seat adjustment OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 306 of 625

ENGINE MECHANICAL AND MOUNTS6A- 15New inlet valves must not be refaced or lapped with

grinding compound.The correct angle for the intake

and exhaust valve head is 44 degrees.10. Install cylinder head.

11. Adjust valve clearance. See MAINTENANCE

AND ADJUSTMENTS.

7. Inspect valve guides. Worn or pitted guides can be

reamed to accept valves with oversize stems. Over-

size valves are occasionally used in production.

Oversize valves are marked

’ 1 u “2” or “A” and are

stamped into the valve stem end and also stamped

near spark plug hole. See Figure 6A-22.

Replacing Rocker Arm Studs1. When replacing rocker arm studs become

neces-

sary, remove air cleaner, rocker arm cover and

rocker arm.

8. Reseat valve seats in cylinder head in the following

sequence:

Intake

NOTE:The rocker arm studs are screwed into the

cylinder head. A tapered part of the stem serves to

a void stud loosening.With 45 degrees cutter, remove burnt structure until

a metallic bright seat is obtained. Lightly coat valve

head with red lead, insert it into guide and turn it

under light pressure several times back and forth.

Thereby a contact pattern is obtained and the seat

width can be measured. If valve does not seat per-

fectly all around, lightly recut valve seat to the estab-

lished seat width of

,049” - .059” with 30 degrees

correction cutter.

ExhaustThe directions for reconditioning intake valve seats

apply in principle also to exhaust valve seat recondi-

tioning with the exception that the valve seat width

should be

.063-,073 in. and different cutters are em-

ployed.

NOTE:

: OTse new valve seals whenever

valves are reconditioned.9. Lube valves with engine oil and reinstall valves,

valve springs, caps and cap retainers using J-8062.

Install valve spring with closely wound coils toward

cylinder head. See Figure

6A-24.2. Attach vise grip pliers to stud being removed and

remove from cylinder head.

3. Screw in new stud. Seat tapered part of stud by

striking stud end with a rubber hammer.

4. Place two turned down rocker arm nuts on

threaded part of stud.

5. Torque stud into cylinder head to 29

lb.ft.

Valve Lifter ServiceThe valve lifters can be removed after removing

rocker arm cover and rocker arms.No oversize lifters have been released due to the

insignificant wear of the valve lifters and cylinder

head guides.

Amply oil respective parts and install in reverse se-

quence to removal.

Carry out hydraulic valve lifter adjustment as ou-

tlined in MAINTENANCE AND ADJUST-

MENTS.

VALVE

I SPRING

CLOSE

WOUND

COILS

TOWARD

HEAD6A-24

Figure 6A-24 Valve SpringCONNECTING ROD BEARINGSA connecting rod bearing consists of two halves or

shells which are alike and interchangeable in rod and

cap. When the shells are placed in rod and cap the

ends extend slightly beyond the parting surfaces so

that when rod bolts are tightened the shells will be

clamped tightly in place to insure positive seating

and to prevent turning. Theends of shells must never

be tiled flush with parting surface of rod or cap.

If a precision type connecting rod bearing becomes

noisy or is worn so that clearance on crankpin is

excessive, a new bearing of proper size must be se-

lected and installed since no provision is made for

adjustment. Under no circumstances should the con-necting rod or cap be filed to adjust the bearing

clearance.

Page 308 of 625

ENGINE MECHANICAL AND MOUNTS6A- 17

seating and to prevent turning.The ends of she//s

must never be tiled flush with parting surface of

crankcase or bearing cap.Crankshaft bearings are the precision type which do

not require reaming to size. Shims are not provided

for adjustment since worn bearings are readily re-

placed with new bearings of proper size. Bearings for

service replacement are furnished in standard size

and undersizes. Under no circumstances should

crankshaft bearing caps be tiIed to adjust for wear in

old bearing.After removal of oil pan, pipe and screen assembly,

perform the following removal, inspection and in-

stallation operations on each crankshaft bearing in

turn so that the crankshaft will be well supported by

the other bearings.

If crankshaft has been removed to check straightness

the following procedure is suggested. Rest crank-

shaft on “V-blocks” at number one and number live

main bearing journals. Check indicator runout at

No. 3 main bearing journal. Total indicator reading

should not exceed

.C012”.1. Since any service condition which affects the

crankshaft bearings may also affect the connecting

rod bearings, it is advisable to inspect connecting rod

bearings

first. If crankpins are worn to the extent

that crankshaft should be replaced or reground, re-

placement of crankshaft bearings only will not be

satisfactory.

If replacement of cylinder block or crankshaft is re-

quired, always check main bearing clearance with

plastic-type gauge to obtain specified limits.

2. Remove one bearing cap, then clean and inspect

lower bearing shell and the crankshaft journal. If

journal surface is scored or ridged, the crankshaft

must be replaced or reground to insure satisfactory

operation with new bearings. Slight roughness may

be polished out with tine grit polishing cloth

thoroughly wetted with engine oil, and burrs may be

honed off with a tine stone.

3. If condition of lower bearing shell and crankshaft

journal is satisfactory, check the bearing clearance

with a plastic-type gauge.

4. When checking a crankshaft bearing with plastic-

type gauging material, turn crankshaft so that oil

hole is up to avoid dripping of oil on the gauge

material. Place paper shims in lower halves of adja-

cent bearings and tighten cap bolts to take the weight

of crankshaft

off the lower shell of beating being

checked.5. If bearing clearance exceeds

.C03”, it is advisable

to install a new bearing; however, if bearing is in

good condition and is not being checked because ofbearing noise, it is not necessary to replace the bear-

ing.6. Loosen all crankshaft bearing cap bolts

l/2 turn,

and remove cap of bearing to be replaced.

7. Remove upper bearing shell by inserting Bearing

Shell Remover and Installer J-8080 in oil hole in

crankshaft, then slowly turning crankshaft so that

the tool rotates the shell out of place by pushing

against the end without the tang. See Figure

6A-27.When turning crankshaft with rear bearing cap

removed hold oil seal to prevent it from rotating out

of position in crankcase.

8. The crankshaft journal cannot be measured with

an outside micrometer when shaft is in place; how-

ever, when upper bearing shell is removed the jour-

nal may be checked for out-of-round by using a

special crankshaft caliper and inside micrometer.

Figure 6A-27 Removing and Installing Crankshaft

Bearing Upper Shell

The caliper should not be applied to journal in line

with oil hole.

If crankshaft journal is more than

.M)12” out-of-

round, the crankshaft should be replaced since the

full mileage cannot be expected from bearings used

with an excessively out-of-round crankshaft.

9. Before installation of bearing shells make sure that

crankshaft journal and the bearing seats in crankcase

and cap are thoroughly cleaned.

10. Coat inside surface of upper bearing shell with

engine oil and place shell against crankshaft journal

so that tang on shell will engage notch in crankcase

when shell is rotated into place.

11. Rotate bearing shell into place as far as possible

by hand, then insert Installer J-8080 in crankshaft oil

hole and rotate crankshaft to push shell into place.

Bearing shell should move into place with very little

Page 347 of 625

6E- 561973 OPEL SERVICE MANUAL

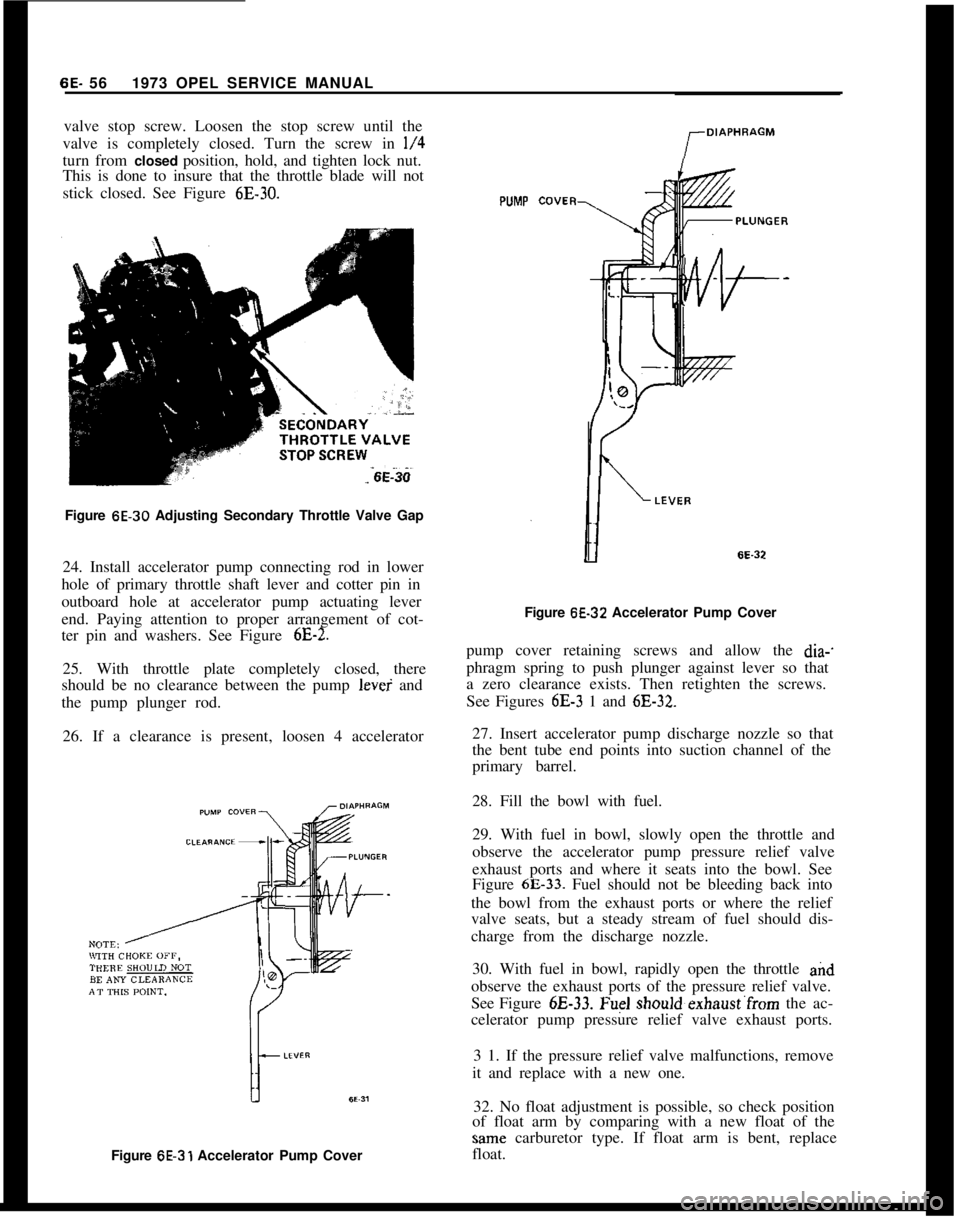

valve stop screw. Loosen the stop screw until the

valve is completely closed. Turn the screw in l/4turn from closed position, hold, and tighten lock nut.

This is done to insure that the throttle blade will not

stick closed. See Figure

6E-30.PUMPFigure 6E-30 Adjusting Secondary Throttle Valve Gap

24. Install accelerator pump connecting rod in lower

hole of primary throttle shaft lever and cotter pin in

outboard hole at accelerator pump actuating lever

end. Paying attention to proper arrangement of cot-

ter pin and washers. See Figure

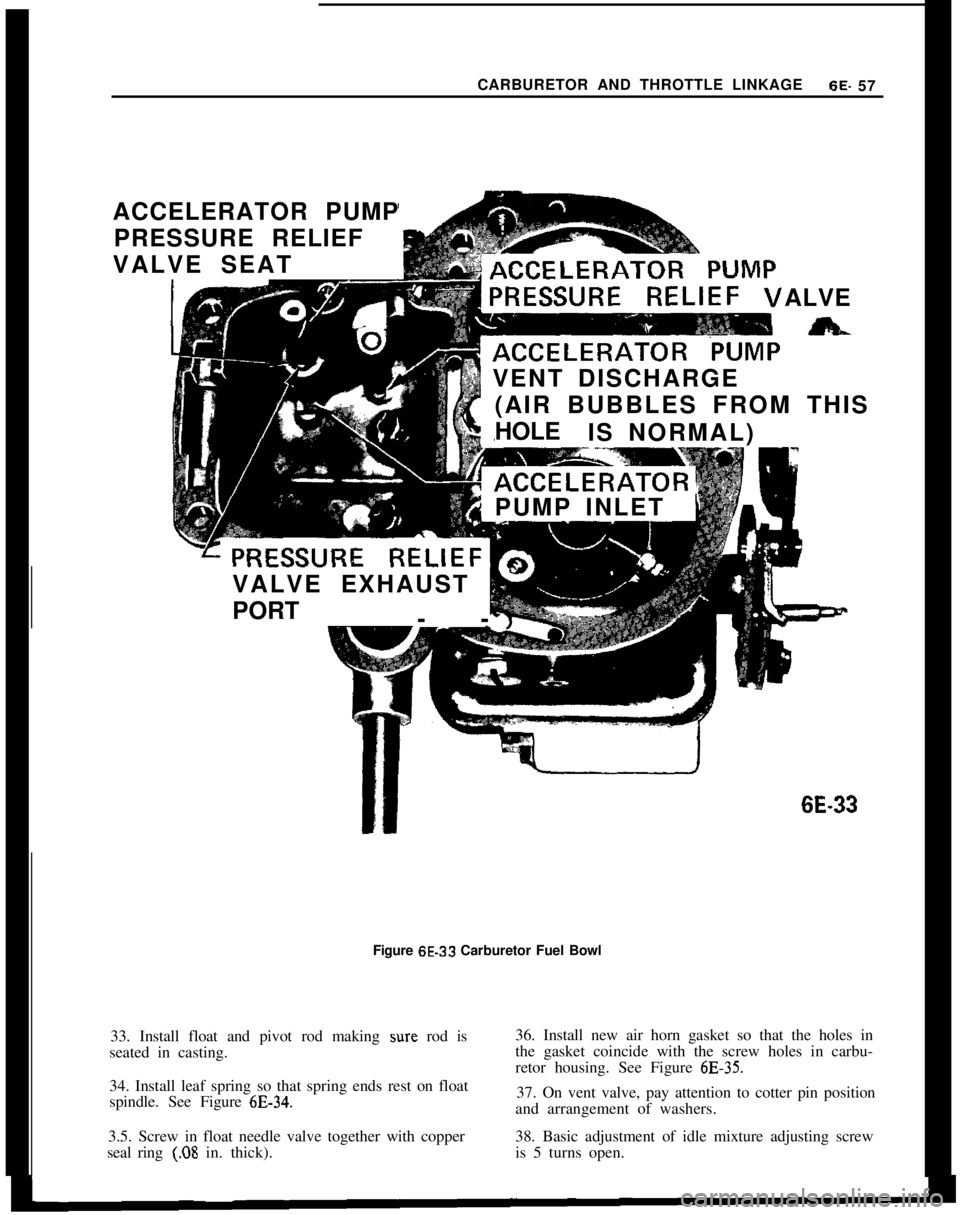

6E-2.25. With throttle plate completely closed, there

should be no clearance between the pump levei and

the pump plunger rod.

26. If a clearance is present, loosen 4 accelerator

Figure

6E-31 Accelerator Pump CoverFigure 6C32 Accelerator Pump Cover

pump cover retaining screws and allow the

dia-’phragm spring to push plunger against lever so that

a zero clearance exists. Then retighten the screws.

See Figures

6E-3 1 and 6E-32.27. Insert accelerator pump discharge nozzle so that

the bent tube end points into suction channel of the

primary barrel.

28. Fill the bowl with fuel.

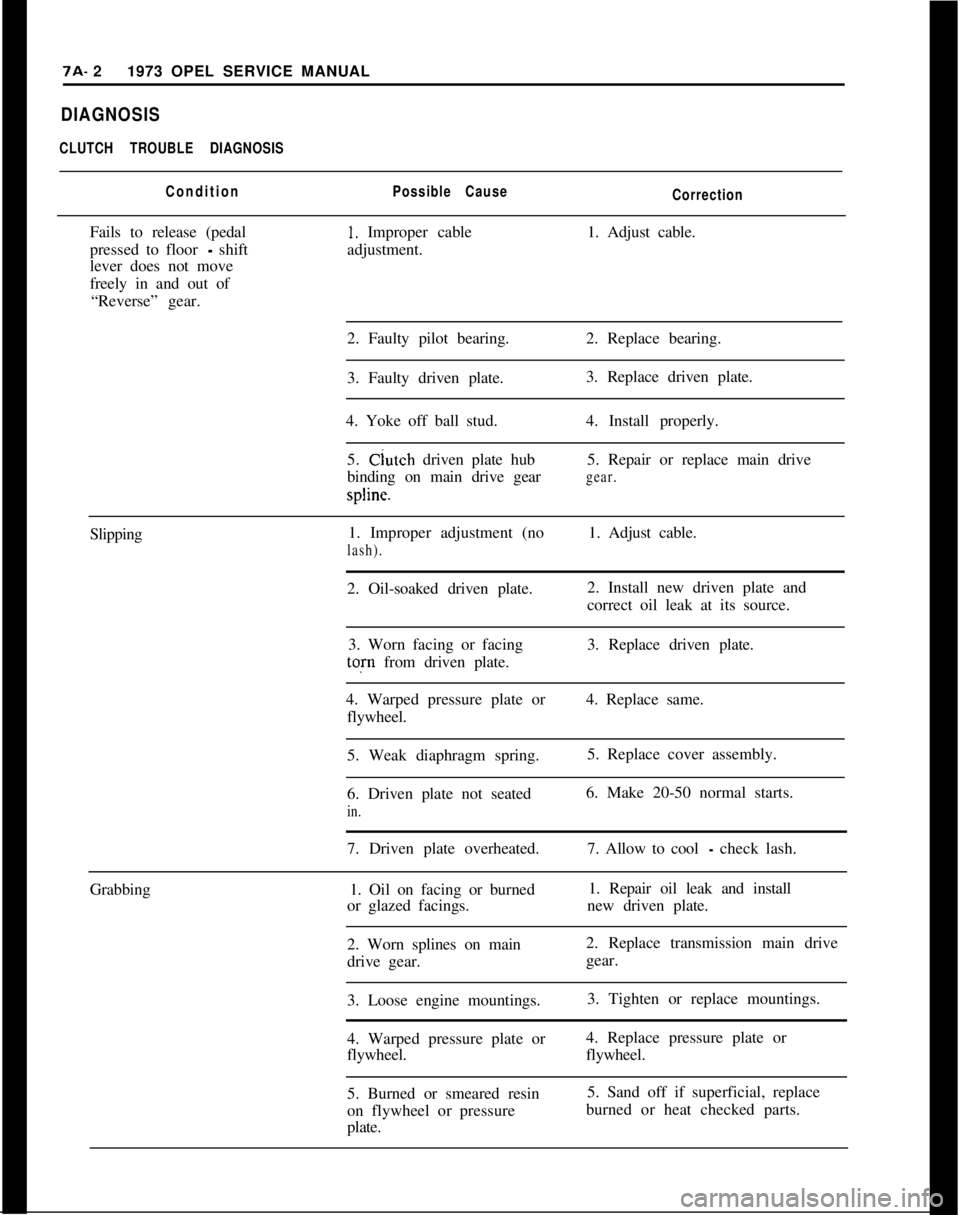

29. With fuel in bowl, slowly open the throttle and

observe the accelerator pump pressure relief valve

exhaust ports and where it seats into the bowl. See

Figure

6E-33. Fuel should not be bleeding back into

the bowl from the exhaust ports or where the relief

valve seats, but a steady stream of fuel should dis-

charge from the discharge nozzle.

30. With fuel in bowl, rapidly open the throttle atid

observe the exhaust ports of the pressure relief valve.

See Figure

6E-33. Fuel should~exhaust’from the ac-

celerator pump pressure relief valve exhaust ports.

3 1. If the pressure relief valve malfunctions, remove

it and replace with a new one.

32. No float adjustment is possible, so check position

of float arm by comparing with a new float of thesame carburetor type. If float arm is bent, replace

float.

Page 348 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 57

ACCELERATOR PUMP

PRESSURE RELIEF

VALVE SEAT

ALVE

VENT DISCHARGE

(AIR BUBBLES FROM THIS

HOLE

IS NORMAL)

PUMP INLET

VALVE EXHAUST

PORT

--6E-33

Figure 6E-33 Carburetor Fuel Bowl

33. Install float and pivot rod making sure rod is

seated in casting.36. Install new air horn gasket so that the holes in

the gasket coincide with the screw holes in carbu-

retor housing. See Figure

6E-35.34. Install leaf spring so that spring ends rest on float

spindle. See Figure

6E-34.37. On vent valve, pay attention to cotter pin position

and arrangement of washers.

3.5. Screw in float needle valve together with copper38. Basic adjustment of idle mixture adjusting screw

seal ring

(.08 in. thick).is 5 turns open.

Page 363 of 625

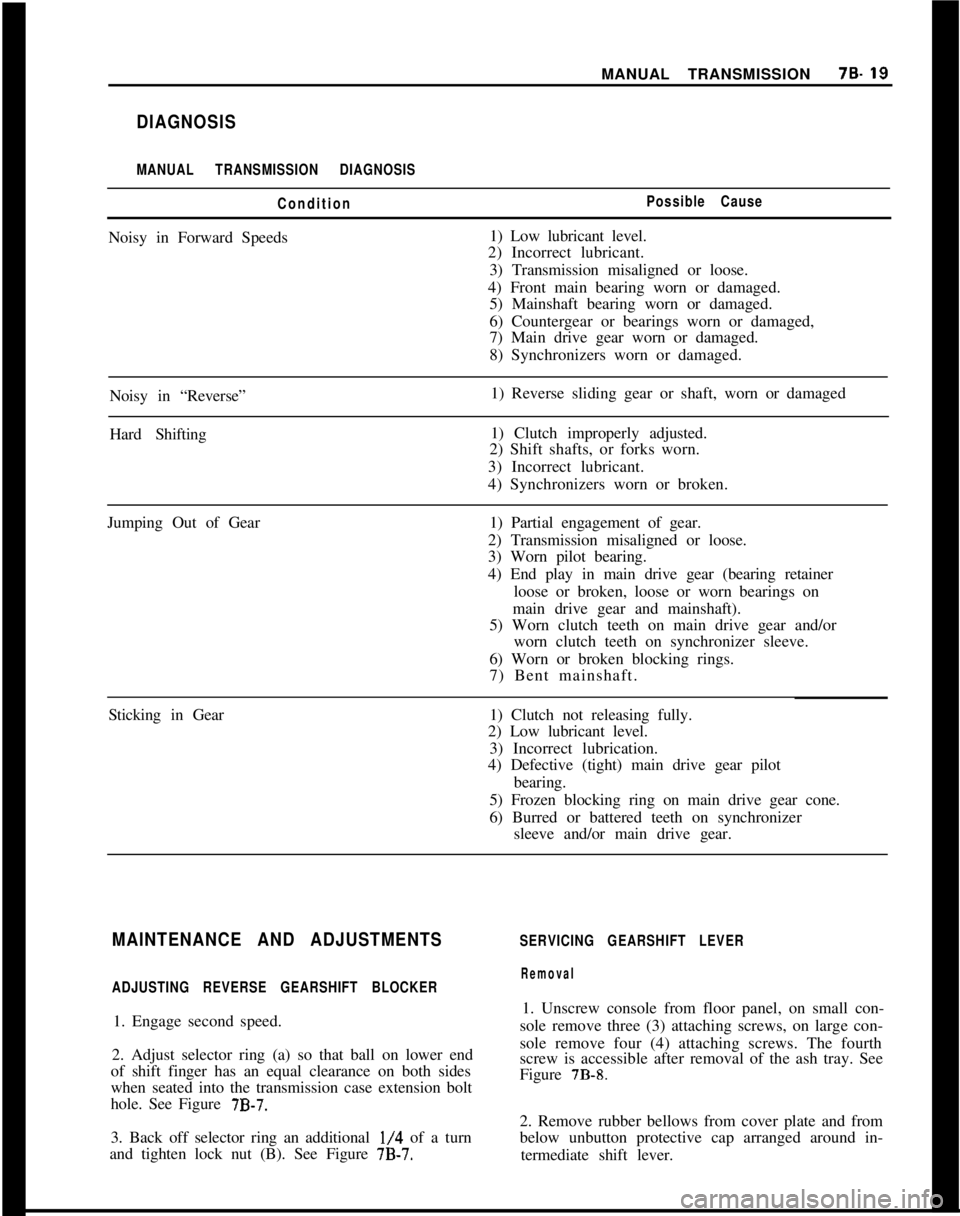

7A- 21973 OPEL SERVICE MANUALDIAGNOSIS

CLUTCH TROUBLE DIAGNOSIS

ConditionPossible Cause

CorrectionFails to release (pedal

1. Improper cable1. Adjust cable.

pressed to floor

- shiftadjustment.

lever does not move

freely in and out of

“Reverse” gear.

2. Faulty pilot bearing.2. Replace bearing.

3. Faulty driven plate.3. Replace driven plate.

4. Yoke off ball stud.4. Install properly.

5. Clutch driven plate hub5. Repair or replace main drive

binding on main drive gear

gear.spline.

Slipping1. Improper adjustment (no1. Adjust cable.

lash).2. Oil-soaked driven plate.2. Install new driven plate and

correct oil leak at its source.

3. Worn facing or facing3. Replace driven plate.tofn from driven plate.

4. Warped pressure plate or4. Replace same.

flywheel.

5. Weak diaphragm spring.5. Replace cover assembly.

6. Driven plate not seated6. Make 20-50 normal starts.

in.7. Driven plate overheated.7. Allow to cool

- check lash.

Grabbing1. Oil on facing or burned1. Repair oil leak and install

or glazed facings.new driven plate.

2. Worn splines on main2. Replace transmission main drive

drive gear.gear.

3. Loose engine mountings.3. Tighten or replace mountings.

4. Warped pressure plate or4. Replace pressure plate or

flywheel.flywheel.

5. Burned or smeared resin5. Sand off if superficial, replace

on flywheel or pressureburned or heat checked parts.

plate.

Page 380 of 625

MANUAL TRANSMISSION76.19

DIAGNOSIS

MANUAL TRANSMISSION DIAGNOSIS

ConditionPossible CauseNoisy in Forward Speeds1) Low lubricant level.

2) Incorrect lubricant.

3) Transmission misaligned or loose.

4) Front main bearing worn or damaged.

5) Mainshaft bearing worn or damaged.

6) Countergear or bearings worn or damaged,

7) Main drive gear worn or damaged.

8) Synchronizers worn or damaged.

Noisy in “Reverse”1) Reverse sliding gear or shaft, worn or damaged

Hard Shifting1) Clutch improperly adjusted.

2) Shift shafts, or forks worn.

3) Incorrect lubricant.

4) Synchronizers worn or broken.

Jumping Out of Gear1) Partial engagement of gear.

2) Transmission misaligned or loose.

3) Worn pilot bearing.

4) End play in main drive gear (bearing retainer

loose or broken, loose or worn bearings on

main drive gear and mainshaft).

5) Worn clutch teeth on main drive gear and/or

worn clutch teeth on synchronizer sleeve.

6) Worn or broken blocking rings.

7) Bent mainshaft.

Sticking in Gear1) Clutch not releasing fully.

2) Low lubricant level.

3) Incorrect lubrication.

4) Defective (tight) main drive gear pilot

bearing.

5) Frozen blocking ring on main drive gear cone.

6) Burred or battered teeth on synchronizer

sleeve and/or main drive gear.

MAINTENANCE AND ADJUSTMENTS

ADJUSTING REVERSE GEARSHIFT BLOCKER1. Engage second speed.

2. Adjust selector ring (a) so that ball on lower end

of shift finger has an equal clearance on both sides

when seated into the transmission case extension bolt

hole. See Figure

7B-7.3. Back off selector ring an additional

l/4 of a turn

and tighten lock nut (B). See Figure

7B-7.SERVICING GEARSHIFT LEVER

Removal1. Unscrew console from floor panel, on small con-

sole remove three (3) attaching screws, on large con-

sole remove four (4) attaching screws. The fourth

screw is accessible after removal of the ash tray. See

Figure

7B-8.2. Remove rubber bellows from cover plate and from

below unbutton protective cap arranged around in-

termediate shift lever.

Page 492 of 625

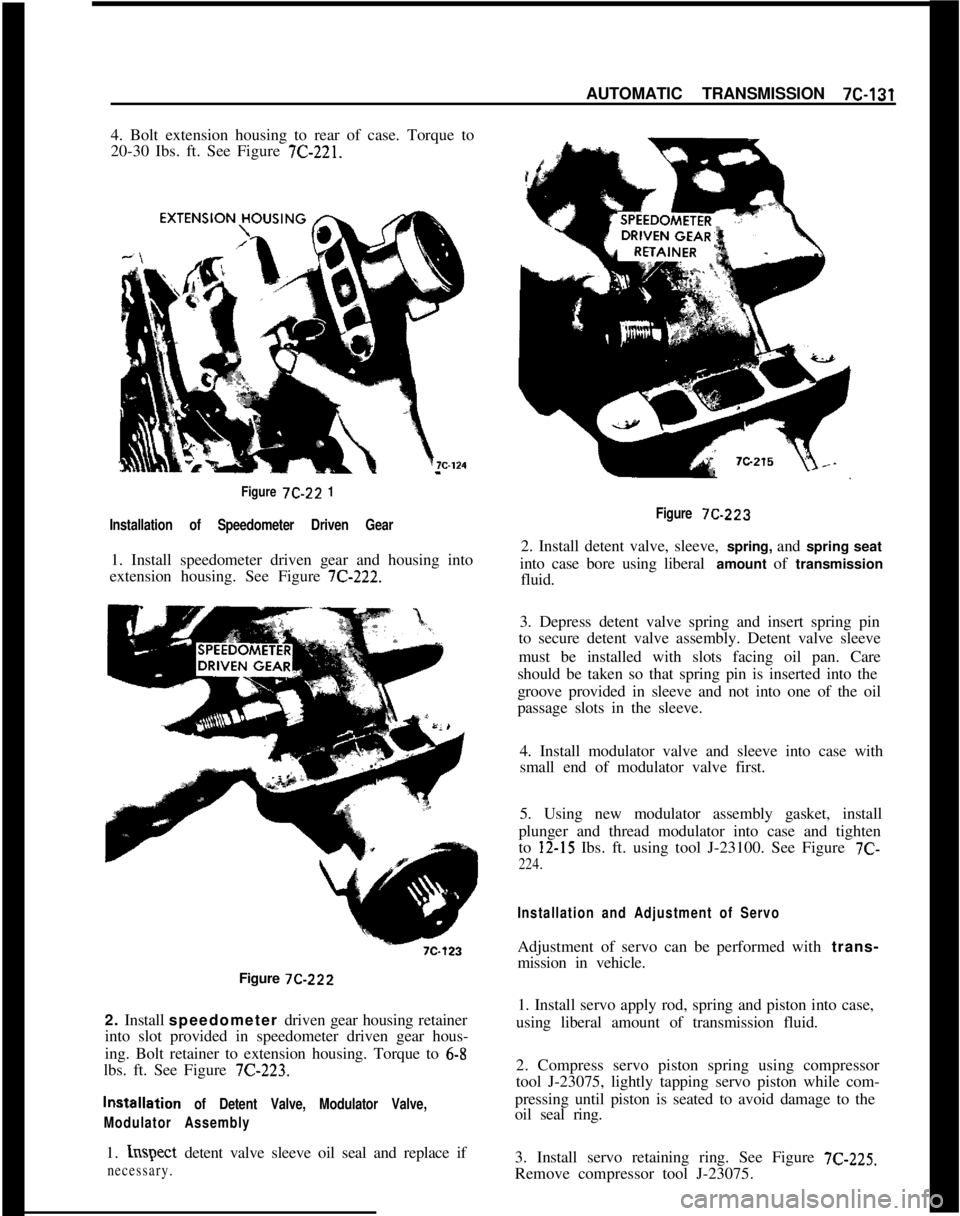

AUTOMATIC TRANSMISSION 7C-1314. Bolt extension housing to rear of case. Torque to

20-30 Ibs. ft. See Figure

7C-221.

Figure 7C-22

1

Installation of Speedometer Driven Gear1. Install speedometer driven gear and housing into

extension housing. See Figure

7C-222.Figure 7C-222

2. Install speedometer driven gear housing retainer

into slot provided in speedometer driven gear hous-

ing. Bolt retainer to extension housing. Torque to

6-Slbs. ft. See Figure

7C-223.

installation of Detent Valve, Modulator Valve,

Modulator Assembly1. inspect detent valve sleeve oil seal and replace if

necessary.Figure 7C-223

2. Install detent valve, sleeve, spring, and spring seat

into case bore using liberal amount of transmission

fluid.

3. Depress detent valve spring and insert spring pin

to secure detent valve assembly. Detent valve sleeve

must be installed with slots facing oil pan. Care

should be taken so that spring pin is inserted into the

groove provided in sleeve and not into one of the oil

passage slots in the sleeve.

4. Install modulator valve and sleeve into case with

small end of modulator valve first.

5. Using new modulator assembly gasket, install

plunger and thread modulator into case and tighten

to

12-15 Ibs. ft. using tool J-23100. See Figure 7C-

224.

Installation and Adjustment of ServoAdjustment of servo can be performed with trans-

mission in vehicle.

1. Install servo apply rod, spring and piston into case,

using liberal amount of transmission fluid.

2. Compress servo piston spring using compressor

tool J-23075, lightly tapping servo piston while com-

pressing until piston is seated to avoid damage to the

oil seal ring.

3. Install servo retaining ring. See Figure

7C-225.Remove compressor tool J-23075.

Page 570 of 625

REFRIGERANT COMPONENTS ALL MODELS96.61

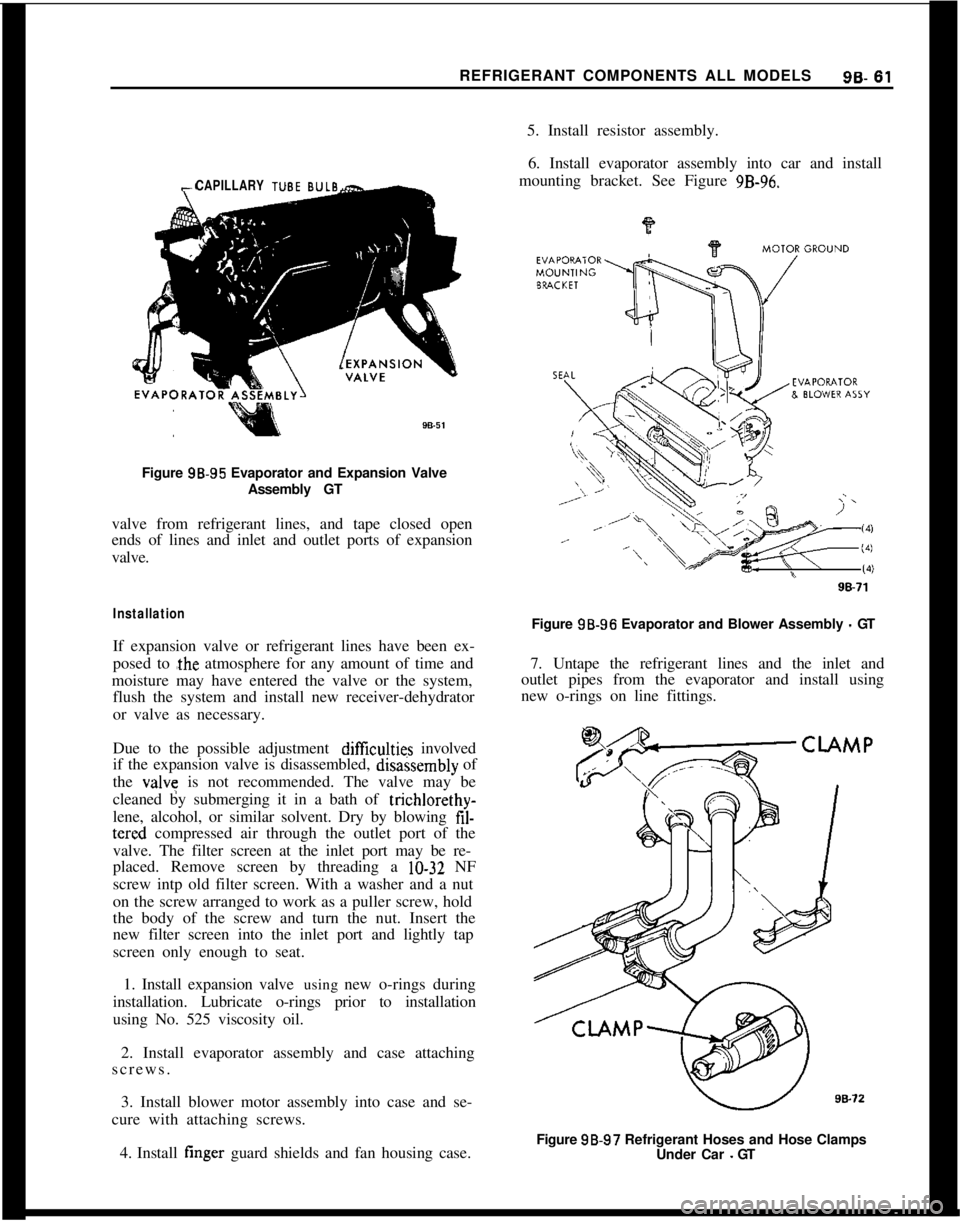

CAPILLARY T”BEFigure 98.95 Evaporator and Expansion Valve

Assembly GT

valve from refrigerant lines, and tape closed open

ends of lines and inlet and outlet ports of expansion

valve.

Installation5. Install resistor assembly.

6. Install evaporator assembly into car and install

mounting bracket. See Figure

9B-96.Figure 98.96 Evaporator and Blower Assembly

- GT

If expansion valve or refrigerant lines have been ex-

posed to

,the atmosphere for any amount of time and

moisture may have entered the valve or the system,

flush the system and install new receiver-dehydrator

or valve as necessary.7. Untape the refrigerant lines and the inlet and

outlet pipes from the evaporator and install using

new o-rings on line fittings.

Due to the possible adjustment difficulties involved

if the expansion valve is disassembled, disaisembly of

the valve is not recommended. The valve may be

cleaned by submerging it in a bath of trichlorethy-

lene, alcohol, or similar solvent. Dry by blowing iil-tered compressed air through the outlet port of the

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw intp old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws.

3. Install blower motor assembly into case and se-

cure with attaching screws.

4. Install finger guard shields and fan housing case.Figure 98-97 Refrigerant Hoses and Hose Clamps

Under Car

- GT

Page 621 of 625

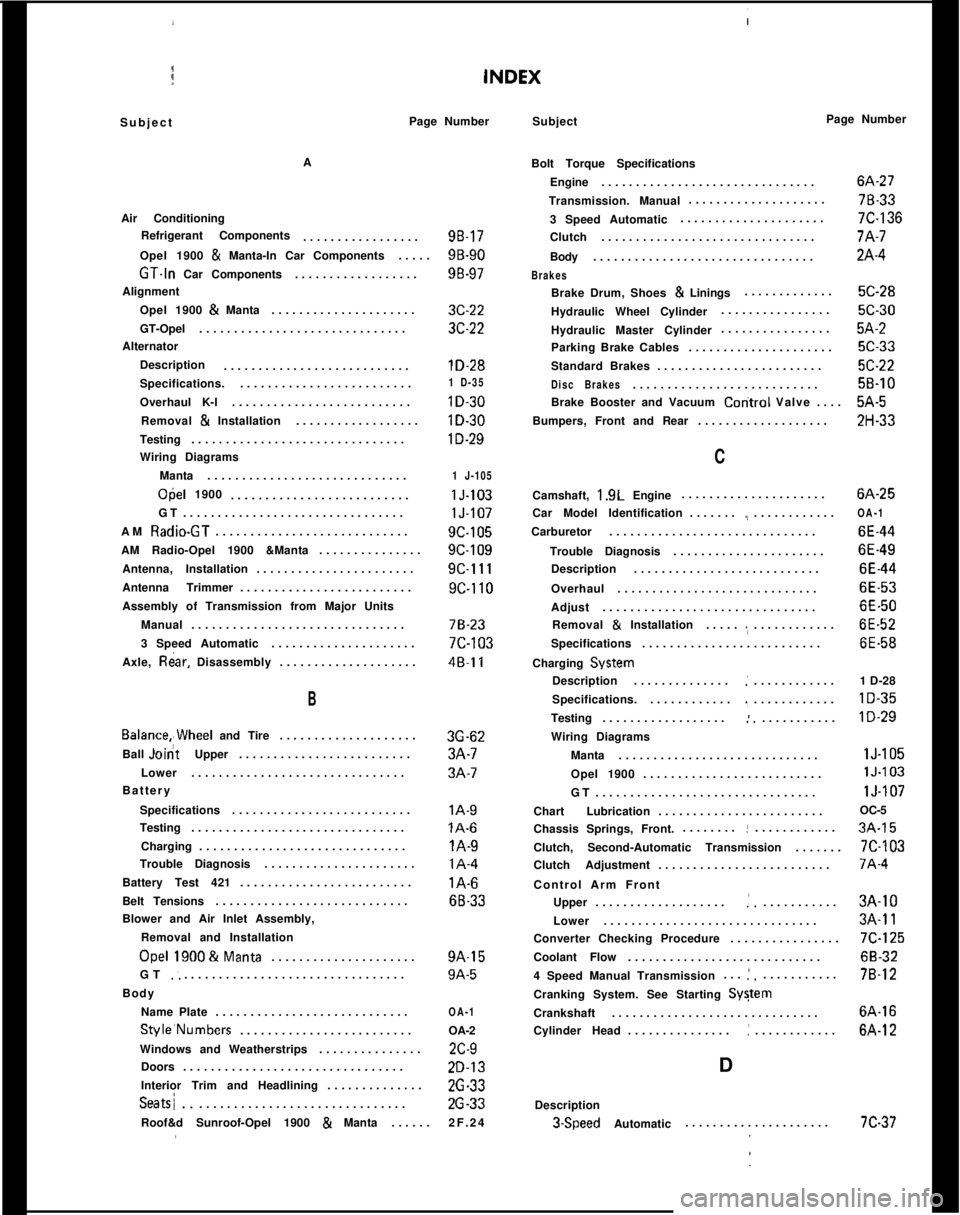

SubjectPage Number

Subject Page Number

A

Air Conditioning Refrigerant Components .................

98.17

Opel 1900

& Manta-In Car Components .....9B-90

GT.ln Car Components..................98-97

Alignment Opel 1900

& Manta .....................3C-22

GT-Opel ..............................

3C-22

Alternator Description ...........................

lD-28

Specifications. .........................1 D-35

Overhaul K-l..........................lD-30

Removal & Installation ..................lD-30

Testing...............................lD-29

Wiring Diagrams

Manta .............................

1 J-105

Opel 1900

..........................lJ-103

GT ................................

lJ-107

AM

Radio-GT............................9C-105

AM Radio-Opel 1900 &Manta ...............

9C-109

Antenna, Installation .......................

9C-111

Antenna Trimmer .........................

9C-110

Assembly of Transmission from Major Units Manual ...............................

78-23

3 Speed Automatic .....................

7C-103

Axle,

R&r, Disassembly ....................48~11

Bolt Torque Specifications

Engine ...............................

6A-27

Transmission. Manual ....................

78-33

3 Speed Automatic .....................

7C-136

Clutch ...............................

7A-7

Body ................................

2A-4

Brakes

Brake Drum, Shoes & Linings .............5C-28

Hydraulic Wheel Cylinder ................

5C-30

Hydraulic Master Cylinder ................

5A-2

Parking Brake Cables .....................

5C-33

Standard Brakes ........................

X-22

Disc Brakes...........................5B-10

Brake Booster and Vacuum

Coritrol Valve ....5A-5

Bumpers, Front and Rear ...................

ZH-33

C

B

Balance,,Wheel and Tire....................3G-62

Ball

J&tUpper .........................3A-7

Lower ...............................

3A-7

Battery

Specifications ..........................

lA-9

Testing...............................lA-6

Charging ..............................lA-9

Trouble Diagnosis ......................lA-4

Battery Test 421.........................l A-6

Belt Tensions ............................

68.33

Blower and Air Inlet Assembly, Removal and Installation

Owl 1900&Manta.....................9A-15

GT

.: ................................9A-5

Body Name Plate ............................

OA-1

Style’Numbers ......................... OA-2

Windows and Weatherstrips ...............

ZC-9

Doors ................................

ZD-13

Interior Trim and Headlining ..............

26-33

Seatsi................................26-33

Roof&d Sunroof-Opel 1900

& Manta ......2F.24 Camshaft,

1.9L

Engine .....................6A-25

Car Model Identification .......

.,............OA-1

Carburetor..............................6E-44

Trouble Diagnosis ......................

6E-49

Description ...........................

6E-44

Overhaul .............................

6E-53

Adjust ...............................

6E-50

Removal

& Installation ......,............6E-52

Specifications ..........................

6E-58

Charging

System

Description ..............

:............ 1 D-28

Specifications. ............

.,............lD-35

Testing..................:............lD-29

Wiring Diagrams

Manta .............................

lJ-105

Opel 1900 ..........................

lJ.103

GT ................................

lJ-107

Chart Lubrication ........................ OC-5

Chassis Springs, Front. ........

!............3A-15

Clutch, Second-Automatic Transmission .......

7C-103

Clutch Adjustment .........................

7A-4

Control Arm Front Upper ...................

:............3A-10

Lower ...............................

3A-11

Converter Checking Procedure ................

7C-125

Coolant Flow ............................

68-32

4 Speed Manual Transmission ...

!,...........7B-12

Cranking System. See Starting

SyStem

Crankshaft..............................6A-16

Cylinder Head ...............

:............6A-12

D

Description

3.Speed Automatic.....................7C-37

Page 624 of 625

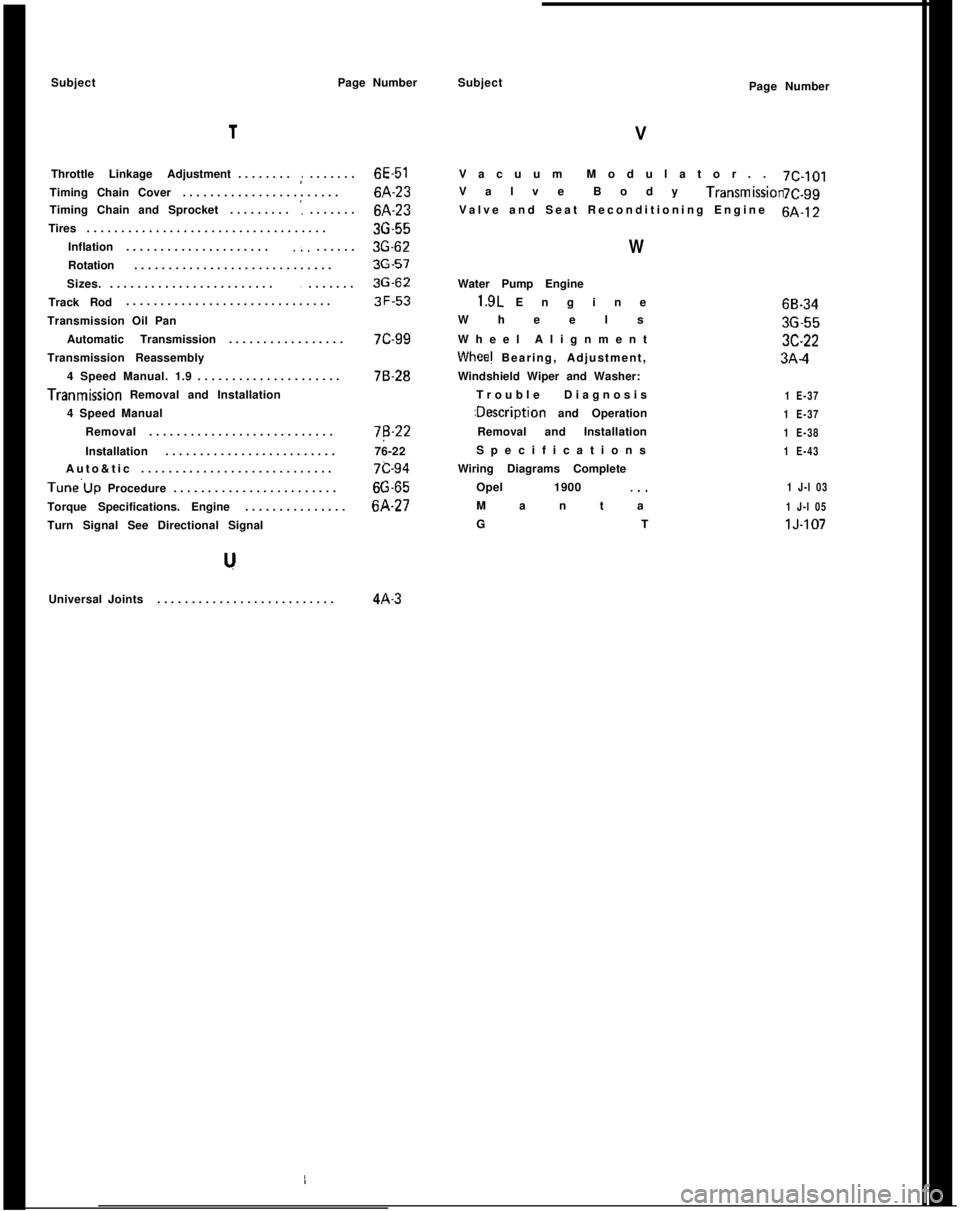

SubjectPage Number1

Throttle Linkage Adjustment........,:.......6E-51

Timing Chain Cover.......................6A-23

Timing Chain and Sprocket.........

':.......6A-23

Tires...................................36-55

Inflation.....................

.;.......3G-62

Rotation.............................36-57

Sizes.........................

........3G-62

Track Rod..............................3F-53

Transmission Oil Pan

Automatic Transmission.................7C-99

Transmission Reassembly

4 Speed Manual. 1.9.....................76-28Tranmission Removal and Installation

4 Speed Manual

Removal...........................7B-22

Installation.........................76-22

Auto&tic............................7c-94Tune’Up Procedure........................66-65

Torque Specifications. Engine...............6A-27

Turn Signal See Directional Signal

Universal Joints..........................4A-3Subject

VPage Number

Vacuum Modulator..7C-101

Valve Body Transmlssmn7C.99

Valve and Seat Reconditioning Engine6A-12

WWater Pump Engine1.9L Engine

Wheels

Wheel Alignment

Whee! Bearing, Adjustment,

Windshield Wiper and Washer:

Trouble Diagnosis:Description and Operation

Removal and Installation

Specifications

Wiring Diagrams Complete

Opel 1900 ._.

Manta

GT

1 E-37

1 E-37

1 E-38

1 E-43

1 J-l 03

1 J-l 05lJ-10768-3436-553C-223A-4