OPEL ASTRA J 2014 Manual user

Manufacturer: OPEL, Model Year: 2014, Model line: ASTRA J, Model: OPEL ASTRA J 2014Pages: 331, PDF Size: 10.13 MB

Page 261 of 331

Vehicle care259

Vehicles with spare wheelVariant 1a: 3-door and 5-door

hatchback with rigid wheel wrench

The jack, the tools and a strap for

securing a damaged wheel are in the

tool box below the spare wheel in the load compartment. The wheel wrenchand the towing eye are in the tool bag

located in the spare wheel well near

the tool box. Spare wheel 3 272.

Variant 1b: 3-door and 5-door

hatchback with foldable wheel

wrench

Same content as variant 1a, but with

a foldable wheel wrench instead of

the rigid wheel wrench located in the

tool bag.

Variant 2: Sports Tourer

The jack, the tools and the towing eye

are in the tool box below the spare

wheel in the load compartment. The

wheel wrench and an extension bolt

for securing a damaged wheel (only

vehicles with temporary spare wheel)

are in the tool bag located in the spare wheel well near the tool box. Spare

wheel 3 272.

Page 262 of 331

260Vehicle care

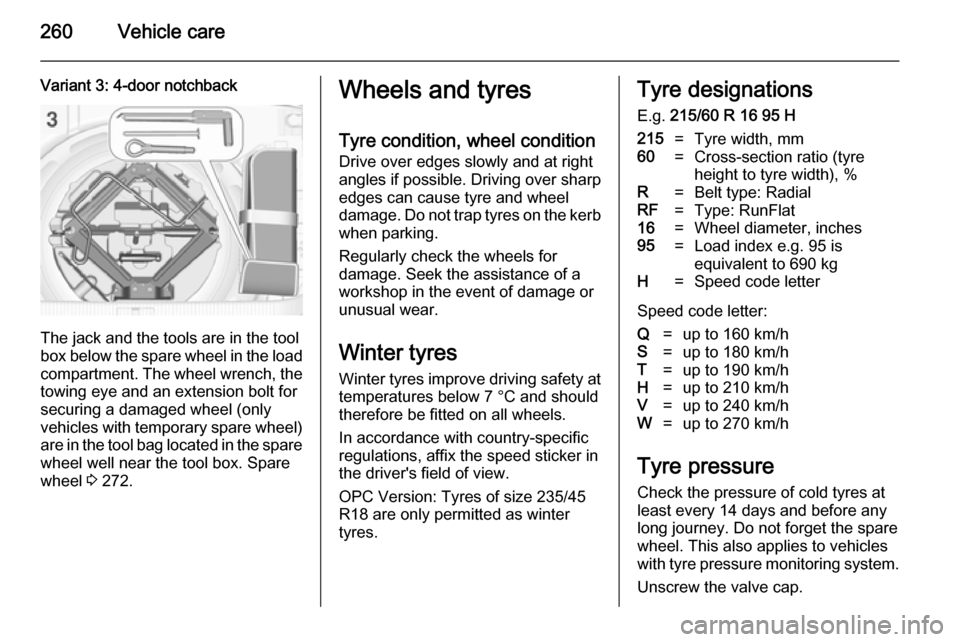

Variant 3: 4-door notchback

The jack and the tools are in the tool

box below the spare wheel in the load

compartment. The wheel wrench, the towing eye and an extension bolt for

securing a damaged wheel (only

vehicles with temporary spare wheel)

are in the tool bag located in the spare wheel well near the tool box. Spare

wheel 3 272.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres Winter tyres improve driving safety attemperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

OPC Version: Tyres of size 235/45

R18 are only permitted as winter tyres.Tyre designations

E.g. 215/60 R 16 95 H215=Tyre width, mm60=Cross-section ratio (tyre

height to tyre width), %R=Belt type: RadialRF=Type: RunFlat16=Wheel diameter, inches95=Load index e.g. 95 is

equivalent to 690 kgH=Speed code letter

Speed code letter:

Q=up to 160 km/hS=up to 180 km/hT=up to 190 km/hH=up to 210 km/hV=up to 240 km/hW=up to 270 km/h

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Page 263 of 331

Vehicle care261

Tyre pressure 3 309 and on the label

on the front left or right door frame.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the body style.

2. Identify the engine identifier code.

Engine data 3 292.

3. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 309.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Tyre pressure monitoring system The tyre pressure monitoring system

checks the pressure of all four wheels

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information

Centre.

Page 264 of 331

262Vehicle care

The menu can be selected by thebuttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X.

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.A detected low tyre pressure

condition is indicated by the control

indicator w 3 119.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 309.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for getting low pressure. Check tyre pressure.

Vehicle messages 3 128.

Page 265 of 331

Vehicle care263

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. Control indicator w

illuminates. For the further three

wheels the system remains

operational.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor: replace

valve core and sealing ring. For

clipped sensor: replace complete

valve stem.Vehicle loading status

Adjust tyre pressure to load condition according to tyre information label ortyre pressure chart 3 309, and select

the relevant setting in the menu Tire

Load in the Driver Information Centre,

Vehicle Information Menu 3 121.

Select:

■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

Auto learn function

After changing wheels, the vehicle

must be stationary for approx.

20 minutes, before the system

recalculates. The following relearn process takes up to 10 minutes of

driving with a minimum speed of

20 km/h. In this case, $ can be

displayed or pressure values can

swap in the Driver Information Centre.

If problems occur during the relearn

process, a warning message is

displayed in the Driver Information

Centre.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Page 266 of 331

264Vehicle careTread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Page 267 of 331

Vehicle care265Tyre chains

Use tyre chains only on front wheels.

9Warning

Damage may lead to tyre blowout.

5-door hatchback, 4-door notchback,

Sports tourer

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).Tyre chains are only permitted on

tyres of size 205/60 R 16 and

215/50 R 17.3-door hatchback

Tyre chains are permitted on tyres of

size 225/55 R 17. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).

Tyre chains are also permitted on

tyres of size 245/45 R 18. Always use fine mesh chains that add no more

than 7 mm to the tyre tread and the

inboard sides (including chain lock).OPC Version

Tyre chains are permitted on tyres of

size 235/45 R 18. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).General

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in a compartment under the floor cover in the load

compartment or, on version with rear

carrier system, in the drawer under

the passenger seat 3 64.

Page 268 of 331

266Vehicle care

The illustrations show different

versions.

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

Page 269 of 331

Vehicle care267

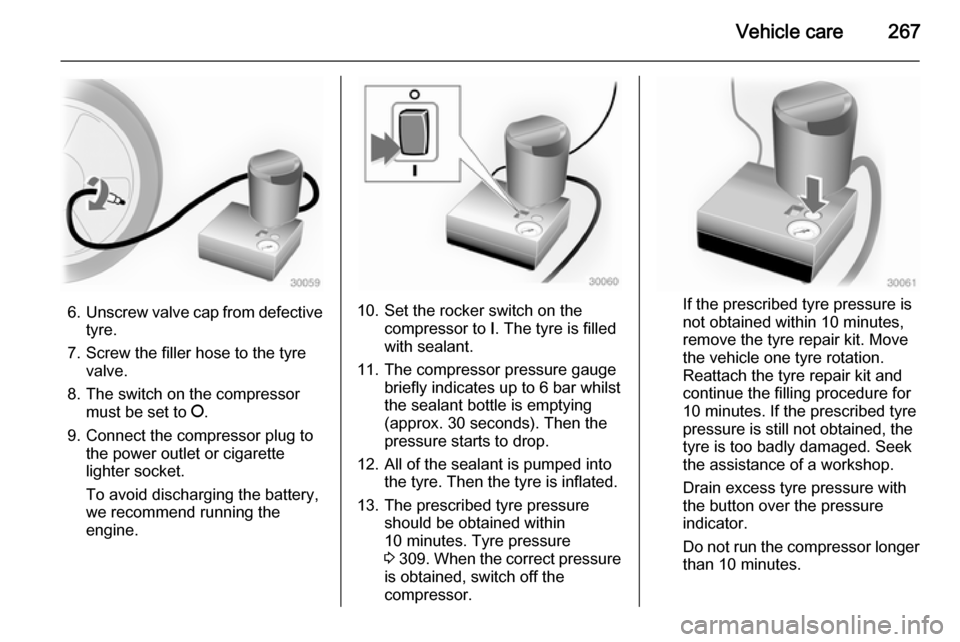

6.Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 309 . When the correct pressure

is obtained, switch off the compressor.If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure

indicator.

Do not run the compressor longer than 10 minutes.

Page 270 of 331

268Vehicle care

14. Detach the tyre repair kit. Pushcatch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 265.