lock OPEL ANTARA 2009 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: ANTARA, Model: OPEL ANTARA 2009Pages: 234, PDF Size: 3.01 MB

Page 183 of 234

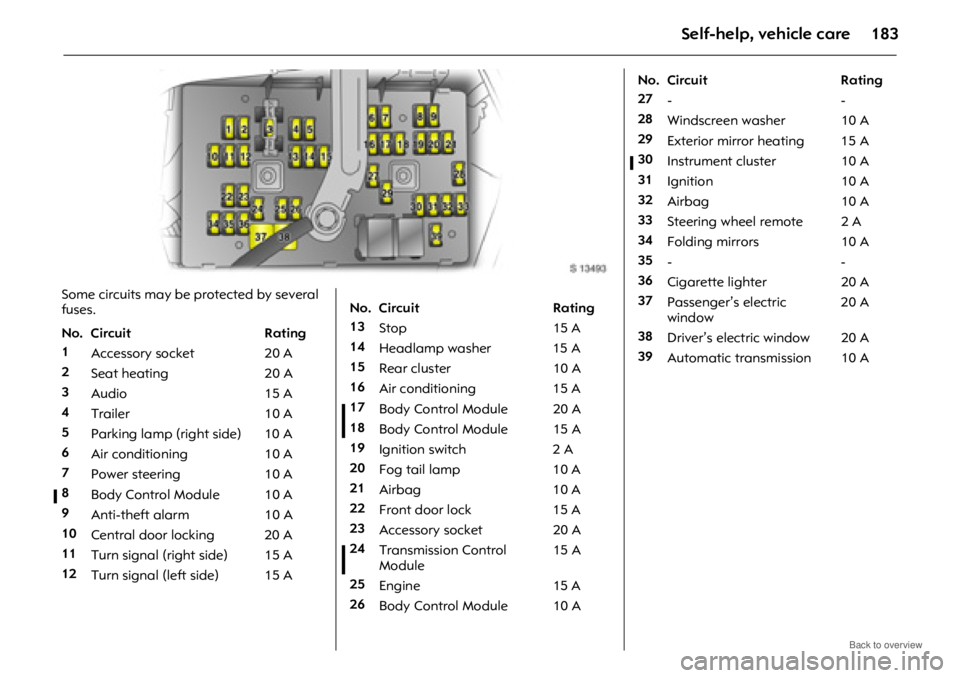

Self-help, vehicle care 183

Some circuits may be protected by several

fuses.

No. Circuit Rating

1Accessory socket 20 A

2 Seat heating 20 A

3 Audio 15 A

4 Trailer 10 A

5 Parking lamp (right side) 10 A

6 Air conditioning 10 A

7 Power steering 10 A

8 Body Control Module 10 A

9 Anti-theft alarm 10 A

10 Central door locking 20 A

11 Turn signal (right side) 15 A

12 Turn signal (left side) 15 ANo. Circuit Rating

13 Stop 15 A

14 Headlamp washer 15 A

15 Rear cluster 10 A

16 Air conditioning 15 A

17 Body Control Module 20 A

18 Body Control Module 15 A

19 Ignition switch 2 A

20 Fog tail lamp 10 A

21 Airbag 10 A

22 Front door lock 15 A

23 Accessory socket 20 A

24 Transmission Control

Module 15 A

25 Engine 15 A

26 Body Control Module 10 A

No. Circuit Rating

27 --

28 Windscreen washer 10 A

29 Exterior mirror heating 15 A

30 Instrument cluster 10 A

31 Ignition 10 A

32 Airbag 10 A

33 Steering wheel remote 2 A

34 Folding mirrors 10 A

35 --

36 Cigarette lighter 20 A

37 Passenger’s electric

window 20 A

38 Driver’s electric window 20 A

39 Automatic transmission 10 A

Page 186 of 234

Self-help, vehicle care186

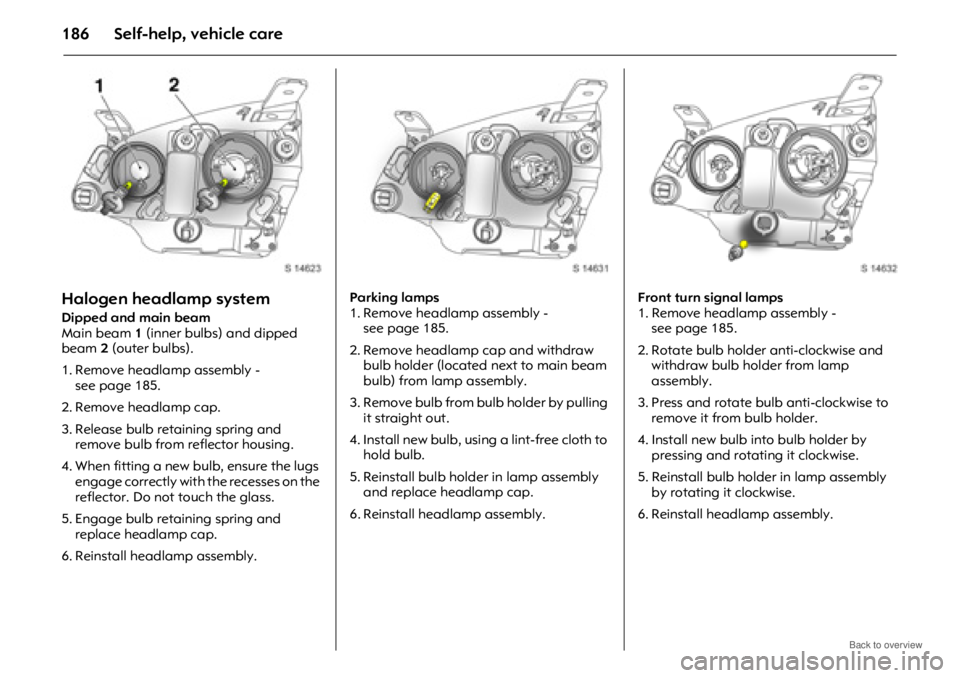

Halogen headlamp system

Dipped and main beam

Main beam 1 (inner bulbs) and dipped

beam 2 (outer bulbs).

1. Remove headlamp assembly - seepage185.

2. Remove headlamp cap.

3. Release bulb retaining spring and remove bulb from reflector housing.

4. When fitting a new bulb, ensure the lugs engage correctly with the recesses on the

reflector. Do not touch the glass.

5. Engage bulb retaining spring and replace headlamp cap.

6. Reinstall headlamp assembly. Parking lamps

1. Remove headlamp assembly -

seepage185.

2. Remove headlamp cap and withdraw bulb holder (located next to main beam

bulb) from lamp assembly.

3. Remove bulb from bulb holder by pulling it straight out.

4. Install new bulb, using a lint-free cloth to hold bulb.

5. Reinstall bulb holder in lamp assembly and replace headlamp cap.

6. Reinstall headlamp assembly. Front turn signal lamps

1. Remove headlamp assembly -

see page 185.

2. Rotate bulb holder anti-clockwise and withdraw bulb holder from lamp

assembly.

3. Press and rotate bulb anti-clockwise to remove it from bulb holder.

4. Install new bulb into bulb holder by pressing and rotating it clockwise.

5. Reinstall bulb holder in lamp assembly

by rotating it clockwise.

6. Reinstall headlamp assembly.

Page 187 of 234

Self-help, vehicle care187

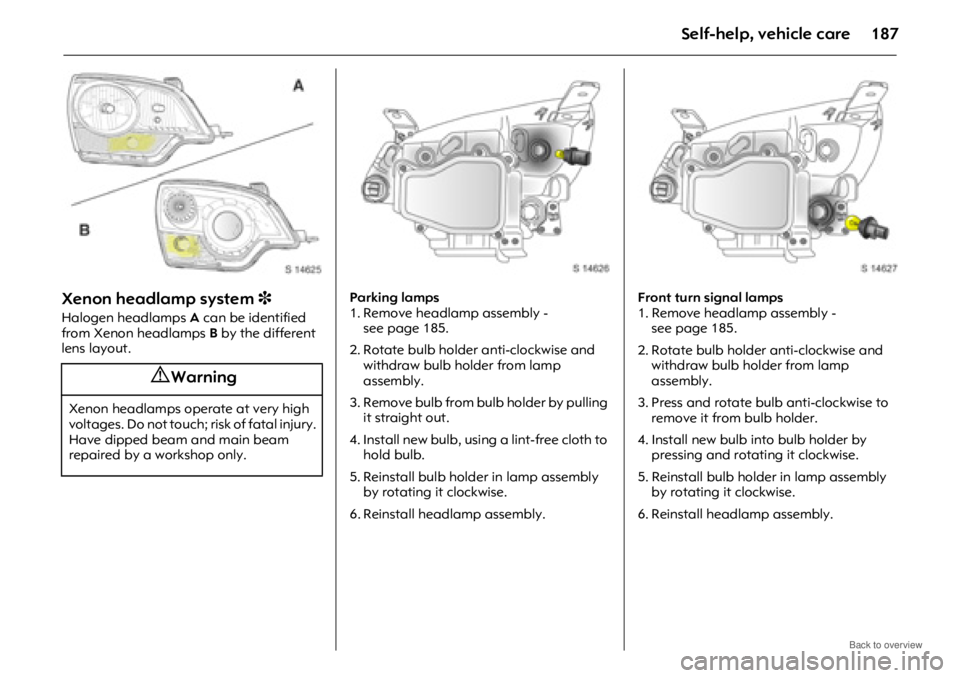

Xenon headlamp system 3

Halogen headlamps A can be identified

from Xenon headlamps B by the different

lens layout. Parking lamps

1. Remove headlamp assembly -

seepage185.

2. Rotate bulb holder anti-clockwise and withdraw bulb holder from lamp

assembly.

3. Remove bulb from bulb holder by pulling it straight out.

4. Install new bulb, using a lint-free cloth to hold bulb.

5. Reinstall bulb holder in lamp assembly by rotating it clockwise.

6. Reinstall headlamp assembly. Front turn signal lamps

1. Remove headlamp assembly -

see page 185.

2. Rotate bulb holder anti-clockwise and withdraw bulb holder from lamp

assembly.

3. Press and rotate bulb anti-clockwise to remove it from bulb holder.

4. Install new bulb into bulb holder by pressing and rotating it clockwise.

5. Reinstall bulb holder in lamp assembly

by rotating it clockwise.

6. Reinstall headlamp assembly.

9 Warning

Xenon headlamps operate at very high

voltages. Do not touch; risk of fatal injury.

Have dipped beam and main beam

repaired by a workshop only.

Page 188 of 234

Self-help, vehicle care188

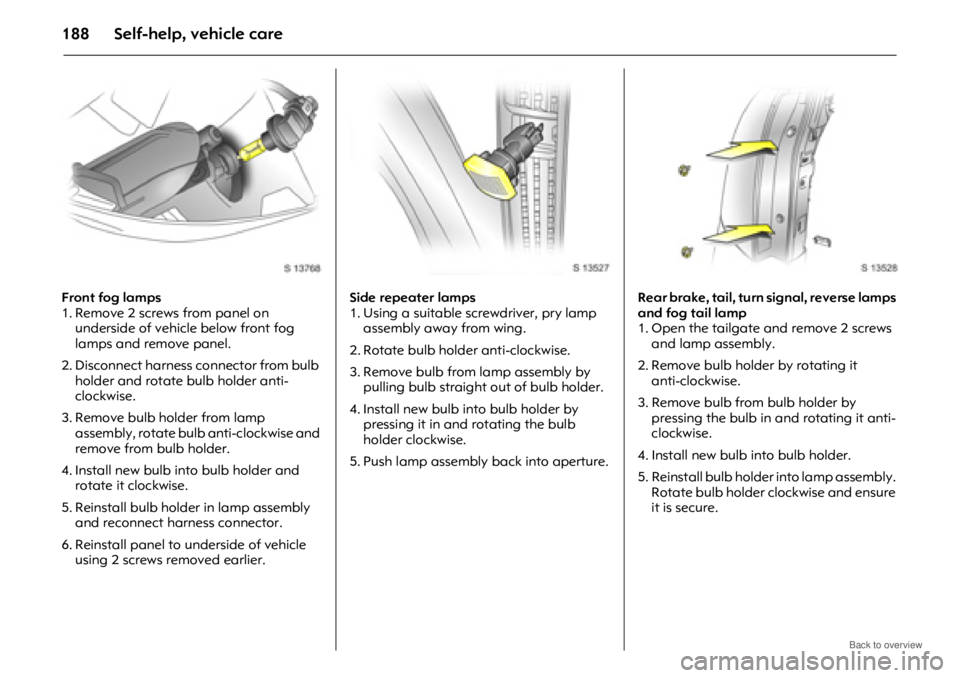

Front fog lamps

1. Remove 2 screws from panel on underside of vehicle below front fog

lamps and remove panel.

2. Disconnect harness connector from bulb holder and rotate bulb holder anti-

clockwise.

3. Remove bulb holder from lamp assembly, rotate bulb anti-clockwise and

remove from bulb holder.

4. Install new bulb in to bulb holder and

rotate it clockwise.

5. Reinstall bulb holder in lamp assembly

and reconnect harness connector.

6. Reinstall panel to underside of vehicle using 2 screws removed earlier. Side repeater lamps

1. Using a suitable screwdriver, pry lamp

assembly away from wing.

2. Rotate bulb holder anti-clockwise.

3. Remove bulb from lamp assembly by pulling bulb straight out of bulb holder.

4. Install new bulb into bulb holder by pressing it in and rotating the bulb

holder clockwise.

5. Push lamp assembly back into aperture. Rear brake, tail, turn signal, reverse lamps

and fog tail lamp

1. Open the tailgate and remove 2 screws

and lamp assembly.

2. Remove bulb holder by rotating it anti-clockwise.

3. Remove bulb from bulb holder by pressing the bulb in and rotating it anti-

clockwise.

4. Install new bulb into bulb holder.

5. Reinstall bulb holder into lamp assembly. Rotate bulb holder clockwise and ensure

it is secure.

Page 189 of 234

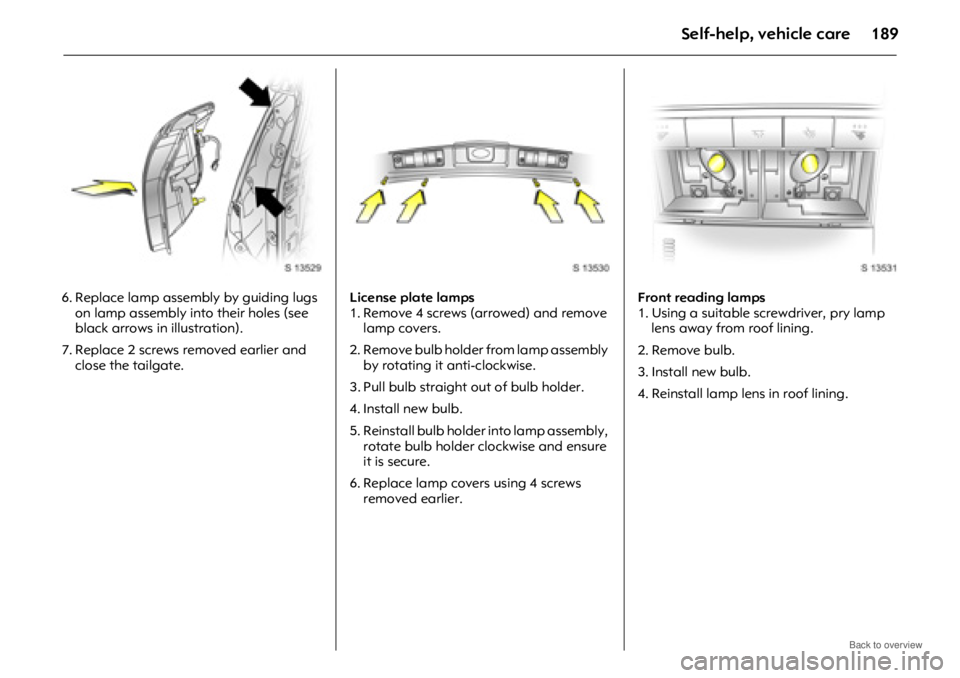

Self-help, vehicle care189

6. Replace lamp assembly by guiding lugs on lamp assembly into their holes (see

black arrows in illustration).

7. Replace 2 screws removed earlier and close the tailgate. License plate lamps

1. Remove 4 screws (arrowed) and remove

lamp covers.

2. Remove bulb holder from lamp assembly by rotating it anti-clockwise.

3. Pull bulb straight out of bulb holder.

4. Install new bulb.

5. Reinstall bulb holder into lamp assembly, rotate bulb holder clockwise and ensure

it is secure.

6. Replace lamp covers using 4 screws removed earlier. Front reading lamps

1. Using a suitable screwdriver, pry lamp

lens away from roof lining.

2. Remove bulb.

3. Install new bulb.

4. Reinstall lamp lens in roof lining.

Page 194 of 234

Self-help, vehicle care194

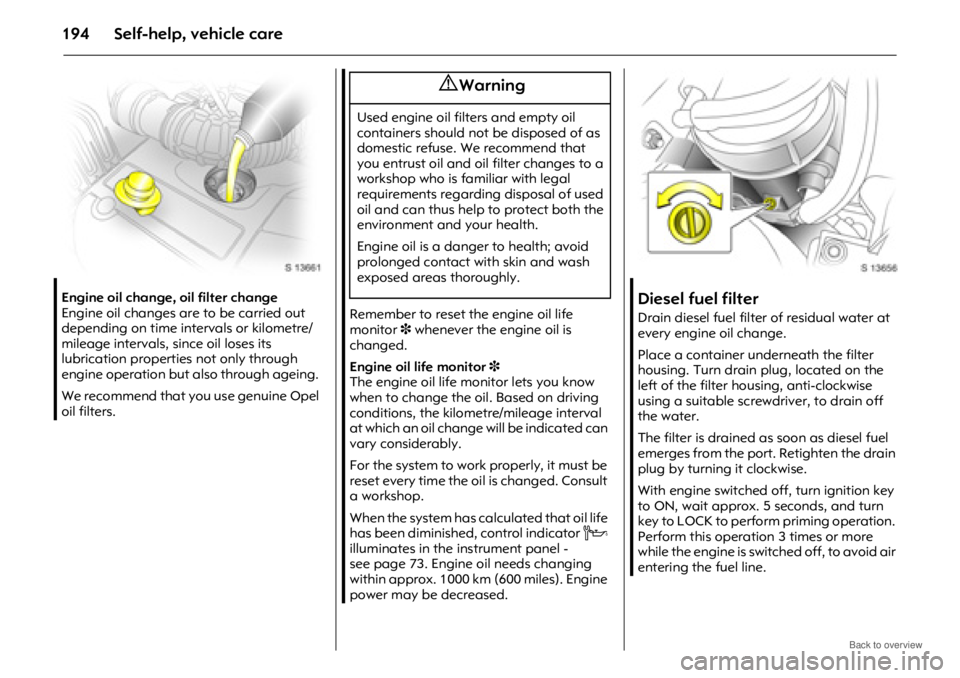

Engine oil change, oil filter change

Engine oil changes are to be carried out

depending on time intervals or kilometre/

mileage intervals, since oil loses its

lubrication properties not only through

engine operation but also through ageing.

We recommend that you use genuine Opel

oil filters.

Remember to reset the engine oil life

monitor 3 whenever the engine oil is

changed.

Engine oil life monitor 3

The engine oil life monitor lets you know

when to change the oil. Based on driving

conditions, the kilometre/mileage interval

at which an oil change will be indicated can

vary considerably.

For the system to work properly, it must be

reset every time the oil is changed. Consult

a workshop.

When the system has calculated that oil life

has been diminished, control indicator C

illuminates in the instrument panel -

see page 73. Engine oil needs changing

within approx. 1000 km (600 miles). Engine

power may be decreased.Diesel fuel filter

Drain diesel fuel filter of residual water at

every engine oil change.

Place a container underneath the filter

housing. Turn drain plug, located on the

left of the filter housing, anti-clockwise

using a suitable screwdriver, to drain off

the water.

The filter is drained as soon as diesel fuel

emerges from the port. Retighten the drain

plug by turning it clockwise.

With engine switched off, turn ignition key

to ON, wait approx. 5 seconds, and turn

key to LOCK to perform priming operation.

Perform this operation 3 times or more

while the engine is switched off, to avoid air

entering the fuel line.

9 Warning

Used engine oil filters and empty oil

containers should not be disposed of as

domestic refuse. We recommend that

you entrust oil and oil filter changes to a

workshop who is familiar with legal

requirements regarding disposal of used

oil and can thus help to protect both the

environment and your health.

Engine oil is a danger to health; avoid

prolonged contact with skin and wash

exposed areas thoroughly.

Page 202 of 234

Self-help, vehicle care202

Vehicle care aids 3

Vehicle wash:

z Car Shampoo

z Sponges

z Chamois Leather

z Wheel Cleaners

z Engine Cleaners

z Glass Cleaners

Exterior care:

z Touch-up Applicator

z Spray and Touch-up Paint

z Car Polishes/Colour Restorers

z Car Waxes/Sealers

z Alloy Wheel Cleaner

z Alloy Wheel Preserver

z Metallic Paintwork Wax

z Rust Preventative

z Lubricant Sprays

z Lock Cylinder Grease

z De-icer Sprays

z Tar Removal Spray

z Insect Remover

z Window Cleaning Spray

z Cleaning Solvent and Antifreeze

Interior care:

z Interior/Upholstery Cleaner Washing

The paintwork of your vehicle is exposed to

environmental influences, e.g. continuous

changes in weather conditions, industrial

waste gases and dust or thawing salts, so

wash and wax your vehicle regularly. When

using automatic car washes, select a

program which includes waxing.

Bird droppings, dead insects, resin, pollen

and the like should be cleaned off

immediately, as they contain aggressive

constituents which can cause paint

damage.

If using a car wash, comply with the

pertinent instructions of the car wash

manufacturer. The windscreen wipers and

tailgate wipers must be switched off –

see pages 92, 93. Remove detachable rod

antenna by unscrewing it.

Do not use high-pressure jet cleaners.

If you wash your vehicle by hand, make

sure that the insides of the wings are also

thoroughly rinsed out. Do not use

household dishwashing liquid, to avoid

removing wax from the paintwork.

Clean edges and folds on opened doors

and flaps as well as the areas they cover.

Thoroughly rinse off and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for paint and window

surfaces; remnants of wax on the windows

will impair vision.

Also wash aluminium trim parts, avoiding

the use of abrasive materials such as

automotive or chrome polish, steam or

caustic soap. Washing with water is

normally sufficient.

Observe national regulations.

Page 205 of 234

Self-help, vehicle care205

Windscreen wiper blades

Wax, such as that used in car washes, can

cause streaks to form on the windscreen

when the wipers are used.

Smearing wiper blades can be cleaned with

a soft cloth and Opel Cleaning Solvent and

Antifreeze, and replaced if necessary –

see page 198. Do not use abrasive

cleaners.

Locks

The locks are lubricated with a high-grade

lock cylinder grease at the factory. Opel

Lock Cylinder Grease prevents the locks

from freezing up.

Only use de-icing agents in emergencies,

as they have a degreasing effect and will

impair the function of the locks. After using

a de-icing agent, have the locks re-greased

by a workshop. Engine compartment

Areas of the engine compartment that are

painted in the same colour as the vehicle

must be looked after

like any other painted

surface.

It is advisable to wash the engine

compartment before and after winter and

preserve it with wax. Cover alternator and

fluid reservoirs with plastic sheets before

washing the engine.

When washing the engine with a steam-jet

cleaner, do not direct the steam-jet at

components of the Anti-lock Brake System

(ABS), the air conditioning system or the

belt drive and its components.

Protective wax that has been applied is

also removed during the engine wash. For

this reason, have the engine, brake system

components in the engine compartment,

axle components with steering, body parts

and cavities thoroughly preserved with

protective wax after the wash.

An engine wash can be performed in the

spring in order to remove dirt that has

adhered to the engine compartment,

which may also have a high salt content.

Check protective wax layer and make good

if necessary. Underbody

Your vehicle has a factory-applied PVC

undercoating in the wheel arches

(including the longitudinal members) which

provides permanent protection and needs

no special maintenance. The surfaces of

the vehicle underbody not covered by PVC

are provided with a durable protective wax

coating in critical areas.

On vehicles which are washed frequently

in automatic car wash

es with underbody

washing facility, the protective wax

coating may be impaire d by dirt-dissolving

additives. Check the underbody after

washing and have it waxed if necessary.

Before the start of the cold weather season,

check the PVC coating and protective wax

coating and, if necessary, have them

restored to perfect condition.

Caution

– commercially available bitumen/

rubber materials can damage the PVC

coating. We recommend that you have

underbody work carried out by a

workshop, who knows the prescribed

materials and has experience in the use

thereof.

The underbody should be washed

following the end of the cold weather

season to remove any dirt adhering to the

underbody since this may also contain salt.

Check protective wax coating and, if

necessary, have it restored to perfect

condition.

Page 207 of 234

Service, maintenance 207

European service schedule

(Antara Z 20 DM, Z 20 DMH, Z 24 XE, Z 32 SE) Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

15

101

30

20 45

30 2

60

40 75

50 3

90

60

Controls, lighting, signalling equi pment and airbags: visual check

steering lock and ignition lock: check xxx

Remote control batteries: replace Every 2 years

Windscreen wipers, windscreen washer system: check, correct xxx

Coolant level and antifreeze: check, correct

Hoses: check for tightness and secure seating xxx

Brake fluid level: check, correct xxx

Battery terminals: check for secu re connections and battery eye xxx

Vehicle system check with TECH2 xxx

Pollen filter: replace xxx

oMore often for when dust, sand or polle n is in the air Agreement with customer

Air cleaner element: replace

xxx

⊕Spark plugs and plug leads: replace Every 90 000 km/60 000 miles

Ribbed V-belt: visual check xxx

⊕Toothed belt and tension roller: visual check xxx

Toothed belt and tension roller: replace - Z 24 XE Every 8 years/120 000 km/80 000 miles

Toothed belt and tension roller: replace - Z 20 DM, Z 20 DMH Every 6 years/90 000 km/60 000 miles

Power steering system: check for leak s. Fluid level: check, correct xxx

Engine oil and oil filter: replace - fixed interval Z 24 XE

2)

2)On vehicles with oil life monitoring, it may be necessary to change the engine oil earlier (control indicator illuminates).

xxxxxx

Z 20 DM, Z 20 DMH, Z 32 SE, except2)xxx

Page 208 of 234

208 Service, maintenance

Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

⊕ Additional operations.

o Under extreme operating conditions and if required by country-specific conditions, the intervals are reduced.

15

10 1

30

20 45

30 2

60

40 75

50 3

90

60

⊕o Diesel fuel filter: drain water

(If relative humidity is high an

d/or fuel is of lower quality) Annually

Fuel filter: replace and drain water - diesel (g rade EN 590) Every 2 years/60 000 km/40 000 miles

Parking brake: check and adjust

Wheel mounting and suspension front an d rear, brake lines, brake pressure

hoses, fuel lines and exhaust system: visual check xxx

Corrosion protection: check and record in Service and Warranty Booklet Annually

Front and rear wheel br akes: check visually xxx

o

⊕Annual service check if annual mileage exceeds 20 000 km Annually

Engine, transmission, PTO, rear differential, A/C compressor: check for leaks xxx

Steering system boots, track rods , final drive: visual check xxx

Track rod end and supporting ball joint: check xxx

⊕Brake and clutch fluid: change Every 2 years

Wheel fastening: loosen and tighten to torque

Tyre condition and pressures: check, correct xxx

⊕Annual service check if annual

mileage exceeds 20 000 km Annually

First aid kit, tyre repair kit and lash ing eyes: visual check Every 2 years

Headlamp aiming: check, adjust x x x

Door hinges, door stop, lock cylinder, lock striker, bonnet catch, tailgate

hinges and check links: lubricate xxx

Test drive, final check

Service interval display and oil life monitor: reset - if applicable xxx