check engine OPEL ASTRA J 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: ASTRA J, Model: OPEL ASTRA J 2017Pages: 295, PDF Size: 8.23 MB

Page 155 of 295

Driving and operating153To reduce the operating forces ofthe parking brake, depress the

brake pedal at the same time.

Control indicator R 3 88.

Electric parking brake

Applying when vehicle is stationary

9 Warning

Pull switch m for approx.

one second, the electric parking

brake operates automatically with

adequate force. For maximum

force, e.g. parking with trailer or on

inclines, pull switch m twice.

The electric parking brake is

applied when control indicator m

illuminates 3 88.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often without engine

running, as this will discharge the

vehicle battery.

Before leaving the vehicle, check the electric parking brake status. Control

indicator m 3 88.

Releasing

Switch on ignition. Keep brake pedal

depressed and then push switch m.

Drive away function

Vehicles with manual transmission:

Depressing the clutch pedal and then

slightly releasing the clutch pedal and

slightly depressing the accelerator

pedal releases the electric parking

brake automatically. This is not

possible when the switch m is pulled

at the same time.

Vehicles with automatic transmission: Engaging D and then depressing the

accelerator pedal releases the

electric parking brake automatically. This is not possible when the switch

m is pulled at the same time.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate

the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Fault

Failure mode of electric parking brake

is indicated by control indicator j and

by a code number or a vehicle

message which is displayed in the

Driver Information Centre. Vehicle

messages 3 99.

Page 191 of 295

Driving and operating189Caution

Use of fuel that does not comply toEN 590 or similar can lead to

engine powerloss, increased wear

or engine damage and may affect

your warranty.

Do not use marine diesel oils, heating

oils, Aquazole and similar diesel-

water emulsions. Diesel fuels must

not be diluted with fuels for petrol

engines.

Fuel for liquid gas operation Liquid gas is known as LPG

(Liquefied Petroleum Gas) or under its French name GPL (Gaz de Pétrole

Liquéfié). LPG is also known as

Autogas.

LPG consists mainly of propane and

butane. The octane rating is between 105 and 115, depending on the

butane proportion. LPG is stored

liquid at around 5 - 10 bar pressure.

The boiling point depends on the

pressure and mixing ratio. At ambient pressure, it is between -42 °C (pure

propane) and -0.5 °C (pure butane).Caution

The system works at an ambient

temperature of approx. -8 °C to

100 °C.

Full function of the LPG system can

only be guaranteed with liquid gas

which complies with the minimum

requirements of DIN EN 589.

Fuel selector

Pressing LPG switches between

petrol and liquid gas operation as

soon as the required parameters (coolant temperature, gas

temperature and minimum engine

speed) have been reached. The

requirements are usually fulfilled after

around 60 seconds (depending on

exterior temperature) and the first firm press on the accelerator. The LED

status shows the current operating

mode.1 off:petrol operation1 flashes:checking conditions

for fuel transition to

liquid gas operation.

Illuminates if

conditions are fulfilled.1 illumi‐

nates:liquid gas operation1 flashes 5

times and

extin‐

guishes:liquid gas tank is

empty or failure in

liquid gas system. A

message is displayed

in the Driver

Information Centre.

If the fuel tank is empty, the engine

will not start.

Page 192 of 295

190Driving and operatingThe selected fuel mode is stored andreactivated at the next ignition cycle if

conditions allow.

As soon as the liquid gas tanks are

empty, petrol operation is

automatically engaged until the

ignition is switched off.

When switching automatically

between petrol or gas operation, a

brief delay of engine tractive power

may be noticeable.

Every six months, run the petrol tank

down until control indicator i

illuminates, then refuel. This helps

maintain fuel quality and system

function for petrol operation.

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

● Is there enough liquid gas present?

● Is there enough petrol present for

starting?Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to gas mode.

In extreme situations, the system may

also switch back to petrol mode if the

minimum requirements are not

fulfilled. If conditions allow, it might be

possible to manually switch back to

liquid gas operation.

Seek the assistance of a workshop in the event of all other faults.Caution

Repairs and adjustments may onlybe made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

9 Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If possible, close the manual shut-off

valve on the multivalve. The

multivalve is located on the liquid gas

tank in the load compartment,

underneath the rear floor cover.

Turn the thumb wheel clockwise.

Page 202 of 295

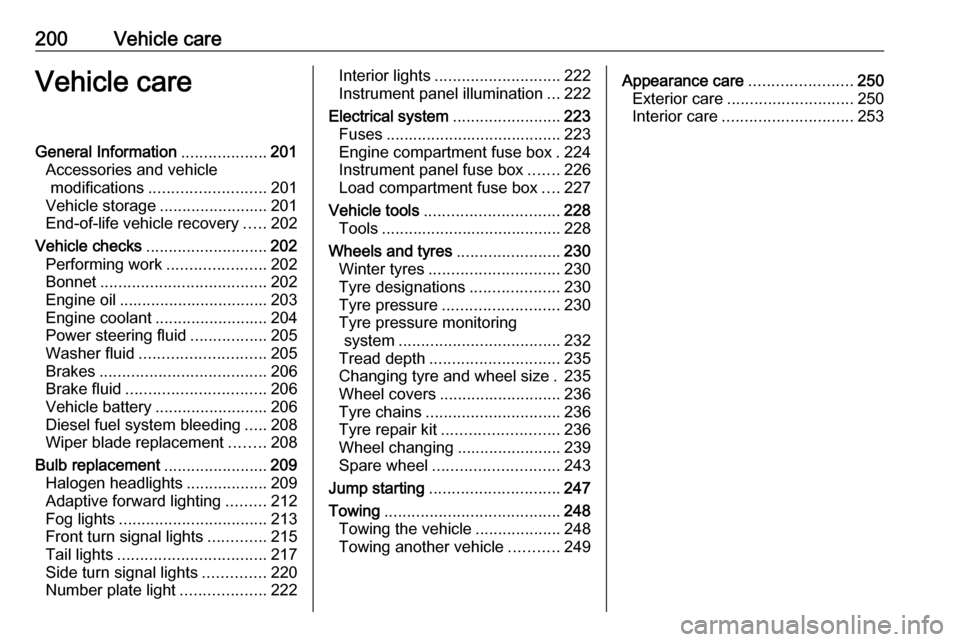

200Vehicle careVehicle careGeneral Information...................201

Accessories and vehicle modifications .......................... 201

Vehicle storage ........................201

End-of-life vehicle recovery .....202

Vehicle checks ........................... 202

Performing work ......................202

Bonnet ..................................... 202

Engine oil ................................. 203

Engine coolant ......................... 204

Power steering fluid .................205

Washer fluid ............................ 205

Brakes ..................................... 206

Brake fluid ............................... 206

Vehicle battery ......................... 206

Diesel fuel system bleeding .....208

Wiper blade replacement ........208

Bulb replacement .......................209

Halogen headlights ..................209

Adaptive forward lighting .........212

Fog lights ................................. 213

Front turn signal lights .............215

Tail lights ................................. 217

Side turn signal lights ..............220

Number plate light ...................222Interior lights ............................ 222

Instrument panel illumination ...222

Electrical system ........................223

Fuses ....................................... 223

Engine compartment fuse box . 224

Instrument panel fuse box .......226

Load compartment fuse box ....227

Vehicle tools .............................. 228

Tools ........................................ 228

Wheels and tyres .......................230

Winter tyres ............................. 230

Tyre designations ....................230

Tyre pressure .......................... 230

Tyre pressure monitoring system .................................... 232

Tread depth ............................. 235

Changing tyre and wheel size . 235

Wheel covers ........................... 236

Tyre chains .............................. 236

Tyre repair kit .......................... 236

Wheel changing .......................239

Spare wheel ............................ 243

Jump starting ............................. 247

Towing ....................................... 248

Towing the vehicle ...................248

Towing another vehicle ...........249Appearance care .......................250

Exterior care ............................ 250

Interior care ............................. 253

Page 203 of 295

Vehicle care201General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

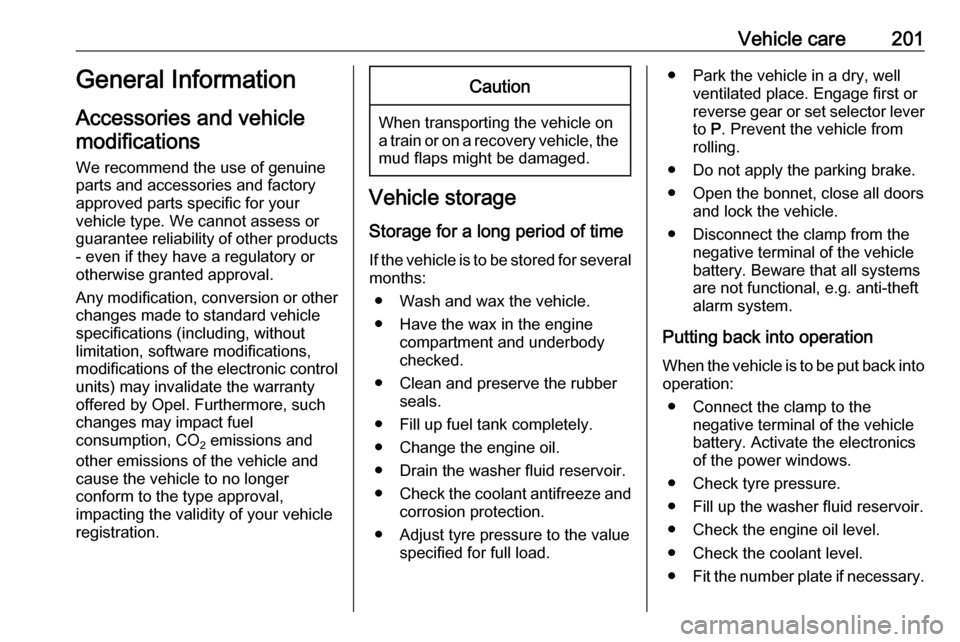

registration.Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

Page 204 of 295

202Vehicle careEnd-of-life vehicle recoveryInformation on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Page 205 of 295

Vehicle care203

Move the safety catch sideways to theleft vehicle side and open the bonnet.

Secure the bonnet support.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 255.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Pull out the dipstick, wipe it clean, insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

Page 207 of 295

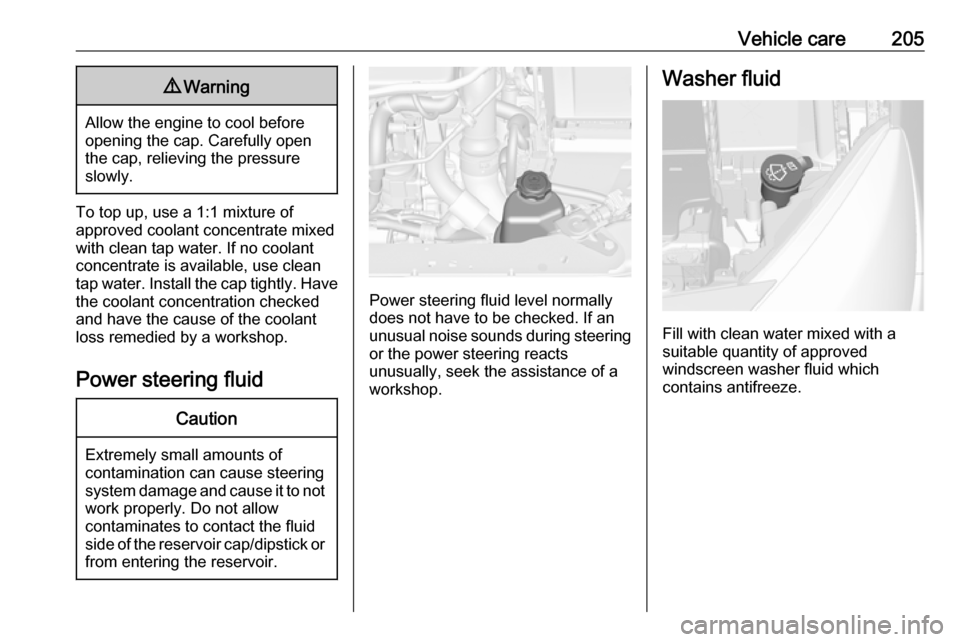

Vehicle care2059Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up, use a 1:1 mixture of

approved coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have

the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Power steering fluid

Caution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap/dipstick or

from entering the reservoir.

Power steering fluid level normally

does not have to be checked. If an

unusual noise sounds during steering or the power steering reacts

unusually, seek the assistance of a workshop.

Washer fluid

Fill with clean water mixed with a

suitable quantity of approved

windscreen washer fluid which

contains antifreeze.

Page 211 of 295

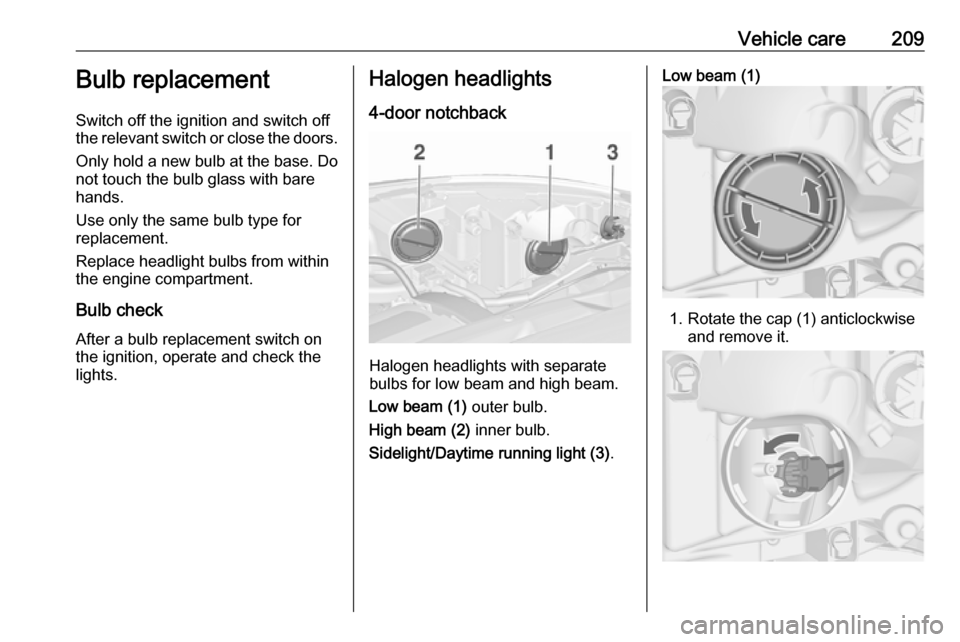

Vehicle care209Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.Halogen headlights

4-door notchback

Halogen headlights with separate

bulbs for low beam and high beam.

Low beam (1) outer bulb.

High beam (2) inner bulb.

Sidelight/Daytime running light (3) .

Low beam (1)

1. Rotate the cap (1) anticlockwise

and remove it.

Page 232 of 295

230Vehicle careWheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.4-door notchback

Tyre size 205/65 R16 is only suitable

as a winter tyre.

All engines except A14XER,

B14XER, B14NEL, B14NET,

B14NET LPG, B16XER:Tyre size 215/50 R17 is only suitable

as a winter tyre.

Tyre designations E.g. 215/60 R 16 95 H215:tyre width, mm60:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent

to 690 kgH:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 265.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.