engine OPEL AMPERA E 2018.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: AMPERA E, Model: OPEL AMPERA E 2018.5Pages: 273, PDF Size: 6.6 MB

Page 216 of 273

214Vehicle care3. Release the bonnet support fromits retainer above the radiator

support and place it securely into

the slotted retainer in the bonnet.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and let it fall into the latch from a low height (20-25 cm).

Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch to avoid dents.

Cooling system

The vehicle has three different

cooling systems.

Regularly check the coolant level of

the respective cooling systems and

have the cause of a possible coolant

loss remedied by a workshop.

Caution

Make sure that you never run the

vehicle with insufficient coolant.

A low coolant level can cause

damage to the vehicle.

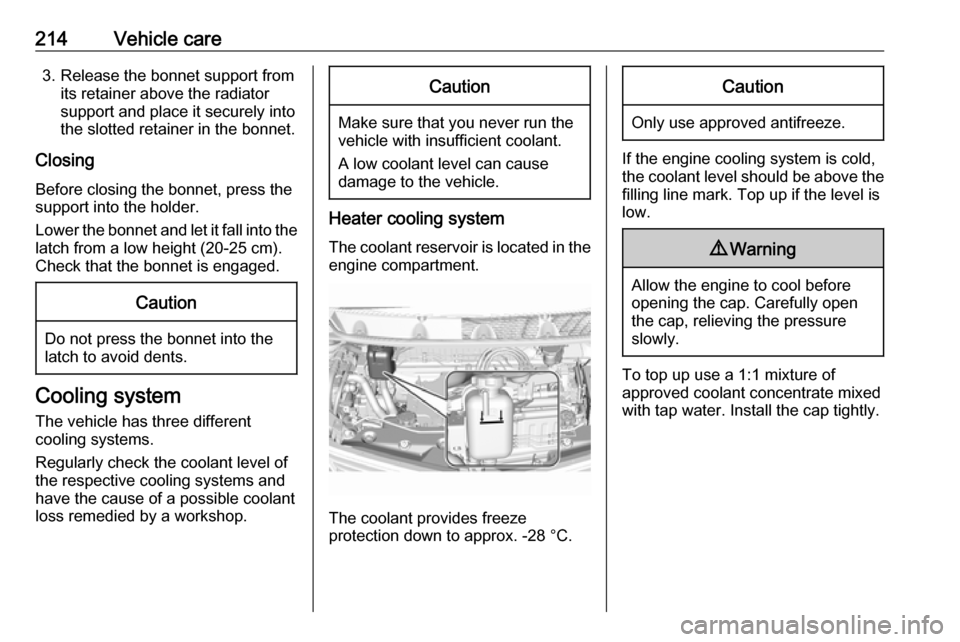

Heater cooling system

The coolant reservoir is located in the engine compartment.

The coolant provides freeze

protection down to approx. -28 °C.

Caution

Only use approved antifreeze.

If the engine cooling system is cold,

the coolant level should be above the

filling line mark. Top up if the level is

low.

9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up use a 1:1 mixture of

approved coolant concentrate mixed

with tap water. Install the cap tightly.

Page 217 of 273

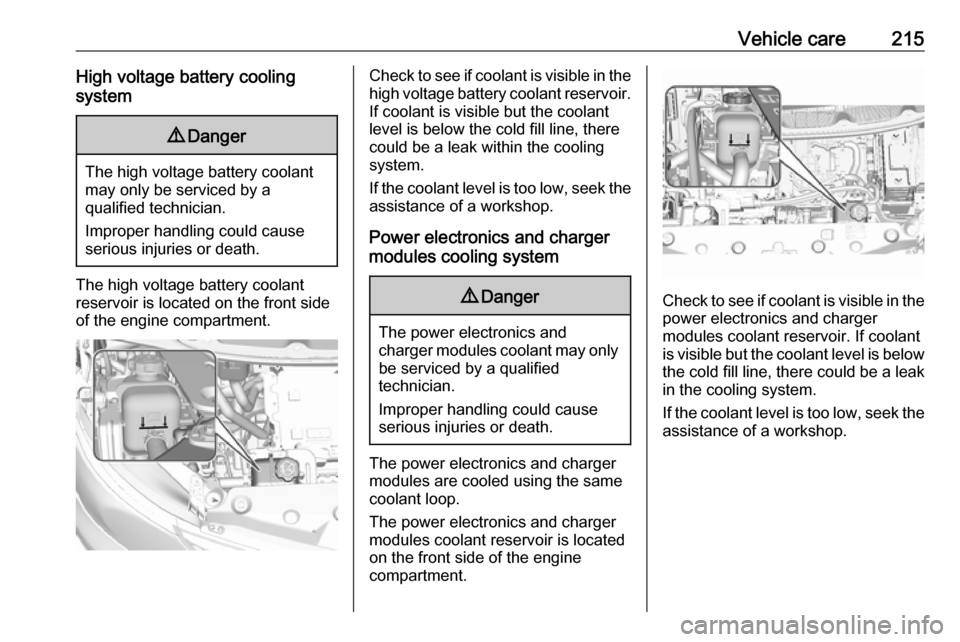

Vehicle care215High voltage battery cooling

system9 Danger

The high voltage battery coolant

may only be serviced by a

qualified technician.

Improper handling could cause serious injuries or death.

The high voltage battery coolantreservoir is located on the front side

of the engine compartment.

Check to see if coolant is visible in the high voltage battery coolant reservoir.

If coolant is visible but the coolant

level is below the cold fill line, there

could be a leak within the cooling

system.

If the coolant level is too low, seek the assistance of a workshop.

Power electronics and charger

modules cooling system9 Danger

The power electronics and

charger modules coolant may only be serviced by a qualified

technician.

Improper handling could cause serious injuries or death.

The power electronics and charger

modules are cooled using the same coolant loop.

The power electronics and charger

modules coolant reservoir is located

on the front side of the engine

compartment.

Check to see if coolant is visible in the

power electronics and charger

modules coolant reservoir. If coolant

is visible but the coolant level is below the cold fill line, there could be a leak

in the cooling system.

If the coolant level is too low, seek the assistance of a workshop.

Page 218 of 273

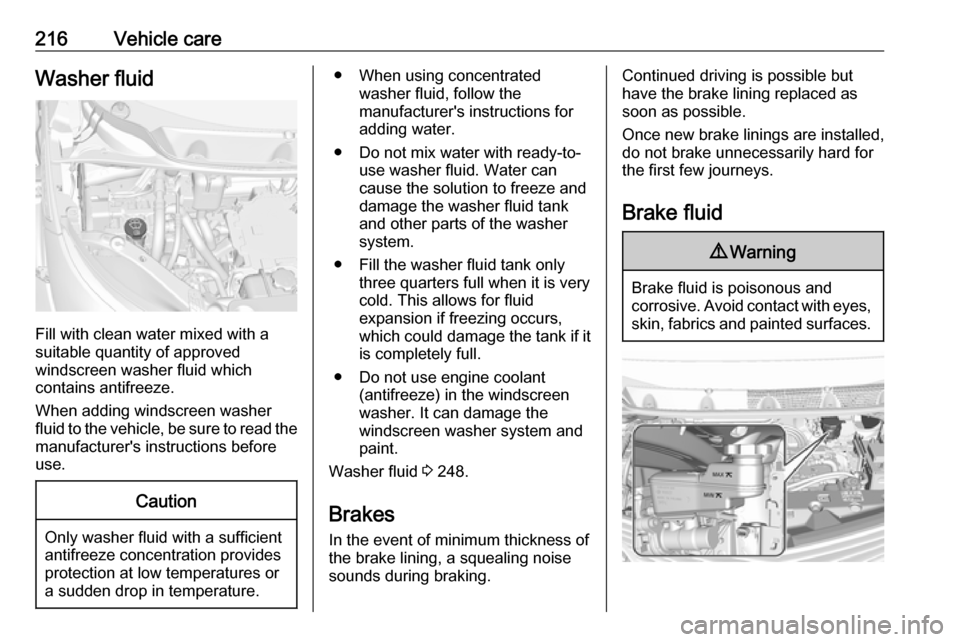

216Vehicle careWasher fluid

Fill with clean water mixed with a

suitable quantity of approved

windscreen washer fluid which

contains antifreeze.

When adding windscreen washer

fluid to the vehicle, be sure to read the

manufacturer's instructions before

use.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

● When using concentrated washer fluid, follow the

manufacturer's instructions for

adding water.

● Do not mix water with ready-to- use washer fluid. Water can

cause the solution to freeze and

damage the washer fluid tank

and other parts of the washer

system.

● Fill the washer fluid tank only three quarters full when it is verycold. This allows for fluid

expansion if freezing occurs,

which could damage the tank if it

is completely full.

● Do not use engine coolant (antifreeze) in the windscreen

washer. It can damage the

windscreen washer system and

paint.

Washer fluid 3 248.

Brakes In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

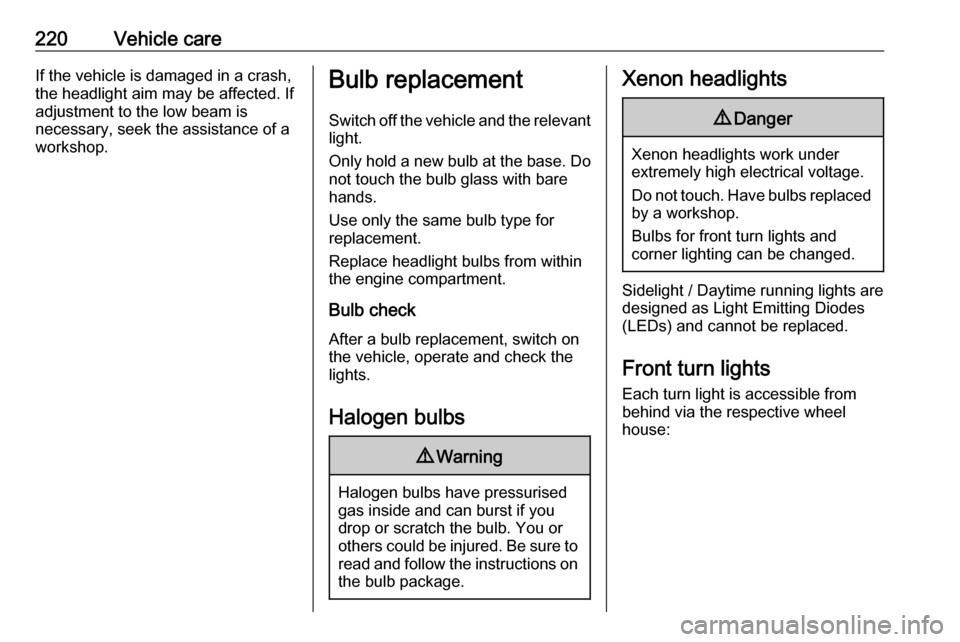

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes,

skin, fabrics and painted surfaces.

Page 220 of 273

218Vehicle careBatteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

There are connecting points for jump

starting in the engine compartment.

Jump starting 3 240.

Remove the 12 V vehicle battery

black negative (−) cable from the

12 V vehicle battery to prevent the

12 V vehicle battery from running

down, or use a battery trickle charger.

Ensure the vehicle is switched off

before connecting or disconnecting

the 12 V vehicle battery.

Vehicle storage 3 211.

Battery discharge protection 3 105.Warning label

Meaning of symbols:

● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the 12 V vehicle battery out

of reach of children.

● The 12 V vehicle battery contains

sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the 12 V vehicle

battery.

Post-crash label

The post-crash label is located in the

door frame 3 152.

Page 222 of 273

220Vehicle careIf the vehicle is damaged in a crash,

the headlight aim may be affected. If

adjustment to the low beam is

necessary, seek the assistance of a

workshop.Bulb replacement

Switch off the vehicle and the relevant

light.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement, switch on

the vehicle, operate and check the

lights.

Halogen bulbs9 Warning

Halogen bulbs have pressurised

gas inside and can burst if you

drop or scratch the bulb. You or others could be injured. Be sure to read and follow the instructions onthe bulb package.

Xenon headlights9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Bulbs for front turn lights and

corner lighting can be changed.

Sidelight / Daytime running lights are

designed as Light Emitting Diodes

(LEDs) and cannot be replaced.

Front turn lights Each turn light is accessible from

behind via the respective wheel

house:

Page 225 of 273

Vehicle care223Electrical system

High voltage devices and wiring9 Warning

Exposure to high voltage may

cause shock, burns, and even

death. The high voltage

components in the vehicle should

only be serviced by specially

trained technicians.

High voltage components are

identified by labels. Do not

remove, open, take apart, or

modify these components. High

voltage cable or wiring has orange covering. Do not probe, tamper

with, cut, or modify high voltage

cable or wiring.

Electrical system overload

The vehicle has fuses and circuit

breakers to protect against an

electrical system overload.

If the current electrical load is too

heavy, the circuit breaker will open

and close, protecting the circuit until

the current load returns to normal or the problem is fixed. This greatly

reduces the chance of circuit

overload and fire caused by electrical

problems.

Fuses and circuit breakers protect the

following parts in the vehicle:

● Headlight wiring

● Windscreen wiper motor

● Power windows and other power accessories

Headlight wiring An electrical overload may cause the

lights to go on and off or in some

cases to remain off. In this case, have

the headlight wiring checked

immediately by a workshop.

Windscreen wipers

If the wiper motor overheats due to

blockage from heavy snow or ice, the windscreen wipers will stop until themotor has cooled down and the wiper

control has been turned off. Afterremoval of the blockage, the wiper

motor will restart when moving the

wiper control to the desired operating

position.

Although the circuit is protected from

electrical overload, mechanical

overload due to heavy snow or ice

may cause wiper linkage damage.

Always clear ice and heavy snow

from the windscreen before using the windscreen wipers. If the overload is

caused by an electrical problem and

not snow or ice, it must be serviced.

Fuses

Data on the replacement fuse must match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● at the front left side of the engine

compartment

● at the left side of the instrument panel

Before replacing a fuse, turn off the

respective switch and the vehicle.

Page 226 of 273

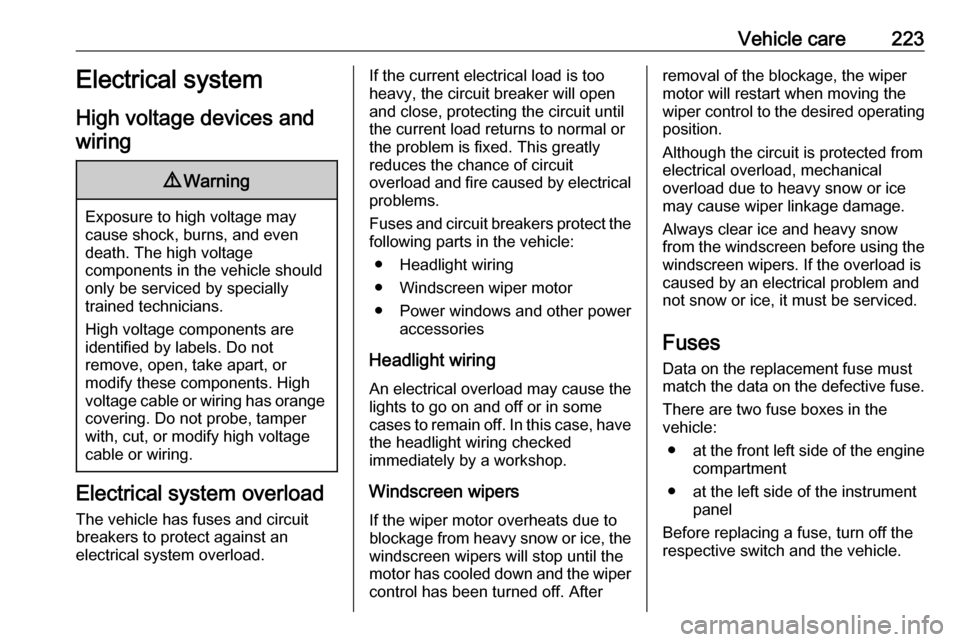

224Vehicle careA blown fuse can be recognised by itsmelted wire. Do not replace the fuse

until the cause of the fault has been

remedied.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

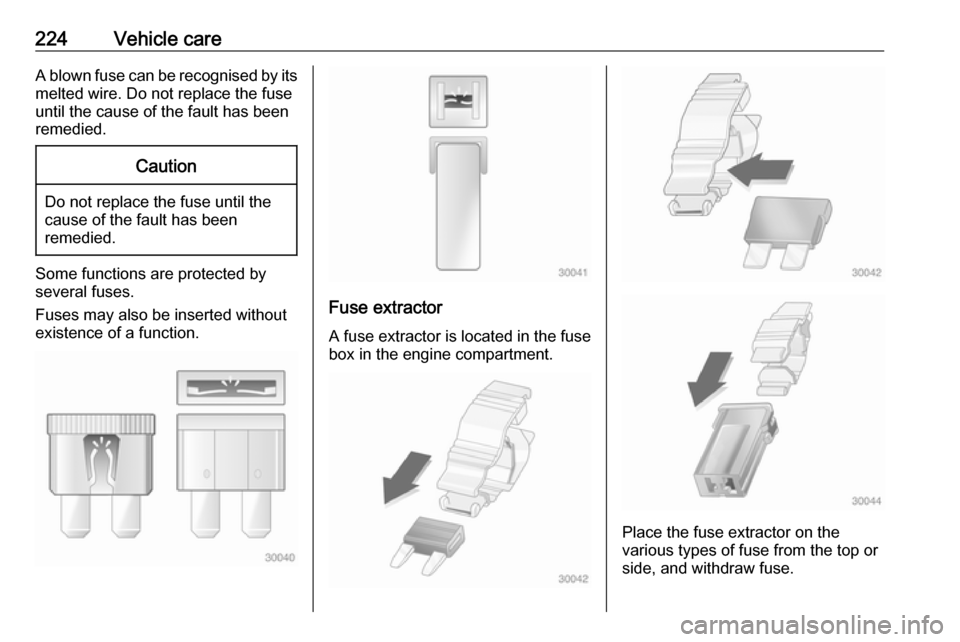

Fuse extractor

A fuse extractor is located in the fuse

box in the engine compartment.

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

Page 227 of 273

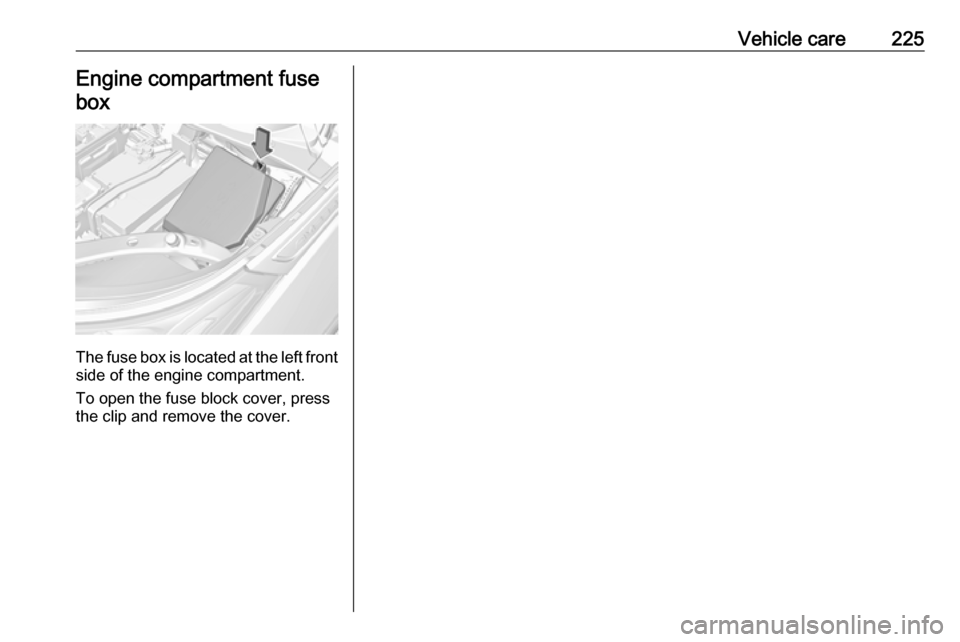

Vehicle care225Engine compartment fusebox

The fuse box is located at the left front

side of the engine compartment.

To open the fuse block cover, press

the clip and remove the cover.

Page 230 of 273

228Vehicle careNumberUsage45Vehicle integration control

module46Integrated chassis control

module47Headlight levelling device48Integrated chassis control

module49Interior rear view mirror50–51E-booster52Rear camera53–54A/C control module55Rechargeable energy

storage system pump56–57Power electronics coolant

pump58Engine control moduleNumberUsage59Electric steering column

lock60HVAC electric heater61On-board charging module62Transmission range control

module 163Electric cooling fan64Engine control module65Auxiliary heater pump66–67Drive unit controller68Rear window defogger69–70A/C control module71–72Transmission range control

moduleNumberUsage73Single power inverter

module74–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

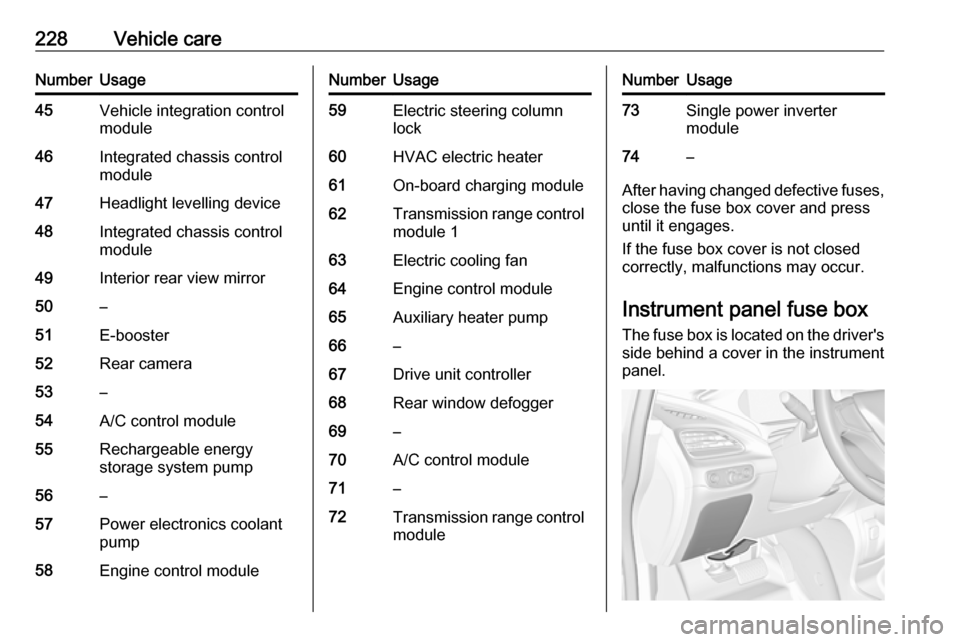

Instrument panel fuse boxThe fuse box is located on the driver's

side behind a cover in the instrument

panel.

Page 240 of 273

238Vehicle care2. Remove the compressor and thesealant bottle.

3. Remove the electrical connection cable and air hose from the

storage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery, we recommend running the

engine.