ECU OPEL ASTRA J 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: ASTRA J, Model: OPEL ASTRA J 2019Pages: 205, PDF Size: 6.25 MB

Page 94 of 205

92Instruments and controlsVehicle location

The vehicle location is transmitted to OnStar when service is requested or

triggered. A message on the Info-

Display informs about this

transmission.

To activate or deactivate the

transmission of the vehicle location,

press and hold j until an audio

message is heard.

The deactivation is indicated by the

status light flashing red and green for a short period of time and each time

the vehicle is started.

Note

If the transmission of the vehicle

location is deactivated, some

services are no longer available.

Note

The vehicle location always remains

accessible to OnStar in the case of

an emergency.

Find the privacy policy in your

account.Software updates

OnStar may remotely carry out software updates without further

notice or consent. These updates are

to enhance or maintain safety and

security or the operation of the

vehicle.

These updates may concern privacy

issues. Find the privacy policy in your account.

Page 125 of 205

Driving and operating123The selected gear is indicated in theinstrument cluster.

If a higher gear is selected when

vehicle speed is too low, or a lower

gear when vehicle speed is too high,

the shift is not executed. This can

cause a message in the Driver

Information Centre.

In manual mode, no automatic

shifting to a higher gear takes place

at high engine revolutions.

Electronic driving programmes

● Following a cold start, the operating temperature

programme increases engine

speed to quickly bring the

catalytic converter to the required

temperature.

● The automatic neutral shift function automatically shifts to

idling when the vehicle is stopped

with a forward gear engaged and the brake pedal is pressed.● Special programmes automatically adapt the shifting

points when driving up inclines or down hills.

● When starting off in snowy or icy conditions or on other slippery

surfaces, the electronic

transmission control selects a

higher gear automatically.

Kickdown

If the accelerator pedal is pressed

down completely in automatic mode,

the transmission shifts to a lower gear

depending on engine speed.

Fault

In the event of a fault, control indicator g illuminates. Additionally, a code

number or a vehicle message is

displayed in the Driver Information

Centre. Vehicle messages 3 79.

The transmission no longer shifts

automatically. Continued travel is possible with manual shifting.Only the highest gear is available.

Depending on the fault, 2nd gear may also be available in manual mode.

Shift only when vehicle is at a

standstill.

Have the cause of the fault remedied

by a workshop.

Interruption of power supply In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position. The ignition key cannot be removed from the ignition switch.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 170.

If the vehicle battery is not the cause

of the fault, release the selector lever.

1. Apply the parking brake.

Page 142 of 205

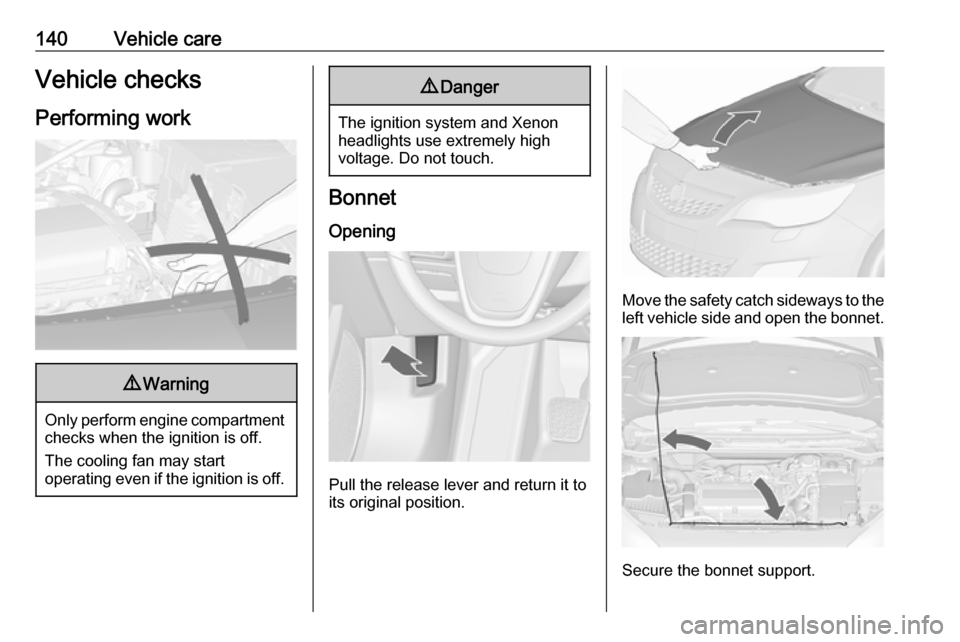

140Vehicle careVehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways to the left vehicle side and open the bonnet.

Secure the bonnet support.

Page 148 of 205

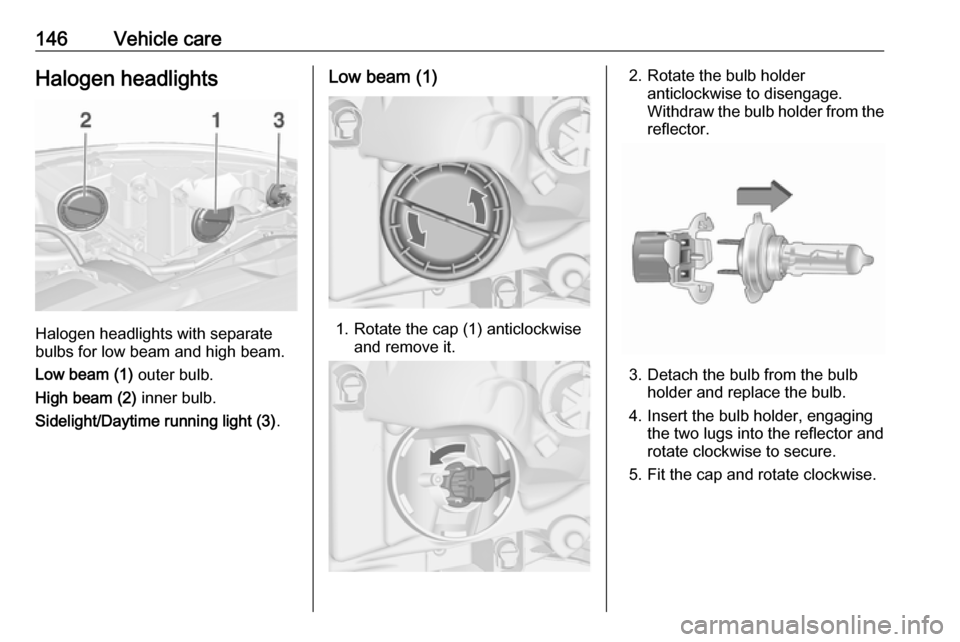

146Vehicle careHalogen headlights

Halogen headlights with separate

bulbs for low beam and high beam.

Low beam (1) outer bulb.

High beam (2) inner bulb.

Sidelight/Daytime running light (3) .

Low beam (1)

1. Rotate the cap (1) anticlockwise

and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder, engaging the two lugs into the reflector androtate clockwise to secure.

5. Fit the cap and rotate clockwise.

Page 149 of 205

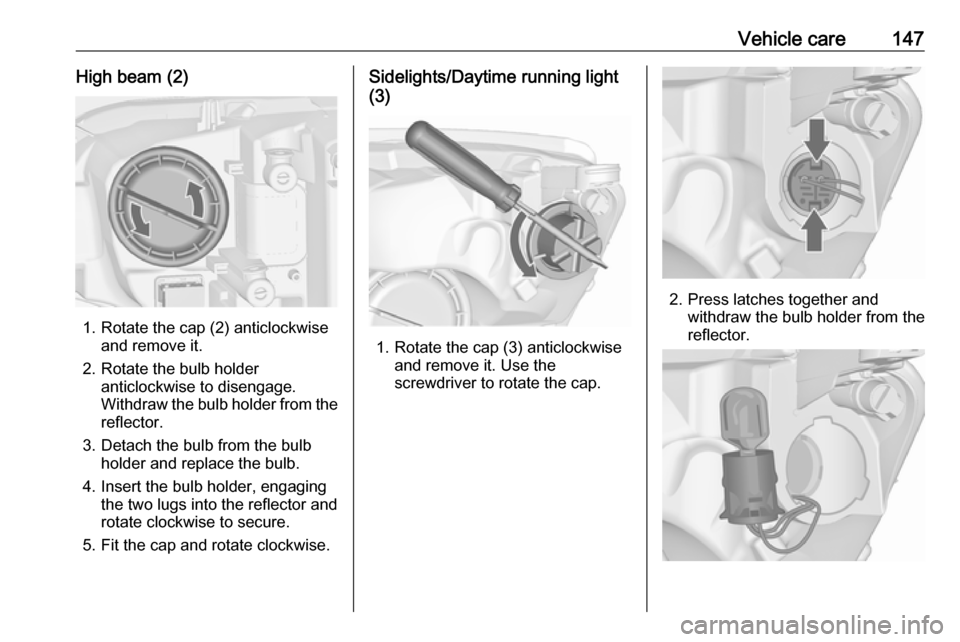

Vehicle care147High beam (2)

1. Rotate the cap (2) anticlockwiseand remove it.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

5. Fit the cap and rotate clockwise.

Sidelights/Daytime running light

(3)

1. Rotate the cap (3) anticlockwise and remove it. Use the

screwdriver to rotate the cap.

2. Press latches together and withdraw the bulb holder from the

reflector.

Page 150 of 205

148Vehicle care3. Remove the bulb from the socketand replace the bulb.

4. Insert the bulb holder into the reflector. Fit the cap and rotate

clockwise.

Adaptive forward lighting9 Danger

Adaptive forward lighting system

uses Xenon headlights.

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Sidelight/Daytime running lights are

designed as Light Emitting Diodes

(LEDs) and cannot be changed.

Bulbs for corner lighting can be

changed.

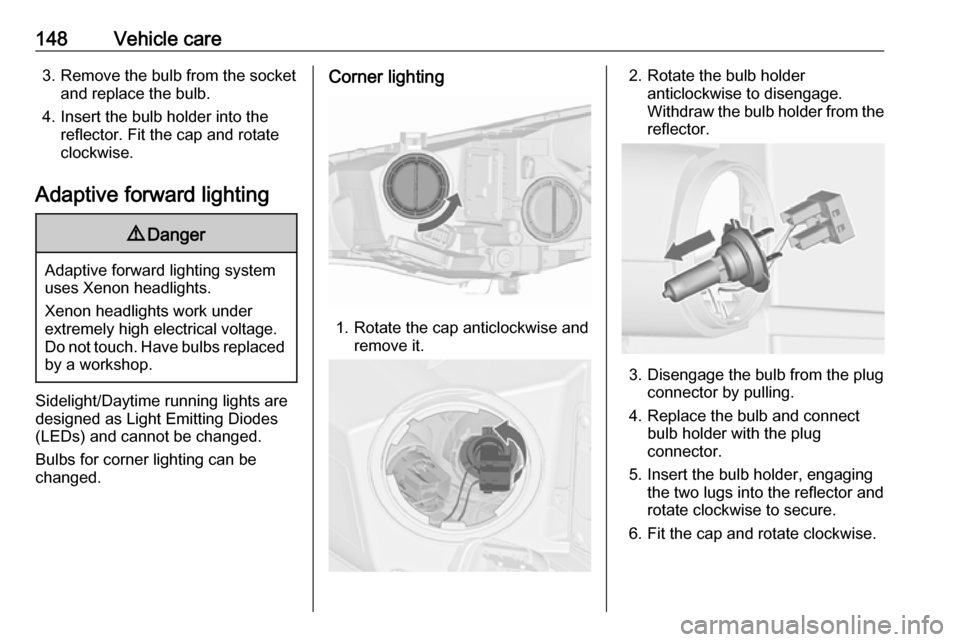

Corner lighting

1. Rotate the cap anticlockwise and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb from the plug connector by pulling.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Page 153 of 205

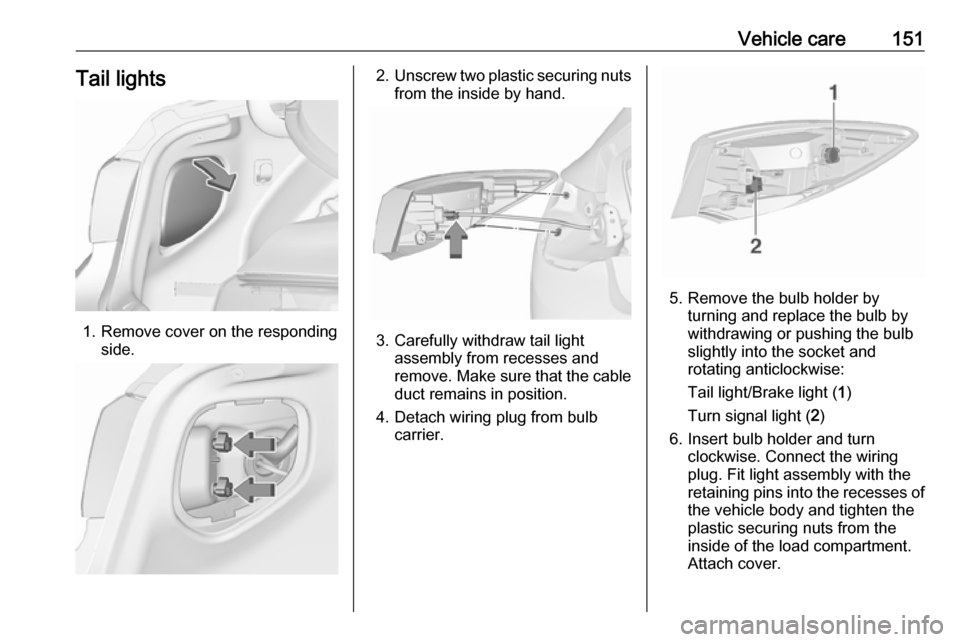

Vehicle care151Tail lights

1. Remove cover on the respondingside.

2.Unscrew two plastic securing nuts

from the inside by hand.

3. Carefully withdraw tail light assembly from recesses and

remove. Make sure that the cable duct remains in position.

4. Detach wiring plug from bulb carrier.

5. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

6. Insert bulb holder and turn clockwise. Connect the wiringplug. Fit light assembly with the

retaining pins into the recesses of

the vehicle body and tighten the

plastic securing nuts from the

inside of the load compartment.

Attach cover.

Page 161 of 205

Vehicle care159No.Circuit18–19Steering wheel heating20–21Heated front seats22–23–24–25–26Deactivated logistic mode27–28–29–30–31Amplifier/Subwoofer32Active damping systemVehicle tools

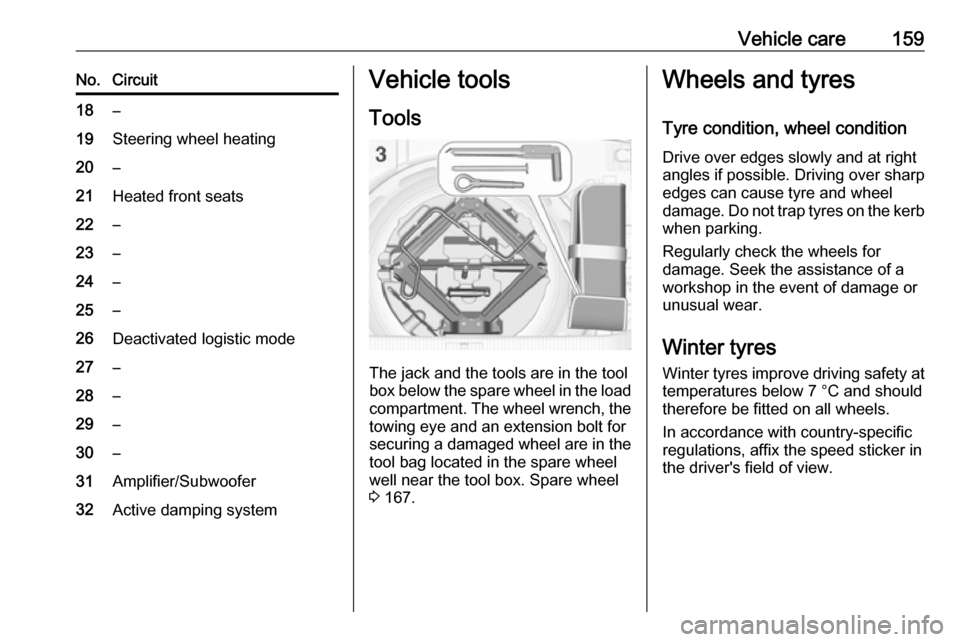

Tools

The jack and the tools are in the tool

box below the spare wheel in the load

compartment. The wheel wrench, the towing eye and an extension bolt for

securing a damaged wheel are in the

tool bag located in the spare wheel

well near the tool box. Spare wheel

3 167.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 169 of 205

Vehicle care167Front arm position of the lifting

platform at the underbody.

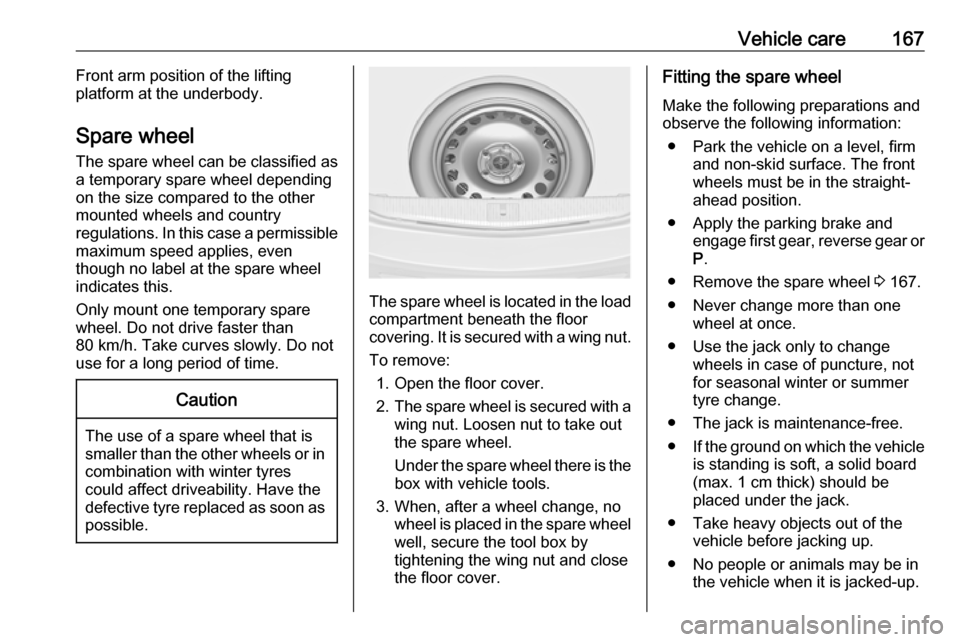

Spare wheel

The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

To remove: 1. Open the floor cover.

2. The spare wheel is secured with a

wing nut. Loosen nut to take out

the spare wheel.

Under the spare wheel there is the box with vehicle tools.

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut and close

the floor cover.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear orP .

● Remove the spare wheel 3 167.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

Page 170 of 205

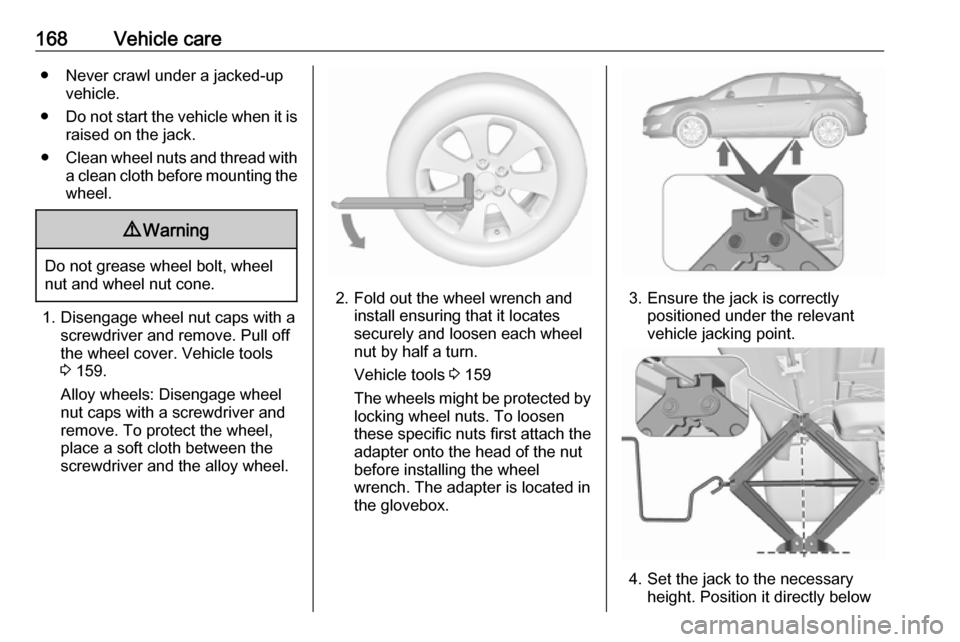

168Vehicle care● Never crawl under a jacked-upvehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 159.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

Vehicle tools 3 159

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the glovebox.3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below