coolant Oldsmobile Silhouette 2004 s Owner's Guide

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 2004, Model line: Silhouette, Model: Oldsmobile Silhouette 2004Pages: 462, PDF Size: 3.1 MB

Page 336 of 462

6. Start the engine and let it run until you can feel the

upper radiator hose getting hot. Watch out for the

engine cooling fans.

7. By this time, the coolant level inside the radiator

®ller neck may be lower. If the level is lower, add

more of the proper DEX-COOL

žcoolant mixture

through the ®ller neck until the level reaches

the base of the ®ller neck.

5-34

Page 337 of 462

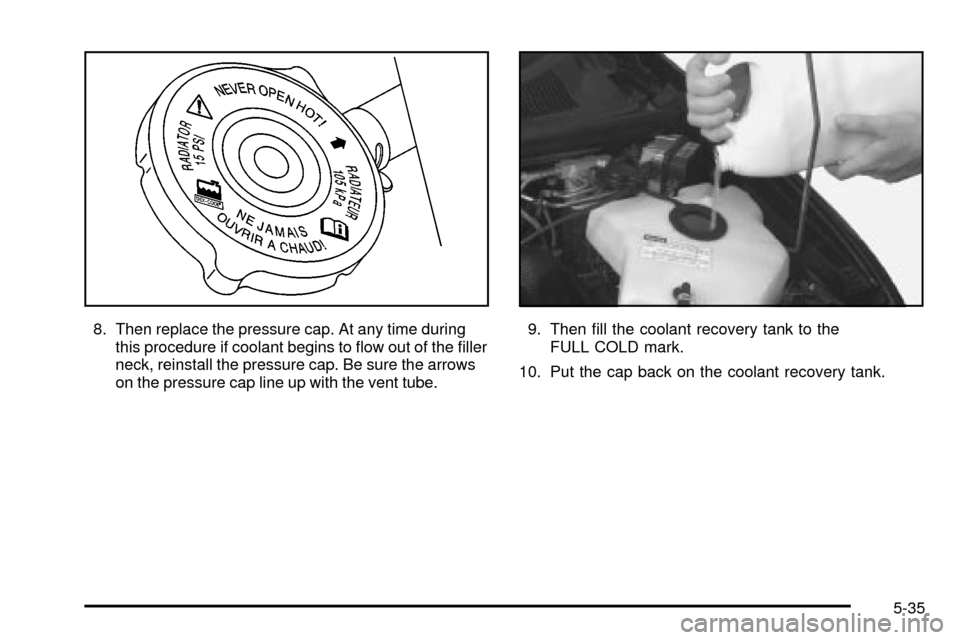

8. Then replace the pressure cap. At any time during

this procedure if coolant begins to ¯ow out of the ®ller

neck, reinstall the pressure cap. Be sure the arrows

on the pressure cap line up with the vent tube.9. Then ®ll the coolant recovery tank to the

FULL COLD mark.

10. Put the cap back on the coolant recovery tank.

5-35

Page 339 of 462

Windshield Washer Fluid

What Washer Fluid to Use

When you need windshield washer ¯uid, be sure to read

the manufacturer's instructions before use. If you will be

operating your vehicle in an area where the temperature

may fall below freezing, use a ¯uid that has sufficient

protection against freezing. See

Engine Compartment

Overview on page 5-12for reservoir location.

Adding Washer Fluid

Open the cap with the

washer symbol on it.

Add washer ¯uid until

the tank is full.

Notice:

·When using concentrated washer ¯uid,

follow the manufacturer's instructions for

adding water.

·Do not mix water with ready-to-use washer ¯uid.

Water can cause the solution to freeze and

damage your washer ¯uid tank and other parts

of the washer system. Also, water does not

clean as well as washer ¯uid.

·Fill your washer ¯uid tank only three-quarters

full when it is very cold. This allows for

expansion if freezing occurs, which could

damage the tank if it is completely full.

·Do not use engine coolant (antifreeze) in your

windshield washer. It can damage your washer

system and paint.

5-37

Page 367 of 462

Belt:A rubber coated layer of cords that is located

between the plies and the tread. Cords may be made

from steel or other reinforcing materials.

Bead:The tire bead contains steel wires wrapped by

steel cords that hold the tire onto the rim.

Bias Ply Tire:A pneumatic tire in which the plies are

laid at alternate angles less than 90 degrees to the

centerline of the tread.

Cold In¯ation Pressure:The amount of air pressure in

a tire, measured in pounds per square inch (psi) or

kilopascals (kPa) before a tire has built up heat

from driving. See

In¯ation - Tire Pressure on page 5-67.

Curb Weight:This means the weight of a motor

vehicle with standard and optional equipment including

the maximum capacity of fuel, oil and coolant, but

without passengers and cargo.

DOT Markings:A code molded into the sidewall of a

tire signifying that the tire is in compliance with the U.S.

Department of Transportation motor vehicle safety

standards. The DOT code includes the Tire Identi®cation

Number (TIN), an alphanumeric designator which can

also identify the tire manufacturer, production plant,

brand and date of production.GVWR:Gross Vehicle Weight Rating, see

Loading

Your Vehicle on page 4-33.

GAWR FRT:Gross Axle Weight Rating for the front

axle, see

Loading Your Vehicle on page 4-33.

GAWR RR:Gross Axle Weight Rating for the rear axle,

see

Loading Your Vehicle on page 4-33.

Intended Outboard Sidewall:The side of an

asymmetrical tire, that must always face outward when

mounted on a vehicle.

Kilopascal (kPa):The metric unit for air pressure.

There are 6.9 kPa's to one psi.

Light Truck (LT-Metric) Tire:A tire used on light duty

trucks and some multipurpose passenger vehicles.

Load Index:An assigned number ranging from 1 to 279

that corresponds to the load carrying capacity of a tire.

Maximum In¯ation Pressure:The maximum air

pressure to which a cold tire may be in¯ated. The

maximum air pressure is molded onto the sidewall.

Maximum Load Rating:The load rating for a tire at the

maximum permissible in¯ation pressure for that tire.

5-65

Page 407 of 462

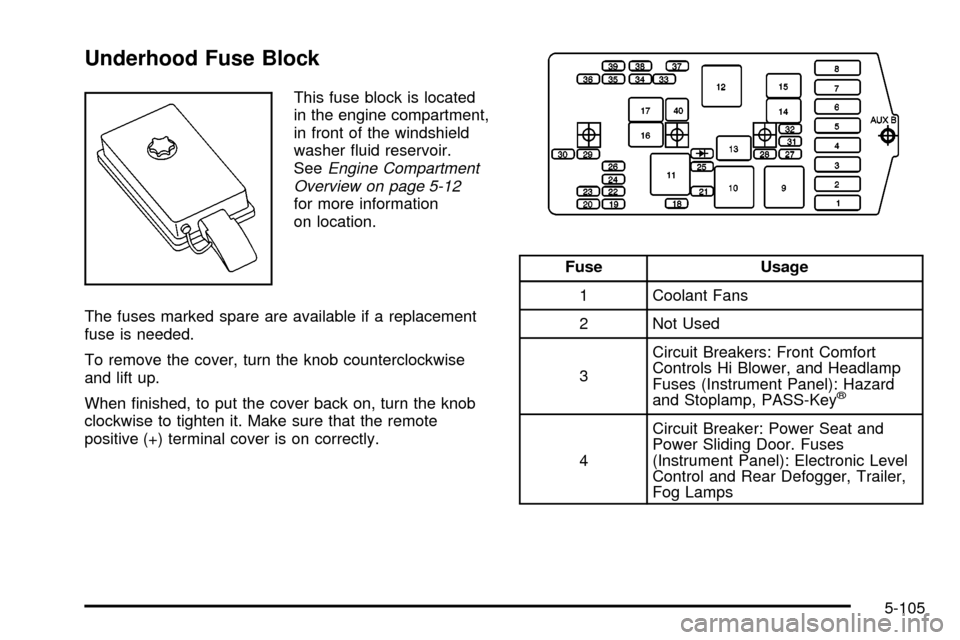

Underhood Fuse Block

This fuse block is located

in the engine compartment,

in front of the windshield

washer ¯uid reservoir.

See

Engine Compartment

Overview on page 5-12

for more information

on location.

The fuses marked spare are available if a replacement

fuse is needed.

To remove the cover, turn the knob counterclockwise

and lift up.

When ®nished, to put the cover back on, turn the knob

clockwise to tighten it. Make sure that the remote

positive (+) terminal cover is on correctly.

Fuse Usage

1 Coolant Fans

2 Not Used

3Circuit Breakers: Front Comfort

Controls Hi Blower, and Headlamp

Fuses (Instrument Panel): Hazard

and Stoplamp, PASS-Key

ž

4Circuit Breaker: Power Seat and

Power Sliding Door. Fuses

(Instrument Panel): Electronic Level

Control and Rear Defogger, Trailer,

Fog Lamps

5-105

Page 408 of 462

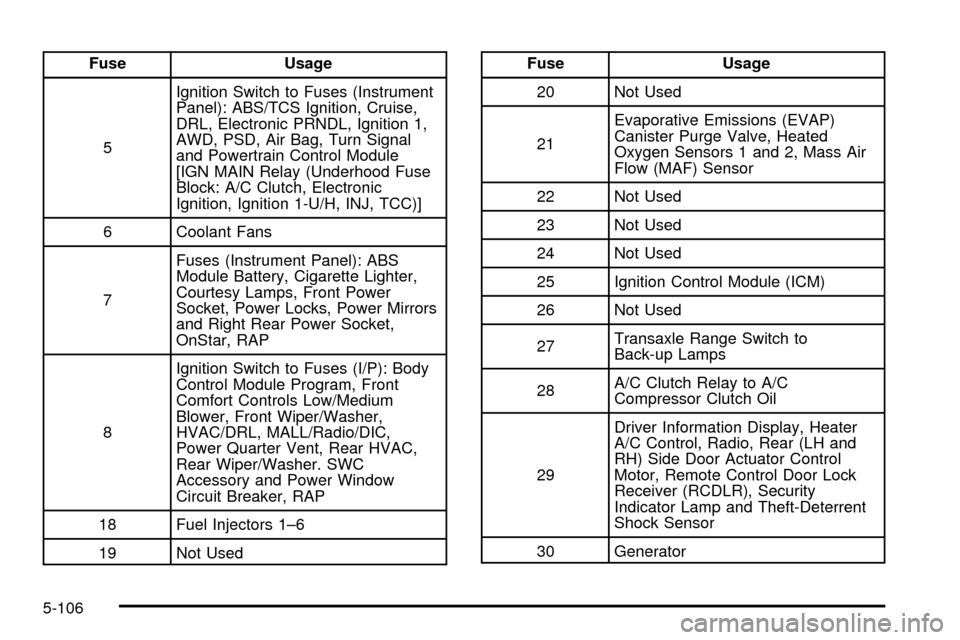

Fuse Usage

5Ignition Switch to Fuses (Instrument

Panel): ABS/TCS Ignition, Cruise,

DRL, Electronic PRNDL, Ignition 1,

AWD, PSD, Air Bag, Turn Signal

and Powertrain Control Module

[IGN MAIN Relay (Underhood Fuse

Block: A/C Clutch, Electronic

Ignition, Ignition 1-U/H, INJ, TCC)]

6 Coolant Fans

7Fuses (Instrument Panel): ABS

Module Battery, Cigarette Lighter,

Courtesy Lamps, Front Power

Socket, Power Locks, Power Mirrors

and Right Rear Power Socket,

OnStar, RAP

8Ignition Switch to Fuses (I/P): Body

Control Module Program, Front

Comfort Controls Low/Medium

Blower, Front Wiper/Washer,

HVAC/DRL, MALL/Radio/DIC,

Power Quarter Vent, Rear HVAC,

Rear Wiper/Washer. SWC

Accessory and Power Window

Circuit Breaker, RAP

18 Fuel Injectors 1±6

19 Not UsedFuse Usage

20 Not Used

21Evaporative Emissions (EVAP)

Canister Purge Valve, Heated

Oxygen Sensors 1 and 2, Mass Air

Flow (MAF) Sensor

22 Not Used

23 Not Used

24 Not Used

25 Ignition Control Module (ICM)

26 Not Used

27Transaxle Range Switch to

Back-up Lamps

28A/C Clutch Relay to A/C

Compressor Clutch Oil

29Driver Information Display, Heater

A/C Control, Radio, Rear (LH and

RH) Side Door Actuator Control

Motor, Remote Control Door Lock

Receiver (RCDLR), Security

Indicator Lamp and Theft-Deterrent

Shock Sensor

30 Generator

5-106

Page 417 of 462

Scheduled Maintenance

Service MaintenanceIMaintenanceII

Change engine oil and ®lter. Reset oil life system. See

Engine Oil on

page 5-13.An Emission Control Service.··

Lubricate chassis components.

See footnote #.··

Visually check for any leaks or damage.

See footnote (k).··

Inspect engine air cleaner ®lter. If necessary, replace ®lter. See

Engine Air

Cleaner/Filter on page 5-18.An Emission Control Service. See footnote ².··

Rotate tires and check in¯ation pressures and wear. See

Tires on page 5-58.··

Inspect brake system.

See footnote (a).··

Check engine coolant and windshield washer ¯uid levels and add ¯uid

as needed.··

Perform any needed additional services. See ªAdditional Required Servicesº

in this section.··

Inspect suspension and steering components.

See footnote (b).·

Inspect engine cooling system.

See footnote (c).·

Inspect wiper blades.

See footnote (d).·

Inspect restraint system components.

See footnote (e).·

Lubricate body components.

See footnote (f).·

Check transaxle ¯uid level and add ¯uid as needed.·

Replace passenger compartment air ®lter.

See footnote (g).·

Inspect throttle system.

See footnote (j).·

6-5

Page 420 of 462

(c)Visually inspect hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace with genuine GM parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken air bag

coverings, and have them repaired or replaced. (The air

bag system does not need regular maintenance.)

(f)Lubricate all key lock cylinders, hood latch

assemblies, secondary latches, pivots, spring anchor

and release pawl, hood and door hinges, rear folding

seats, liftgate hinges, fuel door hinge, power sliding door

cable and sliding door track(s). More frequent lubrication

may be required when exposed to a corrosive

environment. Applying silicone grease on weatherstrips

with a clean cloth will make them last longer, seal

better and not stick or squeak.

(g)If you drive regularly under dusty conditions, the

®lter may require replacement more often.

(h)Change automatic transaxle ¯uid and ®lter if the

vehicle is mainly driven under one or more of these

conditions:

þIn heavy city traffic where the outside temperature

regularly reaches 90ÉF (32ÉC) or higher.

þIn hilly or mountainous terrain.

þWhen doing frequent trailer towing.

þUses such as found in taxi, police or delivery

service.

(i)Drain, ¯ush and re®ll cooling system. See Engine

Coolant on page 5-22for what to use. Inspect hoses.

Clean radiator, condenser, pressure cap and ®ller neck.

Pressure test the cooling system and pressure cap.

(j)

Check system for interference or binding and

for damaged or missing parts. Replace parts as needed.

Replace any components that have high effort or

excessive wear. Do not lubricate accelerator or cruise

control cables.

(k)A ¯uid loss in any vehicle system could indicate a

problem. Have the system inspected and repaired

and the ¯uid level checked. Add ¯uid if needed.

6-8

Page 421 of 462

Owner Checks and Services

These owner checks and services should be performed

at the intervals speci®ed to help ensure the safety,

dependability and emission control performance of your

vehicle. Your GM Goodwrench dealer can assist you

with these checks and services.

Be sure any necessary repairs are completed at once.

Whenever any ¯uids or lubricants are added to your

vehicle, make sure they are the proper ones, as shown

in

Recommended Fluids and Lubricants on page 6-12.

At Each Fuel Fill

It is important to perform these underhood checks at

each fuel ®ll.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil on page 5-13for further

details.

Notice:It is important to check your oil regularly

and keep it at the proper level. Failure to keep your

engine oil at the proper level can cause damage

to your engine not covered by your warranty.

Engine Coolant Level Check

Check the engine coolant level and add

DEX-COOLžcoolant mixture if necessary.

SeeEngine Coolant on page 5-22for further details.

Windshield Washer Fluid Level Check

Check the windshield washer ¯uid level in the windshield

washer tank and add the proper ¯uid if necessary.

At Least Once a Month

Tire In¯ation Check

Visually inspect your tires and make sure tires are

in¯ated to the correct pressures. Do not forget to check

your spare tire. See

Tires on page 5-58for further

details. Check to make sure the spare tire is stored

securely. Push, pull and then try to rotate or turn

the spare tire. If it moves, tighten it. See

Changing a

Flat Tire on page 5-76.

6-9

Page 424 of 462

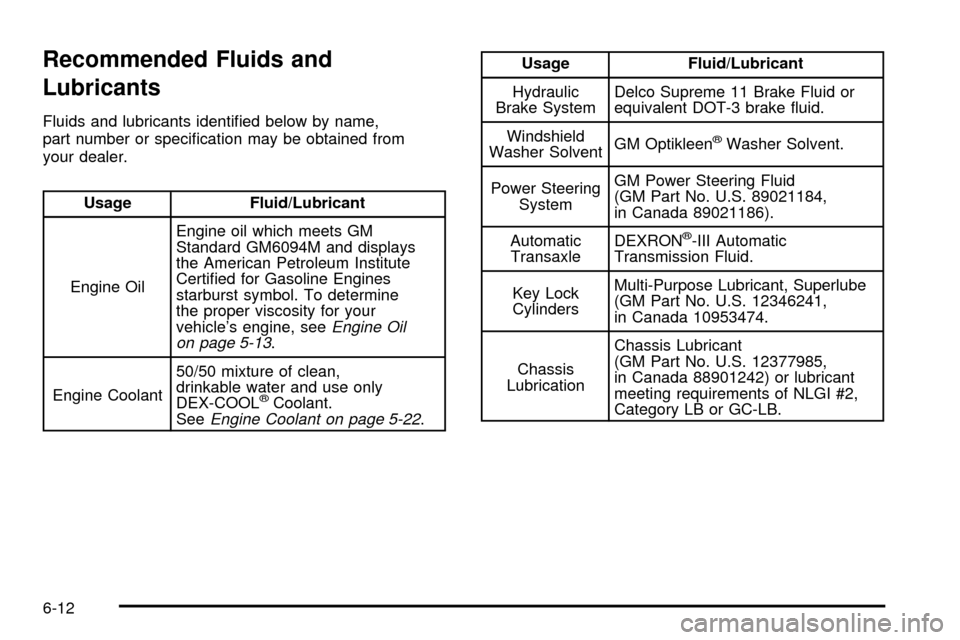

Recommended Fluids and

Lubricants

Fluids and lubricants identi®ed below by name,

part number or speci®cation may be obtained from

your dealer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets GM

Standard GM6094M and displays

the American Petroleum Institute

Certi®ed for Gasoline Engines

starburst symbol. To determine

the proper viscosity for your

vehicle's engine, see

Engine Oil

on page 5-13.

Engine Coolant50/50 mixture of clean,

drinkable water and use only

DEX-COOL

žCoolant.

SeeEngine Coolant on page 5-22.

Usage Fluid/Lubricant

Hydraulic

Brake SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake ¯uid.

Windshield

Washer SolventGM Optikleen

žWasher Solvent.

Power Steering

SystemGM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

TransaxleDEXRON

ž-III Automatic

Transmission Fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474.

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

6-12