Transmission OPEL 1900 1973 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 444 of 625

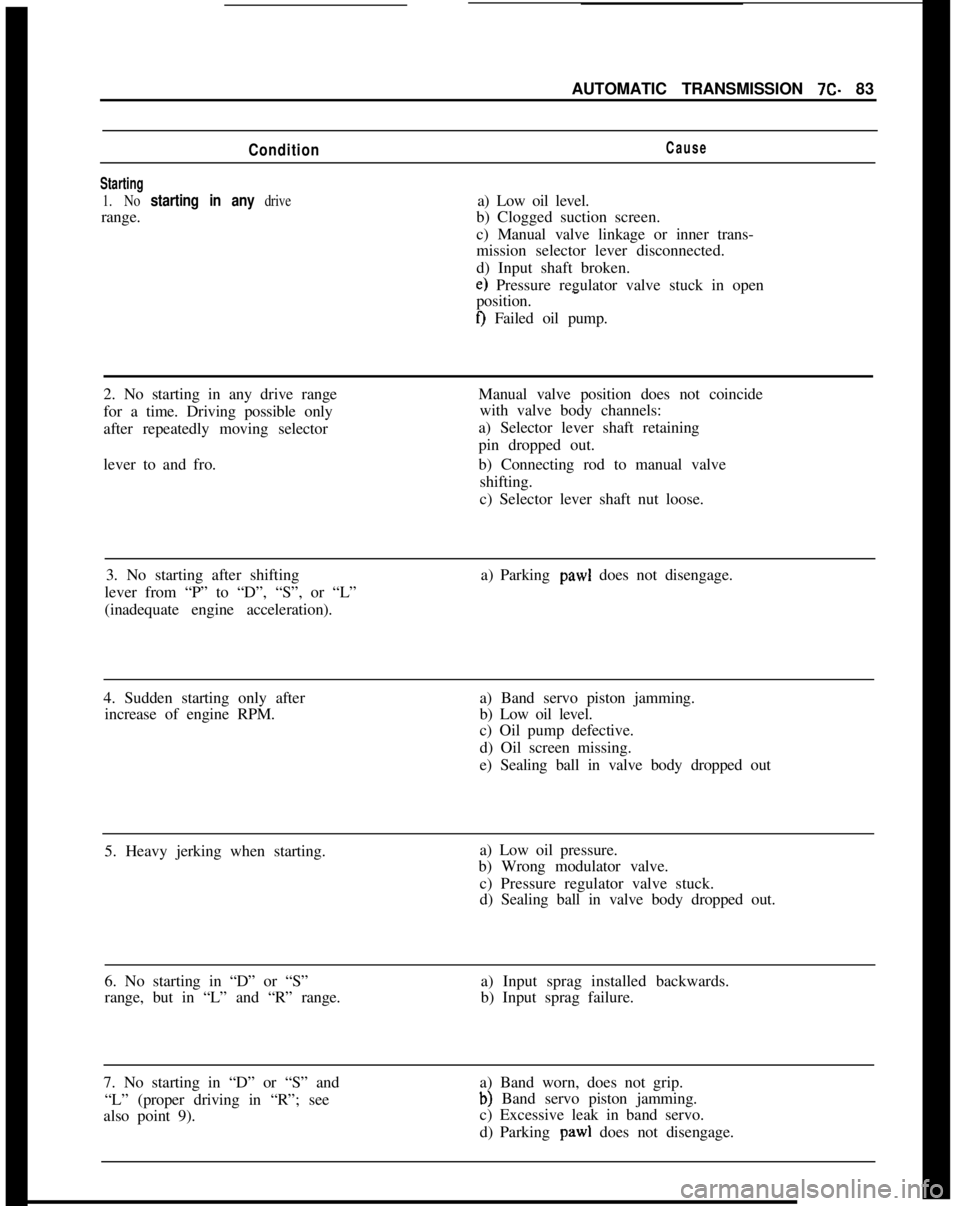

AUTOMATIC TRANSMISSION 7C- 83

ConditionCause

Starting

1. No starting in any driverange.a) Low oil level.

b) Clogged suction screen.

c) Manual valve linkage or inner trans-

mission selector lever disconnected.

d) Input shaft broken.e) Pressure regulator valve stuck in open

position. -0 Failed oil pump.

2. No starting in any drive range

for a time. Driving possible only

after repeatedly moving selector

lever to and fro.Manual valve position does not coincide

with valve body channels:

a) Selector lever shaft retaining

pin dropped out.

b) Connecting rod to manual valve

shifting.

c) Selector lever shaft nut loose.

3. No starting after shifting

lever from “P” to “D”, “S”, or “L”

(inadequate engine acceleration).a) Parking

paw1 does not disengage.

4. Sudden starting only after

increase of engine RPM.a) Band servo piston jamming.

b) Low oil level.

c) Oil pump defective.

d) Oil screen missing.

e) Sealing ball in valve body dropped out

5. Heavy jerking when starting.a) Low oil pressure.

b) Wrong modulator valve.

c) Pressure regulator valve stuck.

d) Sealing ball in valve body dropped out.

6. No starting in “D” or “S”

range, but in “L” and “R” range.a) Input sprag installed backwards.

b) Input sprag failure.

7. No starting in “D” or “S” and

“L” (proper driving in “R”; see

also point 9).a) Band worn, does not grip.

b) Band servo piston jamming.

c) Excessive leak in band servo.

d) Parking

paw1 does not disengage.

Page 445 of 625

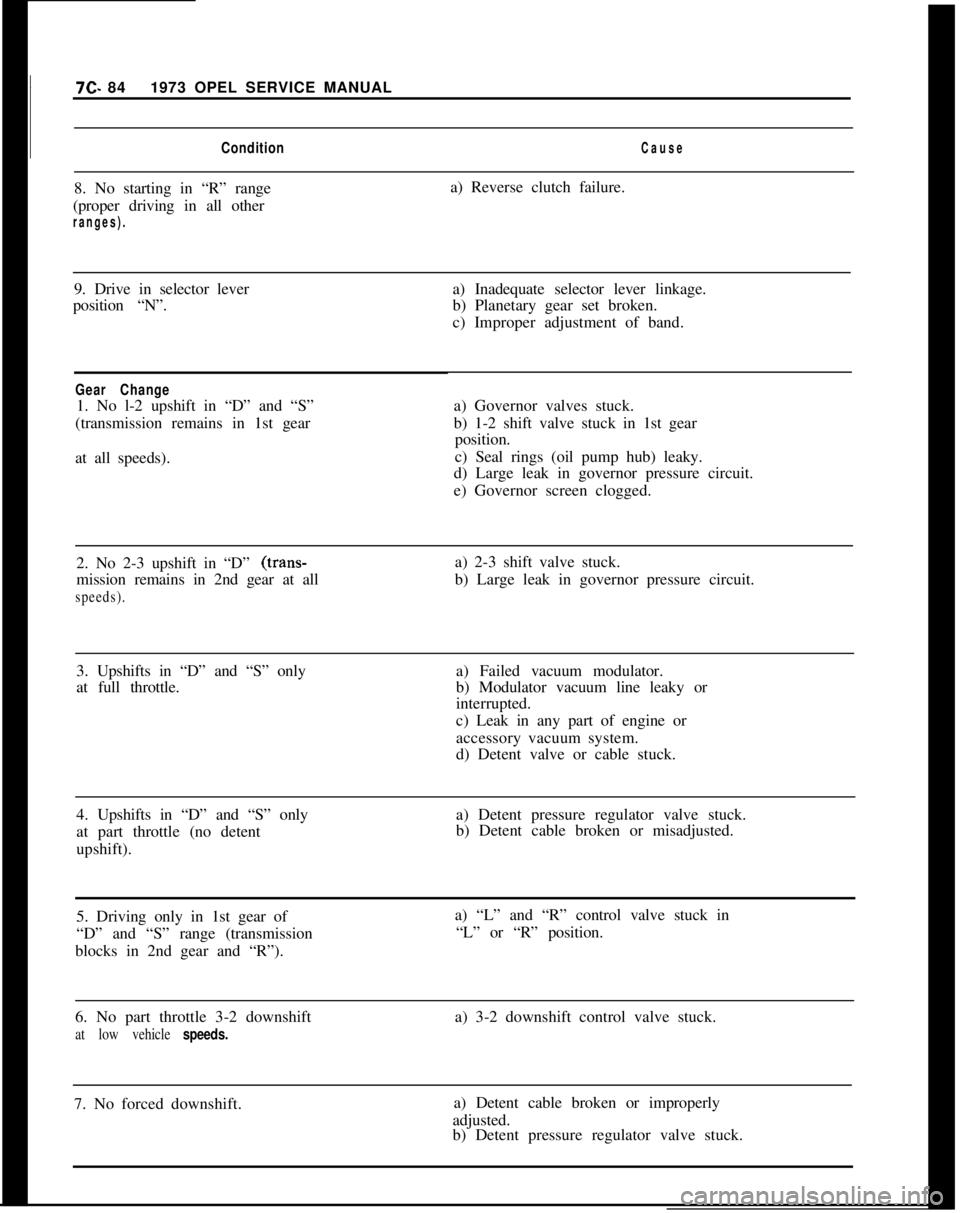

7C. 841973 OPEL SERVICE MANUALConditionCause8. No starting in “R” range

(proper driving in all other

ranges).a) Reverse clutch failure.

9. Drive in selector lever

position “N”.a) Inadequate selector lever linkage.

b) Planetary gear set broken.

c) Improper adjustment of band.

Gear Change1. No l-2 upshift in “D” and “S”

(transmission remains in 1st gear

at all speeds).a) Governor valves stuck.

b) 1-2 shift valve stuck in 1st gear

position.

c) Seal rings (oil pump hub) leaky.

d) Large leak in governor pressure circuit.

e) Governor screen clogged.

2. No 2-3 upshift in “D” (trans-

mission remains in 2nd gear at all

speeds).a) 2-3 shift valve stuck.

b) Large leak in governor pressure circuit.

3. Upshifts in “D” and “S” only

at full throttle.a) Failed vacuum modulator.

b) Modulator vacuum line leaky or

interrupted.

c) Leak in any part of engine or

accessory vacuum system.

d) Detent valve or cable stuck.

4. Upshifts in “D” and “S” only

at part throttle (no detent

upshift).a) Detent pressure regulator valve stuck.

b) Detent cable broken or misadjusted.

5. Driving only in 1st gear of

“D” and “S” range (transmission

blocks in 2nd gear and “R”).a) “L” and “R” control valve stuck in

“L” or “R” position.

6. No part throttle 3-2 downshift

at low vehicle speeds.a) 3-2 downshift control valve stuck.

7. No forced downshift.a) Detent cable broken or improperly

adjusted.

b) Detent pressure regulator valve stuck.

Page 446 of 625

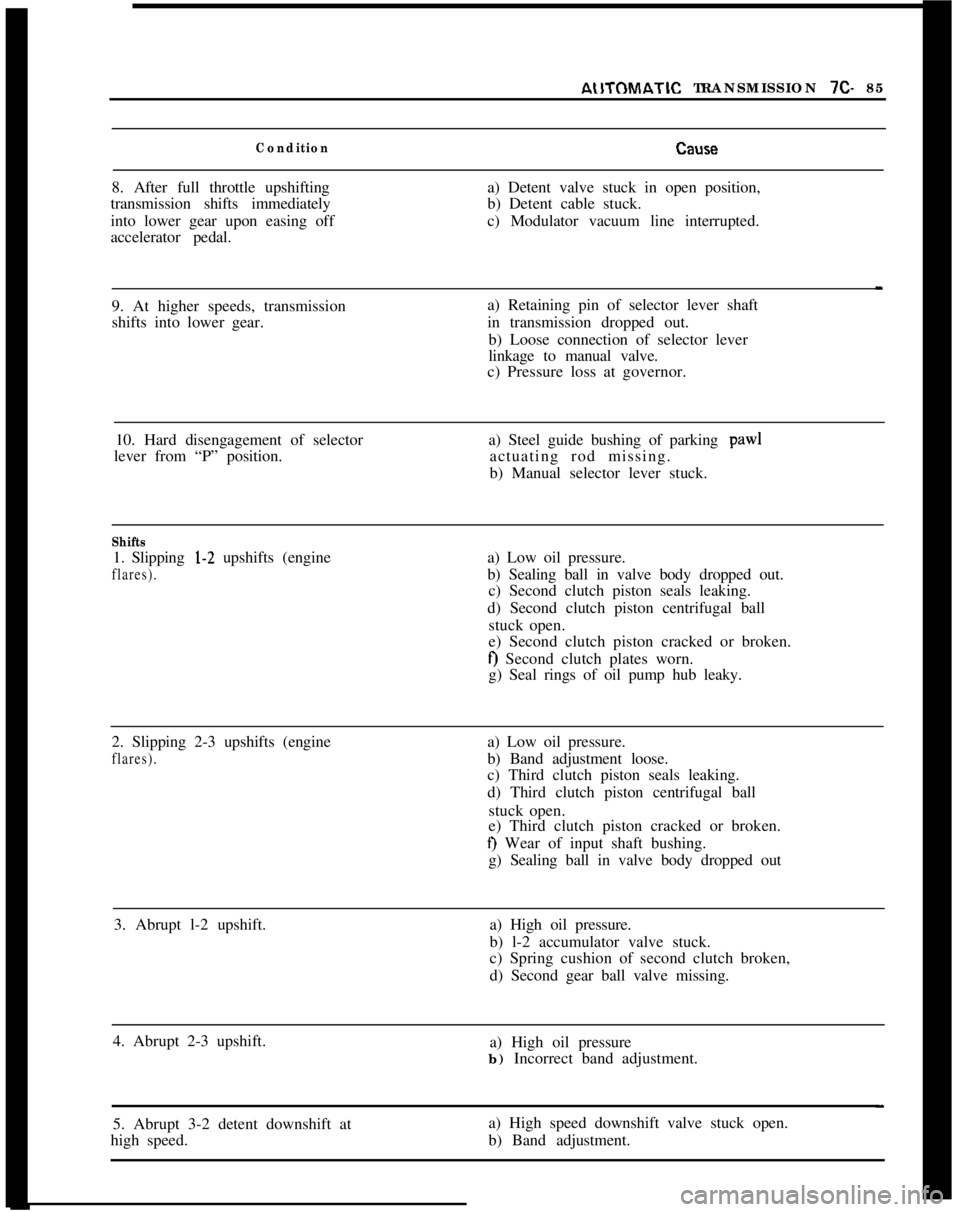

AlITOMATIC TRANSMISSION 7C- 85

ConditionCtSlSl?8. After full throttle upshifting

transmission shifts immediately

into lower gear upon easing off

accelerator pedal.a) Detent valve stuck in open position,

b) Detent cable stuck.

c) Modulator vacuum line interrupted.

9. At higher speeds, transmission

shifts into lower gear.a) Retaining pin of selector lever shaft

in transmission dropped out.

b) Loose connection of selector lever

linkage to manual valve.

c) Pressure loss at governor.

10. Hard disengagement of selector

lever from “P” position.a) Steel guide bushing of parking

paw1actuating rod missing.

b) Manual selector lever stuck.

Shifts1. Slipping l-2 upshifts (engine

flares).a) Low oil pressure.

b) Sealing ball in valve body dropped out.

c) Second clutch piston seals leaking.

d) Second clutch piston centrifugal ball

stuck open.

e) Second clutch piston cracked or broken.

f) Second clutch plates worn.

g) Seal rings of oil pump hub leaky.

2. Slipping 2-3 upshifts (engine

flares).a) Low oil pressure.

b) Band adjustment loose.

c) Third clutch piston seals leaking.

d) Third clutch piston centrifugal ball

stuck open.

e) Third clutch piston cracked or broken.

f) Wear of input shaft bushing.

g) Sealing ball in valve body dropped out

3. Abrupt l-2 upshift.a) High oil pressure.

b) l-2 accumulator valve stuck.

c) Spring cushion of second clutch broken,

d) Second gear ball valve missing.

4. Abrupt 2-3 upshift.

a) High oil pressure

b) Incorrect band adjustment.

5. Abrupt 3-2 detent downshift at

high speed.a) High speed downshift valve stuck open.

b) Band adjustment.

Page 447 of 625

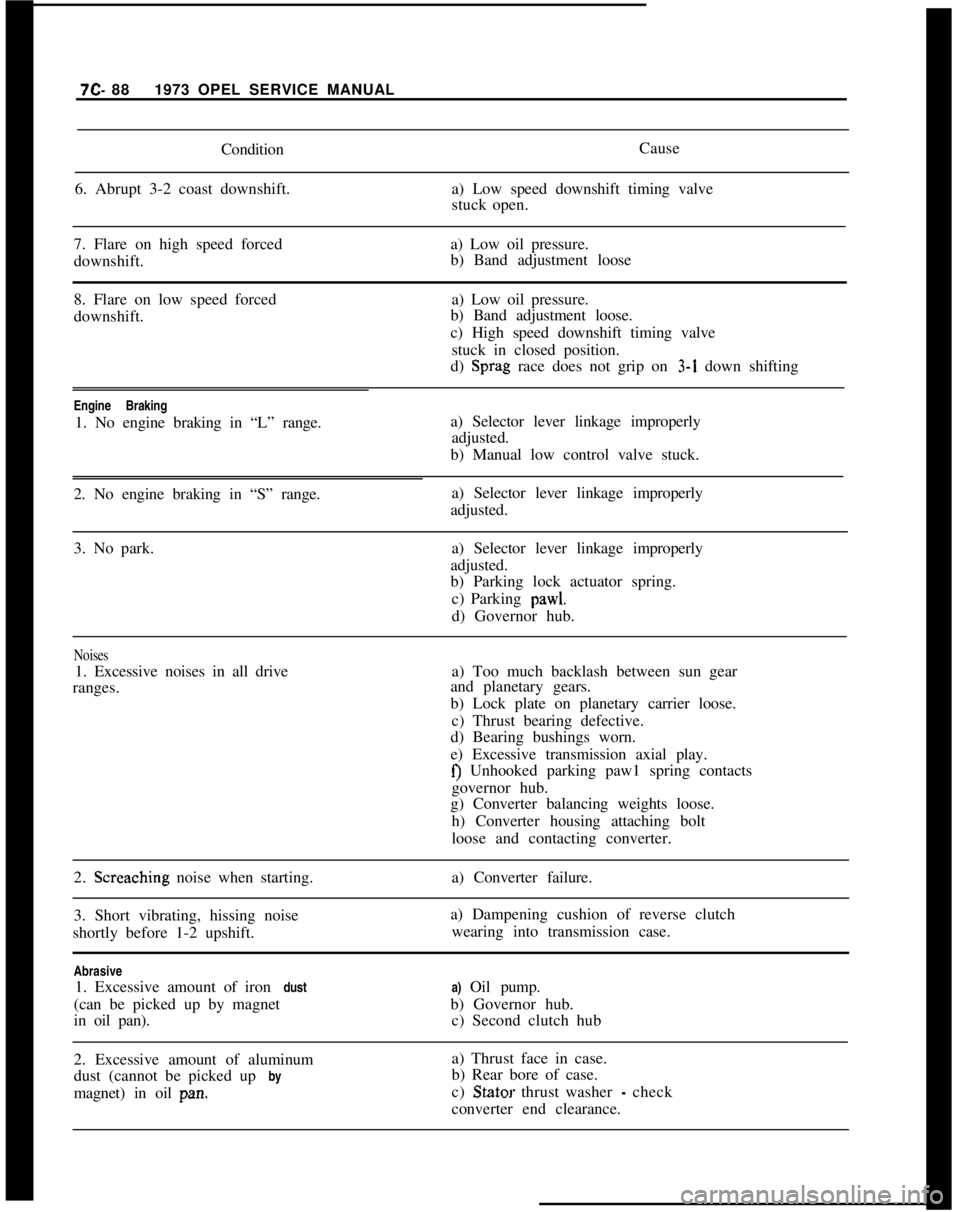

7C- 881973 OPEL SERVICE MANUAL

Condition

6. Abrupt 3-2 coast downshift.Cause

a) Low speed downshift timing valve

stuck open.

7. Flare on high speed forceda) Low oil pressure.

downshift.b) Band adjustment loose

8. Flare on low speed forced

downshift.a) Low oil pressure.

b) Band adjustment loose.

c) High speed downshift timing valve

stuck in closed position.

d) Sprag race does not grip on 3-1 down shifting

Engine Braking

1. No engine braking in “L” range.a) Selector lever linkage improperly

adjusted.

b) Manual low control valve stuck.

2. No engine braking in “S” range.a) Selector lever linkage improperly

adjusted.

3. No park.a) Selector lever linkage improperly

adjusted.

b) Parking lock actuator spring.

c) Parking pawl.

d) Governor hub.

Noises1. Excessive noises in all drive

ranges.a) Too much backlash between sun gear

and planetary gears.

b) Lock plate on planetary carrier loose.

c) Thrust bearing defective.

d) Bearing bushings worn.

e) Excessive transmission axial play.

f) Unhooked parking paw1 spring contacts

governor hub.

g) Converter balancing weights loose.

h) Converter housing attaching bolt

loose and contacting converter.

2. Screaching noise when starting.

3. Short vibrating, hissing noise

shortly before 1-2 upshift.a) Converter failure.

a) Dampening cushion of reverse clutch

wearing into transmission case.

Abrasive

1. Excessive amount of iron dust

(can be picked up by magnet

in oil pan).a) Oil pump.

b) Governor hub.

c) Second clutch hub

2. Excessive amount of aluminum

dust (cannot be picked up by

magnet) in oil pan.a) Thrust face in case.

b) Rear bore of case.

c) Stator thrust washer

- check

converter end clearance.

Page 448 of 625

AUTOMATIC TRANSMISSION 7C- 87

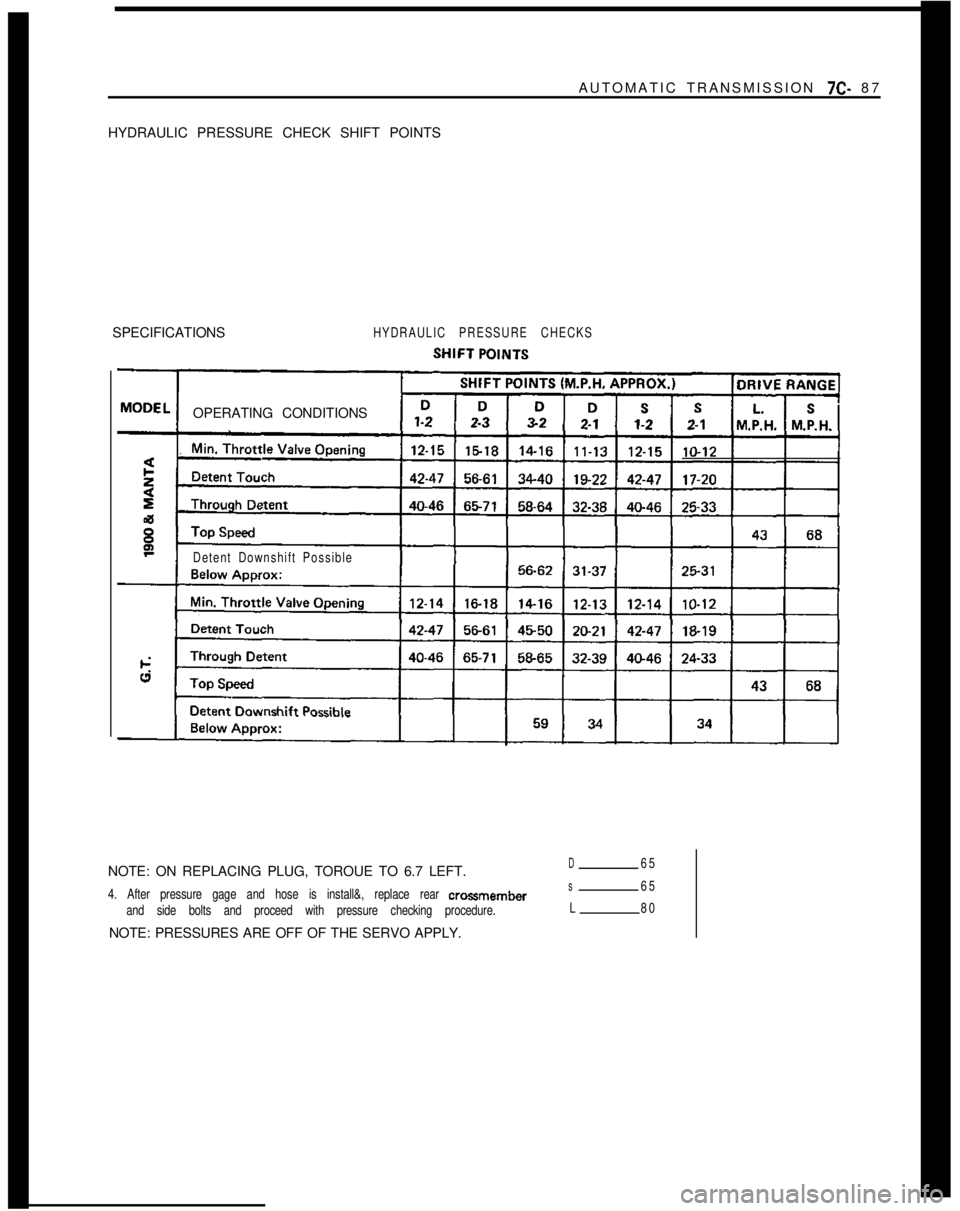

HYDRAULIC PRESSURE CHECK SHIFT POINTS

SPECIFICATIONSHYDRAULIC PRESSURE CHECKSNOTE: ON REPLACING PLUG, TOROUE TO 6.7 LEFT.

D65

4. After pressure gage and hose is install&, replace rear

crossmembers65

and side bolts and proceed with pressure checking procedure.L80NOTE: PRESSURES ARE OFF OF THE SERVO APPLY.OPERATING CONDITIONS

Detent Downshift Possible

Page 450 of 625

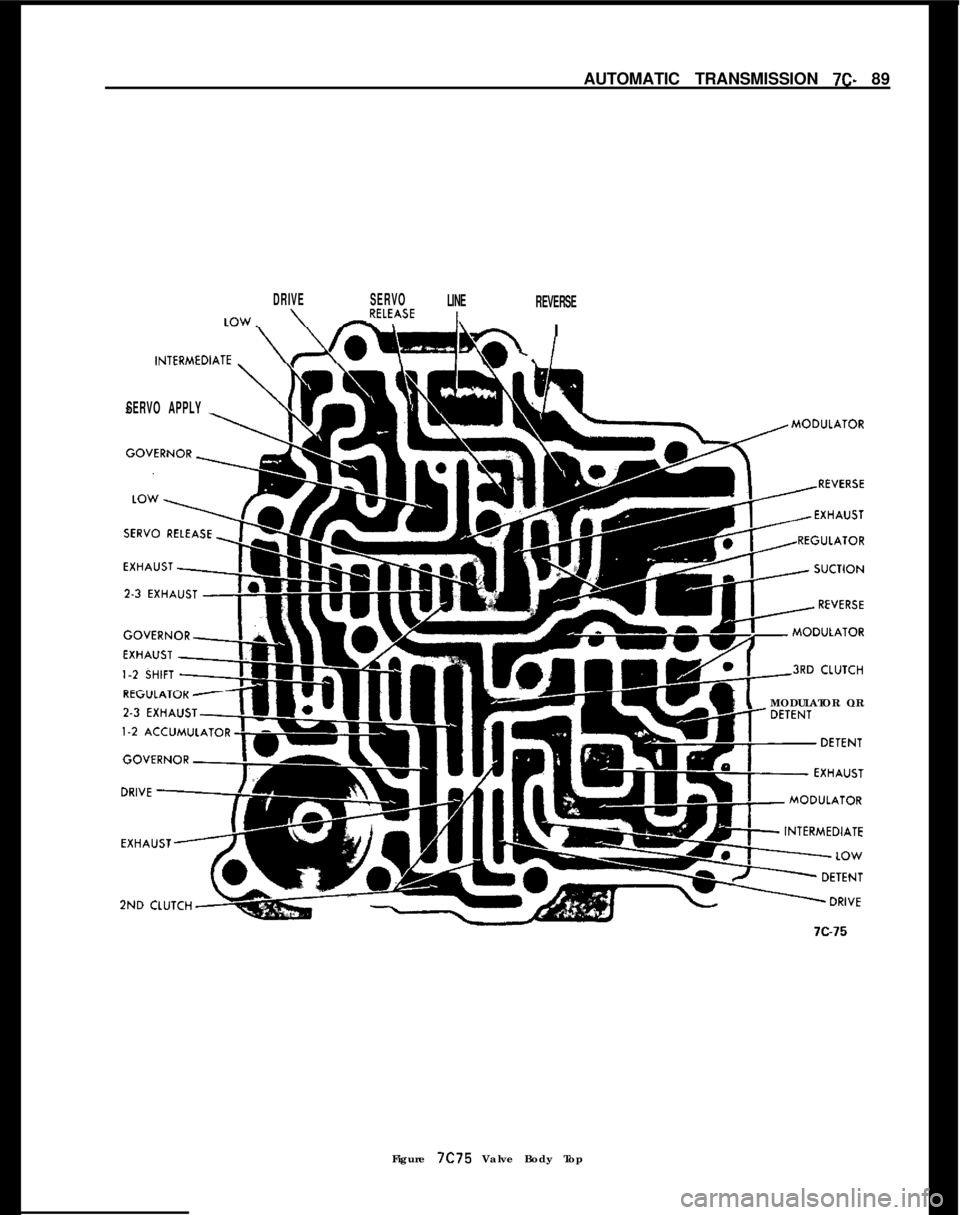

AUTOMATIC TRANSMISSION 7C- 89

DRIVESERVO

LINE

REVERSEI

,NTERMEDlATE\T

SERVO APPLYMODULATOR OR

Figure 7C75 Valve Body Top

Page 452 of 625

AUTOMATIC TRANSMISSION 7C- 91

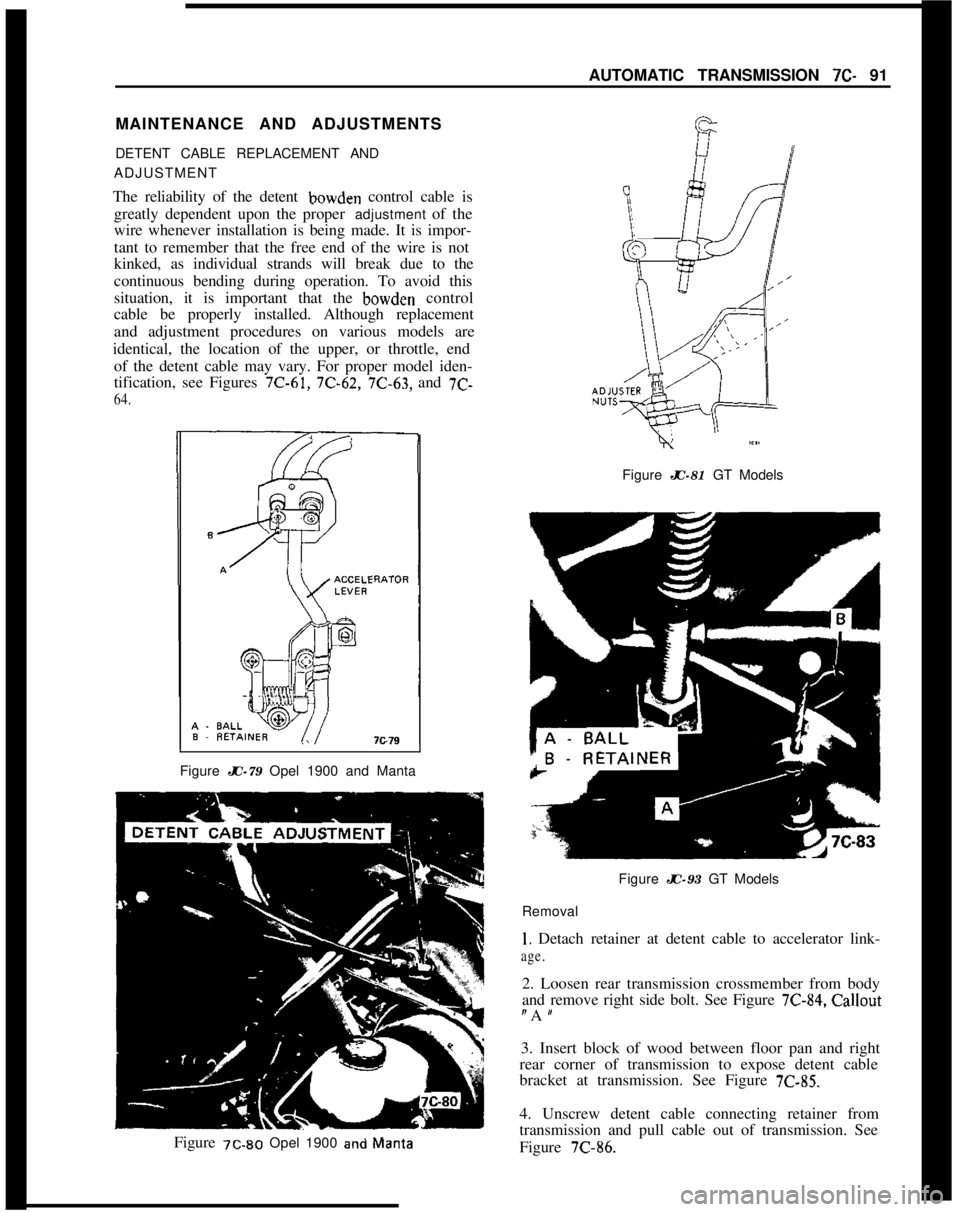

MAINTENANCE AND ADJUSTMENTS

DETENT CABLE REPLACEMENT AND

ADJUSTMENT

The reliability of the detent bowden control cable is

greatly dependent upon the proper adjustment of the

wire whenever installation is being made. It is impor-

tant to remember that the free end of the wire is not

kinked, as individual strands will break due to the

continuous bending during operation. To avoid this

situation, it is important that the bowden control

cable be properly installed. Although replacement

and adjustment procedures on various models are

identical, the location of the upper, or throttle, end

of the detent cable may vary. For proper model iden-

tification, see Figures

7C-61, 7C-62, 7C-63, and 7C-

64.Figure JC-79 Opel 1900 and Manta

Figure

7~80 Opel 1900 and MantaFigure JC-81 GT Models

Figure JC-93 GT Models

Removal

I. Detach retainer at detent cable to accelerator link-

age.2. Loosen rear transmission crossmember from body

and remove right side bolt. See Figure

7C-84, Callout

” A ”3. Insert block of wood between floor pan and right

rear corner of transmission to expose detent cable

bracket at transmission. See Figure

7C-85.4. Unscrew detent cable connecting retainer from

transmission and pull cable out of transmission. See

Figure

7C-86.

Page 454 of 625

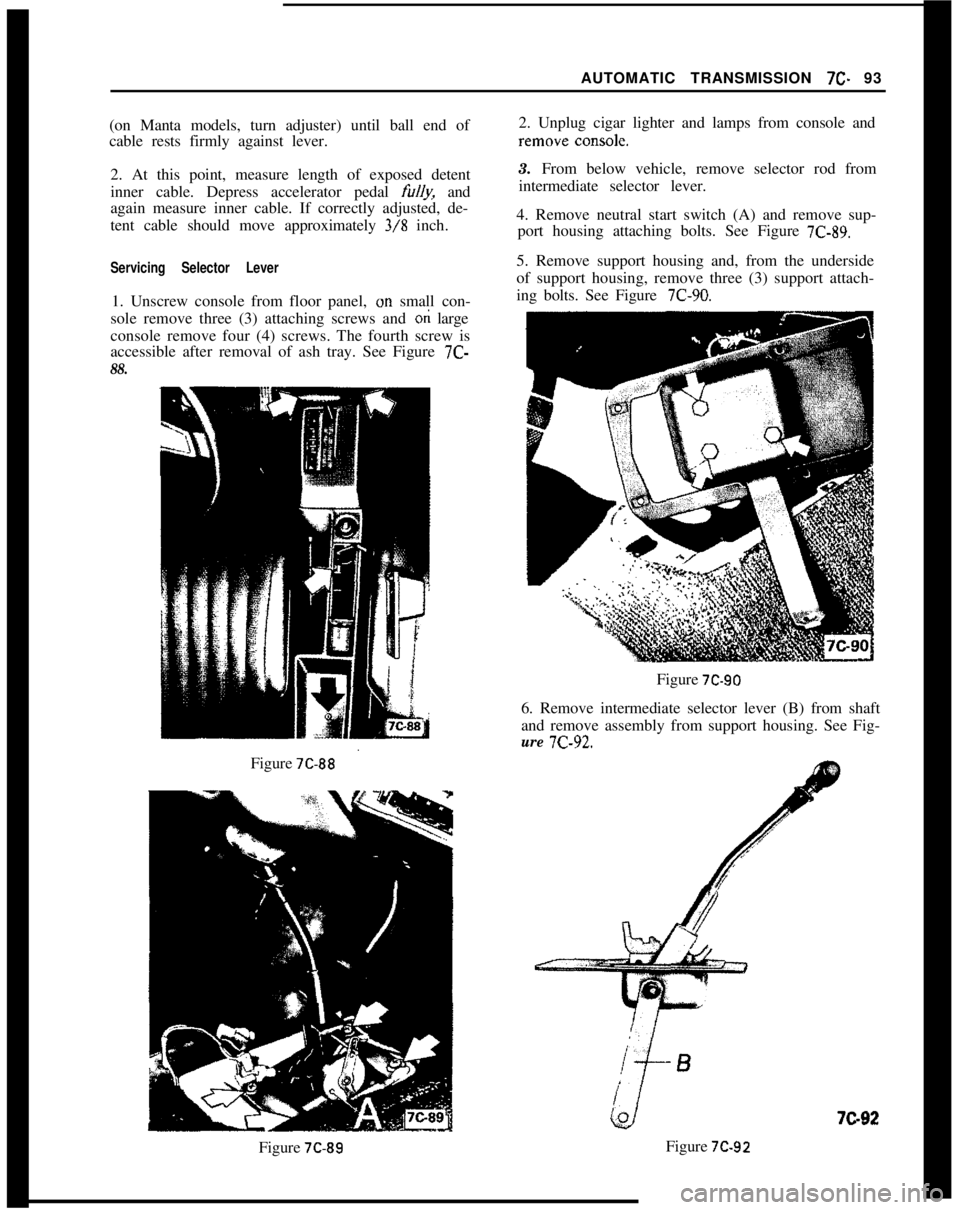

AUTOMATIC TRANSMISSION 7C- 93

(on Manta models, turn adjuster) until ball end of

cable rests firmly against lever.

2. At this point, measure length of exposed detent

inner cable. Depress accelerator pedal fu/fy, and

again measure inner cable. If correctly adjusted, de-

tent cable should move approximately 3/S inch.

Servicing Selector Lever1. Unscrew console from floor panel, on small con-

sole remove three (3) attaching screws and

on large

console remove four (4) screws. The fourth screw is

accessible after removal of ash tray. See Figure 7C-

88.Figure

7C-88Figure

7C-892. Unplug cigar lighter and lamps from console and

remO”e co”sole.

3. From below vehicle, remove selector rod from

intermediate selector lever.

4. Remove neutral start switch (A) and remove sup-

port housing attaching bolts. See Figure

7C-89.5. Remove support housing and, from the underside

of support housing, remove three (3) support attach-

ing bolts. See Figure

7C-90.Figure

7C-906. Remove intermediate selector lever (B) from shaft

and remove assembly from support housing. See Fig-

ure 7C-92.7GB2

Figure

7C.92

Page 455 of 625

7C. 941973 OPEL SERVICE MANUAL

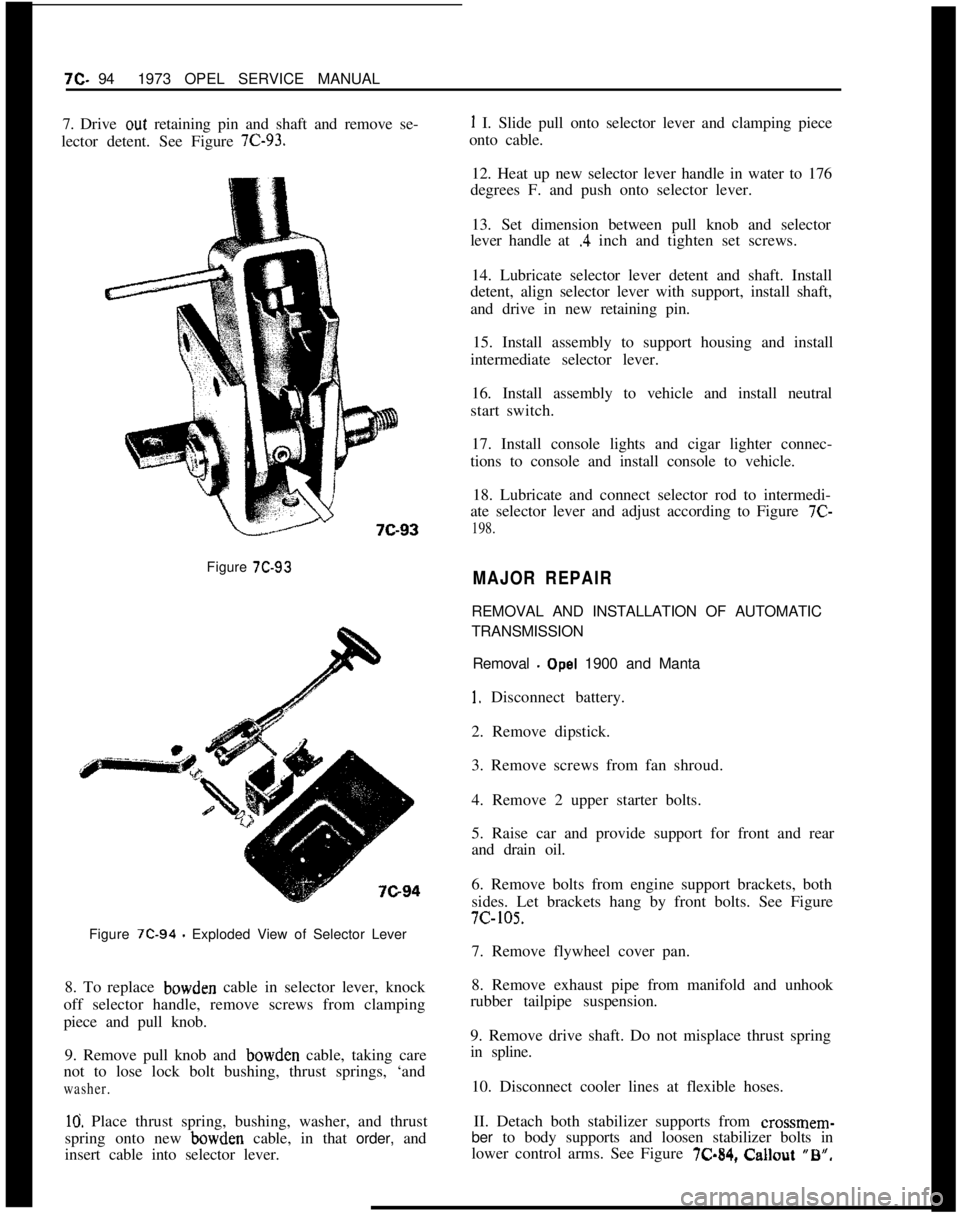

7. Drive out retaining pin and shaft and remove se-

lector detent. See Figure 7C-93.Figure

7C-93Figure

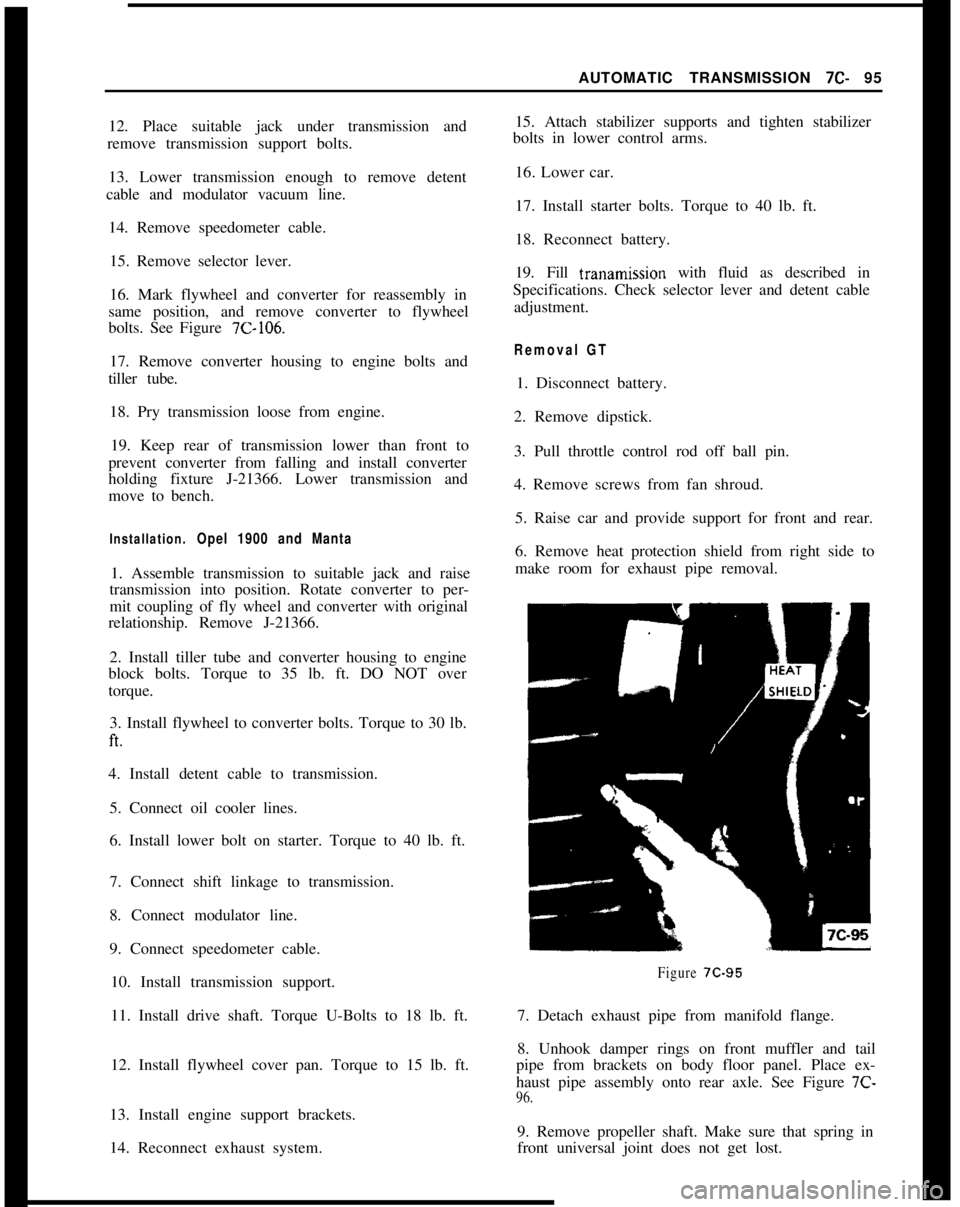

7C-94 - Exploded View of Selector Lever

8. To replace bowden cable in selector lever, knock

off selector handle, remove screws from clamping

piece and pull knob.

9. Remove pull knob and bowden cable, taking care

not to lose lock bolt bushing, thrust springs, ‘and

washer.

10. Place thrust spring, bushing, washer, and thrust

spring onto new bowden cable, in that order, and

insert cable into selector lever.

1 I. Slide pull onto selector lever and clamping piece

onto cable.

12. Heat up new selector lever handle in water to 176

degrees F. and push onto selector lever.

13. Set dimension between pull knob and selector

lever handle at

.4 inch and tighten set screws.

14. Lubricate selector lever detent and shaft. Install

detent, align selector lever with support, install shaft,

and drive in new retaining pin.

15. Install assembly to support housing and install

intermediate selector lever.

16. Install assembly to vehicle and install neutral

start switch.

17. Install console lights and cigar lighter connec-

tions to console and install console to vehicle.

18. Lubricate and connect selector rod to intermedi-

ate selector lever and adjust according to Figure 7C-

198.

MAJOR REPAIRREMOVAL AND INSTALLATION OF AUTOMATIC

TRANSMISSION

Removal

- Opel 1900 and Manta

I. Disconnect battery.

2. Remove dipstick.

3. Remove screws from fan shroud.

4. Remove 2 upper starter bolts.

5. Raise car and provide support for front and rear

and drain oil.

6. Remove bolts from engine support brackets, both

sides. Let brackets hang by front bolts. See Figure7c-105.

7. Remove flywheel cover pan.

8. Remove exhaust pipe from manifold and unhook

rubber tailpipe suspension.

9. Remove drive shaft. Do not misplace thrust spring

in spline.

10. Disconnect cooler lines at flexible hoses.

II. Detach both stabilizer supports from

crossmem-ber to body supports and loosen stabilizer bolts in

lower control arms. See Figure X-84, Callout “B”,

Page 456 of 625

AUTOMATIC TRANSMISSION 7C- 95

12. Place suitable jack under transmission and

remove transmission support bolts.

13. Lower transmission enough to remove detent

cable and modulator vacuum line.

14. Remove speedometer cable.

15. Remove selector lever.

16. Mark flywheel and converter for reassembly in

same position, and remove converter to flywheel

bolts. See Figure 7C-106.17. Remove converter housing to engine bolts and

tiller tube.

18. Pry transmission loose from engine.

19. Keep rear of transmission lower than front to

prevent converter from falling and install converter

holding fixture J-21366. Lower transmission and

move to bench.

Installation. Opel 1900 and Manta1. Assemble transmission to suitable jack and raise

transmission into position. Rotate converter to per-

mit coupling of fly wheel and converter with original

relationship. Remove J-21366.

2. Install tiller tube and converter housing to engine

block bolts. Torque to 35 lb. ft. DO NOT over

torque.

3. Install flywheel to converter bolts. Torque to 30 lb.

ft.4. Install detent cable to transmission.

5. Connect oil cooler lines.

6. Install lower bolt on starter. Torque to 40 lb. ft.

7. Connect shift linkage to transmission.

8. Connect modulator line.

9. Connect speedometer cable.

10. Install transmission support.

11. Install drive shaft. Torque U-Bolts to 18 lb. ft.

12. Install flywheel cover pan. Torque to 15 lb. ft.

13. Install engine support brackets.

14. Reconnect exhaust system.15. Attach stabilizer supports and tighten stabilizer

bolts in lower control arms.

16. Lower car.

17. Install starter bolts. Torque to 40 lb. ft.

18. Reconnect battery.

19. Fill transmission with fluid as described in

Specifications. Check selector lever and detent cable

adjustment.

Removal GT1. Disconnect battery.

2. Remove dipstick.

3. Pull throttle control rod off ball pin.

4. Remove screws from fan shroud.

5. Raise car and provide support for front and rear.

6. Remove heat protection shield from right side to

make room for exhaust pipe removal.

Figure 7C-957. Detach exhaust pipe from manifold flange.

8. Unhook damper rings on front muffler and tail

pipe from brackets on body floor panel. Place ex-

haust pipe assembly onto rear axle. See Figure 7C-

96.9. Remove propeller shaft. Make sure that spring in

front universal joint does not get lost.