OPEL 1900 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 331 of 625

6C- 401973 OPEL SERVICE MANUAL

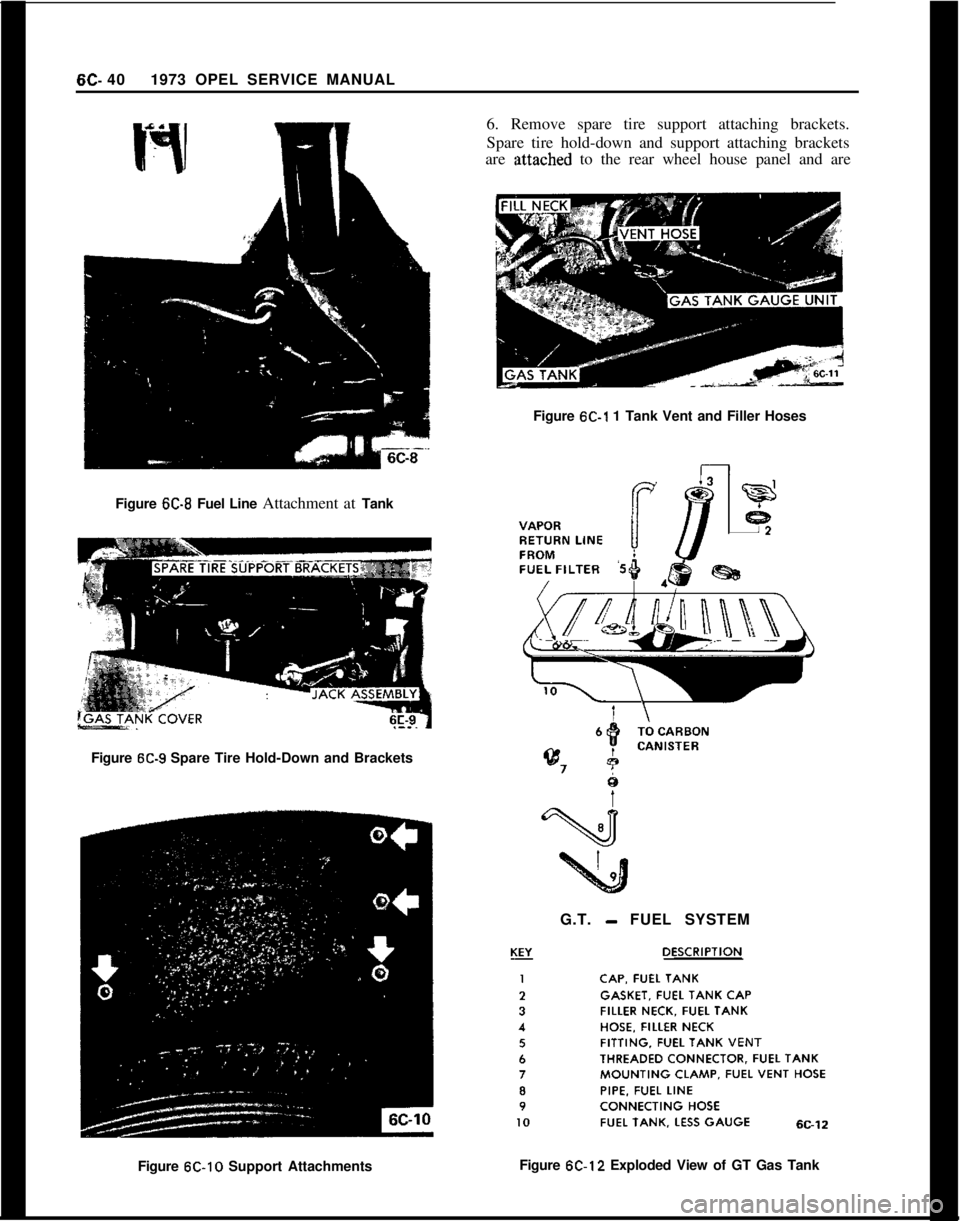

Figure K-8 Fuel Line Attachment at Tank6. Remove spare tire support attaching brackets.

Spare tire hold-down and support attaching brackets

are

;attached to the rear wheel house panel and are

Figure

6C-1 1 Tank Vent and Filler Hoses

Figure

6C-9 Spare Tire Hold-Down and Brackets

G.T.

- FUEL SYSTEM

Figure

612-10 Support AttachmentsFigure 6C-12 Exploded View of GT Gas Tank

Page 332 of 625

FUEL SYSTEM6C- 41

covered with sound deadening compound. See Fig-

ure

6C-10.7. Remove fuel tank vent hose and tiller hose. See

Figure 6C- 11.

8. Remove fuel tank attaching bolts and gauge wire

and remove tank.

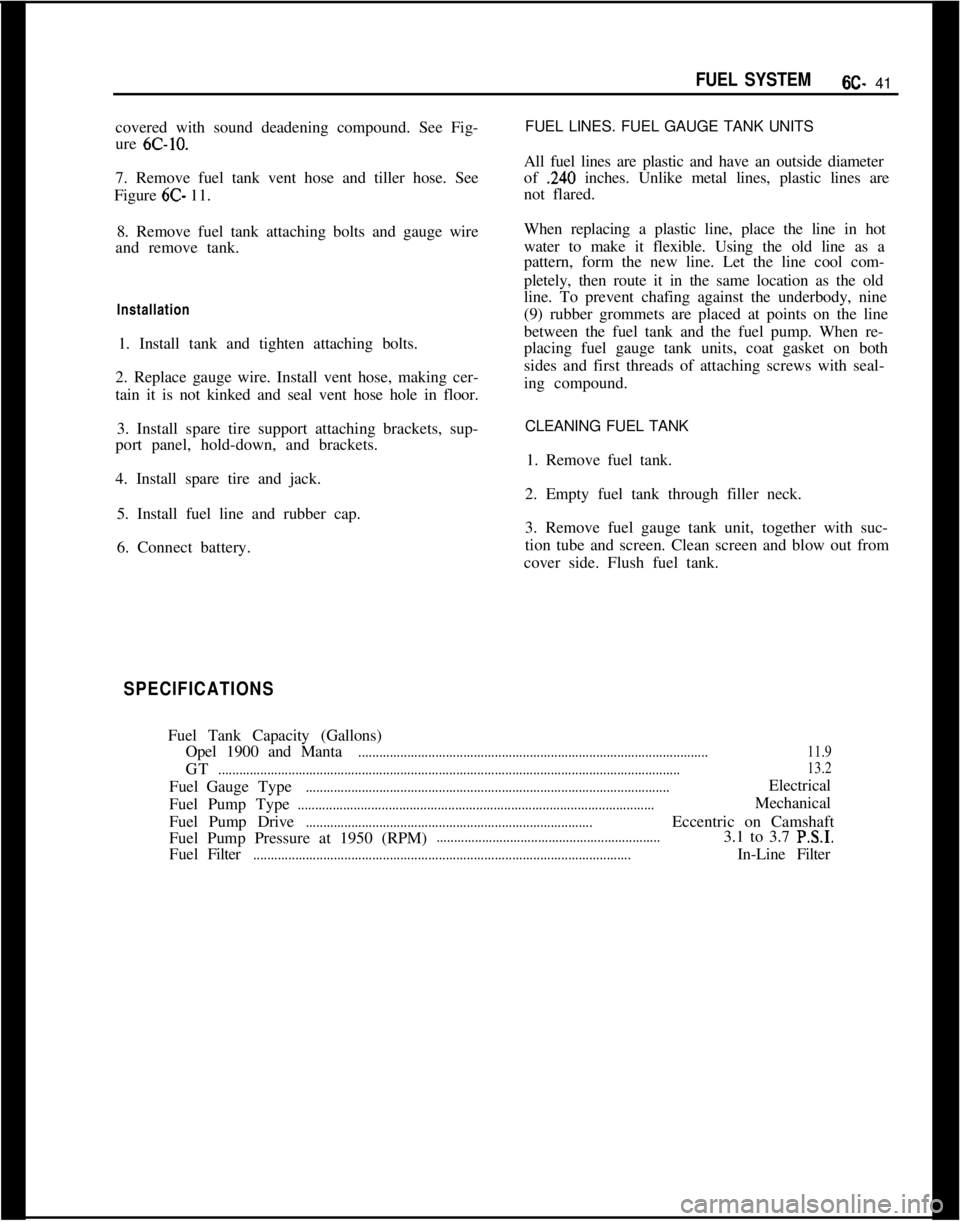

Installation

1. Install tank and tighten attaching bolts.

2. Replace gauge wire. Install vent hose, making cer-

tain it is not kinked and seal vent hose hole in floor.

3. Install spare tire support attaching brackets, sup-

port panel, hold-down, and brackets.

4. Install spare tire and jack.

5. Install fuel line and rubber cap.

6. Connect battery.FUEL LINES. FUEL GAUGE TANK UNITS

All fuel lines are plastic and have an outside diameter

of

,240 inches. Unlike metal lines, plastic lines are

not flared.

When replacing a plastic line, place the line in hot

water to make it flexible. Using the old line as a

pattern, form the new line. Let the line cool com-

pletely, then route it in the same location as the old

line. To prevent chafing against the underbody, nine

(9) rubber grommets are placed at points on the line

between the fuel tank and the fuel pump. When re-

placing fuel gauge tank units, coat gasket on both

sides and first threads of attaching screws with seal-

ing compound.

CLEANING FUEL TANK

1. Remove fuel tank.

2. Empty fuel tank through filler neck.

3. Remove fuel gauge tank unit, together with suc-

tion tube and screen. Clean screen and blow out from

cover side. Flush fuel tank.

SPECIFICATIONSFuel Tank Capacity (Gallons)

Opel 1900 and Manta

....................................................................................................11.9GT

....................................................................................................................................13.2FuelGaugeType

........................................................................................................Electrical

Fuel Pump Type

......................................................................................................Mechanical

Fuel Pump Drive

..................................................................................Eccentric on Camshaft

Fuel Pump Pressure at 1950 (RPM)................................................................3.1 to 3.7 P.S.I.FuelFilter

............................................................................................................In-LineFilter

Page 333 of 625

6D. 421973 OPEL SERVICE MANUAL

EXHAUST SYSTEMS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Page No.

Exhaust System (All Models). . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICA’TIONS:

Torque Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . .

6D-42

6D-42

MAJOR REPAIR

EXHAUST SYSTEM (ALL MODELS)

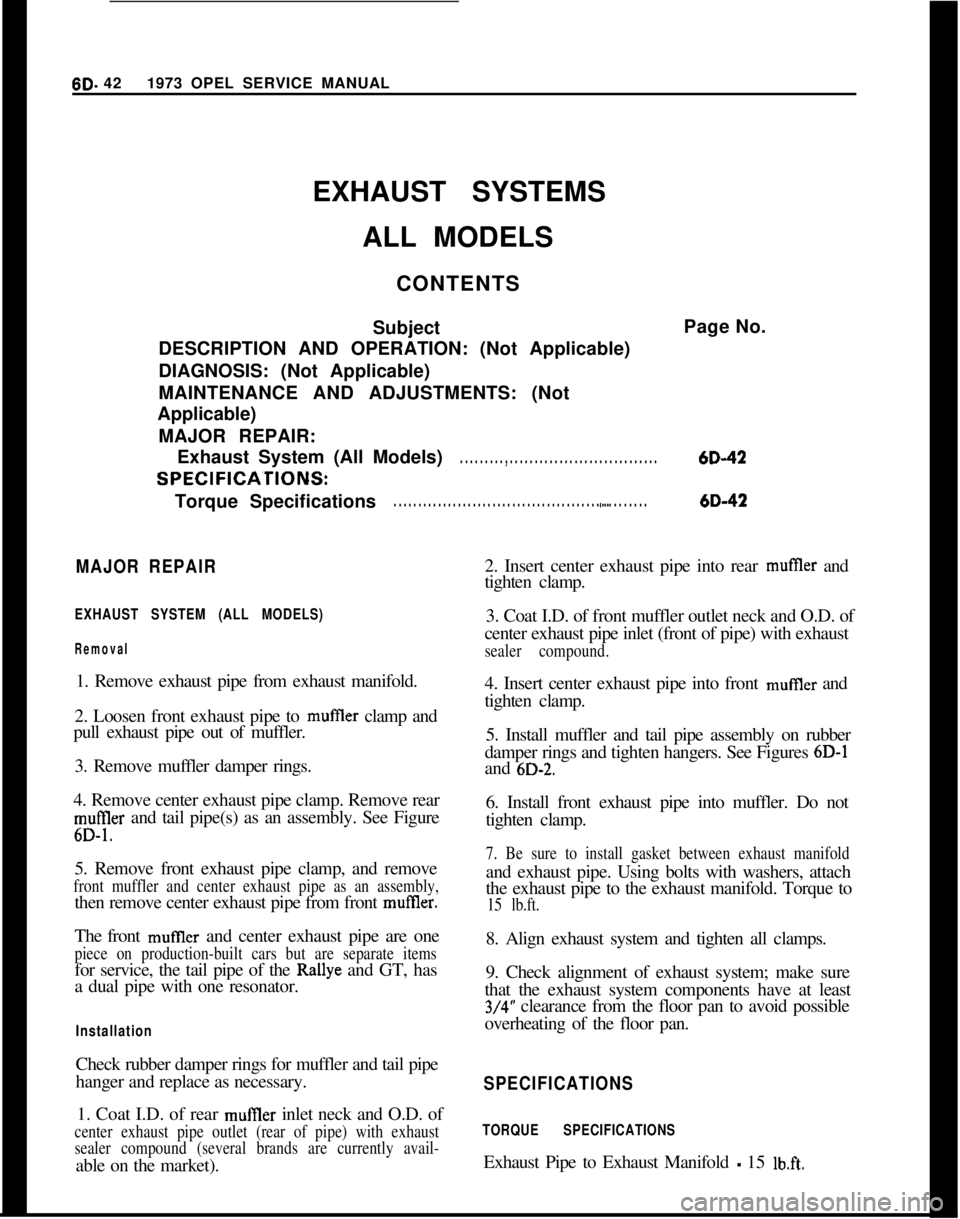

Removal1. Remove exhaust pipe from exhaust manifold.

2. Loosen front exhaust pipe to mufller clamp and

pull exhaust pipe out of muffler.

3. Remove muffler damper rings.

4. Remove center exhaust pipe clamp. Remove rearmut&r and tail pipe(s) as an assembly. See Figure

6D-1.5. Remove front exhaust pipe clamp, and remove

front muffler and center exhaust pipe as an assembly,then remove center exhaust pipe from front mufler.

The front mufIler and center exhaust pipe are one

piece on production-built cars but are separate itemsfor service, the tail pipe of the Rallye and GT, has

a dual pipe with one resonator.

InstallationCheck rubber damper rings for muffler and tail pipe

hanger and replace as necessary.

1. Coat I.D. of rear muffler inlet neck and O.D. of

center exhaust pipe outlet (rear of pipe) with exhaust

sealer compound (several brands are currently avail-able on the market).2. Insert center exhaust pipe into rear mufIler and

tighten clamp.

3. Coat I.D. of front muffler outlet neck and O.D. of

center exhaust pipe inlet (front of pipe) with exhaust

sealer compound.4. Insert center exhaust pipe into front mufiler and

tighten clamp.

5. Install muffler and tail pipe assembly on rubber

damper rings and tighten hangers. See Figures

6D-1and

6D-2.6. Install front exhaust pipe into muffler. Do not

tighten clamp.

7. Be sure to install gasket between exhaust manifoldand exhaust pipe. Using bolts with washers, attach

the exhaust pipe to the exhaust manifold. Torque to

15 lb.ft.8. Align exhaust system and tighten all clamps.

9. Check alignment of exhaust system; make sure

that the exhaust system components have at least

3/4” clearance from the floor pan to avoid possible

overheating of the floor pan.

SPECIFICATIONS

TORQUE SPECIFICATIONSExhaust Pipe to Exhaust Manifold

- 15 lb.ft.

Page 334 of 625

EXHAUST SYSTEMS6D- 43

6D-4Figure 6D-1 Opel 1900 and Manta Exhaust System

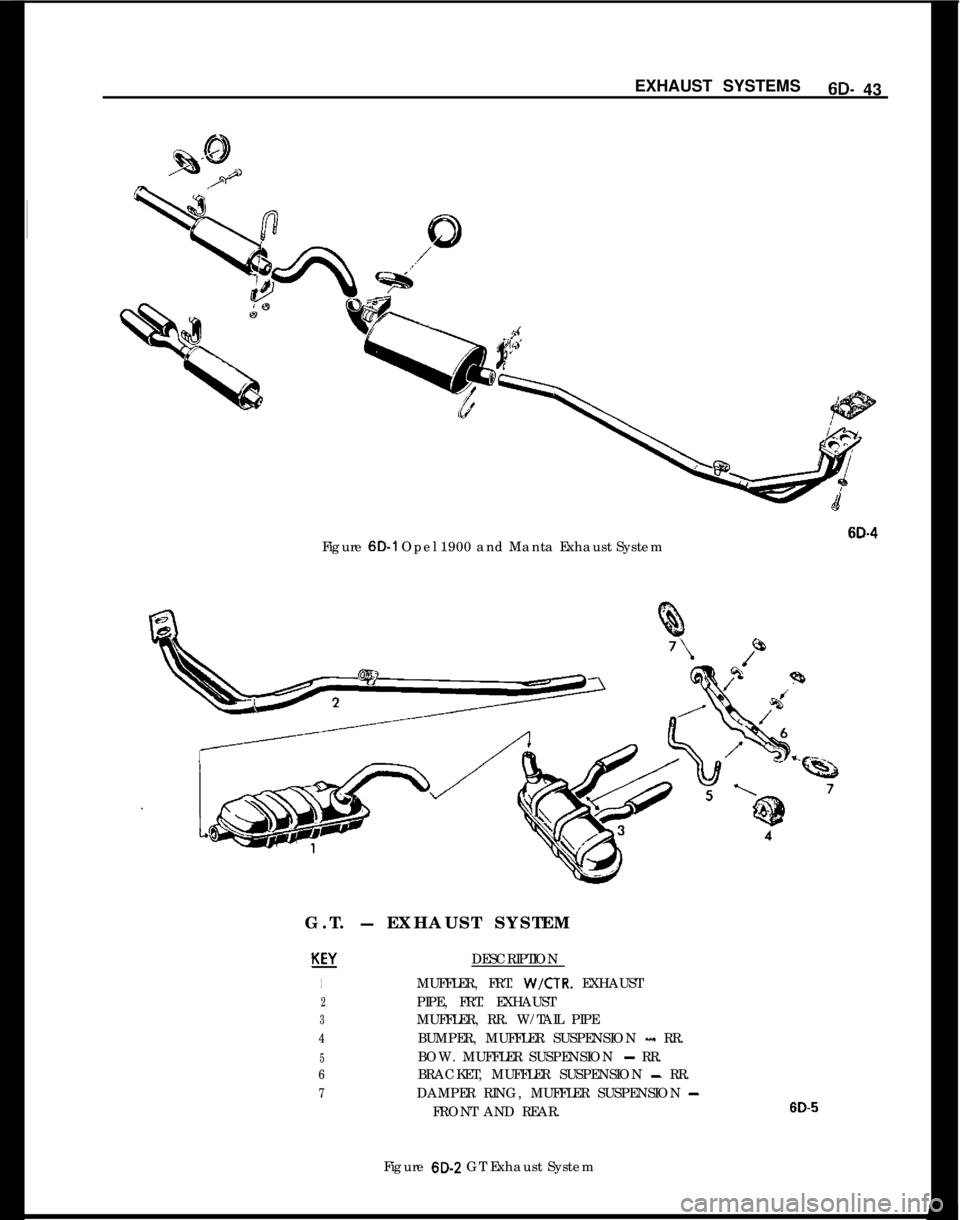

G.T.

- EXHAUST SYSTEM

KEJ

1

2

3

4

5

6

7DESCRIPTION

MUFFLER, FRT. W/CTR. EXHAUST

PIPE, FRT. EXHAUST

MUFFLER, RR. W/TAIL PIPE

BUMPER, MUFFLER SUSPENSION

- RR.

BOW. MUFFLER SUSPENSION

- RR.

BRACKET, MUFFLER SUSPENSION

- RR.

DAMPER RING, MUFFLER SUSPENSION

-FRONT AND REAR.6D-5Figure

6D-2 GT Exhaust System

Page 335 of 625

SE- 441973 OPEL SERVICE MANUAL

CARBURETOR AND THROTTLE LINKAGE

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Carburetor

. . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Carburetor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Idle Speed and Mixture Adjustments

. . . . . . . . . . . . . . . . . . . . . . . .Fast Idle Speed Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Throttle Linkage Adjustment

. . . . . . . . . . . . . . . , . , . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

RemoveandInstallCarburetor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I...Throttle Linkage Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OverhaulCarburetor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Carburetor

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

6E-44

6E-49

6E-50

6E-51

6E-51

6E-52

6E-53

6E-53

6E-58

DESCRIPTION AND OPERATION

CARBURETORThe two-barrel carburetor for all 1973 Opel1

19G0,Manta and GT models is a down-draft carburetor

with two barrels of 1.25 inch diameter each. It has

an automatic choke and a secondary valve operated

by a vacuum diaphragm, except when installed in an

Opel GT. In the GT, the secondary throttle valve is

operated by mechanical linkage from the primary

throttle valve.

The two-barrel carburetor consists of three main

parts

- throttle body, float chamber and air horn.

Each barrel is a separate system, but both barrels

discharge into a common inlet in the intake mani-

fold. The secondary barrel does not have a choke

valve or an accelerator pump. See Figure

6E-2.The throttle valve of the primary barrel is opened

through the throttle linkage. When the primary

throttle valve is almost open, at approximately half

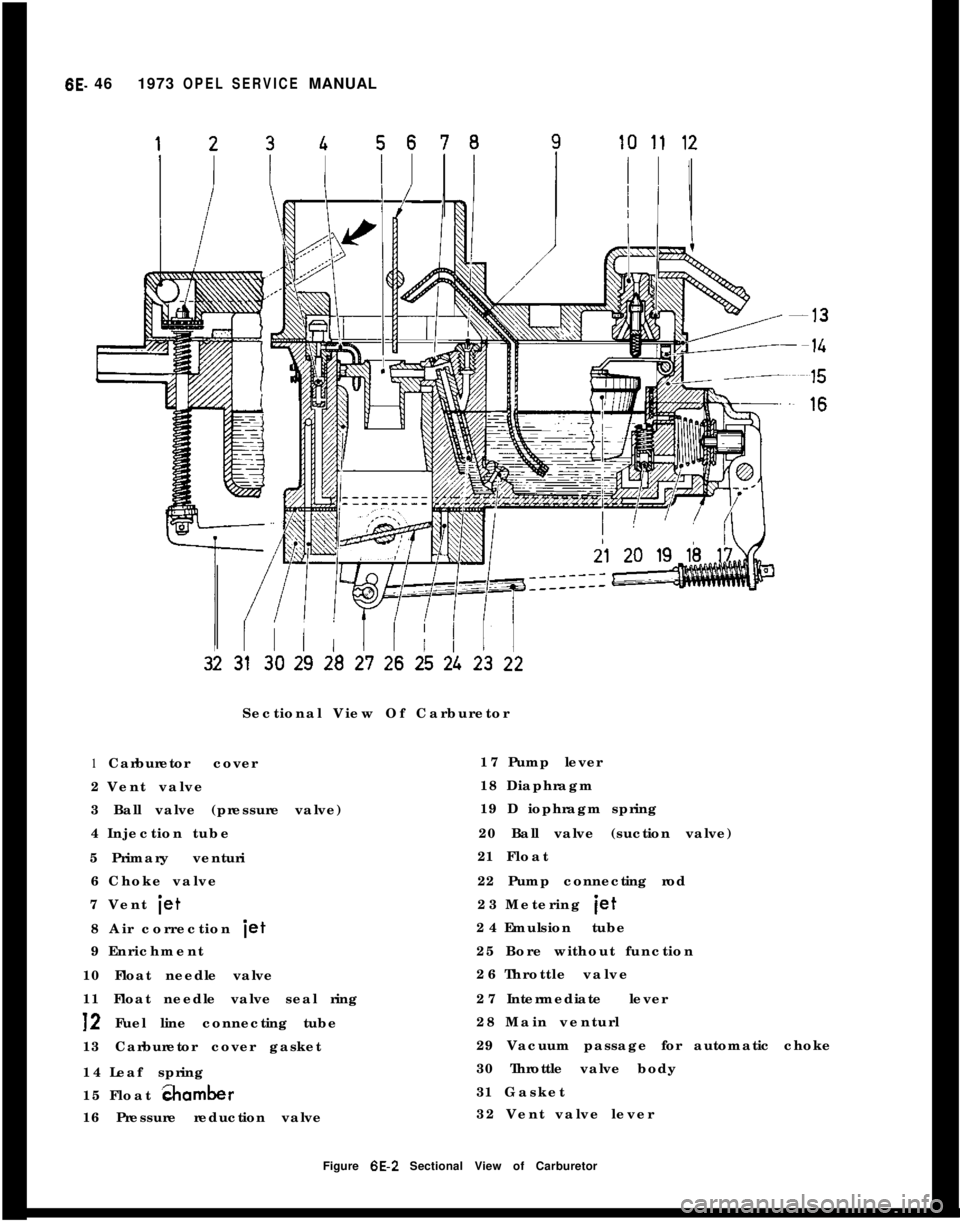

of the maximum engine RPM, the secondary throttlevalve is opened by vacuum applied through a

vacuum diaphragm case. See Figure

6E-3. The sec-

ondary throttle valve on the GT model is opened by

mechanical linkage from the primary throttle shaft.

Choke SystemThe automatic choke is operated by a bi-metal

spring. The tension of the spring

- depending on

temperature of the heater coil

- decreases with rising

temperature and the choke valve opens progressively

until it is completely opened at engine operating tem-

perature. The choke valve is off-set so that choke

valve opening increases as air flow increases.

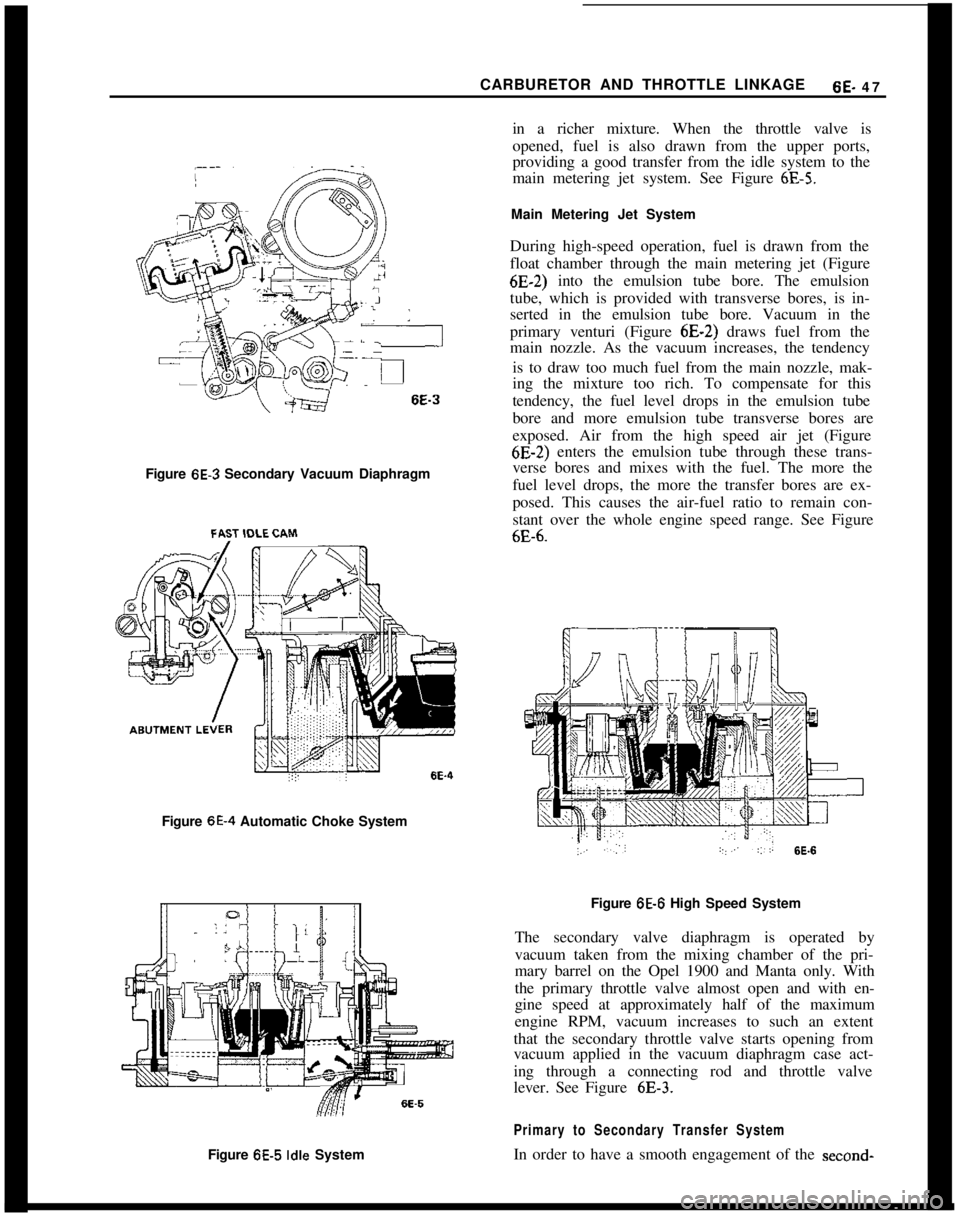

If the choke valve is closed, the throttle valve is

opened slightly to provide a fast idle speed. This is

done through a cam, abutment lever and throttle

connecting link. With the throttle valve opened

slightly, the vacuum during cranking can take effect

up to the choke valve, thereby drawing ample fuel

out of the main nozzle. See Figure

6E-4.With rising temperature of the heater coil, the choke

Page 336 of 625

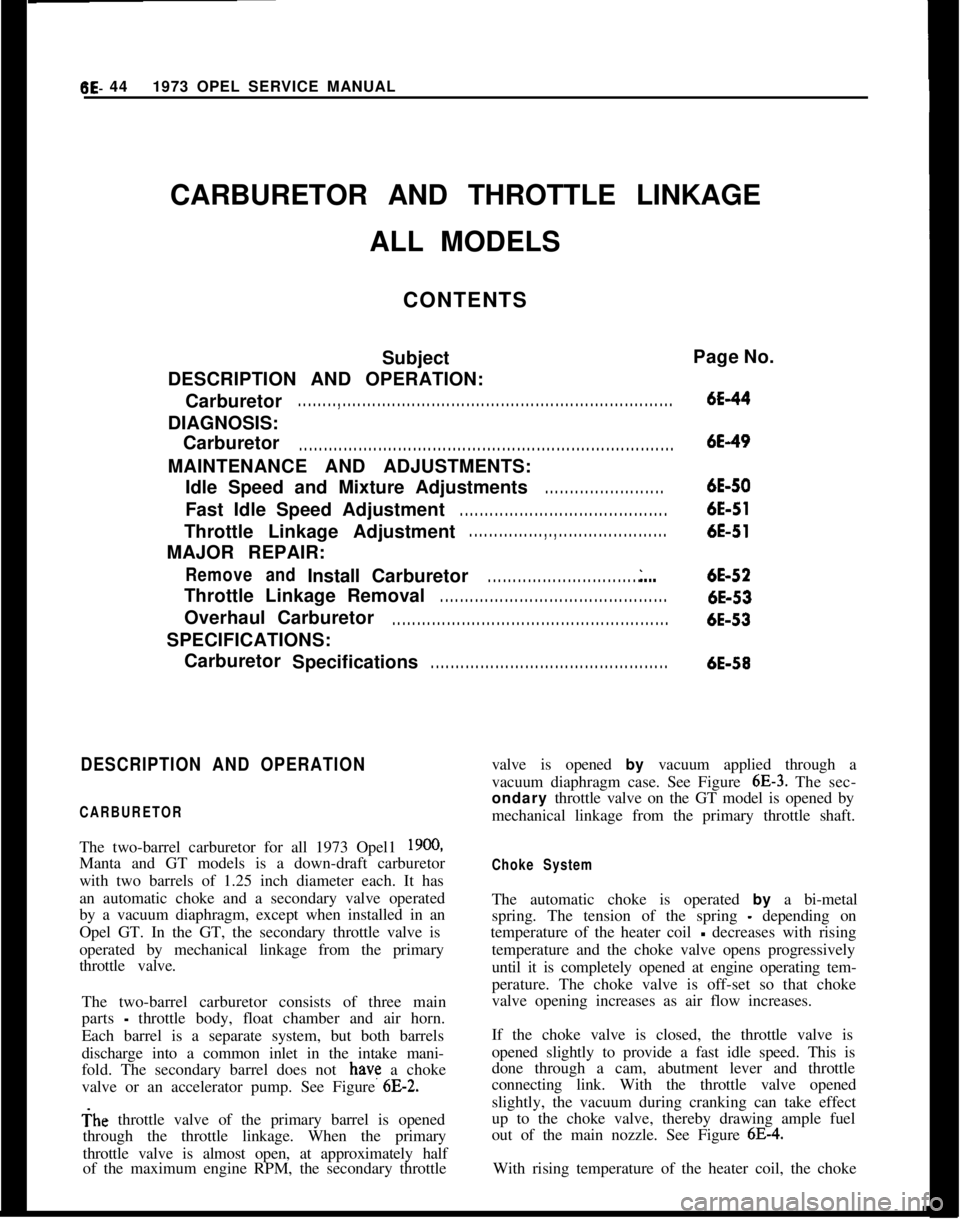

CARBURETOR AND THROTTLE LINKAGE6E- 4512345678Sectional View Of 19 US Carburetor (both barrels)

1 PIug(transition channels, secondary barrel)

6 Float chamber

2Carburetor

cover7Idleairpassage

3Vent tube

8Idleairiet4Transit’

,n iet9 Idle air adjusting screw

5 Transition air iet10 Mixture adjusting screw

6E-1Figure 6E-1 Sectional View of Primary and Secondary Barrels

valve gradually opens and the mixture

become+leaner. During this process, the abutment lever

changes position on the fast idle cam, further closingBefore starting a cold engine slowly, depress the ac-celerator pedal three times before engaging the

starter.

the throttle valve until, the engine is at normal oper-

ating temperature, the choke valve is wide open and

the throttle valve is in slow idle position.

Idle and Part Throttle SystemA choke diaphragm is connected to the intermediate

lever of the choke valve spindle through a pull rod.

The vacuum, which develops below the throttle

valve, takes effect on the diaphragm through a

vacuum passage. See Figure

6E-4. As soon as the

engine starts, this vacuum pulls the choke valve

slightly open; the amount of choke valve opening

depends on the amount of vacuum, which depends

on the engine load. Therefore, with a light engine

load, the choke valve will open slightly; with a heavy

engine load, the valve will close slightly to give a

richer mixture as required for this engine load.At engine idle grid during low speed (part throttle)

operation, fuel is drawn from the emulsion tube bore,

controlled by the idle jet and mixed with air entering

through idle air bleeds (Figure 6E-1) and ports in thethrottle body. This mixture is drawn downward to

the three ports near the throttle valve. When the

throttle valve is closed, the mixture is drawn from

the lowest port and mixed with air by-passing the

throttle valve to form the idle mixture.

Turning the idle mixture screw (Figure

6E-1) inward

results in a leaner mixture, and turning it out results

Page 337 of 625

6E.461973OPELSERVICEMANUAL

Sectional View Of Carburetor

1Carburetor cover

2Vent valve

3 Ball valve (pressure valve)

4Injection tube

5Primary venturi

6Choke valve

7Vent

iet8 Air correction

iet9Enrichment

10 Float needle valve

11 Float needle valve seal ring12 Fuel line connecting tube

13 Carburetor cover gasket

14Leaf spring

15Float

&amber16 Pressure reduction valve17Pump lever

18Diaphragm

19 D iophragm spring

20 Ball valve (suction valve)

21Float

22 Pump connecting rod

23Metering

iet24Emulsion tube

25 Bore without function

26Throttle valve

27Intermediate lever

28Main venturl

29 Vacuum passage for automatic choke

30 Throttle valve body

31Gasket

32 Vent valve lever

Figure 6E-2 Sectional View of Carburetor

Page 338 of 625

CARBURETOR AND THROTTLE LINKAGE65 47

Figure 6E.3 Secondary Vacuum Diaphragm

Figure

6E-4 Automatic Choke System

Figure

6E-5 Idle Systemin a richer mixture. When the throttle valve is

opened, fuel is also drawn from the upper ports,

providing a good transfer from the idle system to the

main metering jet system. See Figure

6E-5.Main Metering Jet System

During high-speed operation, fuel is drawn from the

float chamber through the main metering jet (Figure6E-2) into the emulsion tube bore. The emulsion

tube, which is provided with transverse bores, is in-

serted in the emulsion tube bore. Vacuum in the

primary venturi (Figure 6E-2) draws fuel from the

main nozzle. As the vacuum increases, the tendency

is to draw too much fuel from the main nozzle, mak-

ing the mixture too rich. To compensate for this

tendency, the fuel level drops in the emulsion tube

bore and more emulsion tube transverse bores are

exposed. Air from the high speed air jet (Figure6E-2) enters the emulsion tube through these trans-

verse bores and mixes with the fuel. The more the

fuel level drops, the more the transfer bores are ex-

posed. This causes the air-fuel ratio to remain con-

stant over the whole engine speed range. See Figure

6E-6.Figure

6E-6 High Speed System

The secondary valve diaphragm is operated by

vacuum taken from the mixing chamber of the pri-

mary barrel on the Opel 1900 and Manta only. With

the primary throttle valve almost open and with en-

gine speed at approximately half of the maximum

engine RPM, vacuum increases to such an extent

that the secondary throttle valve starts opening from

vacuum applied in the vacuum diaphragm case act-

ing through a connecting rod and throttle valve

lever. See Figure

6E-3.

Primary to Secondary Transfer SystemIn order to have a smooth engagement of the

second-

Page 339 of 625

6~. 46,1973 OPEL SERVICE MANUAL

ary barrel, it is provided with g transfer system.

When the secondary throttle valve starts to open,

two‘ports (which are normally just above the closed

valve) are uncovered, causing fuel to feed into the

secondary bore just before the secondary nozzle

starts feeding. This provides for an additional enrich-

ment of the air-fuel mixture at the beginning of full

throttle operation. See Figure

6E-7.

nInFlFigure

6E-7 Primary to Secondary Transfer System

Full Thrdttle Enrichment SystemIf the secondary throttle valve is fully opened, the

vacuum in the throttle valve area is reduced so that

the transfer ports (mentioned above) stop feeding.

However, the vacuum increases greatly in the sec-

ondary venturi area. An enrichment tube which pro-

trudes into the primary venturi area, feeds fuel

continuously during full throttle operation. See Fig-

ure

6E-2.

Acceleration SystemWhenever the throttle is closing, the suction stroke

of the diaphragm pump causes fuel to flow from the

float chamber through the inlet ball valve into the

pump chamber. When the throttle valve is opened

the diaphragm is moved inward by the pump con-

necting rod and the pump lever. Fuel is injected into

the primary bore through the injector tube. The

amount of fuel is determined by the pump stroke.

The inlet ball valve in the pump chamber prevents

fuel from flowing back into the float chamber during

the pressure stroke of the pump. The outlet ball valve

prevents air from being drawn into the injector tube

during the suction stroke of the pump. See Figure6E- 8.

Float Bowl VentilationWhile driving, the float bowl is ventilated from insideFigure

6E-8 Acceleration System

the carburetor. That is, the float bowl is connected

through the vent valve with the area under the air

cleaner.

When the engine is idling or off, the ventilation from

inside is cut off and ventilation from the charcoal

canister is cut in. The upper spring now seats the

valve on the upper seat. See Figure

6E-9.

-6E-9

Figure

6E-9 Float Bowl VentilationThe advantage of an inside vent while driving is that

air cleaner restriction does not enrichen the air fuel

mixture. The purpose of the charcoal canister vent

while idling or after shutting-off a hot engine, is to

prevent excess fuel vapors from entering the intakemanifold and outside air. Excess fuel vapors may

cause an idling engine to stall, or may make it dif-

ficult to restart a hot engine.

Page 340 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 49DIAGNOSIS

CARBURETORCondition I

Hesitation or Stall Upon Light AccelerationCorrection

1. Check spark plugs and plug gap. Plug gap should

be

,030 in.

2. Check dwell and timing.

3. Adjust carburetor.

4. Accelerator pump should discharge fuel between

throttle plate and venturi wall with engine off. If aim

is not correct, use needlenose pliers to slightly bend

nozzle so proper aim is achieved. See Figure 6E- 10.

CORRECT ACCELERATOR

PUMP DISCHARGE

NOZZLE AIM

\Figure 6E-10 Pump Shot Aim

Road test car. If hesitation still exists, check for the

folI0 wing:1. Plugged accelerator pump discharge nozzle.2. Dirt in accelerator pump circuit.

3. Defective inlet check ball.

4. Defective accelerator pump pressure relief valve.

5. Defective accelerator pump diaphragm.

6. Maladjusted accelerator pump linkage.

Condition II

Hard Start Afier Hot Soak

CorrectionPerform Steps l-4 in Condition I.

Condition Ill

Hard Start When Engine Is Cold

Correction1. Align groove on choke cover with pointer on

choke housing. See Figure

6E-17.2. Set fast idle.

3. Replace distributor points if pitted.

4. Check spark plugs and gap at

,030.5. Set dwell and timing.

If above procedure does not correct problem, replace

with new automatic choke assembly.

Condition IV

Rough, Erratic, or No Idle

Correction1. Check spark plugs and gap at

,030.2. Check dwell angle and ignition timing.

3. Clean idle jet and passages with air hose. See Fig-

ure

6E-5.4. Check manifold to head bolt torque. Should be 33

lb.ft.5. Check automatic choke linkage alignment.

6. Adjust carburetor.