brake light OPEL ASTRA J 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: ASTRA J, Model: OPEL ASTRA J 2019Pages: 205, PDF Size: 6.25 MB

Page 127 of 205

Driving and operating125Caution

It is not advisable to drive with thehand resting on the selector lever.

Upshift indication 3 70.

Brakes

The brake system comprises two independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek

the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 69.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off the system performs

a self-test which may be audible.

Control indicator u 3 70.

Adaptive brake light

During full braking, all three brake

lights flash for the duration of ABS

control.

Page 128 of 205

126Driving and operatingFault9Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

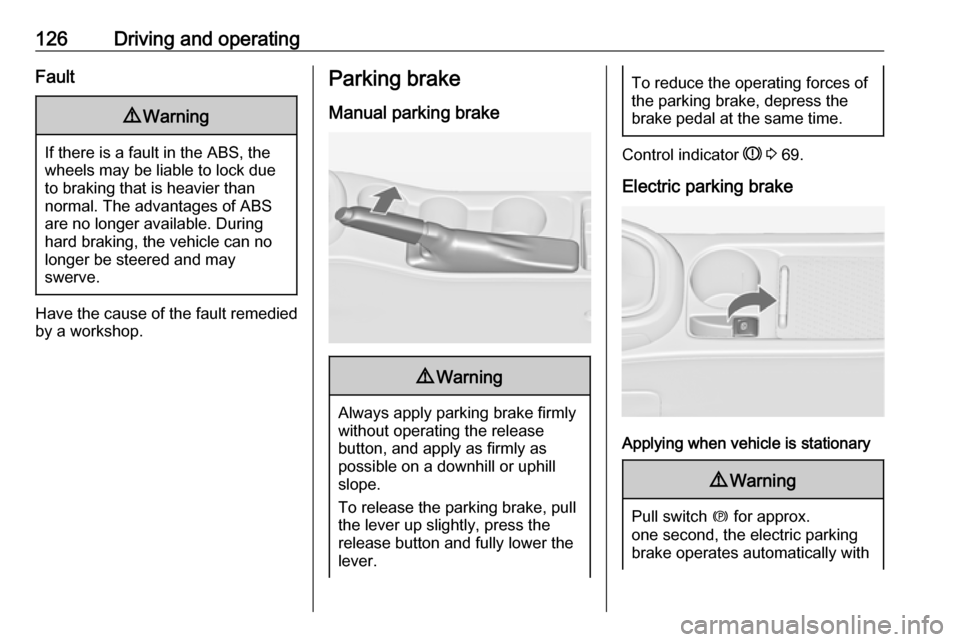

Parking brake

Manual parking brake9 Warning

Always apply parking brake firmly

without operating the release

button, and apply as firmly as

possible on a downhill or uphill

slope.

To release the parking brake, pull

the lever up slightly, press the

release button and fully lower the

lever.

To reduce the operating forces of

the parking brake, depress the

brake pedal at the same time.

Control indicator R 3 69.

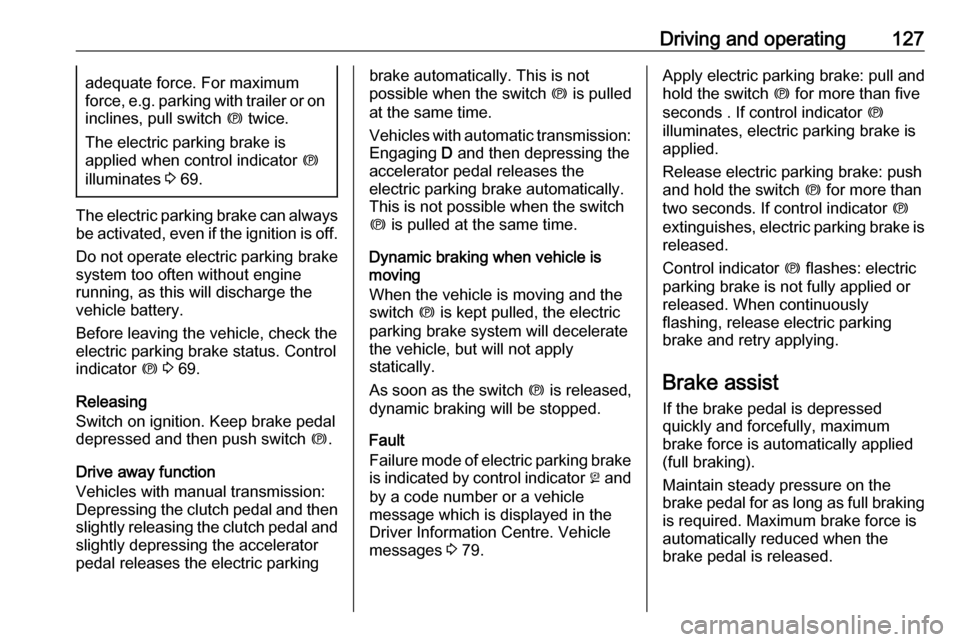

Electric parking brake

Applying when vehicle is stationary

9 Warning

Pull switch m for approx.

one second, the electric parking

brake operates automatically with

Page 129 of 205

Driving and operating127adequate force. For maximum

force, e.g. parking with trailer or on

inclines, pull switch m twice.

The electric parking brake is

applied when control indicator m

illuminates 3 69.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often without engine

running, as this will discharge the

vehicle battery.

Before leaving the vehicle, check the

electric parking brake status. Control

indicator m 3 69.

Releasing

Switch on ignition. Keep brake pedal

depressed and then push switch m.

Drive away function Vehicles with manual transmission:

Depressing the clutch pedal and then slightly releasing the clutch pedal and

slightly depressing the accelerator

pedal releases the electric parking

brake automatically. This is not

possible when the switch m is pulled

at the same time.

Vehicles with automatic transmission: Engaging D and then depressing the

accelerator pedal releases the

electric parking brake automatically.

This is not possible when the switch

m is pulled at the same time.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate

the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Fault

Failure mode of electric parking brake

is indicated by control indicator j and

by a code number or a vehicle message which is displayed in the

Driver Information Centre. Vehicle

messages 3 79.Apply electric parking brake: pull and

hold the switch m for more than five

seconds . If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: push

and hold the switch m for more than

two seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or

released. When continuously

flashing, release electric parking

brake and retry applying.

Brake assist If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the

brake pedal for as long as full braking is required. Maximum brake force is

automatically reduced when the

brake pedal is released.

Page 140 of 205

138Vehicle careVehicle careGeneral Information...................138

Accessories and vehicle modifications .......................... 138

Vehicle storage ........................139

End-of-life vehicle recovery .....139

Vehicle checks ........................... 140

Performing work ......................140

Bonnet ..................................... 140

Engine oil ................................. 141

Engine coolant ......................... 142

Power steering fluid .................142

Washer fluid ............................ 143

Brakes ..................................... 143

Brake fluid ............................... 143

Vehicle battery ......................... 144

Wiper blade replacement ........145

Bulb replacement .......................145

Halogen headlights ..................146

Adaptive forward lighting .........148

Front fog lights ......................... 149

Front turn lights .......................150

Tail lights ................................. 151

Side turn lights ......................... 152

Number plate light ...................153Interior lights ............................ 153

Instrument panel illumination ...153

Electrical system ........................154

Fuses ....................................... 154

Engine compartment fuse box . 155

Instrument panel fuse box .......157

Load compartment fuse box ....158

Vehicle tools .............................. 159

Tools ........................................ 159

Wheels and tyres .......................159

Winter tyres ............................. 159

Tyre designations ....................160

Tyre pressure .......................... 160

Tyre pressure monitoring system .................................... 161

Tread depth ............................. 164

Changing tyre and wheel size . 165

Wheel covers ........................... 165

Tyre chains .............................. 165

Wheel changing .......................166

Spare wheel ............................ 167

Jump starting ............................. 170

Towing ....................................... 172

Towing the vehicle ...................172

Towing another vehicle ...........173

Appearance care .......................174

Exterior care ............................ 174

Interior care ............................. 176General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 153 of 205

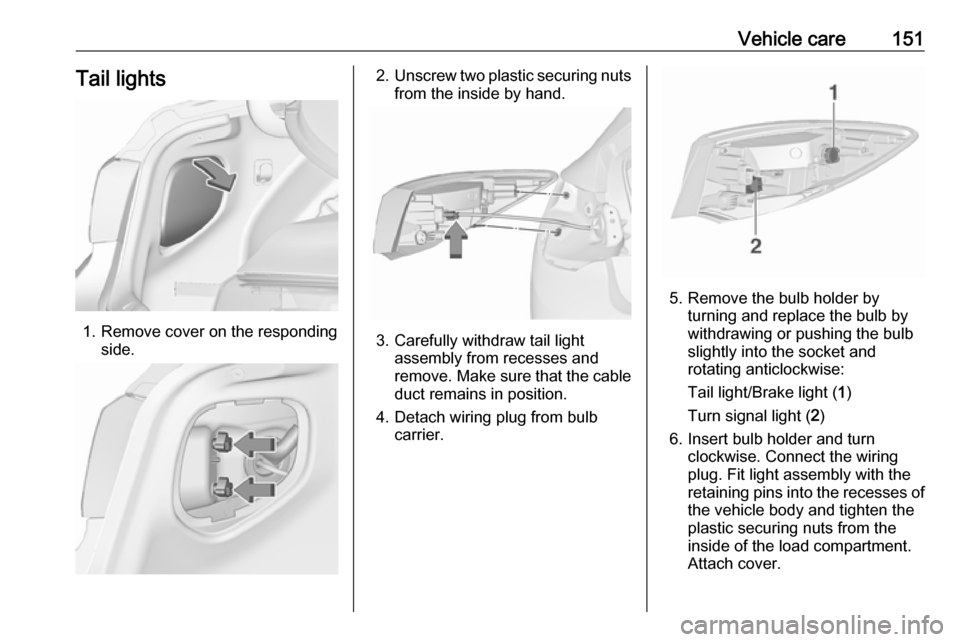

Vehicle care151Tail lights

1. Remove cover on the respondingside.

2.Unscrew two plastic securing nuts

from the inside by hand.

3. Carefully withdraw tail light assembly from recesses and

remove. Make sure that the cable duct remains in position.

4. Detach wiring plug from bulb carrier.

5. Remove the bulb holder by turning and replace the bulb by

withdrawing or pushing the bulb

slightly into the socket and rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

6. Insert bulb holder and turn clockwise. Connect the wiringplug. Fit light assembly with the

retaining pins into the recesses of

the vehicle body and tighten the

plastic securing nuts from the

inside of the load compartment.

Attach cover.

Page 158 of 205

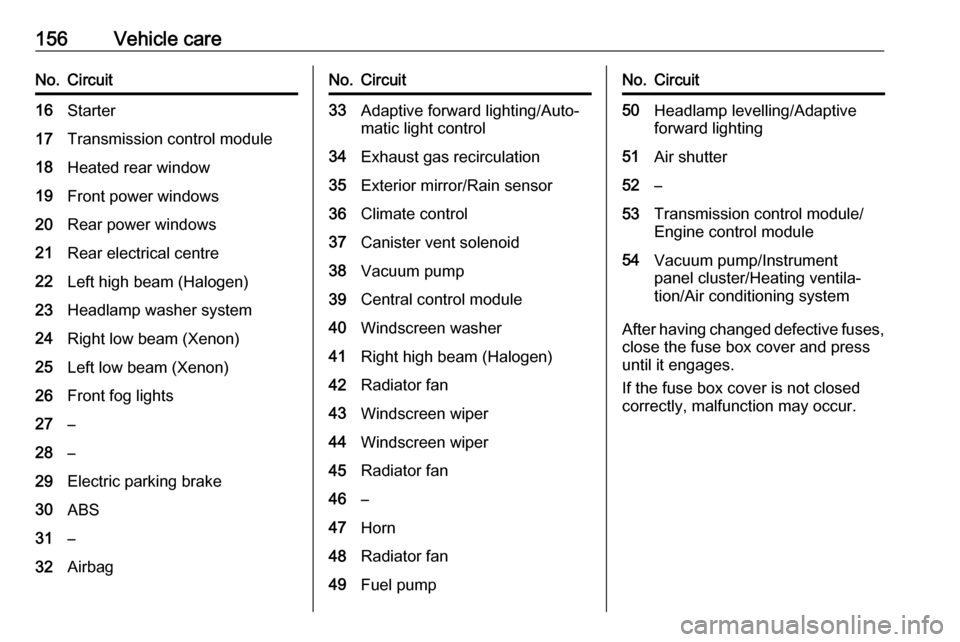

156Vehicle careNo.Circuit16Starter17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear electrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27–28–29Electric parking brake30ABS31–32AirbagNo.Circuit33Adaptive forward lighting/Auto‐

matic light control34Exhaust gas recirculation35Exterior mirror/Rain sensor36Climate control37Canister vent solenoid38Vacuum pump39Central control module40Windscreen washer41Right high beam (Halogen)42Radiator fan43Windscreen wiper44Windscreen wiper45Radiator fan46–47Horn48Radiator fan49Fuel pumpNo.Circuit50Headlamp levelling/Adaptive

forward lighting51Air shutter52–53Transmission control module/

Engine control module54Vacuum pump/Instrument

panel cluster/Heating ventila‐

tion/Air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 165 of 205

Vehicle care163illuminates. For the further three

wheels the system remains

operational.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor: replace

valve core and sealing ring. For

clipped sensor: replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 186, and

select the appropriate setting in the

Tyre load menu in the Driver

Information Centre 3 73. This setting

is the reference for the tyre pressure

warnings.The Tyre Load menu only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission, the

selector lever must be in P.

Select:

● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full load.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until the sensor is matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

Page 174 of 205

172Vehicle care4. Switch on electrical consumers(e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage.

Insert the screwdriver in the slot at the

lower part of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 159.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.

Page 196 of 205

194Customer informationOperating data in the vehicleControl units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate, "seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board the vehicle itself. Control units often

include data storage (including the

vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.Depending on technical equipment

level, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggering

of an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.

Page 200 of 205

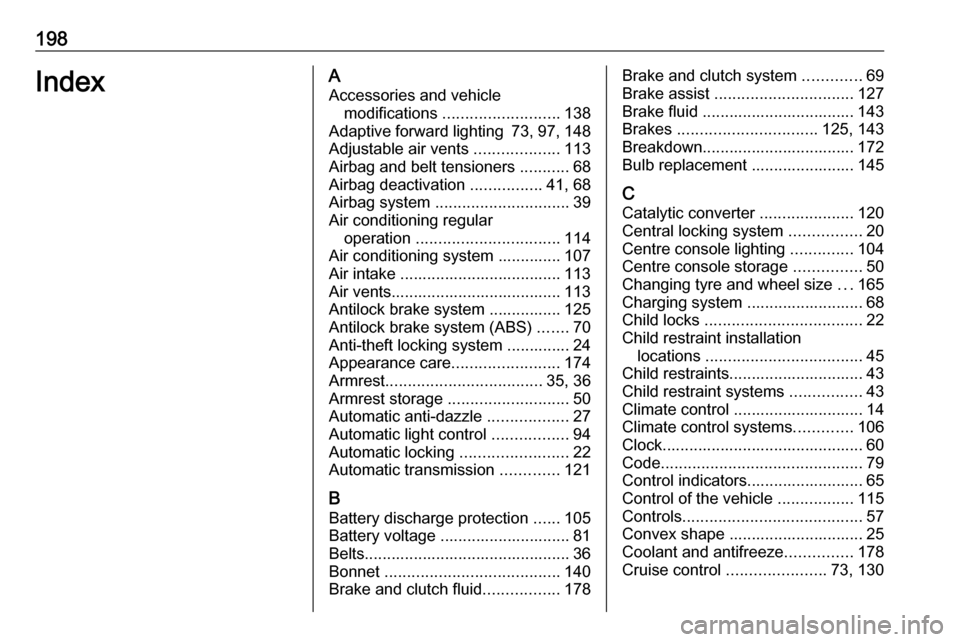

198IndexAAccessories and vehicle modifications .......................... 138

Adaptive forward lighting 73, 97, 148

Adjustable air vents ...................113

Airbag and belt tensioners ...........68

Airbag deactivation ................41, 68

Airbag system .............................. 39

Air conditioning regular operation ................................ 114

Air conditioning system .............. 107

Air intake .................................... 113

Air vents...................................... 113

Antilock brake system ................ 125

Antilock brake system (ABS) .......70

Anti-theft locking system .............. 24 Appearance care ........................174

Armrest ................................... 35, 36

Armrest storage ........................... 50

Automatic anti-dazzle ..................27

Automatic light control .................94

Automatic locking ........................22

Automatic transmission .............121

B Battery discharge protection ......105

Battery voltage ............................. 81

Belts.............................................. 36 Bonnet ....................................... 140

Brake and clutch fluid .................178Brake and clutch system .............69

Brake assist ............................... 127

Brake fluid .................................. 143

Brakes ............................... 125, 143

Breakdown.................................. 172

Bulb replacement ....................... 145

C

Catalytic converter .....................120

Central locking system ................20

Centre console lighting ..............104

Centre console storage ...............50

Changing tyre and wheel size ...165

Charging system .......................... 68

Child locks ................................... 22

Child restraint installation locations ................................... 45

Child restraints.............................. 43

Child restraint systems ................43

Climate control ............................. 14

Climate control systems .............106

Clock............................................. 60

Code ............................................. 79

Control indicators.......................... 65

Control of the vehicle .................115

Controls ........................................ 57

Convex shape .............................. 25

Coolant and antifreeze ...............178

Cruise control ...................... 73, 130