warning OPEL ASTRA J 2015 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2015, Model line: ASTRA J, Model: OPEL ASTRA J 2015Pages: 343, PDF Size: 10.27 MB

Page 261 of 343

Vehicle care259Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

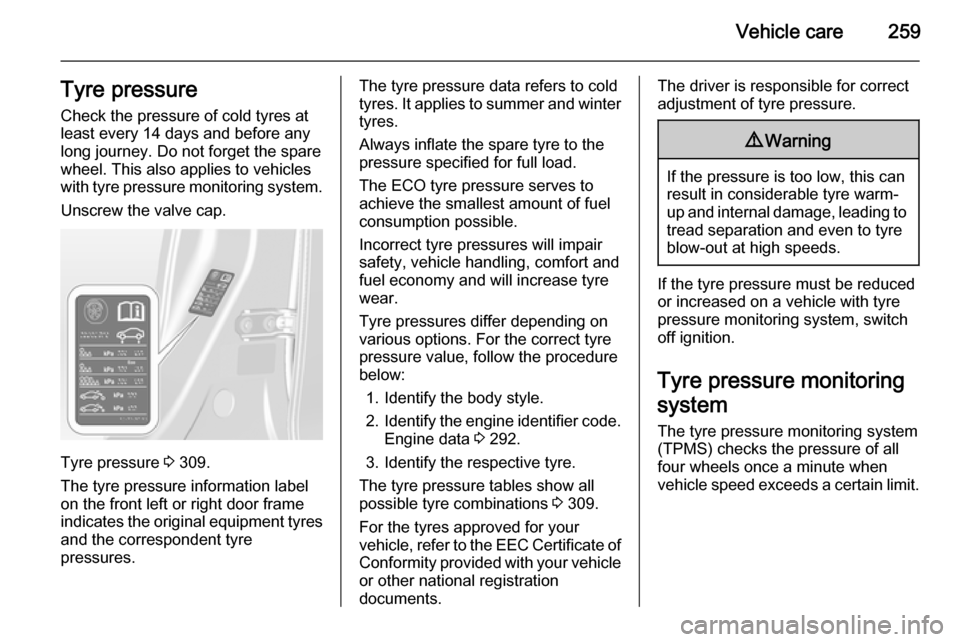

Unscrew the valve cap.

Tyre pressure 3 309.

The tyre pressure information label

on the front left or right door frame

indicates the original equipment tyres

and the correspondent tyre

pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the body style.

2. Identify the engine identifier code.

Engine data 3 292.

3. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 309.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Tyre pressure monitoring system The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.

Page 262 of 343

260Vehicle careCaution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

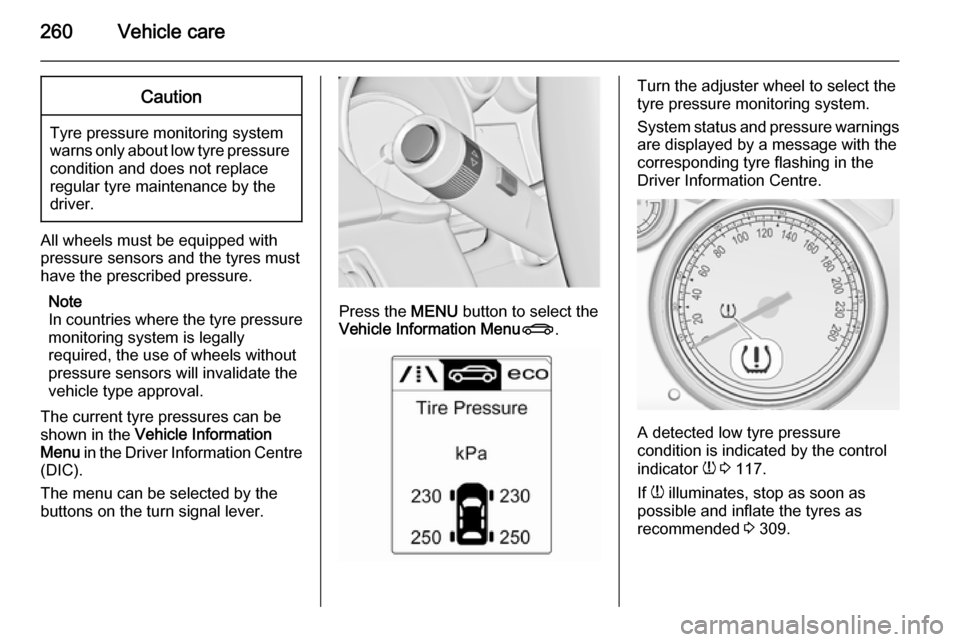

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X.

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 117.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 309.

Page 264 of 343

262Vehicle care

matching process should also be

performed after replacing a spare tyre with a road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: left side front tyre,

right side front tyre, right side rear tyre and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirpconfirms that the sensor

identification code has been

matched to this tyre and wheel

position.

9. Proceed to the right side front tyre,

and repeat the procedure in Step 8.

10. Proceed to the right side rear tyre,

and repeat the procedure in

Step 8.

11. Proceed to the left side rear tyre, and repeat the procedure in

Step 8. The horn sounds twice to

indicate the sensor identification

code has been matched to the left side rear tyre, and the TPMS

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

label.

14. Ensure the tyre loading status is set according selected pressure

3 119.

Page 265 of 343

Vehicle care263

Temperature dependencyTyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the DIC shows the actual tyre

pressure. Therefore it is important to

check tyre pressure with cold tyres.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 266 of 343

264Vehicle care

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, the wheel

covers might not be attached to the

steel wheels.

Tyre chains

Use tyre chains only on front wheels.

9 Warning

Damage may lead to tyre blowout.

5-door hatchback, 4-door notchback

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).

Tyre chains are only permitted on

tyres of size 205/60 R 16,

215/50 R 17 and 215/60 R 16.For the following restrictions apply to

the engines below:

■ Engine A16XHT and A20DTH: tyre

chains only permitted on tyres of

size 205/60 R 16.

■ Engine B16DTH and B16DTL: tyre chains only permitted on tyres of

size 215/60 R 16.Sports tourer

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).

Tyre chains are only permitted on

tyres of size 205/60 R 16,

215/50 R 17 and 215/60 R 16.

For the following restrictions apply to

the engines below:

■ Engine A16XHT and A20DTH: tyre

chains only permitted on tyres of

size 205/60 R 16 and 215/50 R 17.

■ Engine B16DTH and B16DTL: tyre chains only permitted on tyres of

size 215/50 R 17 and 215/60 R 16.

Page 267 of 343

Vehicle care265

3-door hatchback

Tyre chains are permitted on tyres of

size 225/55 R 17. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).

Tyre chains are also permitted on

tyres of size 245/45 R 18. Always use fine mesh chains that add no more

than 7 mm to the tyre tread and the

inboard sides (including chain lock).OPC Version

Tyre chains are permitted on tyres of

size 235/45 R 18. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).General

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in a compartment under the floor cover in the load

compartment or, on version with rear

carrier system, in the drawer under

the passenger seat 3 62.The illustrations show different

versions.

Page 271 of 343

Vehicle care269

■ Never crawl under a jacked-upvehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Clean wheel nuts and thread with a

clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 256.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

Alloy wheels with centre wheel

bolt cap: Disengage centre cap by

inserting and pulling the extractor

in the recess of the brand

emblem, vehicle tools 3 256.

2. Two types of jacks and wheel nut wrenches are possible dependingon the version, vehicle tools

3 256.

Variant 1a with rigid wheel

wrench:Install the wheel wrench ensuring

that it locates securely and loosen

each wheel nut by half a turn.

Variants 1b, 2 and 3 with foldable

wheel wrench:

Page 277 of 343

Vehicle care275

3. Take the extension bolt from thetool bag 3 256 and screw it in

hand-tight using the hexagon key

of the wheel wrench.

4. Store the tool box and the damaged wheel outside up in the

spare wheel well and secure it by

turning the wing nut clockwise on

the bolt.

The floor cover can be placed on the

projecting wheel.

Replace the extension bolt with the

short bolt before placing the

temporary spare wheel in the well after renewing or repairing the

defective wheel.

Stowing the spare wheel back in the well after replacing the

damaged wheel

1. Open the floor cover, untwist and remove wing nut.

Only 3-door hatchback: open floor

cover, remove rear storage,

untwist and remove wing nut and

conus.

2. Only Sports tourer and 4-door notchback with temporary spare

wheel: replace the extension bolt

with the short bolt by using the

hexagon key of the wheel wrench.

3. Place the tools in the tool box or the tool bag 3 256.

4. Place spare wheel outside up in the wheel well and secure by

turning the wing nut right back.Only 3-door hatchback: position

the excentric conus in the recess

of the spare wheel before turning

the wing nut right back.

5. Close floor cover and insert rear storage (only 3-door hatchback).

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if

Page 278 of 343

276Vehicle carethey are not fixed properly. During

a sudden stop or a collision, loose equipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load compartment must always be

secured by the strap.

Temporary spare wheel

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in the front and the full tyre in the rear.

Tyre chains 3 264.

Spare wheel with directional tyre Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

Page 287 of 343

Service and maintenance285

Confirmations

Confirmation of service is recorded in the Service and Warranty Booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

Warranty Booklet is completed

correctly as continuous proof of

service and to assist with warranty

claims. It is also a benefit when selling the vehicle.

Service interval with remainingengine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know

when to change the engine oil.

Service display 3 110.Recommended fluids,

lubricants and parts

Recommended fluids and

lubricants Only use products that meet the

recommended specifications.

Damage resulting from the use of

products not in line with these

specifications will not be covered by

the warranty.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Dexos is the newest engine oil quality

that provides optimum protection for gasoline and diesel engines. If it is

unavailable, engine oils of other listed qualities must be used.

Recommendations for gasoline

engines are also valid for

Compressed Natural Gas (CNG),

Liquified Petroleum Gas (LPG) and

Ethanol (E85) fuelled engines.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 289.

Topping up engine oil

Engine oils of different manufacturers

and brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oil with only

ACEA A1/B1 or only A5/B5 quality is

prohibited, since it can cause long-

term engine damage under certain

operating conditions.