brake OPEL ASTRA J 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: ASTRA J, Model: OPEL ASTRA J 2017Pages: 295, PDF Size: 8.23 MB

Page 208 of 295

206Vehicle careCaution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

after a sudden drop in

temperature.

Use of washer fluid containing

isopropanol can damage exterior

lamps.

Washer fluid 3 255.

Brakes In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

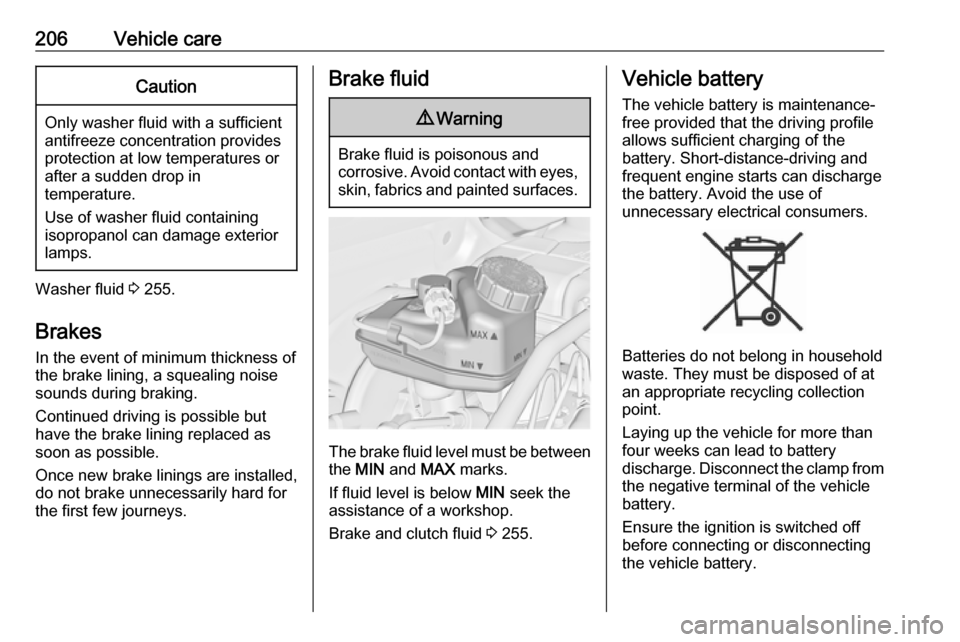

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below MIN seek the

assistance of a workshop.

Brake and clutch fluid 3 255.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Page 220 of 295

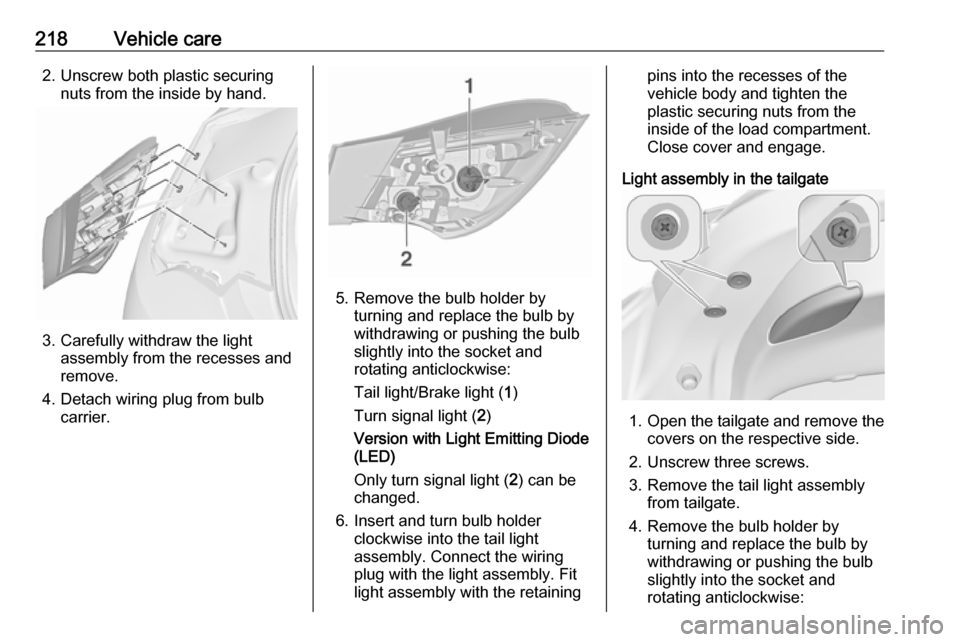

218Vehicle care2. Unscrew both plastic securingnuts from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Detach wiring plug from bulb carrier.

5. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and

rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

Version with Light Emitting Diode (LED)

Only turn signal light ( 2) can be

changed.

6. Insert and turn bulb holder clockwise into the tail light

assembly. Connect the wiring

plug with the light assembly. Fit

light assembly with the retaining

pins into the recesses of the

vehicle body and tighten the

plastic securing nuts from the

inside of the load compartment.

Close cover and engage.

Light assembly in the tailgate

1. Open the tailgate and remove the

covers on the respective side.

2. Unscrew three screws.

3. Remove the tail light assembly from tailgate.

4. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Page 222 of 295

220Vehicle care

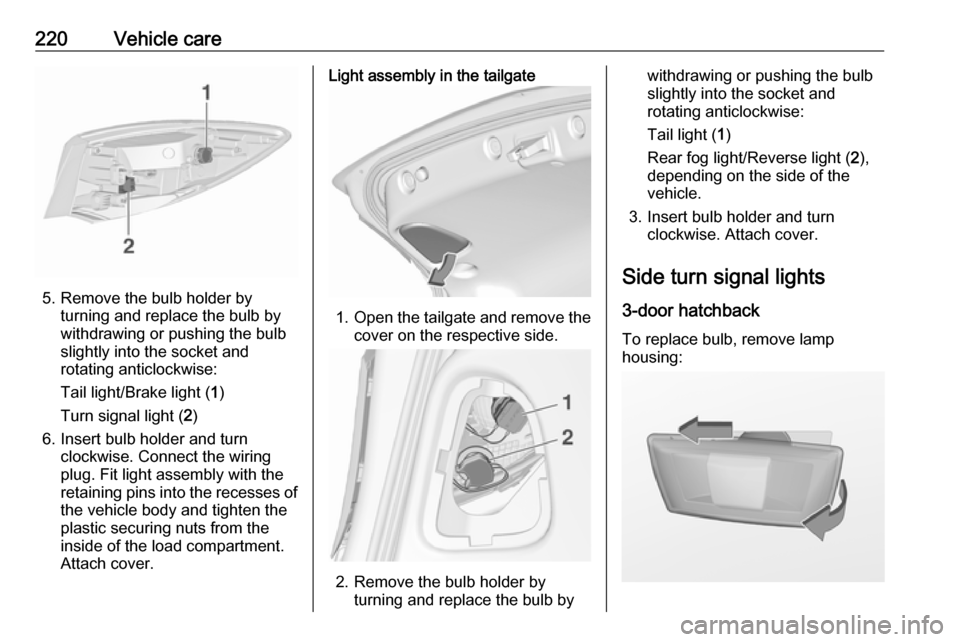

5. Remove the bulb holder byturning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

6. Insert bulb holder and turn clockwise. Connect the wiring

plug. Fit light assembly with the

retaining pins into the recesses of

the vehicle body and tighten the

plastic securing nuts from the

inside of the load compartment.

Attach cover.

Light assembly in the tailgate

1. Open the tailgate and remove the

cover on the respective side.

2. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Tail light ( 1)

Rear fog light/Reverse light ( 2),

depending on the side of the

vehicle.

3. Insert bulb holder and turn clockwise. Attach cover.

Side turn signal lights

3-door hatchback To replace bulb, remove lamp

housing:

Page 227 of 295

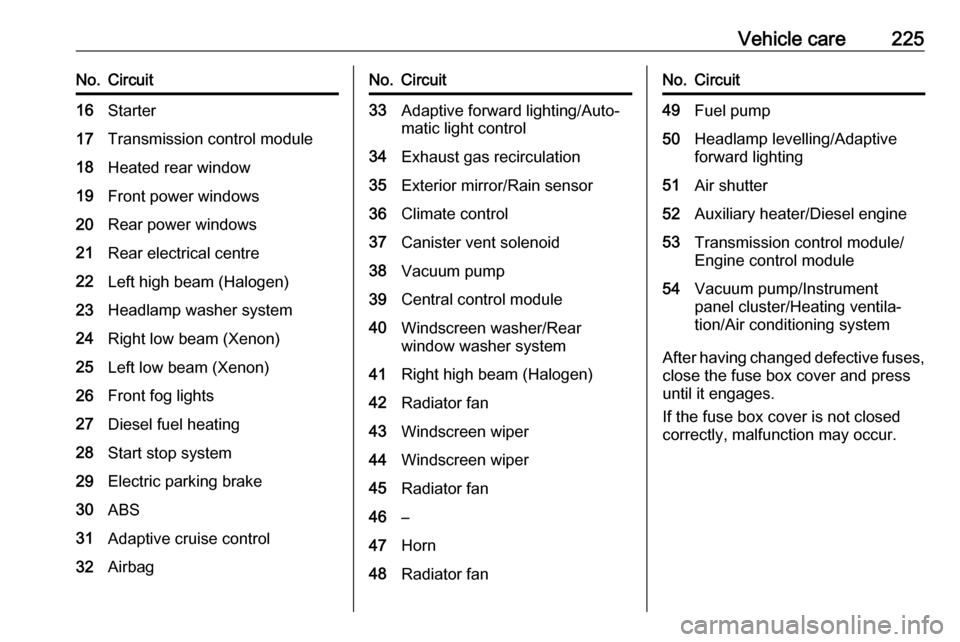

Vehicle care225No.Circuit16Starter17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear electrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27Diesel fuel heating28Start stop system29Electric parking brake30ABS31Adaptive cruise control32AirbagNo.Circuit33Adaptive forward lighting/Auto‐

matic light control34Exhaust gas recirculation35Exterior mirror/Rain sensor36Climate control37Canister vent solenoid38Vacuum pump39Central control module40Windscreen washer/Rear

window washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44Windscreen wiper45Radiator fan46–47Horn48Radiator fanNo.Circuit49Fuel pump50Headlamp levelling/Adaptive

forward lighting51Air shutter52Auxiliary heater/Diesel engine53Transmission control module/

Engine control module54Vacuum pump/Instrument

panel cluster/Heating ventila‐

tion/Air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 235 of 295

Vehicle care233

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 91.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 271.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 99.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. Control indicator w

illuminates. For the further three

wheels the system remains

operational.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor: replace

valve core and sealing ring. For

clipped sensor: replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 271, and

select the appropriate setting in the Tyre load menu in the Driver

Information Centre 3 93. This setting

is the reference for the tyre pressure

warnings.

The Tyre Load menu only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission, the

selector lever must be in P.

Page 236 of 295

234Vehicle care

Select:● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full load.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced.

The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until the sensor is matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate the receiver is in

relearn mode.

7. Start with the left side front wheel.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

Page 238 of 295

236Vehicle careWheel coversWheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Use tyre chains only on front wheels.

9 Warning

Damage may lead to tyre blowout.

4-door notchback

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).

Tyre chains are only permitted on

tyres of size 205/60 R16 and

215/50 R17.3-door hatchback

Tyre chains are permitted on tyres of

size 225/55 R17. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).

Tyre chains are also permitted on

tyres of size 245/45 R18. Always use

fine mesh chains that add no more

than 7 mm to the tyre tread and the inboard sides (including chain lock).OPC Version

Tyre chains are permitted on tyres of

size 235/45 R18. Always use fine

mesh chains that add no more than

10 mm to the tyre tread and the

inboard sides (including chain lock).General

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Page 239 of 295

Vehicle care237Tyre damage exceeding 4 mm or that

is at the tyre's sidewall cannot be

repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in a compartment under the floor cover in the load

compartment.The illustrations show different

versions.

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 242 of 295

240Vehicle careMake the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 243.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

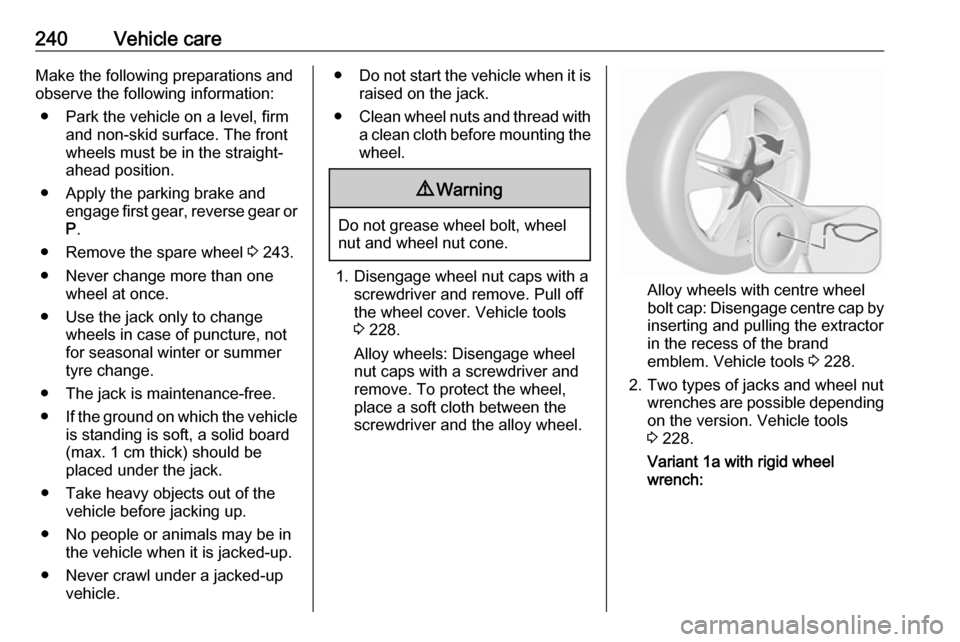

1. Disengage wheel nut caps with a

screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 228.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.Alloy wheels with centre wheel

bolt cap: Disengage centre cap by

inserting and pulling the extractor

in the recess of the brand

emblem. Vehicle tools 3 228.

2. Two types of jacks and wheel nut wrenches are possible dependingon the version. Vehicle tools

3 228.

Variant 1a with rigid wheel

wrench:

Page 249 of 295

Vehicle care247Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen vehicle

battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a vehicle battery.

● Use a booster vehicle battery with the same voltage ( 12 Volts).

Its capacity (Ah) must not be

much less than that of the

discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.