wiring OPEL 1900 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 56 of 625

CHARGING SYSTEMlD- 35

’Figure lD-25 Installing Diode

I

7. Instail rotor together with drive end frame intostator and assemble generator in reverse order ofdisasse+bly. Make sure marks made during disas-

sembly

+-ire aligned.

8. Insta!l pulley and fan. Tighten nut to 30 lb.ft.

9. Test benerator on test bench, if available. If not,

install alternator on car and test.

Alternator Installation

1. Hold /alternator in position and install pivot bolt,

plain washer, lockwasher and nut finger tight.

2. Install alternator belt.

3. Install adjusting brace bolt, lockwasher, plain

washer and nut finger tight.

4.

Posit& a belt tension gage such as Gage J- 23600Figure 1 D-26 Alternator Installation

on belt. Pull alternator outward until gage reads 45

Ibs., then tighten adjusting brace bolt.

5. Tighten alternator pivot bolt.

6. Connect battery lead to alternator.

7. Plug three-way wiring connector into alternator

and engage safety catch.8. Connect battery ground strap.SPECkICATIONS

ALTERNATOR

35, AMPAlternatorNumberRated

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Kl 14V35AZOOutputinVolts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14ContinuousRatedOutputinAmperes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Test Output in Amperes at

2000 Engine RPM. . . . . . . . ..__.._...........................................23 Min.RksistanceofFieldCoilinOhms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4.4Resistanceof StatorWindingsinOhms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-29AlternatorPulleyNutTorqueinLb.Ft.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

BfltTensioninPounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

REGULATORRegulatorNumber

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ADl/14V

Regulator Setting in Volts at 2500 Engine R.P.M.

. . . . . . . . . . ..___................................14 f .5

Page 68 of 625

LIGHTING SYSTEMSlF-472. Install switch in panel.

3. Replace instrument cluster cover.

EXTERIOR LIGHTSModels 51-53-54

Headlamp Sealed Beam Unit Removal1. Remove two screws on headlight ring.

2. Remove four screws holding headlight retainer to

body. See Figure lF-3.

Figure 1 F-l Removing Headlight Switch

I

3.

Rep& two (2) plugs over screws and replace

heater control knobs.

FOG LIGHT OR HEATED REAR GLASS SWITCHRemoval I

1. Removd instrument cluster cover. See Section H.

I

2. Press

ddwn retaining clip and pull switch out. See

Figure lF-2.

Figure 1 F-3 - Removing Headlight Retainer

- Models

51-53-54

3. Disconnect wiring connectors,

4. Remove headlight from inside engine compart-

ment.

Figure 1Fi2 - Removal of Fog Light or Heated Rear

Glass Switch

3. Removelwires from switch.

Installation/

1. Connect;wire to switch,

Installation1. Plug in wiring connector on sealed beam and re-

place four (4) headlight retaining screws.

2. Replace headlight ring.

Models 57-57R

Removal

I. Disconnect wiring connector.

2. Remove four screws holding headlight retainer

from inside engine compartment.

Page 69 of 625

1~- 48 1973 OPEL SERVICE: MANUAL/

3. Disassemble headlight assembly from retaini+g

ring. See Figure lF-4.

i

tFigure 1 F-4

- Headlight Assembly - Models 57.57R

Installation1. Assemble headlight to retaining rings.;

2. Install to body from inside engine compartmept

with four (4) screws.

3. Connect wiring harness.

Parking Light Housing or Lens Removal1. Remove two screws holding lamp lens.:

2. Remove two screws holding housing. See FigurelF- 5.

Figure lF-5 Remove Parking Light Housing

3. Disconnect wiring harness.1. Apply sealer to housing

2. Connect wiring harness.

3. Replace housing in body with two (2) retaining

screws.4. Replace lamp lens.

REAR STOP, TAIL, DIRECTIONAL SIGNAL, OR

BACK-UP LAMP HOUSINGMod&

J-I-53

Removal1. In luggage compartment, unscrew housing attach-

ing nuts. See Figure lF-6.

Figure lF-6 Tail Light Housing Attaching Nuts

Models 5 1-53

Figure lF-7

- Removing Tgil Light Lens - Models

51.53

Page 70 of 625

LIGHTING SYSTEMSlF-492. Take

Le:s off housing. See Figure lF-7.

3. Remove housing.1

Installation;I

1. Install

le$ in housing.

2. Replace

+.Model 54

;,

1, Remove Ilamp lens from outside.

/

2. Remove kear quarter trim pad.

/

3. Remove

ifour screws from inside car. See FigurelF- 8.

Figure 1 F-8

I- Removing Tail Light Housing - Model 54

I

4. Disconnkct wiring connector.

I

1. Connect iwiring to lamp

2. Install hbusing using four (4)

scre%s.3. Replace

p quarter trim pad

4. Replace

Lens,Models

57-$RI

Removal1. Unscrew!lens from housing.2.

III luggage compartment, unscrew three (3) hous-

ing attaching nuts. See Figure lF-9.

Figure lF-9 Tail Light Housing Attaching Nuts

-Models 57.57R

3. Disconnect wire connector.

Installation1. Plug in wiring harness.

2. Replace housing with three (3) attaching nuts.

3. Replace lens.

Rear License Plate Lamp Assembly Removal1. Remove two screws holding housing to bumper.

2. Pull lamp assembly down.

3. To replace bulb, take out two

screws holding lens

in place.

Installation1. Replace bulb and lens to housing.

2. Replace lamp assembly to bumper with two (2)

screws.

SIDE MARKER LIGHTS

Front Removal1. Remove outer lens.

2. Remove two sheet metal screws for housing at-

tachment.

3. Disconnect wire connectors.

Page 71 of 625

1 F- 50 1973 OPEL SERVlCE,MANUAL

Installation

1. Connect wiring harness.

2. Replace housing with two (2) screws.

3. Rep&e lens.

Rear RemovalRemove two screws from support bracket aed

remove housing and lens. See Figure lF-10.

,&y...2&L&-i -:,..; 3O’F’OFigure 1 F-10

- Removing Rear Side Marker Lampx

kallationInstall housing and lens with two (2) attach&gSCFSVS.

INTERIOR LIGHTS

Courtesy Light Removal1. Pry courtesy light out of roof frame, as shown in

Figure 1 F-

11.

t2. Pull wires off flat plugs. See Figure lF-12.

Figure lF-12 -Courtesy Light Wire Connections

Installation1. Connect wires to flat plugs, a) red wire, b)

greywire, and c) brown wire.

2. Push light back into roof frame.

Door Jam Switch Removal1. Remove door jam switch

attach’ing screws.

2. Remove switch and disconnect wire.

Installation1. Connect wire to switch.

Figure lF-1 1

- Removing Courtesy LightFigure 1 F-l 3 Removing Parking Light Lens

Page 82 of 625

I

I

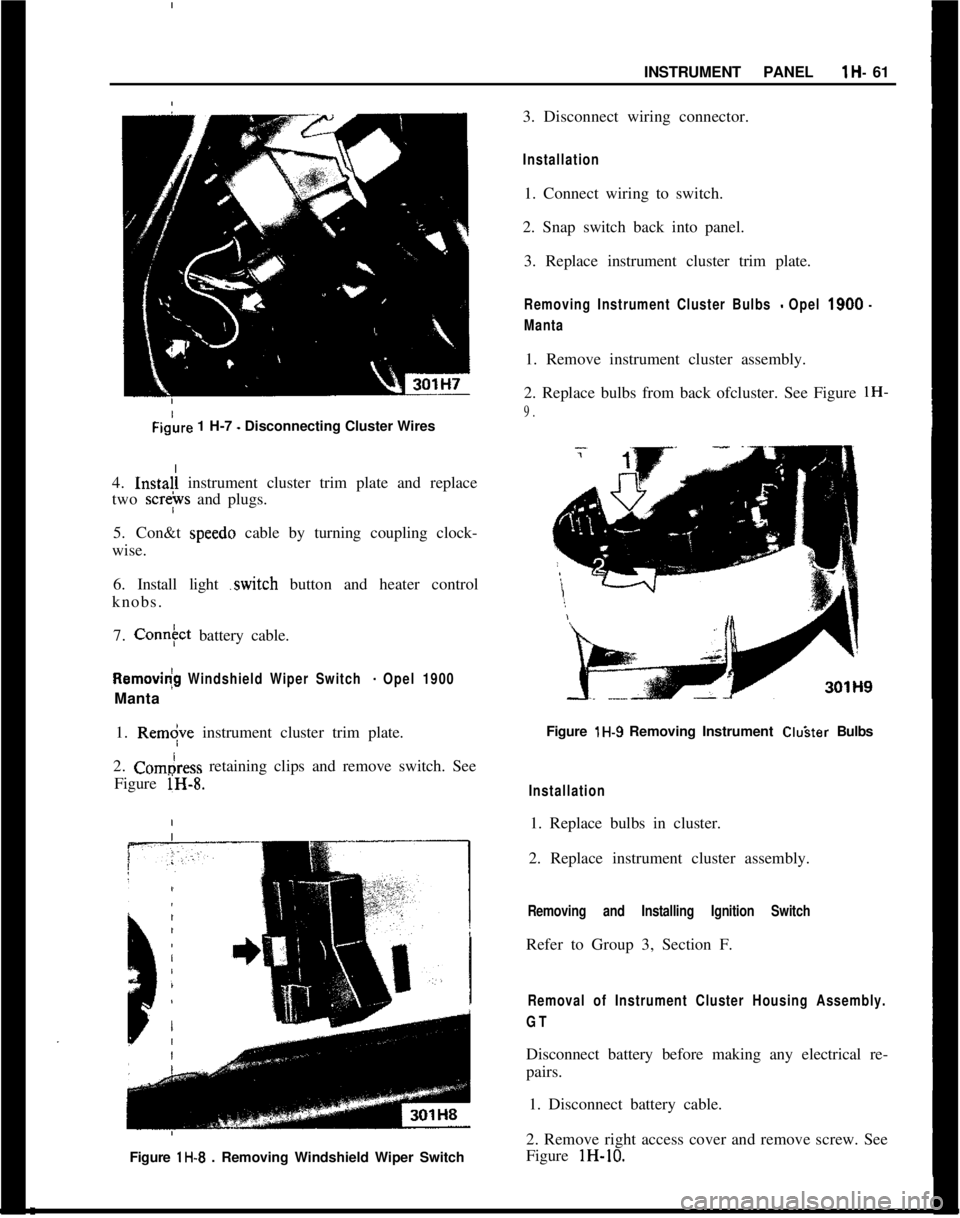

IINSTRUMENT PANELlH- 61Figwe 1 H-7

- Disconnecting Cluster Wires

4. Install instrument cluster trim plate and replace

two screw and plugs.

5. Con&t speed0 cable by turning coupling clock-

wise. 1

6. Install light

.switch button and heater control

knobs. I

I

7. Con+ct battery cable.

Removidg Windshield Wiper Switch - Opel 1900Manta I

1.

Rem* instrument cluster trim plate.

2. Corndress retaining clips and remove switch. See

Figure iH-8.

I

Figure lH-8 . Removing Windshield Wiper Switch3. Disconnect wiring connector.

Installation1. Connect wiring to switch.

2. Snap switch back into panel.

3. Replace instrument cluster trim plate.

Removing Instrument Cluster Bulbs - Opel 1900.

Manta1. Remove instrument cluster assembly.

2. Replace bulbs from back ofcluster. See Figure

lH-

9.Figure lH-9 Removing Instrument

Clu’ster Bulbs

Installation1. Replace bulbs in cluster.

2. Replace instrument cluster assembly.

Removing and Installing Ignition SwitchRefer to Group 3, Section F.

Removal of Instrument Cluster Housing Assembly.

GTDisconnect battery before making any electrical re-

pairs.

1. Disconnect battery cable.

2. Remove right access cover and remove screw. See

Figure lH-10.

Page 84 of 625

I

,INSTRUMENT PANELlH-63Figure l;H-15 Removing Instrument Cluster AssemblyFibure1 H-l 6 Disconnecting Radio Wires

14. Disdonnect antenna lead-in at right lower corner

of radio!

15. Pull’ cluster housing out and turn sideways to

remove

&~y instrument gauge or switches.

I

lnstallaiion

CAUTlOI$ Fasteners in subparagraph B are impor-

tant attaching parts in that they coo/d

affect the

perform>nce of vital components and systems, and-

/or

cou!d result in major repair expense.They must

be

repraced with one of the same part number, or

with an equivalent part if replacement becomes

necessa?y. Do not use a replacement part of lesser

quality

br substitute design. Torque values must be

used as

&ified during reassembly to assure proper

retention of these parts.

1. Plug antenna lead-in cable and power source to

radio. I

2. Put i&trument cluster in position and replace six

(6) screbs in cluster.3. Connect speedometer cable.

4. Raise steering column into position and install hex

head

bolt% Be sure to install ground wire. Tighten

hex head bolts to 14 lb.ft.

5. Tighten tear lock bolts until hex head of bolt is

torn off.

6. Connect ignition and directional signal wire set

plugs.

7. Install flasher unit.

8. Replace screws in right and left lower instrument

panel and replace both access covers.

9. Connect battery cable.

Removal of Combined Switch Assemblies. GT1. Remove instrument cluster.

2. Turn instrument cluster to the side to remove

switch assembly.

3. Remove switch by removing two retaining nuts.

See Figure lH-17.

4. Remove wiring from switch.

Figure 1 H-l 7 Removing Switches

Installation1. Plug wiring into switch.

2. Install switch on panel.

3. Install instrument cluster.

Page 88 of 625

I

GAUGES1 I- 67I

I Condition

Car

&s out of gas with

gauge indicating fuel in

tank. 1

I

I

I

I

IPossible Cause

1. Tank unit misadjusted

2. Defective voltage

stabilizer.Correction

1. Follow corrective action as

stated above (obtain empty

reading on dash)

1. See corrective action above.

Temperature gauge not1. Loose dash gauge1. See corrective action above.

Iattaching nut.

I

I

I2. Defective temperature1. Install 40 ohm resistor

Isending unitbetween temperature sneding

Iunit and ground (disconnect

I

from unit). If dash unit reads

I

full scale, replace temperature

Isending unit.

I

I

I3. Open wiring.1. Follow corrective action as

Istated above (connector socket

Iwith blue wire).Tempkrature gauge indicates

hot when engine temperature1. Incorrect temperature1. Check for correct sending unit

sending unit

normal.(white porcelain) replace if

incorrect.

2. i>efective temperaturesending unit.1. See corrective action above.

3. Dkfective voltage

stabilizer.

1. See Corrective action above.

GAS

GdUGE TROUBLE DIAGNOSIS - GT4. Disconnect the tank unit lead wire (light blue with

black tracer) from the tank unit.

An inoperative gas gauge reading can normally be

found to result from a poor grounding condition

within the circuit. Using the procedure as outlined

below may lead to the correction of the inoperative

reading without replacement of either the tank unit

or the

dph unit.5. Connect ihe stock tank unit; ground unit, and

operate manually.

6. If the dash unit shows a correct reading, then

replacement of the tank unit is required as the cor-

rection.

1. Makelcertain the gas tank (ground) strap is prop-

erly secured.A correct reading will be one which resembles the

movement of the manually-operated tank unit.

2. Make’certain the ground wire (brown in color) for

gasoline/ and temperature gauges is properly con-

nected tb the windshield wiper motor and is secured.

(This

gl?ound wire is also common for the heater

blower

etor.)7. If the dash unit does not show a correct reading,

then its replacement is necessary.

If the adove procedure does not produce a satisfac-

tory gaube reading, an attempt to isolate the defec-

tive

par<, i.e. tank or dash unit should be made.

3. Rem&e a tank unit from parts stock.MAJOR

AEPAIR

OPEL 1900. MANTA

Removing Voltage Stabilizer1. Remove instrument cluster housing assembly.

Page 93 of 625

1 J- 72 1973 OPEL SERVICE MANUAL

I

WIRING IDIAGRAMS

CONTENTS

Subject

1973 WIRING DIAGRAMS: Windshield Wiper and

Horn:- Opel 1900 -

Manta....................................I.............. ..............................

Windshield Wiper and Horn’- Rallye ..........................

Windshield Wiper

andHorn!-GT

..................................

Turn Signal and Hazard Flasher

-

Opel 1900 - Manta !

........................................................

Turn Signal and Hazard Flasher

- GT ..........................

Oil, Fuel,

Temp.: Tach, Stop and Brake

Warning Light

.GT........................................................

Blower Motor, Lighter and

Rackup Lights -

Qpel 1900.Manta ........................................................

Blower Motor and Lighter

.,GT....................................

Indicator Lights and Gauges

- Opel 1900 -

Manta ........................................................................\

........

Indicator Lights

andGauges.Rallye ..........................

Dome Light and Buzzer

- Opel 1900 - Manta..........

Dome Light, Buzzer and Clock - GT ............................

Headlamps

- Opel 1900 ’

....................................................

Headlamps

.Mantaj............................................................

Headlamps and Fog Lights

.Rallye ..............................

Headlamps, Parking, Tail and Instrument

PanelLighting.GT ........................................................

Left Parking and Tail Lights

- Opel 1900 -

Manta ..................................i.............................................

Right Parking and Tail Lights

- Opel 1900 -

Manta................. ..*............................................................

Starting, Ignition and Charging

-

Opel 1900.Manta..........i.............................................

Starting, Ignition and Charging

- GT ..........................

Instrument

Panel.GT ......................................................

A/C Generatorand Regulator

- All Models..............

Seat Belt Warning System (Manual Transmission)

-Opel1909-Manta ..........................

Seat Belt Warning System (Automatic Transmission)

.Opel 1900 - Manta..........................

Seat Belt Warning System (Manual Transmission)

- GT........................................................ Page No.

1 J-74

1 J-75

1 J-76

1 J-77

1 J-78

1 J-79

1 J-80

lJ-81

1 J-82

1 J-83

1 J-84

1 J-85

1 J-86

1 J-87

1 J-88

1 J-89

1 J-90

1 J-91

1 J-92

1 J-93

1 J-94

1 J-95

1 J-96

1 J-97

1 J-98

Page 94 of 625

I

/WIRING DIAGRAMS13-73ISeat Belt Warning System (Automatic

Page No.Transmission)

.GT.......................................................lJ-99HeatedRear Glass

.Opel1900.Manta...................15-100Heated Rear Glass

.GT..................................................*,lJ-101Opel 1900 Color Schematic.........................................

lJ-103Manta

ColorSchematic.................................................1 J-105GT

ColorSchematic

.........................................................1 J-107