fuel cap OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 330 of 625

FUEL SYSTEMSC- 39

MAJOR REPAIR

FUEL TANK OPEL 1900 AND MANTAThe fuel tank is located below the luggage compart-

ment floor panel and is attached with a strap.

The plastic tank vent hoses join in a connector from

where the fuel vapors escape through a fourth

ho%attached to the upper flange of the tank.

On all vehicles, the vent hose is connected to an

activated carbon container mounted to the front

wheel house panel.

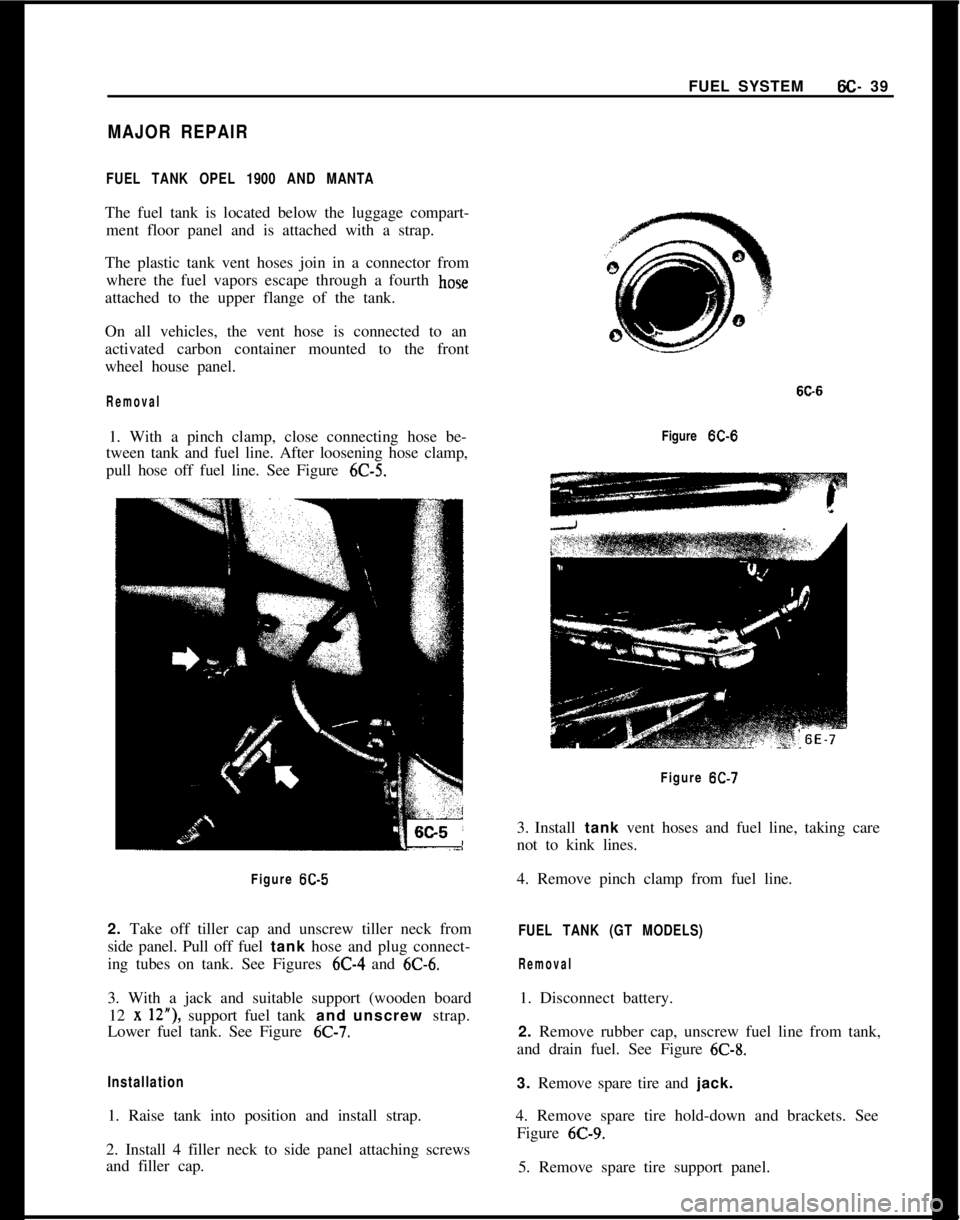

Removal1. With a pinch clamp, close connecting hose be-

tween tank and fuel line. After loosening hose clamp,

pull hose off fuel line. See Figure

6C-5.Figure

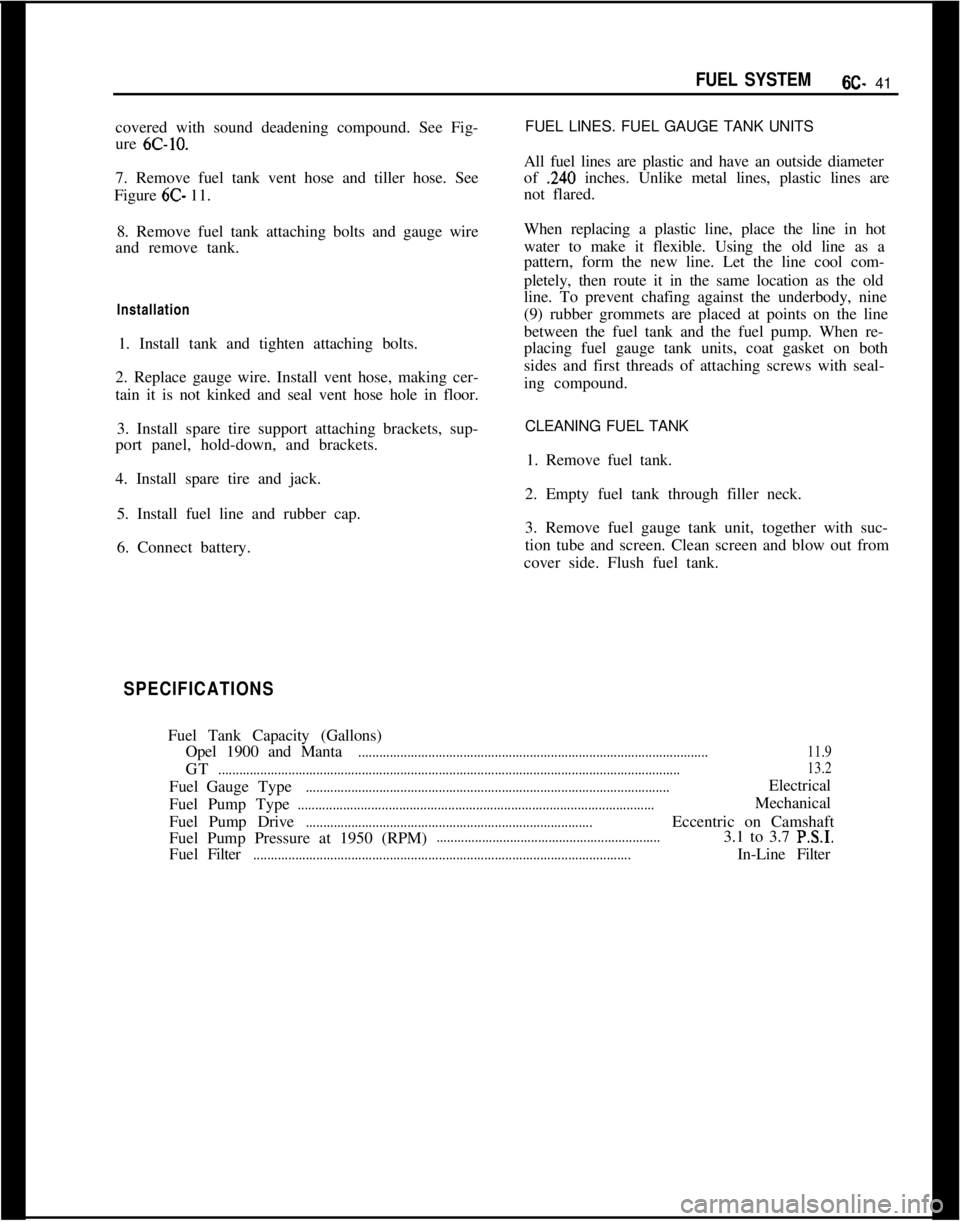

6C-52. Take off tiller cap and unscrew tiller neck from

side panel. Pull off fuel tank hose and plug connect-

ing tubes on tank. See Figures 6C-4 and

6C-6.3. With a jack and suitable support (wooden board

12

x 12”), support fuel tank and unscrew strap.

Lower fuel tank. See Figure

6C-7.

Installation1. Raise tank into position and install strap.

2. Install 4 filler neck to side panel attaching screws

and filler cap.Figure

K-6Figure

6C-73. Install tank vent hoses and fuel line, taking care

not to kink lines.

4. Remove pinch clamp from fuel line.

FUEL TANK (GT MODELS)

Removal1. Disconnect battery.

2. Remove rubber cap, unscrew fuel line from tank,

and drain fuel. See Figure

6C-8.3. Remove spare tire and jack.

4. Remove spare tire hold-down and brackets. See

Figure

6C-9.5. Remove spare tire support panel.

Page 332 of 625

FUEL SYSTEM6C- 41

covered with sound deadening compound. See Fig-

ure

6C-10.7. Remove fuel tank vent hose and tiller hose. See

Figure 6C- 11.

8. Remove fuel tank attaching bolts and gauge wire

and remove tank.

Installation

1. Install tank and tighten attaching bolts.

2. Replace gauge wire. Install vent hose, making cer-

tain it is not kinked and seal vent hose hole in floor.

3. Install spare tire support attaching brackets, sup-

port panel, hold-down, and brackets.

4. Install spare tire and jack.

5. Install fuel line and rubber cap.

6. Connect battery.FUEL LINES. FUEL GAUGE TANK UNITS

All fuel lines are plastic and have an outside diameter

of

,240 inches. Unlike metal lines, plastic lines are

not flared.

When replacing a plastic line, place the line in hot

water to make it flexible. Using the old line as a

pattern, form the new line. Let the line cool com-

pletely, then route it in the same location as the old

line. To prevent chafing against the underbody, nine

(9) rubber grommets are placed at points on the line

between the fuel tank and the fuel pump. When re-

placing fuel gauge tank units, coat gasket on both

sides and first threads of attaching screws with seal-

ing compound.

CLEANING FUEL TANK

1. Remove fuel tank.

2. Empty fuel tank through filler neck.

3. Remove fuel gauge tank unit, together with suc-

tion tube and screen. Clean screen and blow out from

cover side. Flush fuel tank.

SPECIFICATIONSFuel Tank Capacity (Gallons)

Opel 1900 and Manta

....................................................................................................11.9GT

....................................................................................................................................13.2FuelGaugeType

........................................................................................................Electrical

Fuel Pump Type

......................................................................................................Mechanical

Fuel Pump Drive

..................................................................................Eccentric on Camshaft

Fuel Pump Pressure at 1950 (RPM)................................................................3.1 to 3.7 P.S.I.FuelFilter

............................................................................................................In-LineFilter

Page 349 of 625

6E- 581973 OPEL SERVICE MANUAL

Figure 6E-34 Leaf Spring Installed

1 6E-36

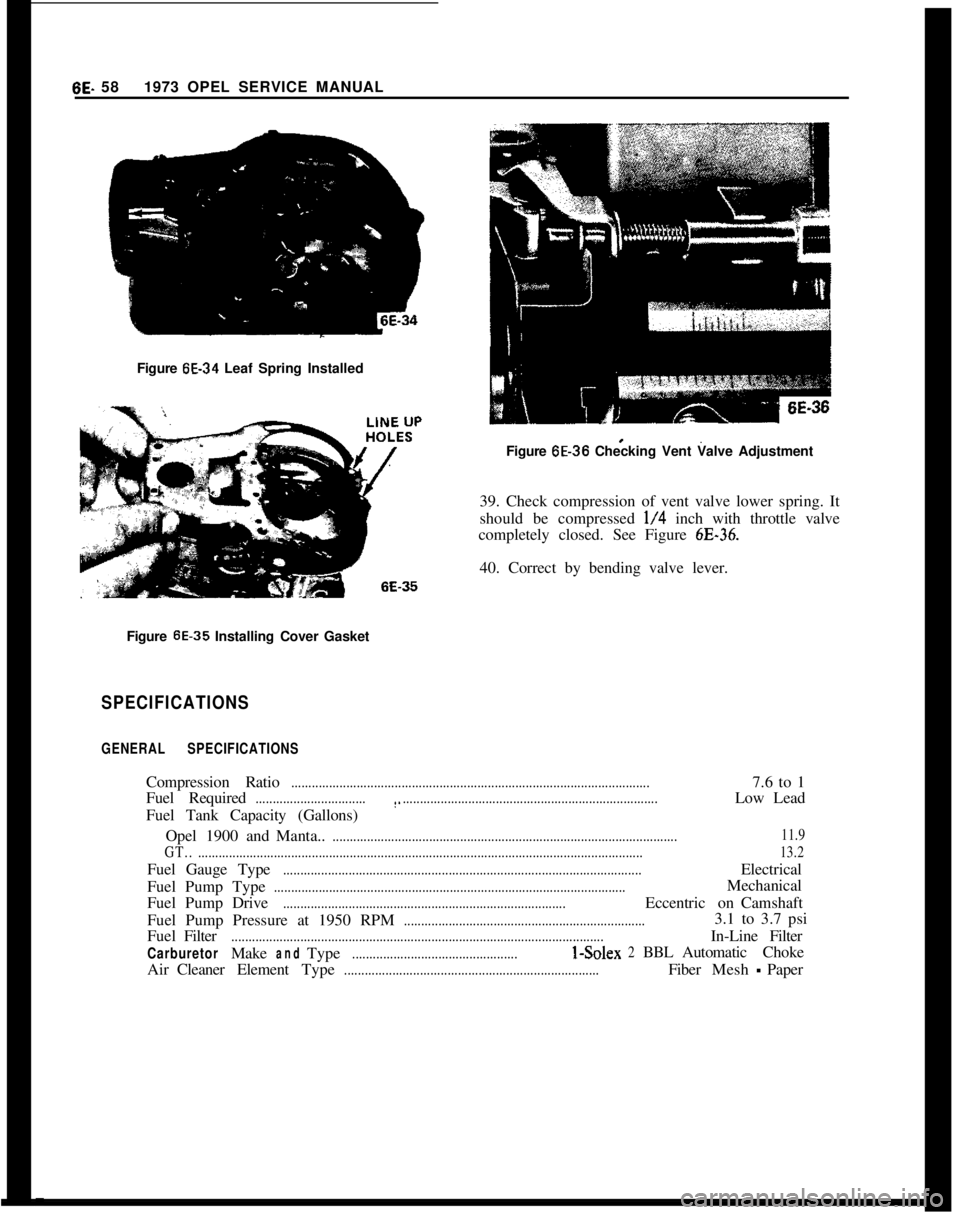

Figure 6E-36 Checking Vent Valve Adjustment

39. Check compression of vent valve lower spring. It

should be compressed

l/4 inch with throttle valve

completely closed. See Figure

6E-36.40. Correct by bending valve lever.

Figure

6E-35 Installing Cover Gasket

SPECIFICATIONS

GENERAL SPECIFICATIONSCompression Ratio

........................................................................................................7.6 to 1

Fuel Required

................................(...........................................................................Low Lead

Fuel Tank Capacity (Gallons)

Opel1900andManta..

....................................................................................................11.9

GT...................................................................................................................................13.2Fuel Gauge Type

........................................................................................................Electrical

FuelPumpType

......................................................................................................Mechanical

FuelPumpDrive

..................................................................................EccentriconCamshaft

Fuel Pump Pressure at 1950 RPM

......................................................................3.1 to 3.7 psi

FuelFilter

............................................................................................................In-LineFilter

CarburetorMakeandType................................................I-Solex2BBLAutomaticChoke

AirCleanerElementType

..........................................................................FiberMesh-Paper

Page 351 of 625

6F- 601973 OPEL SERVICE MANUAL

EMISSION CONTROL SYSTEMS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DescriptionandOperationofO.E.C.S.. . . . . . . . . . . . . . . . . . . . . . . .Exhaust

GasRecirculationSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Testing Therm0 Air Cleaner Operation

. . . . . . . . . . . . . . . . . . . . . .Exhaust

GasRecirculationSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Exhaust GAS Recirculation System

. . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Replacement of O.E.C.S. Units

. . . . . . . . . .SPECIFICATIONS:

Opel Emission Control System Specifications

. . . . . . . .Page No.

6F-60

6F-62

6F-62

6F-636F-636F-636F-64

DESCRIPTION AND OPERATION

OPEL EMISSION CONTROL SYSTEM (O.E.C.S.)All 1973 cars must be capable of passing certain tests

which measure the quantity of unburned impurities

in the exhaust system. Federal law places a limit on

the hydrocarbon and carbon monoxide emissions

from the exhaust system. The purpose of this law is

to keep the atmosphere cleaner, particularly in popu-

lous areas where these impurities add to the smog

problem. Basically, excessive exhaust emissions are

caused by incomplete combustion of the air-fuel mix-

ture in the cylinders.

The basic components of the OECS on the 1.9 liter

engines are (1) leaned out carburetion, (2) heated air

(except GT), and (3) tuned spark timing.

(1) The carburetor idle system is leaned out and

special features are incorporated into the carburetors

to make possible additional idle mixture adjustments

over and above those manufactured into the carbu-

retors.

(2) The heated air package consists of a heat stove,

a corrugated paper heated air pipe, and an air cleanercontaining a temperature controlled door operated

by vacuum through a temperature sensor. See Figure6F-1.The heat stove is a sheet metal cover, shaped to and

bolted onto the exhaust manifold. Air drawn in along

Figure

6F-1 Heated Air System Installed