height OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 291 of 625

5C- 321973 OPEL SERVICE MANUAL

Never use copper tubing because copper is subject to

fatigue cracking which would result in brake failure.2. Cut tubing to length. The correct length may be

determined by measuring the old pipe using a cord

and adding l/8” for each double lap flare.

To make up a brake pipe assembly, proceed as fol-

lows:3. Double lap flare tubing ends, using a suitable flar-

ing tool such as J-8051. Follow the instructions in-

cluded in the tool set. Make sure fittings are installed

1. Procure the recommended tubing and fittings of

the correct size. (Outside diameter of tubing is used

to specify size.)before starting second flare.

4. Bend pipe assembly to match old pipe.

SPECIFICATIONS

BRAKE SPECIFICATIONS

Torque Specifications

Use a reliable torque wrench to tighten the parts listed to insure proper

tightness without straining or distorting parts. These specifications are for

clean and lightly-lubricated threads only; dry or dirty threads produce in-

creased friction which prevents

accurage measurement of tightness.

PartName

TorqueNut

BoltBrakeHose to Front WheelBrake Cylinder

Brake Backing Plate to Steering Knuckle(Uccer

Bolts)Lb&.

22

22...BoltBrake Backing’Plate to Steering Knuckle and

SteeringArm(Lower

Bolts)............................................

BoltBackingPlatetoRearAxleHousing................................

NutMaster Cylinder Actuator Rod to BrakePedal

..............

BoltWheelBrake Cylinder to Brake Backing Plate

..............

General Specifications47

43

5

5OperatingMechanism,ServiceBrakes

....................................................................Hydraulic

Parking Brakes

..........................................................................................Lever and Cables

Operation of Service Brakes Independent of

ParkingBrakes

..................................................................................................................Yes

WheelBrakes,Service

......................................................................................FrontandRear

Parking.

..................................................................................................................Rear Only

BrakePedalHeightAdjustment......................................................................................None

Static Pressure in Hydraulic System When Brakes

are Released

- Drum Brakes................................................................................4 psi Min.

Static Pressure in Hydraulic System to Rear

BrakesOnly

-DiscBrakes..................................................................................

4psiMin.

Brake Master Cylinder (for Drum Brakes) Bore

............................................................13/16

Wheel Cylinder Size

- Rear - All.......................................................................................: 5/8

Approved Hydraulic Brake ,Fluid

..........................................GM or Delco Supreme No. 11

Fluid Level in Reservoir

..........................................................................Fill to “Max.” Level

BrakeDrumRebore,Max&urnAllowable Inside

Diameter........................................

9.090Max. Allowable Out-of-Round

...........................................................................................CKl4Rear Brake Drum Size. New

............................................................................................

9.060

Page 358 of 625

2. If inspection of contact points indicates excessive

burning, pitting or wear, check condenser and re-

place if necessary.

3. Inspect all connections and wires in the primary

ignition circuit. Correct any abnormal conditions

found.Carburetor1. Clean fuel strainer in fuel pump. To prevent fuel

leakage in pump, disconnect “IN” line from pump

and raise end above fuel level. The in-line fuel filter

should be replaced every 12,000 miles or every 12

months.

2. Check for freedom of choke valve operation and

clean shaft if necessary, with suitable solvent.

3. Inspect throttle cable or linkage bracket and re-

turn spring for wear. With helper depressing acceler-

ator pedal to floor, check for wide open throttle.

Adjust accelerator pedal height so wide open throttle

is obtained when pedal is within

l/2 inch from floor.

Lubricate linkage pivot points with engine oil.

Air CleanerCheck paper element every 6,000 miles and replace

every

24,ooO miles. If a vehicle is operated in dusty

territory, check condition of air cleaner element

more frequently and replace if necessary.

Fan Belt1. Inspect belt for wear, cracks or frayed points.

Replace and/or adjust as necessary. Specified ten-

sion for belt using Gauge J-23600 is 45 lbs.

Cooling System1. Inspect the radiator, water pump, cylinder head

areas and all radiator and heater hose connections

for evidence of engine coolant leaks.

2. Inspect all hoses for deterioration from gas and oil

contact. Correct as required.

Inspection should be made with engine operating at

normal temperature, cooling system completely

filled, temperature control lever fully open and nor-

mal pressure in the system. Normal pressure should

be 13.2 to 15.2 psi.

Engine Lubrication SystemInspect engine for evidence of oil leakage. Correctany abnormal condition with sealastic or new seals

and gaskets.

Battery

1. Inspect battery, battery mount and cables and

check electrolyte level. Proper level should be just

above the cell plates.

CAUTION:Do not over fill.

2. Determine the serviceability of the battery by ap-

plying the 421 Battery Test.

Positive Crankcase VentilationClean crankcase ventilator metered orifice in the in-

take manifold fitting every 6,000 miles. Also all hoses

and fittings should be inspected, cleaned and re-

placed, if necessary.

To clean, remove rubber hose from metered orifice

and apply air pressure to orifice to remove any for-

eign particles that may be trapped.

Valve Lifter AdjustmentRefer to Engine Mechanical and Mounts section for

valve lifter adjustment procedure.

Engine Tune-Up Instrument ChecksThe following instrument checks and adjustments

serve as a final check on engine condition. These

checks may discover some new problems that may

not have been obvious before. The engine is also

given its final adjustments that will assure maximum

performance, reliability, and proper emission con-

trol.

Refer to Electrical Group for checking procedures of

the following:

Cranking Voltage Check

Ignition Timing

Distributor Advance

Ignition Output

Secondary Resistance

Current Output and Voltage Setting

Idle Speed and Mixture AdjustmentsRefer to carburetor section.

Page 485 of 625

7C.1241973 OPEL SERVICE MANUAL

14. Remove the downshift timing valve plug retain-

ing pin and remove downshift timing valve plug.

Remove the low speed downshift timing valve and

spring.

15. Remove the manual low and r&erse control

valve retaining pin. Remove the spring and the

manual low control valve and the reverse control

valve.

16. Remove the l-2 accumulator valve retaining pin

and remove the l-2 accumulator valve plug, l-2 ac-

cumulator valve and spring.

17. A clean work area which is free of dirt and dust

should be used to inspect, clean and install the valves

in the valve body. Handle valve components with

clean hands and tools. Since most valve failures are

caused initially by dirt or other foreign matter pre-

venting a valve from functioning properly, a

thorough cleaning of all the components with a

cleaning solvent is essential. Do not use paraffin toclean out the valve body passages and valve bore.

Compressed air may be used to blow out the pas-

sages.18. Inspect each valve for free movement in its re-

spective bore in

t.he valve body. If necessary, use

crocus cloth to remove small burrs on a valve. Do

not remove the sharp edges of the valves as these

edges perform a cleaning action within the bore.

19. Inspect the valve springs for distortion or col-

lapsed coils. Replace the entire valve body assembly

if any parts are damaged.

20. Inspect the transfer plate for dents or distortion.

Replace transfer plate if necessary.

21. Reassemble the valves, springs, plugs and retain-

ing pins in their proper location and order into the

valve body using a liberal amount of transmission

fluid. See the spring data chart which includes the

spring identification sizes in the event springs have

been disarranged.

LocationApplication

PumpPressureRegulator Valve....................................................

PumpPrimingValve

...........................................................

.............Valve Body1.2ShiftValve......................................................................

Valve Body2-3ShiftValve......................................................................

Valve BodyDetentPressureRegulatorValve......................................

Valve BodyHigh-Speed Timing Valve....................................................

Valve BodyLow-Speed

TimingValve....................................................

Valve BodyReverse and Low Control Valve

........................................

CSSDetentValve..........................................................................

Valve Body1-2 Accumulator Valve........................................................

Valve Body3-2Control

Valve..................................................................

Gov. BodySecondary

Governor Valve................................................

Valve BodyAccumulator Piston

..............................................................

CaseServo Return..........................................................................SHVOServoCushion

........................................................................

Clutch PackClutchReturn(All)................................................................ SPRING IDENTIFICATION CHART

FreeOuter

HeightDiameter

2.756

,7601.043

,3202.467

,7201.769

,7001.625,474

1.349

,4061.380,406

1.343

,4062.569

,6751.072

,5201.853

.4061.317

,4061.9171.224

2.2401.850

1.0391.267

1.050

,42422. Install spring and accumulator piston in valve

body.

23. Compress accumulator piston with C-clamp and

install retaining ring.

24. Install new valve body gasket.2. Inspect and clean oil passages with cleaning sol-

vent and air.

3. Check for good retention of band anchor pins.

25. Bolt the transfer plate and gasket to the valve

body. Torque to 6-8 lbs. ft.

Disassembly, Inspection and Reassembly of Case

1. Inspect case for damage. See Figure

7C-202.4. Inspect all threaded holes for thread damage.

5. Inspect detent valve and modulator valve bores for

scratches or scoring.

6. Inspect case bushing inside of case at rear. If

da-maged, remove bushing with remover and installer

tool J-23 130-3 and driver handle J-8092. See Figure

7C-203.

Page 507 of 625

8A-61973 OPEL SERVICE MANUAL

9. On installation make sure that the gaps between

headlamp housing in closed position and headlamp

opening is equal all round and housing is flush in its

height with the body.

REMOVAL AND INSTALLATION OF HEADLAMP

CABLE ASSEMBLY

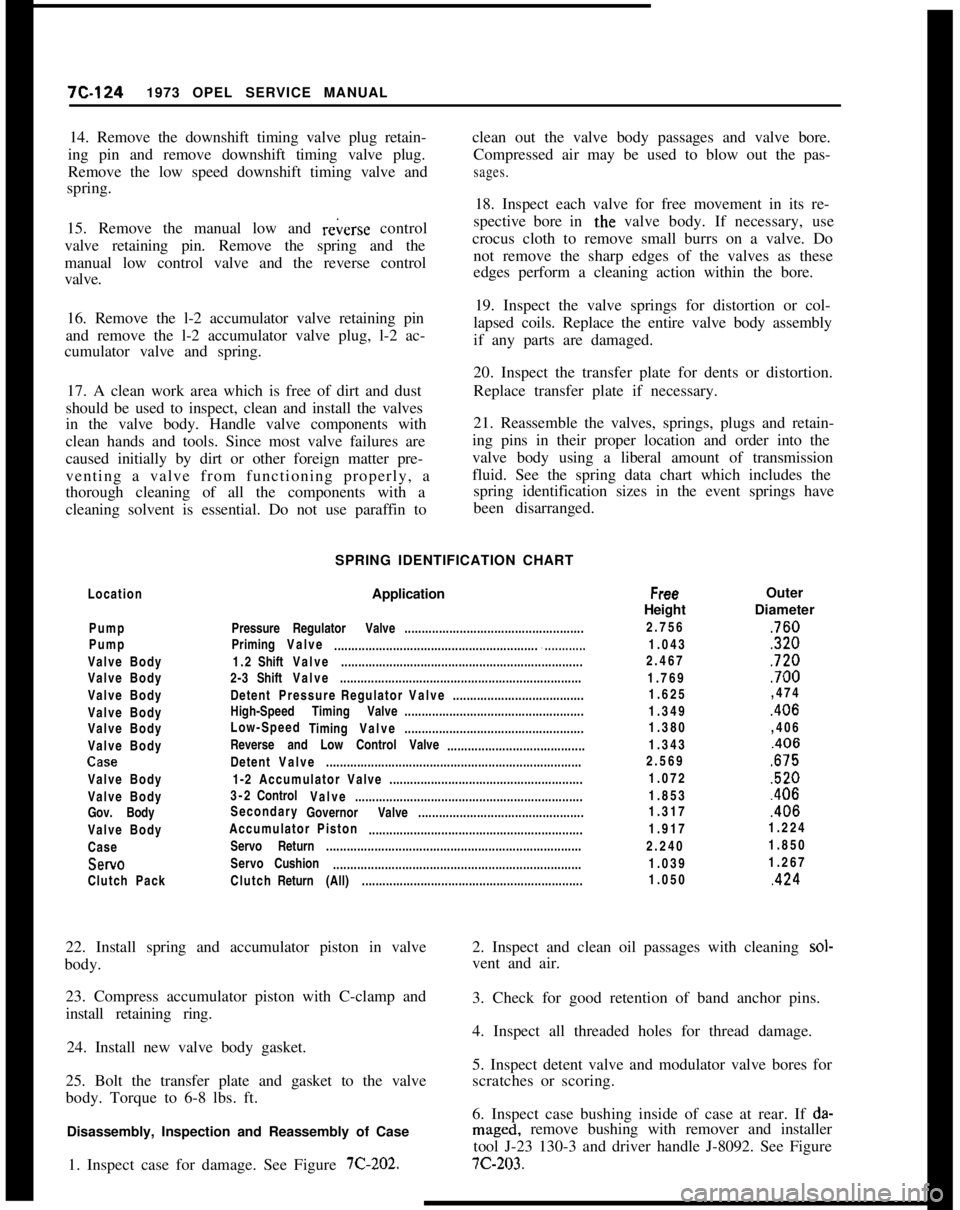

Removal1. Remove cotter pin. See Figure

EA-13 “CL”2. Remove trunion block and nut. See Figure SA-13

“D.”

3. Remove outer adjusting nut and pull cable

through bearing. See Figure 8A-13 “B.”

4. Pull cable through front chassis support.

5. Hoist car.

6. Remove wire clip and unsnap ball seat at control

lever. See Figure 8A-14 “A.”

7. Remove ball-socket and lock nut. See Figure SA-

14

“B.”8. Remove rear adjusting nut. See Figure 8A-14

“CL”9. Remove cable from retainers.

Figure SA-13 Removing Headlamp Trunion Block

Installation10. Thread cable through bearing and clip retainers.Figure 8A-14 Removing Ball Seat at Control Lever

11. Install adjusting lock nut approximately

l/2” on

thread. See Figure 8A-13 “B.’

12. Install lock nut and ball stud on end of cable. See

Figure 8A-14 “B.”

13. Connect ball stud to control lever with clip. See

Figure 8A-14 “A.”

14. Adjust lock nut under vehicle for maximum cable

length. See Figure 8A-14

“CL”15. Thread cable through proper openings in body

and install adjusting lock nut, trunion lock nut, trun-

ion, and lock clip.

16. Adjust cable length for proper headlight operat-

ion.

REMOVAL AND INSTALLATION OF RADIATOR

GRILLE

(GT)

RemovalRemove screws securing grille screen to opening.

InstallationInstall grille screen to opening and secure with

screws.

REMOVAL AND INSTALLATION OF

RADIATOR GRILLE EXTENSIONS

(GTI

Removal

1. Remove hex head screw and washer holding grille

extension to baffle plate.

Page 533 of 625

9B-24 1973 OPEL SERVICE MANUAL

Figure 9B-15 Compressor Assembly - GT Shown

Figure 3B-16 Condenser Assembly

condenser. The refrigerant vapor gives up its heat,

which is quickly and easily radiated into the sur-

rounding air through the large finned surfaces of the

condenser. In giving up its heat, the refrigerant vapor

condenses back into liquid which collects in a pool

at the bottom of the condenser.

As we have said before, when the refrigerant con-

denses into a liquid, it again is ready for boiling in the

evaporator. So, we can run a pipe from the condenser

back to the evaporator.

Main Units of the SystemThese three units then; the evaporator, the compres-

sor, and the condenser are the main working

parts of any typical air conditioning system. We have

the evaporator where the refrigerant boils andchanges into a vapor, absorbing heat as it does so. We

have the pump or compressor to put pressure on the

refrigerant so it can get rid of its heat. And we have

a condenser outside the car body to help discharge

the heat into the surrounding air.

Pressure and FlowThere is one more unit that co-operates with thesethree. It doesn’t do any real work, but it does act as

sort of a traffic officer in controlling the flow of the

refrigerant through the system. To get a better idea

of what this does. let’s first do a li,ttle exoerimentine

with an ordinary’ tire pump.

When we use a

t,ire pump to Sate an automobile

tire, we are creating pressure only because we are

“pushing” against the air already entrapped inside

the tire. If you question this, just try pumping up a

tire that has a large puncture in it. You could pump

all day, and still not be able to build up any pressure.

As fast as you would pump the air in, it would leak

out through the puncture.

Abou~t all you would be

doing would be circulating nice fresh air through the

tire.

1Jnless you have something lo push against - to

block the tlow of air

- you can’t create more than a

mere semblance of pressure.

The same situation holds true in an air conditioning

system. The compressor can pump refrigerant vapor

through the system, but unless it has something to

push against, it cannot build up pressure. All the

compressor would be doing would be to circulate the

vapor without increasing its

pres,sure.Yet we can’t just block the flow through the system

entirely. All we want to do is put pressure on the

refrigerant vapor so it will condense at normal tem-

peratures. What’s more, this

musi: be done some time

after the vapor leaves the evaporator and before it

returns again as a liquid. We can’t have high pressure

in the evaporator because that would slow down the

boiling of the refrigerant and thus penalize the re-

frigerating effect.

Controlling Pressure and FlowPressure and flow can be controlled with a float

valve, or with a pressure-regulating valve. They do

the same job, but in a different way.

Since the float valve type will give us a better idea of

pressure and flow control, let’s look at it first (Fig.

9B-17).It consists simply of a float that rides on the surface

of the liquid refrigerant. As the refrigerant liquid

boils and passes off as a vapor, naturally the liquid

level drops lower and lower. Correspondingly, the

float, because it rides on the surface of the refriger-

ant, also drops lower and lower as the liquid goes

down.By means of a simple system of mechanical linkage,

the downward movement of the float opens a valve

to let refrigerant in. The incoming liquid raises the

fluid level and, of course, the float rides up with it.

When the surface level of the refrigerant liquid re-

aches a desired height, the float: will have risen far

Page 548 of 625

REFRIGERANT COMPONENTS ALL MODELS96-39

In all instances where the indications of refrigerant

shortage continues, additional refrigerant should be

added in

l/4 lb. increments until the sight glass is

clear.

An additional charge of l/4 lb. should be ad-

ded as a reserve. In no case should the system be

overcharged.

LEAK TESTING SYSTEM

The following two methods are recommended when attempting to locate refrigerant leaks in the system.

Loss of

regrigerant is always indicative of a leak since

refrigerant is not consumed and does not wear out.

1. Open Flame Method

- This method utilizes a gas

operated torch type leak detector (J-6084). Use of

this method is recommended when checking for

leaks in confined areas. To perform test, light torch

and adjust to obtain a pale blue flame, approximately

3/8 inch in height, in burner.

Explore for leaks by moving end of search tube

around suspected area. Check bottom of connections

since Refrigerant-12 is heavier than air and will be more apparent at underside of fittings. The flame

color will turn yellow-green when a small leak is

detected. Large leaks will turn the flame blue or

purple.

WARNING:

Do not breathe fumes resdting from

burning of

refrigerant gas. These fumes az ex-

tremeiy poisonous.

2. Liquid Leak Detectors - This method utilizes a

solution which will bubble (soap solution) to signify

a gas leak. Use of this method of checking is recom-

mended for locating small leaks.

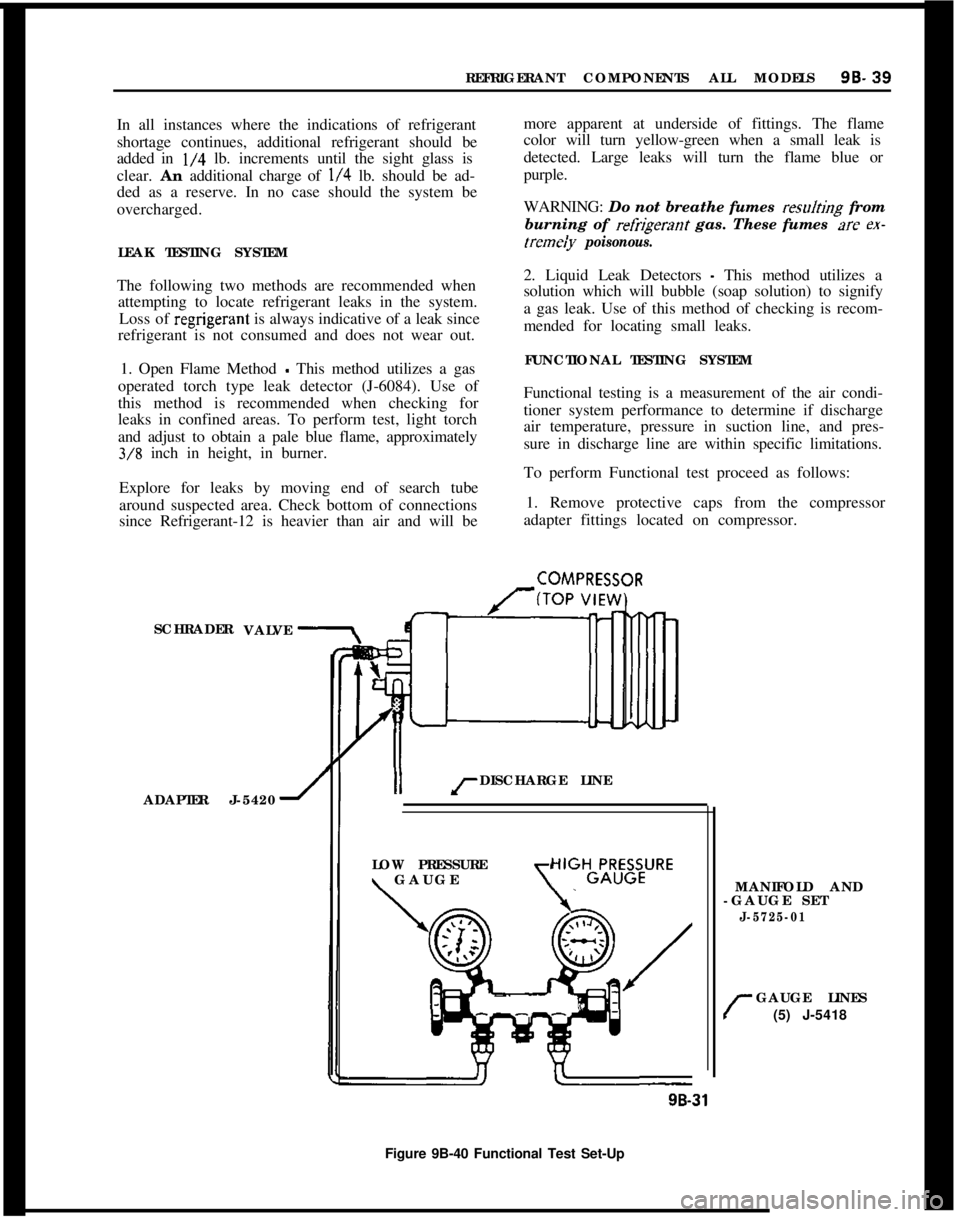

FUNCTIONAL TESTING SYSTEM

Functional testing is a measurement of the air condi-

tioner system performance to determine if discharge

air temperature, pressure in suction line, and pres-

sure in discharge line are within specific limitations.

To perform Functional test proceed as follows:

1. Remove protective caps from the compressor

adapter fittings located on compressor.

SCHRADER

ADAPTER J-5420

1II rDISCHARGE LINE

COMPRESSOR

VALVE

LOW PRESSURE

\ GAUGE\

HIGHGLR;B;URE

MANIFOLD AND

-GAUGE SET

J-5725-01

r

GAUGE LINES

(5) J-5418

9B-31

Figure 9B-40 Functional Test Set-Up

Page 613 of 625

RADIO. GT9c- 105

RADIO

GTCONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS:

RadioTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Antenna Trimmer Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

RemovingandInstallingRadio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

Page No.

9c-105

9C-106

9c-107

DIAGNOSIS

RADIO TROUBLE DIAGNOSISBecause radio problems are most often repaired at

United Delco authorized warranty repair stations,

the tendency for many dealer servicemen is to

remove the set when a problem is reported, without

any preliminary diagnosis. This results in a large

number of radios showing up as “NO TROUBLE

FOUND” units when received by the warranty re-

pair stations. This indicates that the trouble can

often be corrected without removal of the radio.

The inconvenience to an owner of driving without a

radio while his set is being serviced at a warranty

station can frequently be avoided if the following

quick checks are used to eliminate external radio

system :problems before removing the radio for re-

pair.

Always determine from the owner the exact nature

of the radio problem as an aid to diagnosis. Knowing

whether the condition is intermittent or constant,

whether it occurs with engine off or running, with

car stationary or moving, will help to pinpoint the

problem. Never turn on radio with speaker discon-

nected.

Radio Ii

Inoperative.1. Turn on the radio. The dial should light and a

thump should be heard from the speaker.a. If a thump is heard, go to Step No. 2 for antenna

check.b. If no thump is heard,

check the fuse.

(1) If fuse is bad, replace and try radio again. Race

engine and, if fuse blows again,‘remove the radio and

speaker assembly for repair by

4 trained radio techni-

cian.

(2) If fuse is good, check to

s&e that the speaker-to-

receiver interconnecting cable is connected securely.

If there is still no thump when the radio is turned on,

remove the receiver and speaker for repair.

2. Check the antenna by substituting with one held

out the car window.

a. If radio is still dead with substitute antenna,

remove the receiver and spea!er for repair.

b. If radio operates near normal with substitute an-

tenna, some part of the car antenna or lead-in is at

fault.

Radio Reception Is Weak1. Check to see if antenna trimmer is peaked.

a. Position antenna at a height of 31 inches.

b. Tune radio to weak station at or near 1400 KHz

on the dial, and turn volume control to maximum.

Page 614 of 625

9C-106 1973 OPEL SERVICE MANUAL

c. Adjust trimmer screw for maximum volume.

d. If antenna trimmer does not have a definite peak, check for defective antenna by substitution.

2. Check that the speaker connection is plugged in

SXUdY.

3. If the radio is still weak, remove the receiver and

speaker assembly for repair.

Radio Is Noisy

1. Radio is noisy all the time:

a. Check for defective antenna by striking antenna

with hand. If static is heard while tapping, replace

antenna.

b. If antenna is not defective, remove receiver and

speaker for repair.

2. Radio is noisy only when jarred:

a. Check antenna as in Step No. 1 above.

b. Check speaker connection. If speaker connection is not at fault, remove receiver and speaker for re-

pair.

3. Radio is noisy when engine is running:

a. Check noise suppressor by substituting on genera-

tor with known good one.

b. Check to see that antenna is mounted securely,

grounding the antenna base to the fender. The an-

tenna lead-in wire is shielded and the shield should

have good ground connection at the receiver and the

antenna base.

c. Check for other car wiring, passing too close to

radio receiver case.

d. If engine noise is still present, remove receiver and

speaker for repair.

4. Radio is noisy when car equipment is operated,

such as directional lights or brake lights:

Check for defective antenna lead-in wire or, loose

antenna mounting, as in Step No. 3b above.

MAINTENANCE AND ADJUSTMENTS

ANTENNA TRIMMER ADJUSTMENT

An antenna trimmer adjusment screw is provided for

matching of the antenna coil in the receiver to the car antenna. This adjustment must always be made after

installation of a receiver or an antenna, or after re-

pair to these units. This adjustment should also be

performed whenever radio reception is unsatisfac-

tory.

1. Position antenna to a height of 31 inches.

2. Tune receiver

tb a weak station at or near 1400

KHz that can barely be heard

with volume turned

fully up.

3. Insert a small-bladed screwdriver in antenna trim-

Figure 9C-1 Location of Access Trim Plug

Figure

9C-2 Removing Hex Head Screw

Page 617 of 625

RADIO - OPEL 1900 - MANTA9c- 109

RADIO

OPEL 1900

- MANTA

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS:

RadioTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Antenna Trimmer Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal&InstallationRadio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal81InstallationAntenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:Page No.

9c-109

9c-110

9c-111

9c-111

DIAGNOSIS

RADIO TROUBLE DIAGNOSISBecause radio problems are most often repaired at

United Delco authorized warranty repair stations,

the tendency for many dealer servicemen is to

remove the set when a problem is reported, without

any preliminary diagnosis. This results in a large

number of radios showing up as “NO TROUBLE

FOUND” units when received by the warranty re-

pair stations. This indicates that the trouble can

often time be corrected without removal of the radio.

The inconvenience to an owner of driving without a

radio while his set is being serviced at a warranty

station can frequently be avoided if the following

quick checks are used to eliminate external radio

system Problems before removing the radio for re-

pair.

Always determine from the owner the exact nature

of the radio problem as an aid to diagnosis. Knowing

whether! the condition is intermittent or constant,whether::it occurs with engine off or running, with

car stationary or moving, will help to pinpoint theproblem: Never turn on radio with speaker discon-

nected.

Radio Is Inoperative

1. Turn on the radio. The dial should light and a

thump should be heard from the speaker.a. If a thump is heard, go to

Step No. 2 for antenna

check.b. If no thump is heard, check the fuse.

(1) If fuse is bad, replace and try radio again. Race

engine and, if fuse blows again, remove the radio and

speaker assembly for repair by a trained radio techni-

cian.

(2) If fuse is good, check to see that the speaker to

receiver interconnecting cable is connected securely.

If there is still no thump when the radio is turned on,

remove the receiver and speak+ for repair.

2. Check the antenna by substituting with one held

out the car window.

a. If radio is still dead with’substitute antenna,

remove the receiver and speaker for repair.

b. If radio operates near normal with substitute an-

tenna, some part of the car antenna or lead-in is at

fault.

Radio Reception Is Weak1. Check to see if antenna

tri$mer is peaked.

a. Position antenna at a height,of 31 inches.

b. Tune radio to weak station at or near 1400 KHz

on the dial, and turn volume control to maximum.

Page 618 of 625

9C-110 197j 6PEi SERVICE MANUAL

c. Adjust trimmei screw for maximum volume,

d. If antenna trir&ner does not have a definite peak,

check for defective ant&ma by substitution.

2. Check that the speaker connection is plugged in

securely.3. If the radio is still weak, remove the receiver and

speaker assembly for repair.

Radio Is Noisy1. Radio is noisy all the time:

a. Check for defective antenna by striking antenna

with hand. If static is heard while tapping, replace

antenna.

b. If antenna is not defective, remove receiver and

speaker for ripair.

2. Radio is noisy only when jarred:

a. Check antenna as in Step No. 1 above.

b. Check speaker connection. If speaker connection

is not at fault, remove receiver and speaker for re-

pair.

3. Radio is noisy when engine is running:

a. Check noise suppressor by substituting on genera-

tor with known good one.

b. Check to see that antenna is mounted securely,

grounding the antenna base to the fender. The an-

tenna lead-in wire is shielded and the shield should

have good ground corinection at the receiver and the

antenna base.

c. Check for other car wiring passing too close to

radio receiver case.

d. If engine noise is still present, remove receiver and

speaker for repair.

4. Radio is noisy when car equipment is operated,

such as directional lights or brake lights:

Check for defective antenna lead-in wire or loose

antenna mounting, as in Step No. 3b above.

5. Radio is noisy only on dry days when car is mov-

ing:

Wheel and tire static will occur only during dry

weather. To check to see if noise is wheel static or tire

static, drive car until noise is noticed. Touch the

brake. If noise disappears, it is wheel static. If noise

persists, it is tire static. Static may be eliminated in

two ways:a. Wheel static may be eliminated by installation of

static collectors in the front wheels. It is important

to make sure the button on the end of the spiral

collector rides evenly in the spindle. Grease and dirt

can cause poor contact between static collector and

the cap, which would result in wheel static, even with

the collectors installed.

b. Tire static is eliminated by injecting graphite tire

static powder in all

five (5) tires. Either a special gun

or a plastic squeeze bottle can be used to insert pow-

der.MAINTENANCE AND ADJUSTMENTS

ANTENNA TRIMMER ADJUSTMENTAn antenna trimmer adjustment screw is provided

for matching of the antenna coil in the receiver to the

car antenna. This adjustment must always be made

after installation of a receiver or an antenna, or after

repair to these units. This adjustment should also be

performed whenever radio reception is unsatisfac-

tory.1. Position antenna to a height of 31 inches.

2. Tune receiver to a weak station at or near 1400

KHz that can barely be heard with volume turned

fully up.

3. Insert a small-bladed screwdriver in antenna trim-

mer screw and rotate screw until maximum volume

is achieved.

Figure 9C-15 Radio Control Knobs