start stop button OPEL ANTARA 2017 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: ANTARA, Model: OPEL ANTARA 2017Pages: 225, PDF Size: 6.18 MB

Page 128 of 225

126Driving and operatingStarting the vehicle at low

temperatures

In extremely cold temperatures, i.e.

below -20 °С, it may be necessary to

crank the engine for up to

30 seconds for it to start.

Turn key to position START and hold

until engine starts. Start attempts

should not last longer than

30 seconds. If engine does not start, wait 10 seconds before repeatingstarting procedure.

Ensure the engine oil is of the correct viscosity, the correct fuel is used,

vehicle services are performed

regularly and the battery is sufficiently

charged.

Turbo engine warm-up Upon start-up, engine available

torque may be limited for a short time,

especially when the engine

temperature is cold. The limitation is

to allow the lubrication system to fully protect the engine.Overrun cut-off

The fuel supply is automatically cut-

off during overrun, i.e. when the

vehicle is driven with a gear engaged

but accelerator is released.

Stop-start system The stop-start system helps to save

fuel and to reduce the exhaust

emissions. When conditions allow, it

switches off the engine as soon as the

vehicle is at a low speed or at a

standstill, e.g. at a traffic light or in a

traffic jam. It starts the engine

automatically as soon as the clutch is depressed. A vehicle battery sensor

ensures that an Autostop is only performed if the vehicle battery is

sufficiently charged for a restart.

Activation

The stop-start system is available as soon as the engine is started, the

vehicle starts-off and the conditions

as stated below in this section are

fulfilled.Deactivation

Deactivate the stop-start system

manually by pressing s. The

deactivation is indicated when the

LED in the button extinguishes.

Fuel economy mode 3 122.

Autostop If the vehicle is at a low speed or at a

standstill, activate an Autostop as

follows:

● Depress the clutch pedal

● set the lever to neutral

● release the clutch pedal

Page 187 of 225

Vehicle care185If the tyre pressure is to be reduced or

increased, switch off the ignition. Tyre

pressures 3 182, 3 212.

General information The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 187.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

The tyre pressure monitoring system

valve cores and sealing rings must be

replaced each time the tyres are

changed.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new tyre/wheel position after

rotating the tyres or replacing one or

more of the tyre pressure sensors.The tyre pressure sensor matching

process should also be performed

after replacing a spare tyre with a

road tyre containing a tyre pressure

sensor. The control indicator w and

the warning message should

extinguish at the next ignition cycle.

The sensors are matched to the tyre/

wheel positions, using a TPMS

relearn tool, in the following order:

● left front tyre

● right front tyre

● right rear tyre

● left rear tyre

Consult your workshop for service or

to purchase a relearn tool.

There are two minutes to match the

first tyre/wheel position, and

five minutes overall to match all four

tyre/wheel positions. If it takes longer, the matching process stops and must

be restarted.The tyre pressure sensor matching

process is as follows:

1. Apply the electrical parking brake 3 143 ; on vehicles with automatic

transmission move the selector

lever to position P.

2. Turn the ignition on 3 125.

3. Initiate the TPMS Learn Mode by simultaneously pressing p and

q on the radio remote control,

- or -

Press INFO on the Infotainment

system until a tyre learn message appears on the Info-display.

Press and hold OK.

The horn sounds twice and the left front turn signal also illuminates

as confirmation that Learn Mode

has been enabled.

4. Start with the left front tyre. 5. Place the relearn tool against the tyre sidewall, near the valve stem.

Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

Page 191 of 225

Vehicle care1896. Press the on/off button to turn the

tyre repair kit on. The tyre is filled

with sealant.

The pressure gauge briefly shows a high pressure while the sealant

canister is emptying. Then the

pressure starts to drop.

All of the sealant is pumped into

the tyre. Then the tyre is inflated.

7. Inflate the tyre to the recommended inflation pressure

using the pressure gauge. The

prescribed tyre pressure should

be obtained within 10 minutes

3 212 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.Drain excess tyre pressure with

the button next to the pressure

gauge.

Do not run the compressor for

longer than 10 minutes.

8. Detach the tyre repair kit and replace the tyre valve cap.

9. Remove any excess sealant using a cloth.

10. Take the label indicating maximum permitted speed from

the sealant canister and affix in

the driver's field of view.

11. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than

10 minutes) stop and check tyre

pressure.

If the tyre pressure has fallen

slightly, set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen by more than 68 kPa (0.68 bar), the

vehicle must not be driven. Seek

the assistance of a workshop.

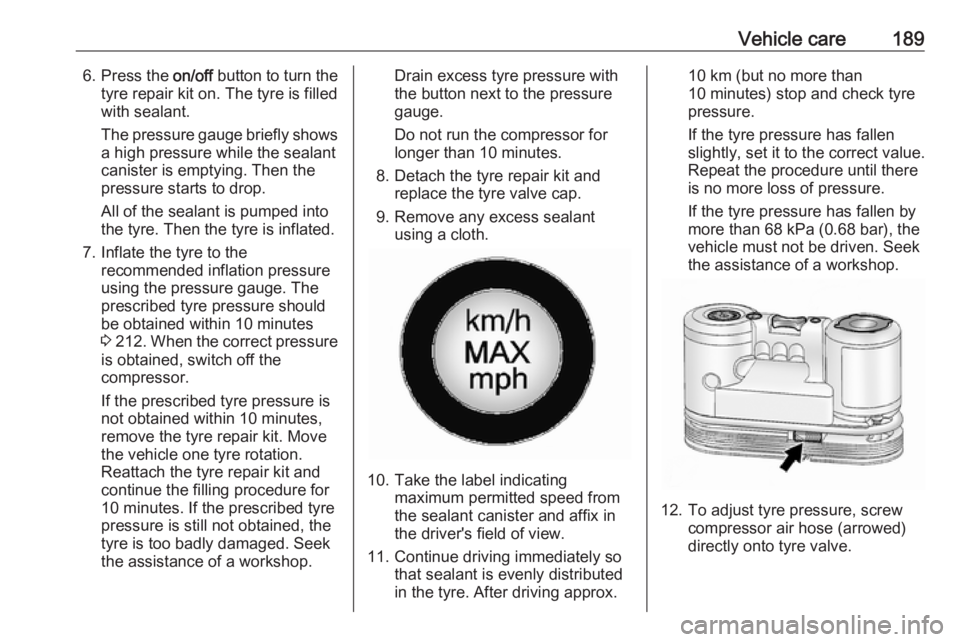

12. To adjust tyre pressure, screw compressor air hose (arrowed)

directly onto tyre valve.