warning OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 94 of 625

I

/WIRING DIAGRAMS13-73ISeat Belt Warning System (Automatic

Page No.Transmission)

.GT.......................................................lJ-99HeatedRear Glass

.Opel1900.Manta...................15-100Heated Rear Glass

.GT..................................................*,lJ-101Opel 1900 Color Schematic.........................................

lJ-103Manta

ColorSchematic.................................................1 J-105GT

ColorSchematic

.........................................................1 J-107

Page 100 of 625

I

WIRING DIAGRAMS15.79

IIFigure lJ-6

Oil. Fuel. Temp. Tach, Stop and Brake Warning Light. GT

I

Page 118 of 625

WIRING DIAGRAMSlJ- 97

cI

&N

/I

IFigure 1 J-24 Seat Belt Warning System (Automatic Transmission) Opel 1900 Manta

Page 120 of 625

WIRING DIAGRAMSlJ-99Figure

lJ-26 Seat Belt Warning System (Automatic Transmissionl - GT

Page 273 of 625

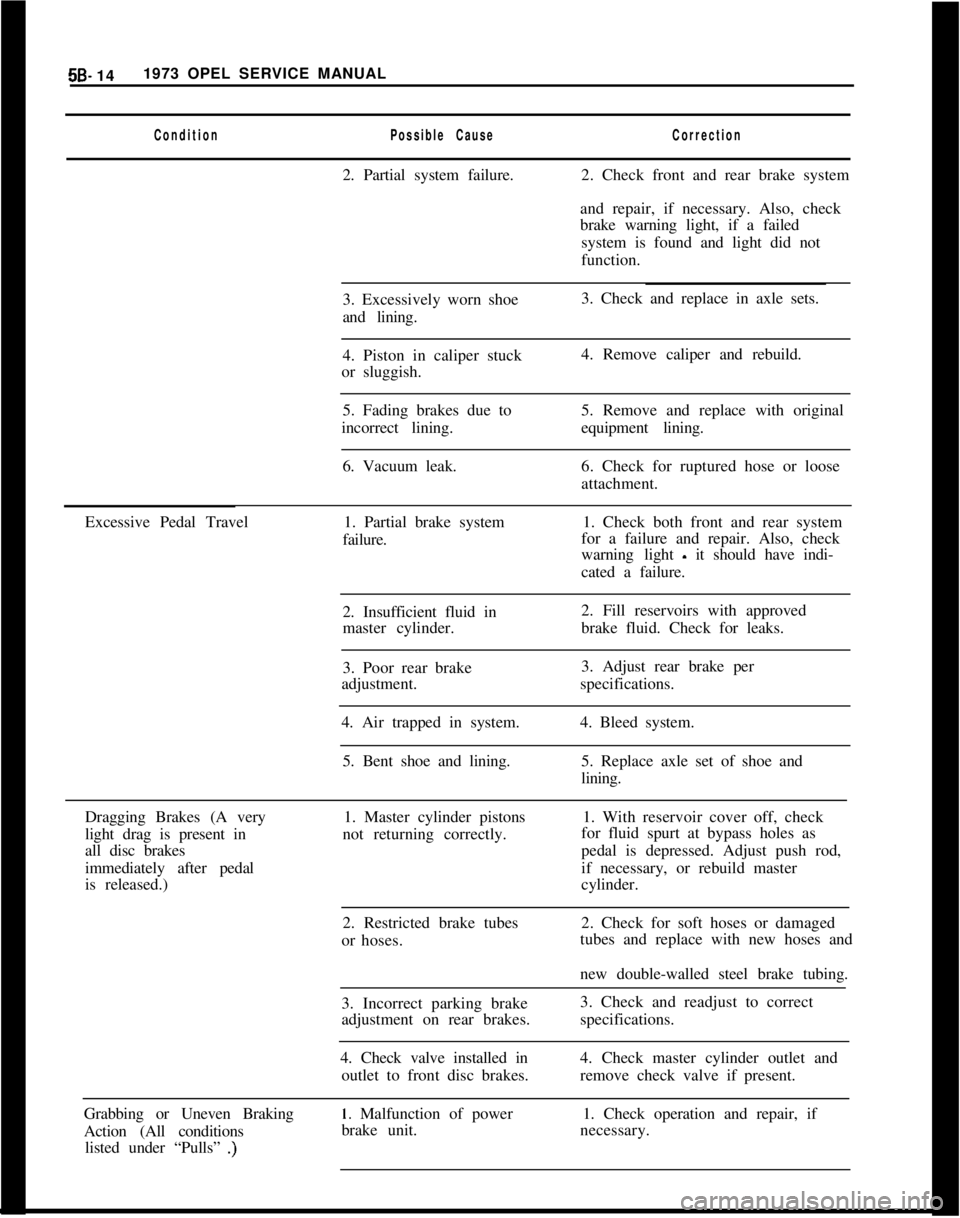

5B- 141973 OPEL SERVICE MANUALConditionPossible CauseCorrection2. Partial system failure.2. Check front and rear brake system

and repair, if necessary. Also, check

brake warning light, if a failed

system is found and light did not

function.

3. Excessively worn shoe

and lining.3. Check and replace in axle sets.

4. Piston in caliper stuck

or sluggish.4. Remove caliper and rebuild.

5. Fading brakes due to

incorrect lining.

6. Vacuum leak.5. Remove and replace with original

equipment lining.

6. Check for ruptured hose or loose

attachment.

Excessive Pedal Travel1. Partial brake system

failure.1. Check both front and rear system

for a failure and repair. Also, check

warning light

- it should have indi-

cated a failure.

2. Insufficient fluid in

master cylinder.

3. Poor rear brake

adjustment.2. Fill reservoirs with approved

brake fluid. Check for leaks.

3. Adjust rear brake per

specifications.

4. Air trapped in system.4. Bleed system.

5. Bent shoe and lining.5. Replace axle set of shoe and

lining.

Dragging Brakes (A very

light drag is present in

all disc brakes

immediately after pedal

is released.)1. Master cylinder pistons

not returning correctly.1. With reservoir cover off, check

for fluid spurt at bypass holes as

pedal is depressed. Adjust push rod,

if necessary, or rebuild master

cylinder.

2. Restricted brake tubes2. Check for soft hoses or damaged

or hoses.tubes and replace with new hoses and

new double-walled steel brake tubing.

3. Incorrect parking brake

adjustment on rear brakes.3. Check and readjust to correct

specifications.

Grabbing or Uneven Braking

Action (All conditions

listed under “Pulls”

.)4. Check valve installed in

outlet to front disc brakes.

1. Malfunction of power

brake unit.4. Check master cylinder outlet and

remove check valve if present.

1. Check operation and repair, if

necessary.

Page 323 of 625

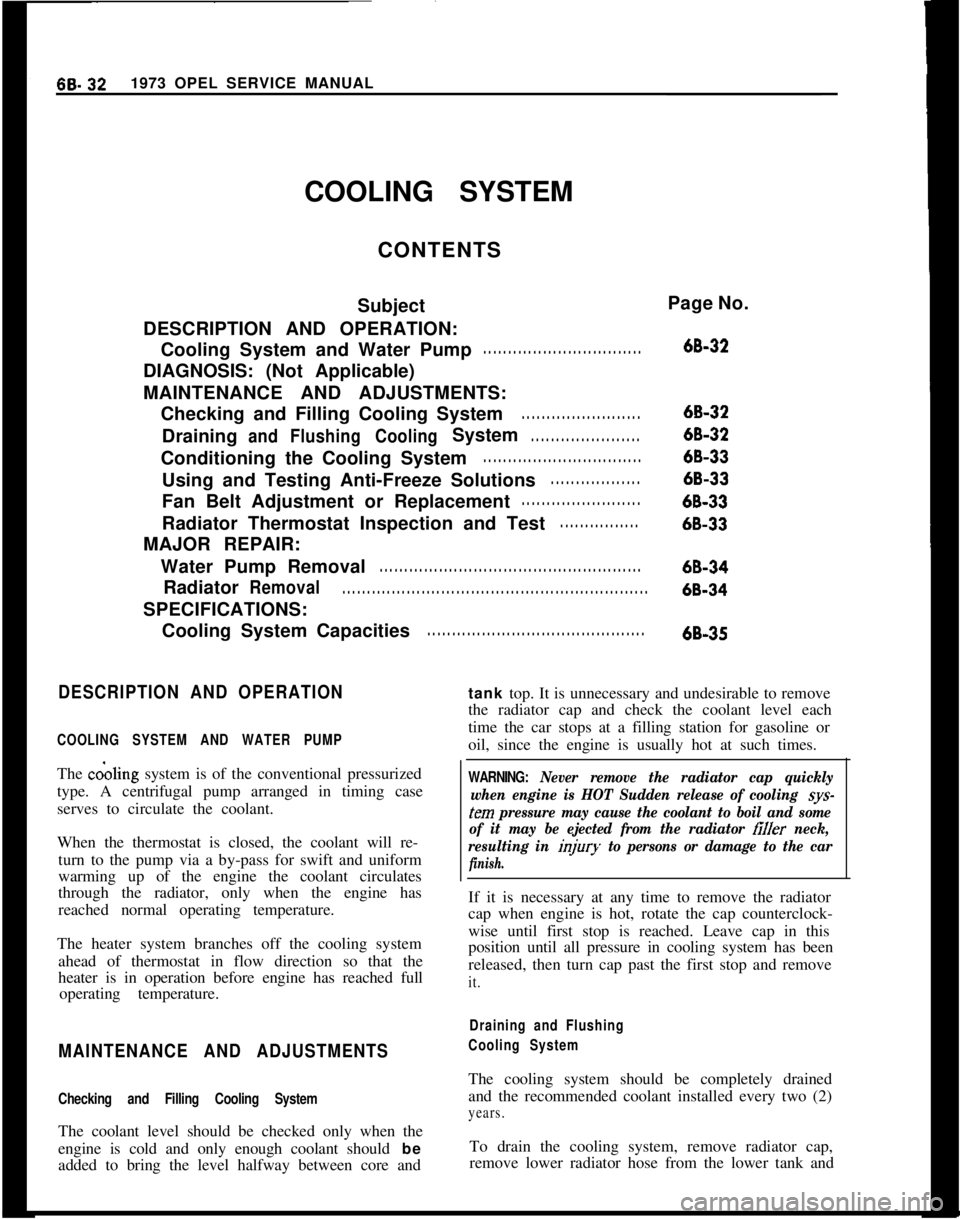

66.321973 OPEL SERVICE MANUAL

COOLING SYSTEM

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Cooling System and Water Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Checking and Filling Cooling System

. . . . . . . . . . . . . . . . . . . . . . . .Draining

andFlushingCoolingSystem. . . . . . . . . . . . . . . . . . . . . .Conditioning the Cooling System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using and Testing Anti-Freeze Solutions

. . . . . . . . . . . . . . . . . .Fan Belt Adjustment or Replacement

. . . . . . . . . . . . . . . . . . . . . . . .Radiator Thermostat Inspection and Test

. . . . . . . . . . . . . . . .MAJOR REPAIR:

Water Pump Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radiator

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Cooling System Capacities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

68-32

6B-32

68-32

68-33

68-33

68-33

68-33

68-34

68-34

6B-35

DESCRIPTION AND OPERATION

COOLING SYSTEM AND WATER PUMPThe coiling system is of the conventional pressurized

type. A centrifugal pump arranged in timing case

serves to circulate the coolant.

When the thermostat is closed, the coolant will re-

turn to the pump via a by-pass for swift and uniform

warming up of the engine the coolant circulates

through the radiator, only when the engine has

reached normal operating temperature.

The heater system branches off the cooling system

ahead of thermostat in flow direction so that the

heater is in operation before engine has reached full

operating temperature.

MAINTENANCE AND ADJUSTMENTS

Checking and Filling Cooling SystemThe coolant level should be checked only when the

engine is cold and only enough coolant should be

added to bring the level halfway between core andtank top. It is unnecessary and undesirable to remove

the radiator cap and check the coolant level each

time the car stops at a filling station for gasoline or

oil, since the engine is usually hot at such times.

WARNING: Never remove the radiator cap quickly

when engine is HOT Sudden release of cooling

sys-

tern pressure may cause the coolant to boil and some

of it may be ejected from the radiator

filler neck,

resulting in

inl’ury to persons or damage to the car

finish.If it is necessary at any time to remove the radiator

cap when engine is hot, rotate the cap counterclock-

wise until first stop is reached. Leave cap in this

position until all pressure in cooling system has been

released, then turn cap past the first stop and remove

it.

Draining and Flushing

Cooling SystemThe cooling system should be completely drained

and the recommended coolant installed every two (2)

years.To drain the cooling system, remove radiator cap,

remove lower radiator hose from the lower tank and

Page 324 of 625

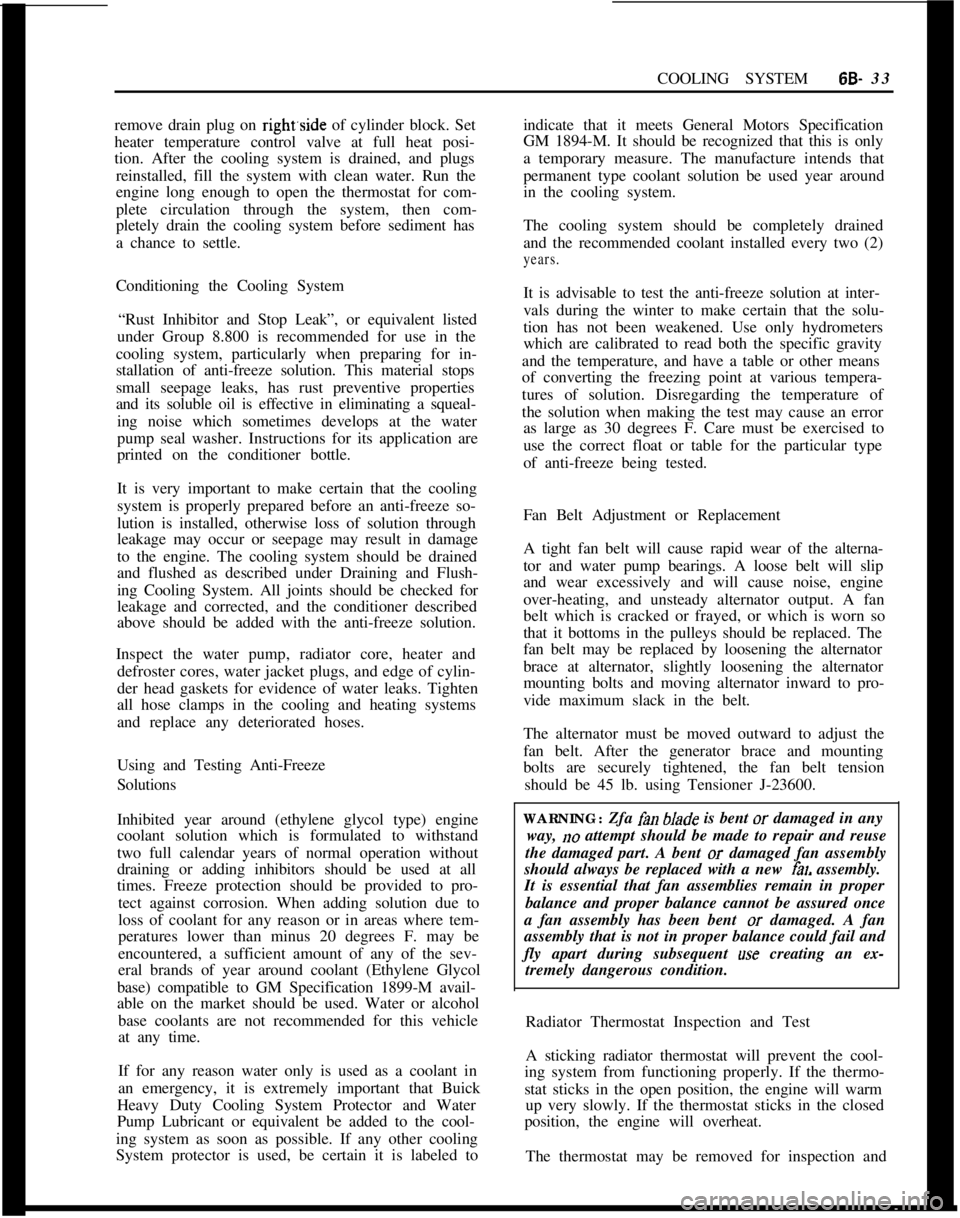

COOLING SYSTEM6B- 33

remove drain plug on right.side of cylinder block. Set

heater temperature control valve at full heat posi-

tion. After the cooling system is drained, and plugs

reinstalled, fill the system with clean water. Run the

engine long enough to open the thermostat for com-

plete circulation through the system, then com-

pletely drain the cooling system before sediment has

a chance to settle.

Conditioning the Cooling System

“Rust Inhibitor and Stop Leak”, or equivalent listed

under Group 8.800 is recommended for use in the

cooling system, particularly when preparing for in-

stallation of anti-freeze solution. This material stops

small seepage leaks, has rust preventive properties

and its soluble oil is effective in eliminating a squeal-

ing noise which sometimes develops at the water

pump seal washer. Instructions for its application are

printed on the conditioner bottle.

It is very important to make certain that the cooling

system is properly prepared before an anti-freeze so-

lution is installed, otherwise loss of solution through

leakage may occur or seepage may result in damage

to the engine. The cooling system should be drained

and flushed as described under Draining and Flush-

ing Cooling System. All joints should be checked for

leakage and corrected, and the conditioner described

above should be added with the anti-freeze solution.

Inspect the water pump, radiator core, heater and

defroster cores, water jacket plugs, and edge of cylin-

der head gaskets for evidence of water leaks. Tighten

all hose clamps in the cooling and heating systems

and replace any deteriorated hoses.

Using and Testing Anti-Freeze

Solutions

Inhibited year around (ethylene glycol type) engine

coolant solution which is formulated to withstand

two full calendar years of normal operation without

draining or adding inhibitors should be used at all

times. Freeze protection should be provided to pro-

tect against corrosion. When adding solution due to

loss of coolant for any reason or in areas where tem-

peratures lower than minus 20 degrees F. may be

encountered, a sufficient amount of any of the sev-

eral brands of year around coolant (Ethylene Glycol

base) compatible to GM Specification 1899-M avail-

able on the market should be used. Water or alcohol

base coolants are not recommended for this vehicle

at any time.

If for any reason water only is used as a coolant in

an emergency, it is extremely important that Buick

Heavy Duty Cooling System Protector and Water

Pump Lubricant or equivalent be added to the cool-

ing system as soon as possible. If any other cooling

System protector is used, be certain it is labeled toindicate that it meets General Motors Specification

GM 1894-M. It should be recognized that this is only

a temporary measure. The manufacture intends that

permanent type coolant solution be used year around

in the cooling system.

The cooling system should be completely drained

and the recommended coolant installed every two (2)years.It is advisable to test the anti-freeze solution at inter-

vals during the winter to make certain that the solu-

tion has not been weakened. Use only hydrometers

which are calibrated to read both the specific gravity

and the temperature, and have a table or other means

of converting the freezing point at various tempera-

tures of solution. Disregarding the temperature of

the solution when making the test may cause an error

as large as 30 degrees F. Care must be exercised to

use the correct float or table for the particular type

of anti-freeze being tested.

Fan Belt Adjustment or Replacement

A tight fan belt will cause rapid wear of the alterna-

tor and water pump bearings. A loose belt will slip

and wear excessively and will cause noise, engine

over-heating, and unsteady alternator output. A fan

belt which is cracked or frayed, or which is worn so

that it bottoms in the pulleys should be replaced. The

fan belt may be replaced by loosening the alternator

brace at alternator, slightly loosening the alternator

mounting bolts and moving alternator inward to pro-

vide maximum slack in the belt.

The alternator must be moved outward to adjust the

fan belt. After the generator brace and mounting

bolts are securely tightened, the fan belt tension

should be 45 lb. using Tensioner J-23600.

WARNING: Zfa

fan blade is bent or damaged in any

way, no attempt should be made to repair and reuse

the damaged part. A bent or damaged fan assembly

should always be replaced with a new

fal. assembly.

It is essential that fan assemblies remain in proper

balance and proper balance cannot be assured once

a fan assembly has been bent or damaged. A fan

assembly that is not in proper balance could fail and

fly apart during subsequent

we creating an ex-

tremely dangerous condition.

Radiator Thermostat Inspection and Test

A sticking radiator thermostat will prevent the cool-

ing system from functioning properly. If the thermo-

stat sticks in the open position, the engine will warm

up very slowly. If the thermostat sticks in the closed

position, the engine will overheat.

The thermostat may be removed for inspection and

Page 362 of 625

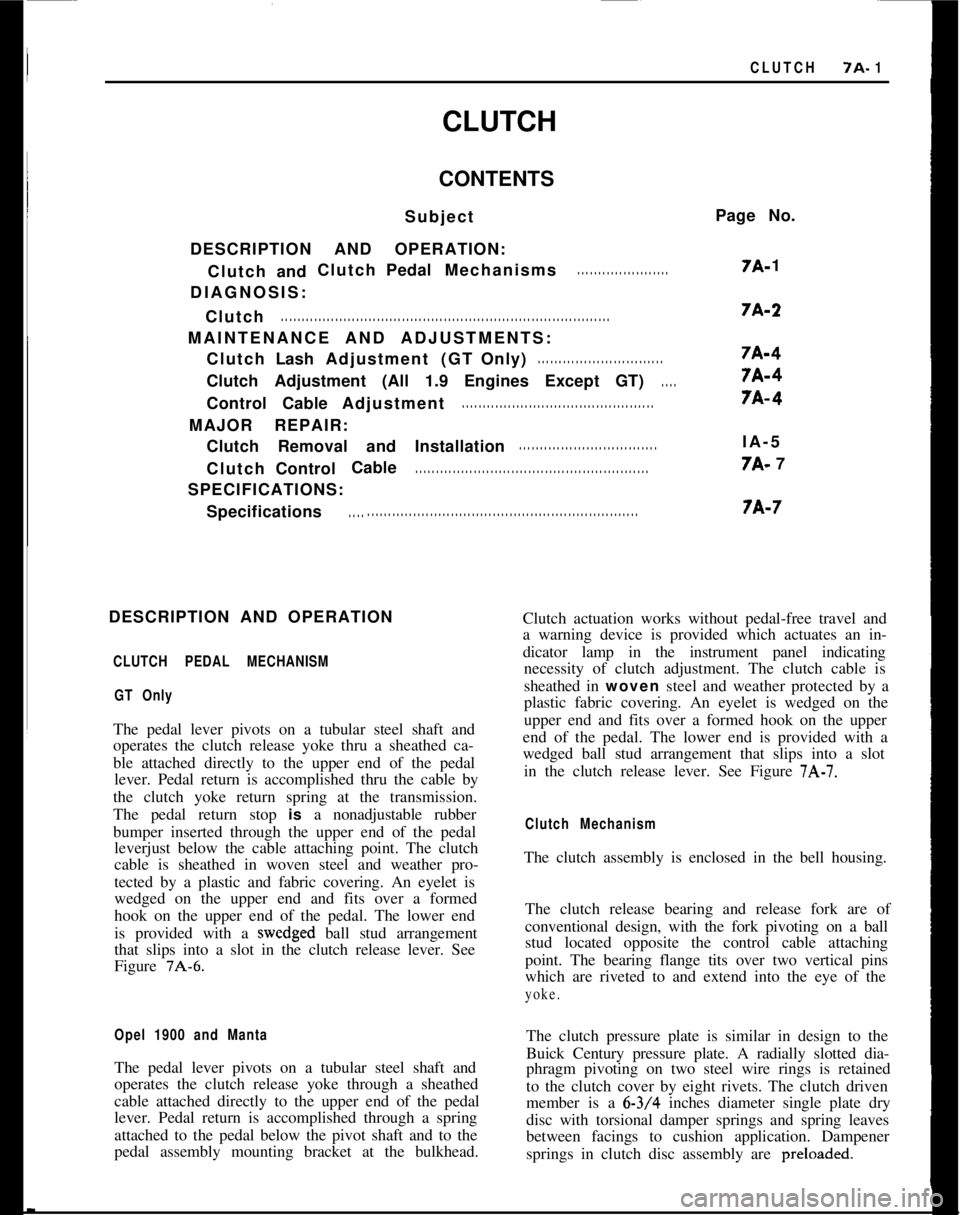

CLUTCH7A. 1

CLUTCH

CONTENTS

Subject

DESCRIPTION AND OPERATION: Clutch andClutch

PedalMechanisms

. . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS:

Clutch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .

MAINTENANCE AND ADJUSTMENTS: Clutch LashAdjustment (GTOnly)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Adjustment (All 1.9 Engines Except GT). . . .

Control CableAdjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .

MAJOR REPAIR:

Clutch Removal and Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Control Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS:

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No.

7A-

1

7A-2

7A-4

7A-4

7A-4

IA-5

7A- 7

7A-7

DESCRIPTION AND OPERATION

CLUTCH PEDAL MECHANISM GT Only

The pedal lever pivots on a tubular steel shaft and

operates the clutch release yoke thru a sheathed ca-

ble attached directly to the upper end of the pedallever. Pedal return is accomplished thru the cable by

the clutch yoke return spring at the transmission.

The pedal return stop

is a nonadjustable rubber

bumper inserted through the upper end of the pedal leverjust below the cable attaching point. The clutch

cable is sheathed in woven steel and weather pro-

tected by a plastic and fabric covering. An eyelet is

wedged on the upper end and fits over a formed

hook on the upper end of the pedal. The lower end

is provided with a

wedged ball stud arrangement

that slips into a slot in the clutch release lever. See

Figure

7A-6.

Opel 1900 and Manta

The pedal lever pivots on a tubular steel shaft and

operates the clutch release yoke through a sheathed

cable attached directly to the upper end of the pedal

lever. Pedal return is accomplished through a spring

attached to the pedal below the pivot shaft and to the

pedal assembly mounting bracket at the bulkhead. Clutch actuation works without pedal-free travel and

a warning device is provided which actuates an in-

dicator lamp in the instrument panel indicating

necessity of clutch adjustment. The clutch cable is

sheathed in

woven steel and weather protected by a

plastic fabric covering. An eyelet is wedged on the

upper end and fits over a formed hook on the upper

end of the pedal. The lower end is provided with a

wedged ball stud arrangement that slips into a slot in the clutch release lever. See Figure

7A-7.

Clutch Mechanism

The clutch assembly is enclosed in the bell housing.

The clutch release bearing and release fork are of

conventional design, with the fork pivoting on a ball

stud located opposite the control cable attaching

point. The bearing flange tits over two vertical pins

which are riveted to and extend into the eye of the

yoke.

The clutch pressure plate is similar in design to the

Buick Century pressure plate. A radially slotted dia-

phragm pivoting on two steel wire rings is retained

to the clutch cover by eight rivets. The clutch driven

member is a

6-3/4 inches diameter single plate dry

disc with torsional damper springs and spring leaves

between facings to cushion application. Dampener

springs in clutch disc assembly are

preloaded.

Page 541 of 625

98-32 1973 OPEL SERVICE MANUAL

inserting it in the connection. Another precaution -inspect the fitting for burrs which can cut the

“0”ring.

Restrictions

Restrictions may be due to powdered desiccant or

dirt and foreign matter. This may result in starved

evaporator and loss of cooling, or a seized compres-

SOT.When the amount of moisture in a system sufti-

ciently exceeds the capacity of the desiccant, it can

break down the desiccant and cause it to powder.

The powder passes through the dehydrator screen

with the refrigerant liquid and is carried to the ex-

pansion valve screen. While some of it may pass

through the valve screen into the evaporator, it may

quickly build up to cause a restriction.

Due to the fact that sufftcient oil can not be returned

to the compressor, it may seize.

Dirt

Dirt, which is any foreign material, may come from

cleaner residues, cutting, machining, or preserving

oils, metal dust or chips, lint or dust, loose rust,

soldering or brazing fluxes, paint or loose oxide

scale. These can also cause seized bearings by abra-

sion or wedging, discharge and expansion valve fail-

ure, decomposition of refrigerant and oil, or

corrosion of metal parts.

CorrosionCorrosion and its by-products can restrict valve and

drier screens, rough bearing surfaces or rapid fatigu-

ing of discharge reeds. This can result in high tem-

perature and pressure, decomposition or leaks. In

any event, this means a wrecked compressor.

From this, we can see the vicious circle that can be

produced in a refrigerating system to cause its fail-

ure. Corrosion can be the indirect cause of leaks, and

leaks can be the direct cause of corrosion. We can

also see the important role we as servicemen play in

maintaining chemical stability.

The major cause of corrosion is moisture.

Moisture

Moisture is the greatest enemy of refrigerating sys-

tems. Combined with metal, it produces oxide, Iron

Hydroxide and Aluminum Hydroxide. Combined

with R-12 it produces Carbonic acid, Hydrochloric

acid, and Hydrofluoric acid. Moisture can also cause

freeze-up of expansion valve and powdered desic-

cant.Although high temperature and dirt are responsible

for many difficulties in refrigerating systems, in most

instances it is the presence of moisture in the system

that accelerates these conditions. It can be said,themfore, that moisture is the greatest enemy of all.

The acids that it produces, in combination with both

the metals and the refrigerant, cause damaging

COT-

rosion. While the corrosion may not form as rapidly

with R-12 as with some other refrigerants, the even-

tual formation is as damaging.

If the operating pressure and temperature in the

evaporator is reduced to the freezing point, moisture

in the refrigerant can collect at the orifice of the

expansion valve and freeze. This temporarily re-

stricts the flow of liquid causing erratic cooling.

As previously mentioned, moisture in excess of the

desiccant’s capacity can cause it to powder.

YOU SHOULD KNOW AND REMEMBER..That the inside of the refrigerat,ion system is com-

pletely sealed from the outside world. And if that

seal remains broken at any point

- the system will

soon be destroyed. That complete and positive seal-

ing of the entire system is vitally important and that

this sealed condition is absolutely necessary to retain

the chemicals and keep them in a pure and proper

condition.

That all parts of the refrigeration system are under

pressure at all times, whether operating or idle, and

that any leakage. points are continuously losing re-

frigerant and oil.

That the leakage of refrigerant can be so silent that

the complete charge may be lost without warning.

That refrigerant gas is heavier than air and will rap-

idly drop to the floor as it flows from a point of

leakage.

That the pressure in the system may momentarily

become as high as 400 lbs. per square inch, and that

under such pressure the molecules of refrigerant are

forced out through the smallest opening or pore.

That the compressor is continually giving up some

lubricating oil to the circulating refrigerant and de-

pends upon oil in the returning refrigerant for con-

tinuous replenishment. Any stoppage or major loss

of refrigerant will therefore be fatal to the compres-

SOT.That the extreme internal dryness of a properly proc-

essed system is a truly desert condition, with the

drying material in the receiver holding tightly on to

the tiny droplets of residual moisture.

Page 548 of 625

REFRIGERANT COMPONENTS ALL MODELS96-39

In all instances where the indications of refrigerant

shortage continues, additional refrigerant should be

added in

l/4 lb. increments until the sight glass is

clear.

An additional charge of l/4 lb. should be ad-

ded as a reserve. In no case should the system be

overcharged.

LEAK TESTING SYSTEM

The following two methods are recommended when attempting to locate refrigerant leaks in the system.

Loss of

regrigerant is always indicative of a leak since

refrigerant is not consumed and does not wear out.

1. Open Flame Method

- This method utilizes a gas

operated torch type leak detector (J-6084). Use of

this method is recommended when checking for

leaks in confined areas. To perform test, light torch

and adjust to obtain a pale blue flame, approximately

3/8 inch in height, in burner.

Explore for leaks by moving end of search tube

around suspected area. Check bottom of connections

since Refrigerant-12 is heavier than air and will be more apparent at underside of fittings. The flame

color will turn yellow-green when a small leak is

detected. Large leaks will turn the flame blue or

purple.

WARNING:

Do not breathe fumes resdting from

burning of

refrigerant gas. These fumes az ex-

tremeiy poisonous.

2. Liquid Leak Detectors - This method utilizes a

solution which will bubble (soap solution) to signify

a gas leak. Use of this method of checking is recom-

mended for locating small leaks.

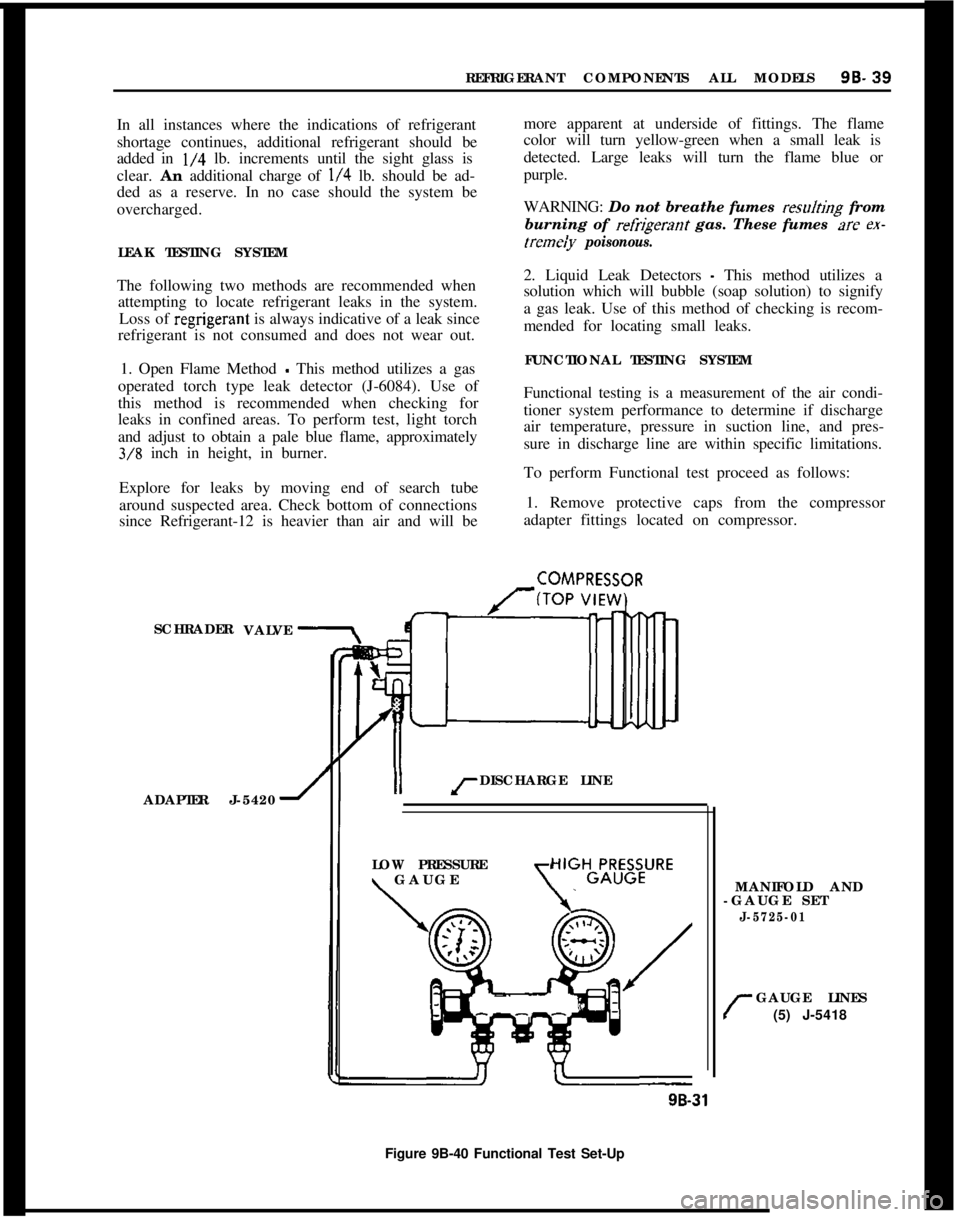

FUNCTIONAL TESTING SYSTEM

Functional testing is a measurement of the air condi-

tioner system performance to determine if discharge

air temperature, pressure in suction line, and pres-

sure in discharge line are within specific limitations.

To perform Functional test proceed as follows:

1. Remove protective caps from the compressor

adapter fittings located on compressor.

SCHRADER

ADAPTER J-5420

1II rDISCHARGE LINE

COMPRESSOR

VALVE

LOW PRESSURE

\ GAUGE\

HIGHGLR;B;URE

MANIFOLD AND

-GAUGE SET

J-5725-01

r

GAUGE LINES

(5) J-5418

9B-31

Figure 9B-40 Functional Test Set-Up