs. Make sure any

Listed below are inspections and services which should be necessary repairs are completed at once.

performed at least twice a year (for instance, each spring and

Restraint Systems

Steering, Suspension

and Front-Wheel-

Drive Axle Boot and

Seal Inspection

Exhaust System

Inspection

Throttle Linkage

Inspection

Brake System Inspection

~~ ~

WHAT SHOULD BE DONE

~ ~~~

Now and then, make sure all your belts, buckles, latch plates, retractors, anchorages and

reminder systems are working properly. Look for any loose parts or damage.

If you see anything

that might keep

a restraint system from doing its job, have it repaired.

Inspect the front and rear suspension

and steering system for damaged, loose or missing parts,

signs of wear, or lack of lubrication. Inspect the power steering lines and hoses for proper

hookup, binding, leaks, cracks, chafing, etc. Clean and then inspect the drive axle boot seals for

damage, tears or leakage. Replace seals if necessary.

Inspect the complete exhaust system. Inspect the body near the exhaust system. Look for broken,

damaged, missing or out-of-position parts as well

as open seams, holes, loose connections, or

other conditions which could cause a heat build-up in the floor pan or could let exhaust fumes

into the vehicle. See

Engine Exhaust in the Index.

Inspect the throttle linkage for interference or binding, and for damaged or missing parts.

Replace parts as needed.

Inspect the complete system. Inspect brake lines and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc. Inspect disc brake pads for wear and rotors for surface condition. Also inspect

drum brake linings for wear and cracks. Inspect other brake parts, including drums, wheel

cylinders, calipers, parking brake, etc. Check parking brake adjustment.

You may need to have

your brakes inspected more often

if your driving habits or conditions result in frequent braking.

NOTE:

A low brake fluid level can indicate worn disc brake pads which may need to be serviced.

Also, if the brake system warning light stays on or comes on, something may be wrong with the

brake system. See the

Index under Brake System Warning Light. If your anti-lock brake system

warning light stays on or comes on, something may be wrong with the anti-lock brake system.

See the

Index under Anti-Lock Brake System Wawing Light.

ProCarManuals.com