crankshaft OPEL 1900 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 41 of 625

I

ilC- 201973 OPEL SERVICE MANUAL

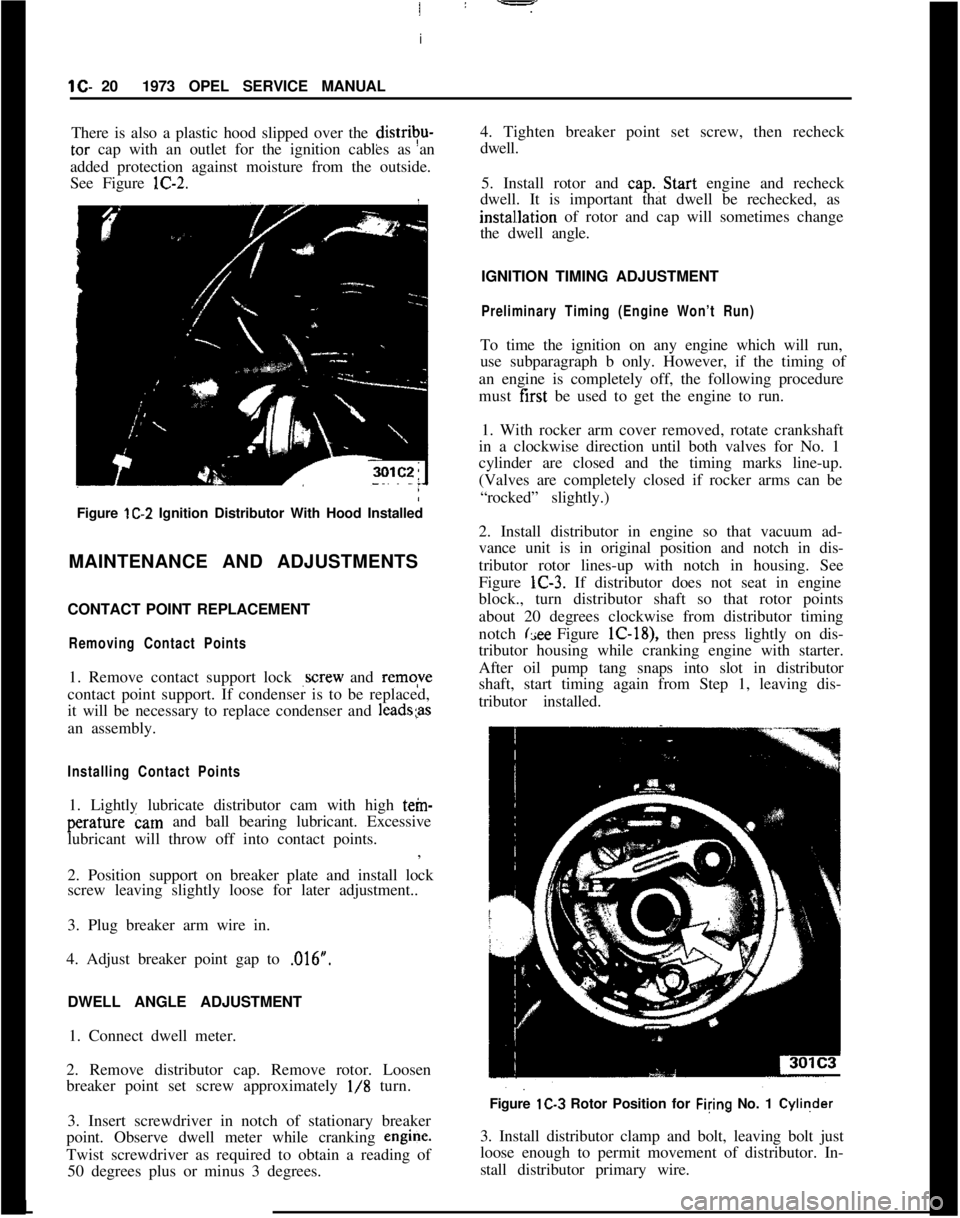

There is also a plastic hood slipped over the distrivu-tar cap with an outlet for the ignition cables as an

added protection against moisture from the outside.

See Figure lC-2.

Figure lC-2 Ignition Distributor With Hood Installed

MAINTENANCE AND ADJUSTMENTS

CONTACT POINT REPLACEMENT

Removing Contact Points1. Remove contact support lock

,screw and remqve

contact point support. If condenser is to be replaced,

it will be necessary to replace condenser and

1eads;asan assembly.

Installing Contact Points1. Lightly lubricate distributor cam with high tein-perature cam and ball bearing lubricant. Excessive

lubricant will throw off into contact points.

:

,

2. Position support on breaker plate and install lock

screw leaving slightly loose for later adjustment..

3. Plug breaker arm wire in.

4. Adjust breaker point gap to ,016”.

/

DWELL ANGLE ADJUSTMENT

1. Connect dwell meter.

2. Remove distributor cap. Remove rotor. Loosen

breaker point set screw approximately

l/8 turn.

3. Insert screwdriver in notch of stationary breaker

point. Observe dwell meter while cranking engine.

Twist screwdriver as required to obtain a reading of

50 degrees plus or minus 3 degrees.4. Tighten breaker point set screw, then recheck

dwell.

5. Install rotor and cap.~Start engine and recheck

dwell. It is important that dwell be rechecked, as

instal~lation of rotor and cap will sometimes change

the dwell angle.

IGNITION TIMING ADJUSTMENT

Preliminary Timing (Engine Won’t Run)To time the ignition on any engine which will run,

use subparagraph b only. However, if the timing of

an engine is completely off, the following procedure

must first be used to get the engine to run.

1. With rocker arm cover removed, rotate crankshaft

in a clockwise direction until both valves for No. 1

cylinder are closed and the timing marks line-up.

(Valves are completely closed if rocker arms can be

“rocked” slightly.)

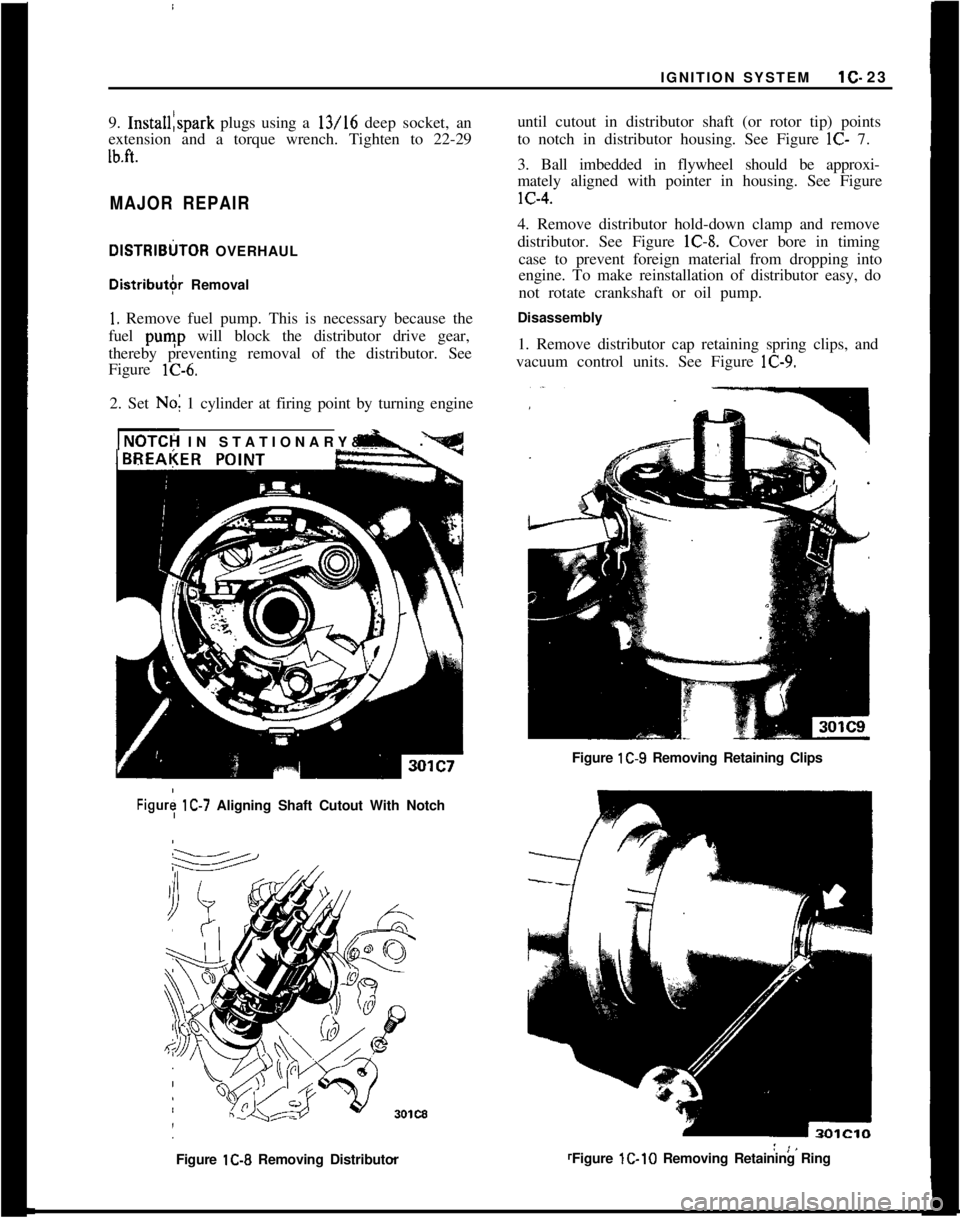

2. Install distributor in engine so that vacuum ad-

vance unit is in original position and notch in dis-

tributor rotor lines-up with notch in housing. See

Figure lC-3. If distributor does not seat in engine

block., turn distributor shaft so that rotor points

about 20 degrees clockwise from distributor timing

notch

(see Figure lC-18), then press lightly on dis-

tributor housing while cranking engine with starter.

After oil pump tang snaps into slot in distributor

shaft, start timing again from Step 1, leaving dis-

tributor installed.

Figure lC-3 Rotor Position for Filing No. 1 Cyliqder

3. Install distributor clamp and bolt, leaving bolt just

loose enough to permit movement of distributor. In-

stall distributor primary wire.L

Page 44 of 625

IGNITION SYSTEMlC- 23

9. Install:spark plugs using a 13/16 deep socket, an

extension and a torque wrench. Tighten to 22-29Ib.ft. 1

MAJOR REPAIRDlSTRlBtiTOR OVERHAULDistributbr Removal

1. Remove fuel pump. This is necessary because the

fuel

punp will block the distributor drive gear,

thereby preventing removal of the distributor. See

Figure lC-6.

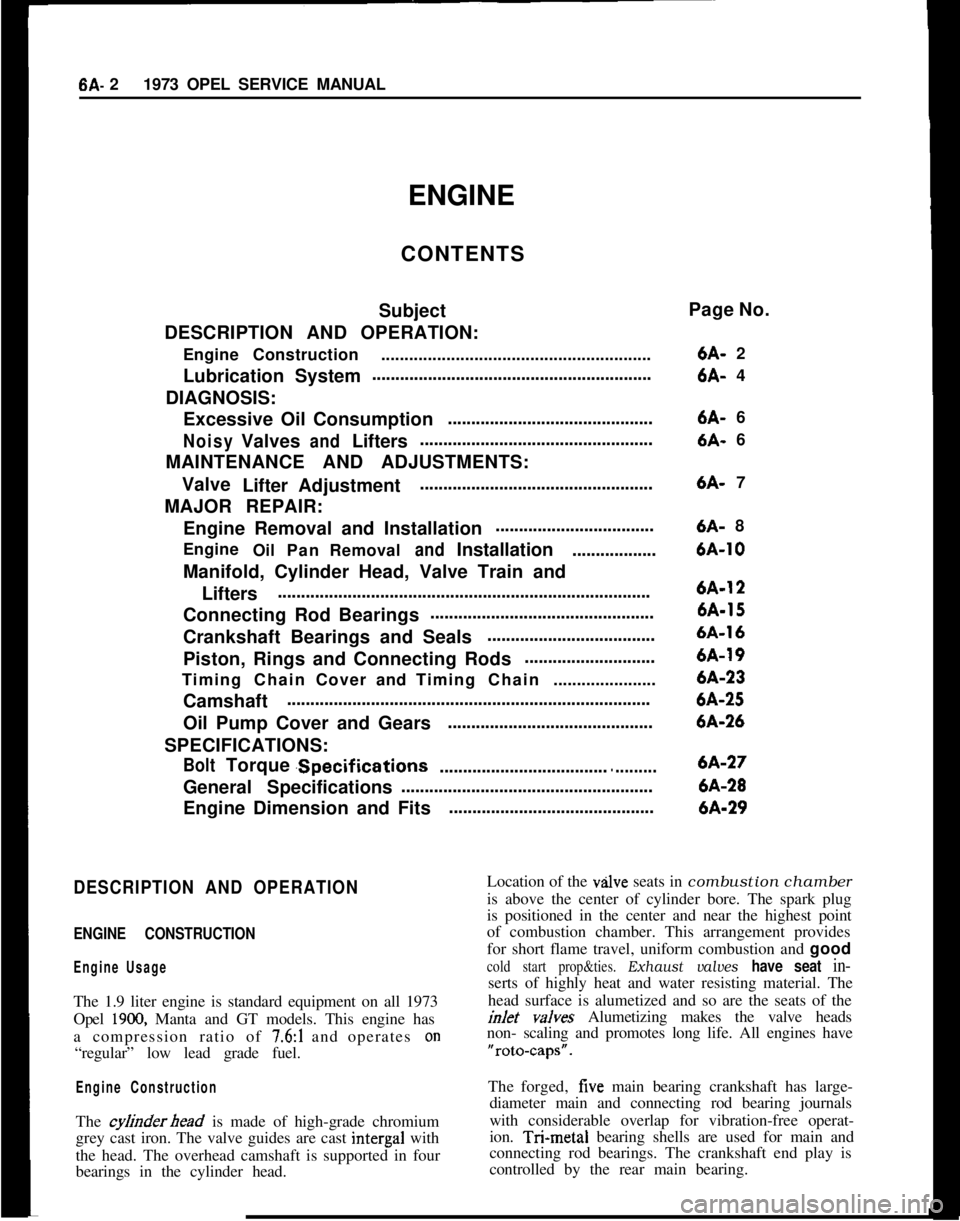

2. Set No; 1 cylinder at firing point by turning engine

INOTCH IN STATIONARY& -.until cutout in distributor shaft (or rotor tip) points

to notch in distributor housing. See Figure

lC- 7.

3. Ball imbedded in flywheel should be approxi-

mately aligned with pointer in housing. See FigurelC-4.

4. Remove distributor hold-down clamp and remove

distributor. See Figure lC-8. Cover bore in timing

case to prevent foreign material from dropping into

engine. To make reinstallation of distributor easy, do

not rotate crankshaft or oil pump.

Disassembly

1. Remove distributor cap retaining spring clips, and

vacuum control units. See Figure lC-9.

Figure lC-9 Removing Retaining Clips

Figury lC-7 Aligning Shaft Cutout With Notch

Figure lC-8 Removing DistributorFigure lC-10 Removing Retaining Ring

Page 293 of 625

6A- 21973 OPEL SERVICE MANUAL

ENGINE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

EngineConstruction..........................................................

LubricationSystem............................................................

DIAGNOSIS:

Excessive Oil Consumption............................................NoisyValvesandLifters..................................................

MAINTENANCE AND ADJUSTMENTS:

Valve

LifterAdjustment..................................................

MAJOR REPAIR:

Engine Removal and Installation..................................

Engine

OilPanRemoval

andInstallation..................

Manifold, Cylinder Head, Valve Train and

Lifters................................................................................

Connecting Rod Bearings................................................

Crankshaft Bearings and Seals....................................

Piston, Rings and Connecting Rods............................

TimingChainCoverandTimingChain......................

Camshaft..............................................................................

Oil Pump Cover and Gears............................................

SPECIFICATIONS:

BoltTorque.Specifications

..............................................General Specifications......................................................

Engine Dimension and Fits............................................Page No.

6A- 2

6A- 4

6A- 6

6A- 6

6A- 7

6A- 86A-106A-126A-156A-166A-196A-236A-256A-266A-276A-286A-29

DESCRIPTION AND OPERATION

ENGINE CONSTRUCTION

Engine UsageThe 1.9 liter engine is standard equipment on all 1973

Opel

1900, Manta and GT models. This engine has

a compression ratio of

7.6:1 and operates on“regular” low lead grade fuel.

Engine ConstructionThe

cyfinderhead is made of high-grade chromium

grey cast iron. The valve guides are cast intergal with

the head. The overhead camshaft is supported in four

bearings in the cylinder head.Location of the

vzllve seats in combustion chamber

is above the center of cylinder bore. The spark plug

is positioned in the center and near the highest point

of combustion chamber. This arrangement provides

for short flame travel, uniform combustion and good

cold start prop&ties. Exhaust valves have seat in-serts of highly heat and water resisting material. The

head surface is alumetized and so are the seats of the

inlet v&es Alumetizing makes the valve heads

non- scaling and promotes long life. All engines have“rota-caps”.

The forged, five main bearing crankshaft has large-

diameter main and connecting rod bearing journals

with considerable overlap for vibration-free operat-

ion. T&metal bearing shells are used for main and

connecting rod bearings. The crankshaft end play is

controlled by the rear main bearing.

Page 294 of 625

ENGINE MECHANICAL AND MOUNTS6A- 3

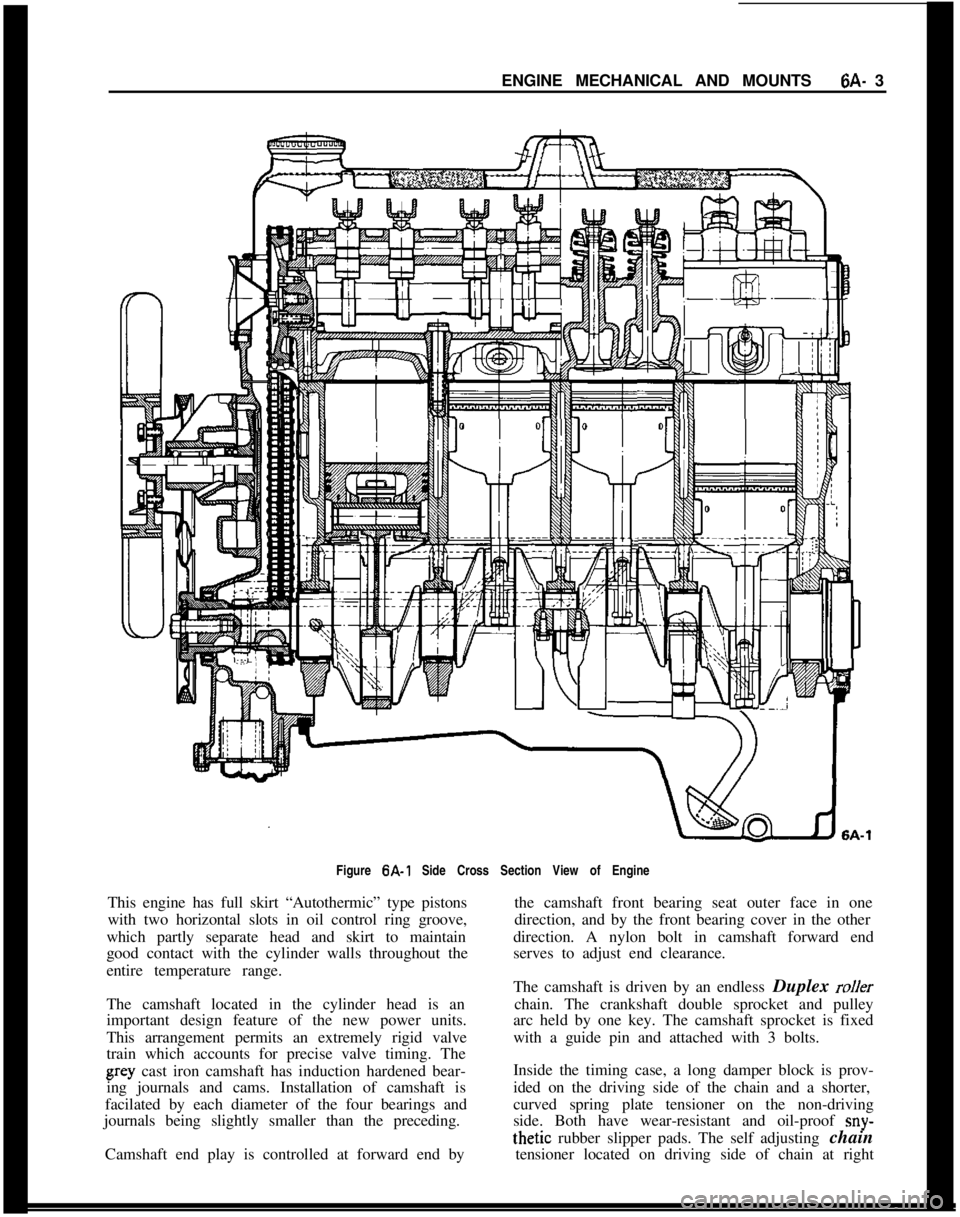

Figure 6A-1 Side Cross Section View of Engine

This engine has full skirt “Autothermic” type pistons

with two horizontal slots in oil control ring groove,

which partly separate head and skirt to maintain

good contact with the cylinder walls throughout the

entire temperature range.

The camshaft located in the cylinder head is an

important design feature of the new power units.

This arrangement permits an extremely rigid valve

train which accounts for precise valve timing. Thegray cast iron camshaft has induction hardened bear-

ing journals and cams. Installation of camshaft is

facilated by each diameter of the four bearings and

journals being slightly smaller than the preceding.

Camshaft end play is controlled at forward end bythe camshaft front bearing seat outer face in one

direction, and by the front bearing cover in the other

direction. A nylon bolt in camshaft forward end

serves to adjust end clearance.

The camshaft is driven by an endless Duplex

rollerchain. The crankshaft double sprocket and pulley

arc held by one key. The camshaft sprocket is fixed

with a guide pin and attached with 3 bolts.

Inside the timing case, a long damper block is prov-

ided on the driving side of the chain and a shorter,

curved spring plate tensioner on the non-driving

side. Both have wear-resistant and oil-proof

sny-thetic rubber slipper pads. The self adjusting chain

tensioner located on driving side of chain at right

Page 295 of 625

6A. 41973 OPEL SERVICE MANUAL

hand side above crankshaft sprocket, has a plunger

head with oil- proof and wear-resistant synthetic

rubber pad, which is pressed against chain by both

spring and oil pressure.

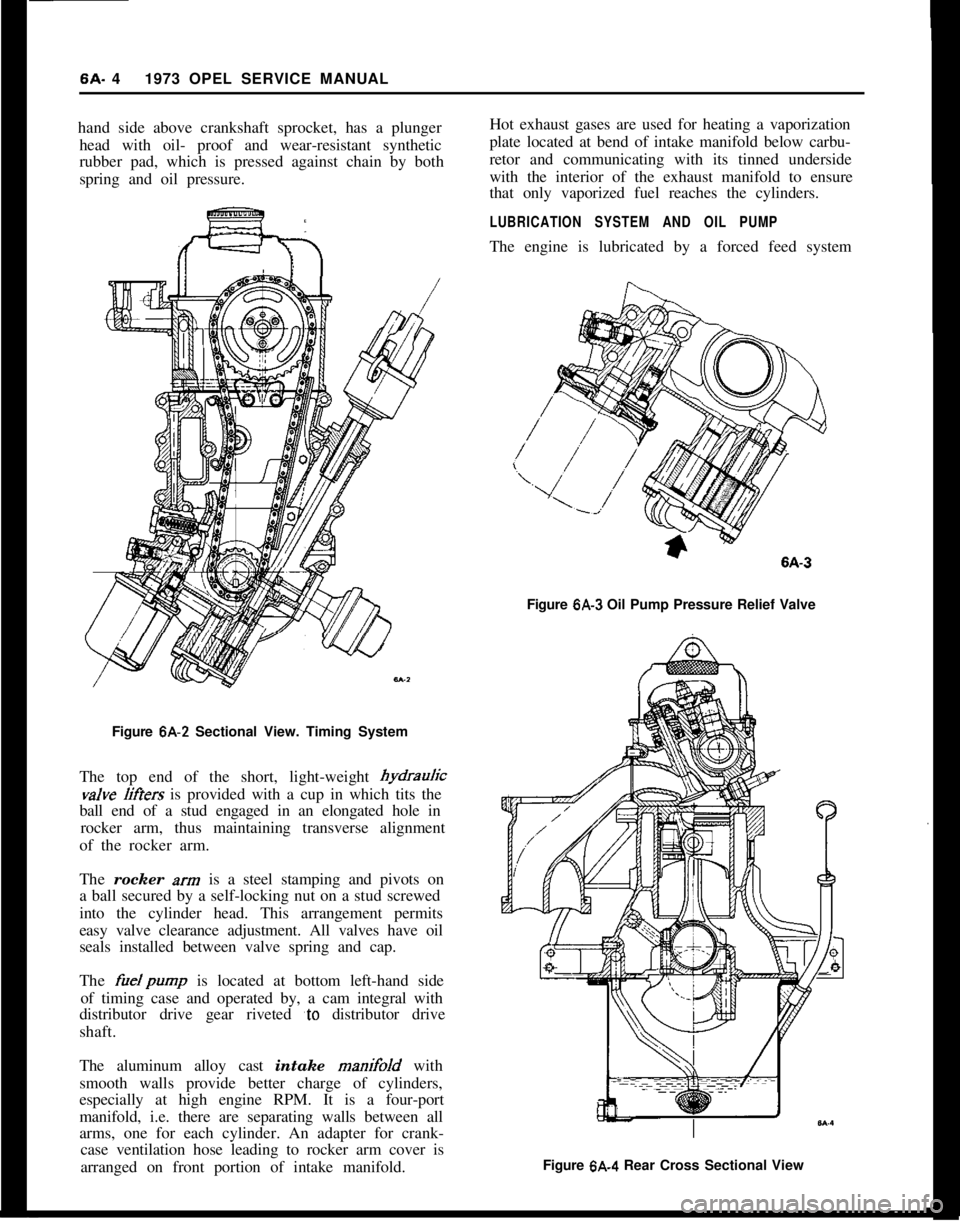

Figure 6A-2 Sectional View. Timing System

The top end of the short, light-weight hydrauricvalve

liffers is provided with a cup in which tits the

ball end of a stud engaged in an elongated hole in

rocker arm, thus maintaining transverse alignment

of the rocker arm.

The rocker

xrn is a steel stamping and pivots on

a ball secured by a self-locking nut on a stud screwed

into the cylinder head. This arrangement permits

easy valve clearance adjustment. All valves have oil

seals installed between valve spring and cap.

The

fuelpump is located at bottom left-hand side

of timing case and operated by, a cam integral with

distributor drive gear riveted

‘to distributor drive

shaft.

The aluminum alloy cast intake manifold with

smooth walls provide better charge of cylinders,

especially at high engine RPM. It is a four-port

manifold, i.e. there are separating walls between all

arms, one for each cylinder. An adapter for crank-

case ventilation hose leading to rocker arm cover is

arranged on front portion of intake manifold.Hot exhaust gases are used for heating a vaporization

plate located at bend of intake manifold below carbu-

retor and communicating with its tinned underside

with the interior of the exhaust manifold to ensure

that only vaporized fuel reaches the cylinders.

LUBRICATION SYSTEM AND OIL PUMPThe engine is lubricated by a forced feed system

Figure

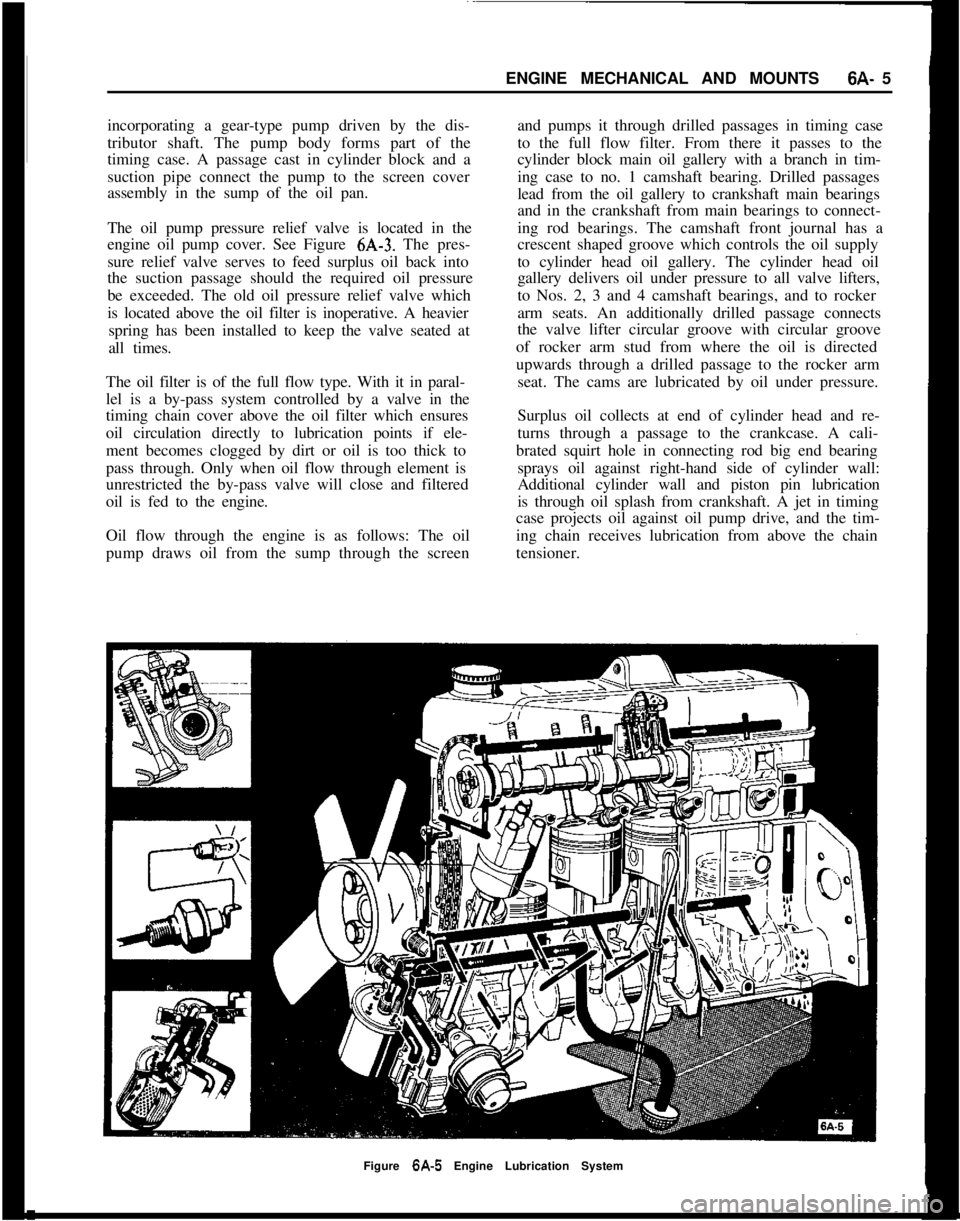

6A-3 Oil Pump Pressure Relief Valve

Figure 6A.4 Rear Cross Sectional View

Page 296 of 625

ENGINE MECHANICAL AND MOUNTS6A- 5

incorporating a gear-type pump driven by the dis-

tributor shaft. The pump body forms part of the

timing case. A passage cast in cylinder block and a

suction pipe connect the pump to the screen cover

assembly in the sump of the oil pan.

The oil pump pressure relief valve is located in the

engine oil pump cover. See Figure 6A-3. The pres-

sure relief valve serves to feed surplus oil back into

the suction passage should the required oil pressure

be exceeded. The old oil pressure relief valve which

is located above the oil filter is inoperative. A heavier

spring has been installed to keep the valve seated at

all times.

The oil filter is of the full flow type. With it in paral-

lel is a by-pass system controlled by a valve in the

timing chain cover above the oil filter which ensures

oil circulation directly to lubrication points if ele-

ment becomes clogged by dirt or oil is too thick to

pass through. Only when oil flow through element is

unrestricted the by-pass valve will close and filtered

oil is fed to the engine.

Oil flow through the engine is as follows: The oil

pump draws oil from the sump through the screenand pumps it through drilled passages in timing case

to the full flow filter. From there it passes to the

cylinder block main oil gallery with a branch in tim-

ing case to no. 1 camshaft bearing. Drilled passages

lead from the oil gallery to crankshaft main bearings

and in the crankshaft from main bearings to connect-

ing rod bearings. The camshaft front journal has a

crescent shaped groove which controls the oil supply

to cylinder head oil gallery. The cylinder head oil

gallery delivers oil under pressure to all valve lifters,

to Nos. 2, 3 and 4 camshaft bearings, and to rocker

arm seats. An additionally drilled passage connects

the valve lifter circular groove with circular groove

of rocker arm stud from where the oil is directed

upwards through a drilled passage to the rocker arm

seat. The cams are lubricated by oil under pressure.

Surplus oil collects at end of cylinder head and re-

turns through a passage to the crankcase. A cali-

brated squirt hole in connecting rod big end bearing

sprays oil against right-hand side of cylinder wall:

Additional cylinder wall and piston pin lubrication

is through oil splash from crankshaft. A jet in timing

case projects oil against oil pump drive, and the tim-

ing chain receives lubrication from above the chain

tensioner.

Figure 6A-5 Engine Lubrication System

Page 307 of 625

6A- 161973 OPEL SERVICE MANUALInspection of Connecting Rod Bearings and

Crankshaft JournalsRemove oil pan.

After removal of oil pan, disconnect two connecting

rods at a time from crankshaft and inspect the bear-

ings and crankpin journals. While,tuming crankshaft

it is necessary to

t&porarily reconnect the rods to

crankshaft to avoid possibility of damaging the jour-

nals through contact with loose rods.

If connecting rod bearings are chipped or scored they

should be replaced. If bearings

are in good physical

condition check for proper clearance on crankpins as

described under, checking clear$nce and selecting

replacement connecting rod beartngs.

If crankpin journals are scored or ridged, the crank-

shaft must be replaced, or reground for undersize

bearings, to insure satisfactory life of connecting rod

bearings. Slight roughness may be polished out withfine grit polishing cloth thoroughly wetted with en-

gine oil. Burrs may be honed off with a fine oil stone.

Use an outside micrometer to check crankpins for

out- of-round. If crankpins are mpre than

,002” out-

of- round, satisfactory life of new ,bearings cannot be

expected.

Checking Clearance and Selecting Replacement

Connecting Rod BearingsService bearings are furnished in standard size and

several undersizes. The clearance of connecting rod

(and crankshaft) bearings may be checked by use of

Plastigage, Type PG-1 (green), or equivalent, which

is soluble in oil.

1. Remove connecting rod cap with bearing shell.

Wipe off oil from bearing and crankpin journal, also

blow oil out of hole in crankshaft.

2. Place a piece of the plastic-type gauge material

Figure 6A-25 Checking Bearing

Cleatance WithPlastic-Type Gaugelengthwise along the bottom center of the lower bear-

ing shell (Figure 6A-25, view A), then install cap

with shell and tighten nuts to 36 lb. ft. Do not turn

crankshaft with gauge type material in bearing.

3. Remove bearing cap with bearing shell, the flat-

tened piece of gauge will be found adhering to either

the bearing shell or the crankpin. Do not remove it.

4. Using the scale printed on the envelope, measure

the flattened piece of gauge at its widest point. The

number within the graduation which closely corre-

sponds to the width of the gauge, indicates the bear-

ing clearance in thousandths of an inch. See Figure6A-25, View B.

5. The desired clearance with a new bearing is.0006”- .0025”. If bearing has been in service it is

advisable to install a new bearing if the clearance

exceeds .003”, however if bearing is in good condi-

tion and is not being checked because of bearing

noise, it is not necessary to replace the bearing.

6. After the proper size bearing has been selected,

clean off the gauge, oil thoroughly, reinstall cap with

bearing shell and tighten nuts to 36 lb. ft.

CRANKSHAFT BEARINGS AND SEALS

Replacement of Crankshaft BearingsA crankshaft bearing consists of two halves or shells

which are identical and are interchangeable in cap

and crankcase. All crankshaft bearings except the

rear main bearing are identical. The crankshaft end

thrust is taken up the rear (No. 5) main bearing.

Figure 6A-26 Engine Crankshaft Bearings

When the shells are placed in crankcase and bearing

cap, the ends extend slightly beyond the parting

sur-faces so that when cap bolts are tightened the shells

will be clamped tightly in place to insure positive

Page 308 of 625

ENGINE MECHANICAL AND MOUNTS6A- 17

seating and to prevent turning.The ends of she//s

must never be tiled flush with parting surface of

crankcase or bearing cap.Crankshaft bearings are the precision type which do

not require reaming to size. Shims are not provided

for adjustment since worn bearings are readily re-

placed with new bearings of proper size. Bearings for

service replacement are furnished in standard size

and undersizes. Under no circumstances should

crankshaft bearing caps be tiIed to adjust for wear in

old bearing.After removal of oil pan, pipe and screen assembly,

perform the following removal, inspection and in-

stallation operations on each crankshaft bearing in

turn so that the crankshaft will be well supported by

the other bearings.

If crankshaft has been removed to check straightness

the following procedure is suggested. Rest crank-

shaft on “V-blocks” at number one and number live

main bearing journals. Check indicator runout at

No. 3 main bearing journal. Total indicator reading

should not exceed

.C012”.1. Since any service condition which affects the

crankshaft bearings may also affect the connecting

rod bearings, it is advisable to inspect connecting rod

bearings

first. If crankpins are worn to the extent

that crankshaft should be replaced or reground, re-

placement of crankshaft bearings only will not be

satisfactory.

If replacement of cylinder block or crankshaft is re-

quired, always check main bearing clearance with

plastic-type gauge to obtain specified limits.

2. Remove one bearing cap, then clean and inspect

lower bearing shell and the crankshaft journal. If

journal surface is scored or ridged, the crankshaft

must be replaced or reground to insure satisfactory

operation with new bearings. Slight roughness may

be polished out with tine grit polishing cloth

thoroughly wetted with engine oil, and burrs may be

honed off with a tine stone.

3. If condition of lower bearing shell and crankshaft

journal is satisfactory, check the bearing clearance

with a plastic-type gauge.

4. When checking a crankshaft bearing with plastic-

type gauging material, turn crankshaft so that oil

hole is up to avoid dripping of oil on the gauge

material. Place paper shims in lower halves of adja-

cent bearings and tighten cap bolts to take the weight

of crankshaft

off the lower shell of beating being

checked.5. If bearing clearance exceeds

.C03”, it is advisable

to install a new bearing; however, if bearing is in

good condition and is not being checked because ofbearing noise, it is not necessary to replace the bear-

ing.6. Loosen all crankshaft bearing cap bolts

l/2 turn,

and remove cap of bearing to be replaced.

7. Remove upper bearing shell by inserting Bearing

Shell Remover and Installer J-8080 in oil hole in

crankshaft, then slowly turning crankshaft so that

the tool rotates the shell out of place by pushing

against the end without the tang. See Figure

6A-27.When turning crankshaft with rear bearing cap

removed hold oil seal to prevent it from rotating out

of position in crankcase.

8. The crankshaft journal cannot be measured with

an outside micrometer when shaft is in place; how-

ever, when upper bearing shell is removed the jour-

nal may be checked for out-of-round by using a

special crankshaft caliper and inside micrometer.

Figure 6A-27 Removing and Installing Crankshaft

Bearing Upper Shell

The caliper should not be applied to journal in line

with oil hole.

If crankshaft journal is more than

.M)12” out-of-

round, the crankshaft should be replaced since the

full mileage cannot be expected from bearings used

with an excessively out-of-round crankshaft.

9. Before installation of bearing shells make sure that

crankshaft journal and the bearing seats in crankcase

and cap are thoroughly cleaned.

10. Coat inside surface of upper bearing shell with

engine oil and place shell against crankshaft journal

so that tang on shell will engage notch in crankcase

when shell is rotated into place.

11. Rotate bearing shell into place as far as possible

by hand, then insert Installer J-8080 in crankshaft oil

hole and rotate crankshaft to push shell into place.

Bearing shell should move into place with very little

Page 309 of 625

6A- 18 1973 OPEL SERVICE MANUAL

pressure. If heavy pressure is required, shell was not

started squarely and will be distorted if force into place.

12. Place lower bearing shell in bearing cap, then

check clearance

with plastic-type gauge, as previ-

ously described.

13. The desired clearance with a new bearing is

.0009” to .0025”. If this clearance cannot be obtained

with a standard size bearing, insert an undersize

bearing and check again

w&h plastic-type gauge

material.

14. When the proper size bearing has been selected,

clean out all plastic gauge material, oil the lower

shell and reinstall bearing cap. Clean the bolt holes

and lube bolts, then torque cap bolts to 72 lb. ft. The

crankshaft should turn freely at flywheel rim; how-

ever, a very slight drag is permissible if an undersize

bearing is used.

15. If the thrust bearing shell is disturbed or replaced

it is necessary to line up the thrust surfaces of the

bearing shell before the cap bolts are tightened. To

do this, move the crankshaft fore and aft the limit of

its travel several times (last movement fore) with the

thrust bearing cap bolts finger tight.

16. After bearing is installed and tested, loosen all

bearing cap bolts

l/2 turn and continue with other

bearings. When bearings have been installed and

tested, tighten all bearing cap bolts to 72 lb. ft.

17. Replace rear bearing oil seals.

18. Install pipe and screen assembly and oil pan.

Installation of Rear Bearing Oil

Seals (Engine in Vehicle)

1. Remove transmission, bell housing and clutch.

Refer to appropriate section for removal procedures.

Figure 6A-28 Removing Rear Main Oil Seal

2. Remove flywheel.

3. Punch a hole into oil seal and screw in a sheet

metal screw and pull out oil seal. See Figure

6A-28.

4. To insure proper sealing, lubricate seal with a

suitable protective grease and install on taper ring

J-22928. Turn seal to ensure lip of seal is not turned

back. See Figure

6A-27.

OIL SEAL’6A-29

Figure

6A-29 Installing Oil Seal on Tool J-22928

5. Place tapered ring with oil seal on crankshaft

flange and move lip of seal

over rear of crankshaft.

Be careful not to tilt seal.

Figure 6A-30 Installing Rear Main Bearing Oil Seal

6. Drive in oil seal using Tool J-22928-2. See Figure

6A-30.

7. Install flywheel, clutch, bell housing and transmis-

.

Page 311 of 625

6A. 201973 OPEL SERVICE MANUAL

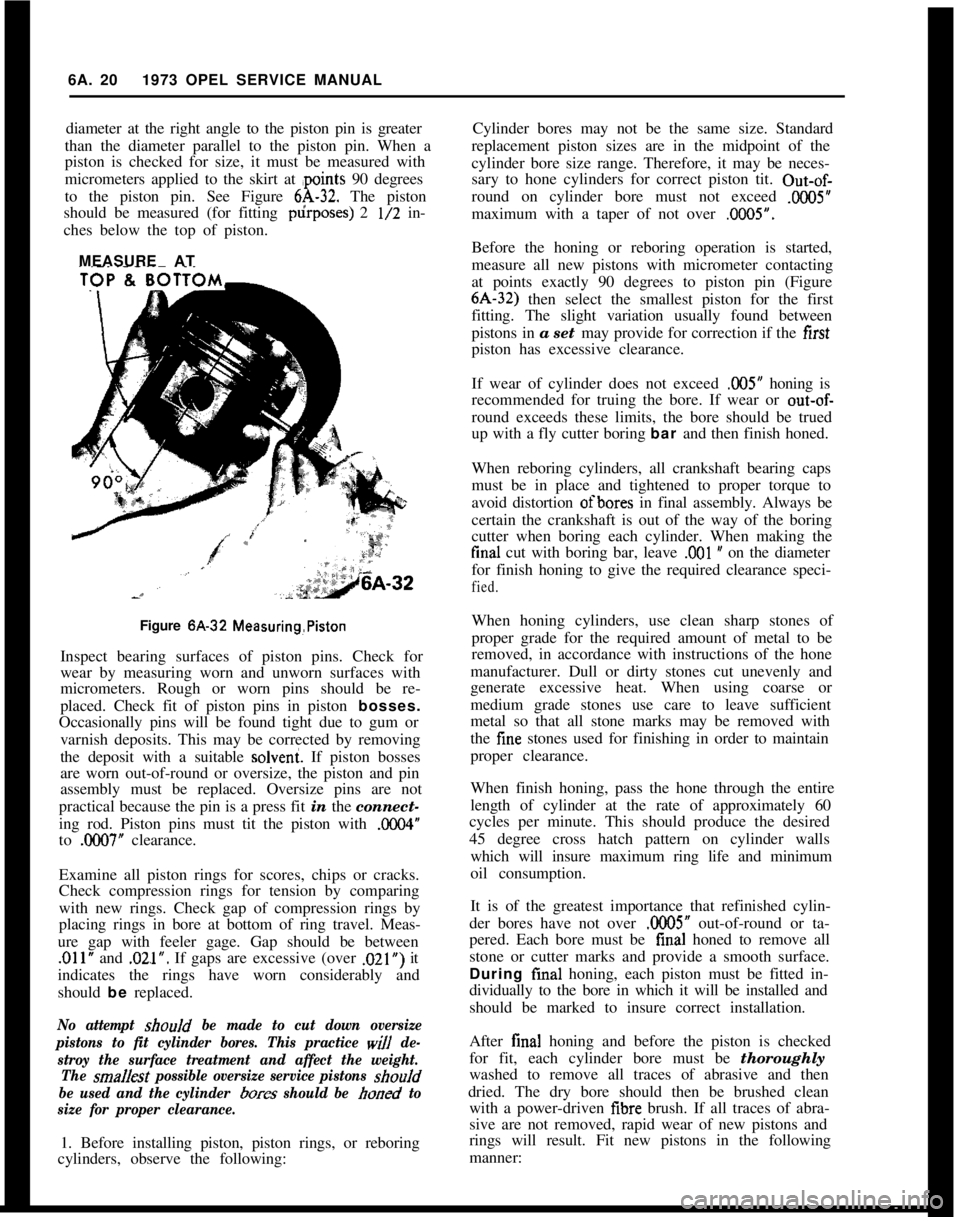

diameter at the right angle to the piston pin is greater

than the diameter parallel to the piston pin. When a

piston is checked for size, it must be measured with

micrometers applied to the skirt at ,points 90 degrees

to the piston pin. See Figure

6A-32. The piston

should be measured (for fitting p&poses) 2

l/2 in-

ches below the top of piston.

MEASURE AT

Figure 6A-32

Measuring,PistonInspect bearing surfaces of piston pins. Check for

wear by measuring worn and unworn surfaces with

micrometers. Rough or worn pins should be re-

placed. Check fit of piston pins in piston bosses.

Occasionally pins will be found tight due to gum or

varnish deposits. This may be corrected by removing

the deposit with a suitable solveni. If piston bosses

are worn out-of-round or oversize, the piston and pin

assembly must be replaced. Oversize pins are not

practical because the pin is a press fit in the connect-

ing rod. Piston pins must tit the piston with

0X4”to

.OCHl7” clearance.

Examine all piston rings for scores, chips or cracks.

Check compression rings for tension by comparing

with new rings. Check gap of compression rings by

placing rings in bore at bottom of ring travel. Meas-

ure gap with feeler gage. Gap should be between

,011” and .02.1”. If gaps are excessive (over .021”) it

indicates the rings have worn considerably and

should be replaced.

No attempt should be made to cut down oversize

pistons to fit cylinder bores. This practice

will de-

stroy the surface treatment and affect the weight.

The

sma/Jest possible oversize service pistons shouId

be used and the cylinder

bores should be honed to

size for proper clearance.1. Before installing piston, piston rings, or reboring

cylinders, observe the following:Cylinder bores may not be the same size. Standard

replacement piston sizes are in the midpoint of the

cylinder bore size range. Therefore, it may be neces-

sary to hone cylinders for correct piston tit. Out-of-

round on cylinder bore must not exceed

.ooO5”maximum with a taper of not over

.OilO5”.Before the honing or reboring operation is started,

measure all new pistons with micrometer contacting

at points exactly 90 degrees to piston pin (Figure6A-32) then select the smallest piston for the first

fitting. The slight variation usually found between

pistons in a set may provide for correction if the first

piston has excessive clearance.

If wear of cylinder does not exceed

.005” honing is

recommended for truing the bore. If wear or

out-of-round exceeds these limits, the bore should be trued

up with a fly cutter boring bar and then finish honed.

When reboring cylinders, all crankshaft bearing caps

must be in place and tightened to proper torque to

avoid distortion ofbores in final assembly. Always be

certain the crankshaft is out of the way of the boring

cutter when boring each cylinder. When making thefinal cut with boring bar, leave

,001 w on the diameter

for finish honing to give the required clearance speci-

fied.When honing cylinders, use clean sharp stones of

proper grade for the required amount of metal to be

removed, in accordance with instructions of the hone

manufacturer. Dull or dirty stones cut unevenly and

generate excessive heat. When using coarse or

medium grade stones use care to leave sufficient

metal so that all stone marks may be removed with

the fine stones used for finishing in order to maintain

proper clearance.

When finish honing, pass the hone through the entire

length of cylinder at the rate of approximately 60

cycles per minute. This should produce the desired

45 degree cross hatch pattern on cylinder walls

which will insure maximum ring life and minimum

oil consumption.

It is of the greatest importance that refinished cylin-

der bores have not over

.0005” out-of-round or ta-

pered. Each bore must be final honed to remove all

stone or cutter marks and provide a smooth surface.

During final honing, each piston must be fitted in-

dividually to the bore in which it will be installed and

should be marked to insure correct installation.

After final honing and before the piston is checked

for fit, each cylinder bore must be thoroughly

washed to remove all traces of abrasive and then

dried. The dry bore should then be brushed clean

with a power-driven iibre brush. If all traces of abra-

sive are not removed, rapid wear of new pistons and

rings will result. Fit new pistons in the following

manner: