warning OPEL ASTRA K 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: ASTRA K, Model: OPEL ASTRA K 2017Pages: 305, PDF Size: 9.11 MB

Page 230 of 305

228Vehicle careWasher fluid

Fill with clean water mixed with a

suitable quantity of approved

windscreen washer fluid which

contains antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Washer fluid 3 273.

Brakes

In the event of minimum thickness of

the brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below MIN seek the

assistance of a workshop.

Brake and clutch fluid 3 273.

Page 232 of 305

230Vehicle care

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Opel vehicle battery.

Note

Using an AGM vehicle battery

different from the original Opel

vehicle battery may result in a lower performance.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 161.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 265.

Warning label

Meaning of symbols: ● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of 40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.

Page 246 of 305

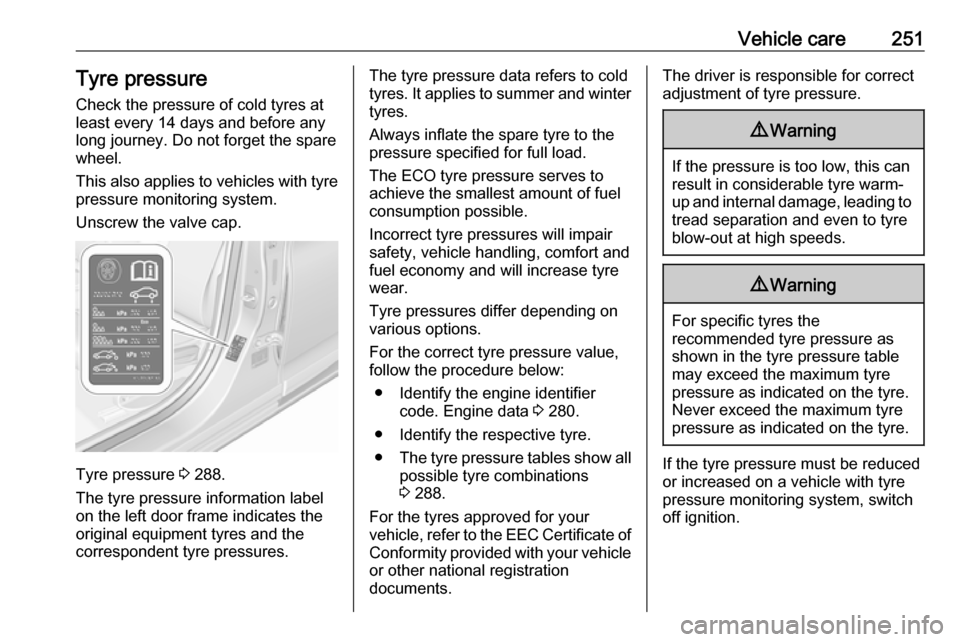

244Vehicle careNo.Circuit18Diesel exhaust system19Diesel exhaust system20–21DC/AC Converter22ABS23Washer system for windscreen

and rear window24–25Diesel fuel heating26Transmission control module27Power tailgate module28–29Heated rear window30Mirror defrost31–32DC transformer/LED display/

Electrical heater/Climate

control/Glow plug controllerNo.Circuit33Anti theft warning34Horn35Power outlet load compartment36Right high beam (Halogen)/

Right low beam (LED)37Left high beam (Halogen)38LED headlight/Automatic head‐

light range adjustment39Front fog light40OnStar41Water in fuel sensor/Water

pump42Manual headlight range adjust‐

ment43Fuel pump44Rear view camera/Inside rear

view mirror/Trailer module45LED headlight left/Automatic

headlight range adjustment leftNo.Circuit46Instrument cluster47Steering column lock48Rear wiper49–50LED headlight right/Automatic

headlight range adjustment

right51Left low beam (LED)52Engine control module/Trans‐

mission control module53–54Windscreen wiper55Diesel exhaust system56–57–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 250 of 305

248Vehicle careNo.Circuit1–2DC/AC Inverter3Trailer module4Power seat passenger side5–6Distance warning module7–8–9Rear seat heating (on vehicles

without alarm horn)10Service11–12Front seat heating (on vehicles

with alarm horn)13Rear seat heating (on vehicles

with alarm horn)14Ignition15Seat ventilationNo.Circuit16Trailer outlet17Trailer outlet18–19–20–21Electrical rear seat folding22Power tailgate

After having changed defective fuses,

close the fuse box cover and press

until it engages.

Additional fuses are located near the

vehicle battery.

No.Circuit1Fuel pump2Engine control module3Power supply

Page 253 of 305

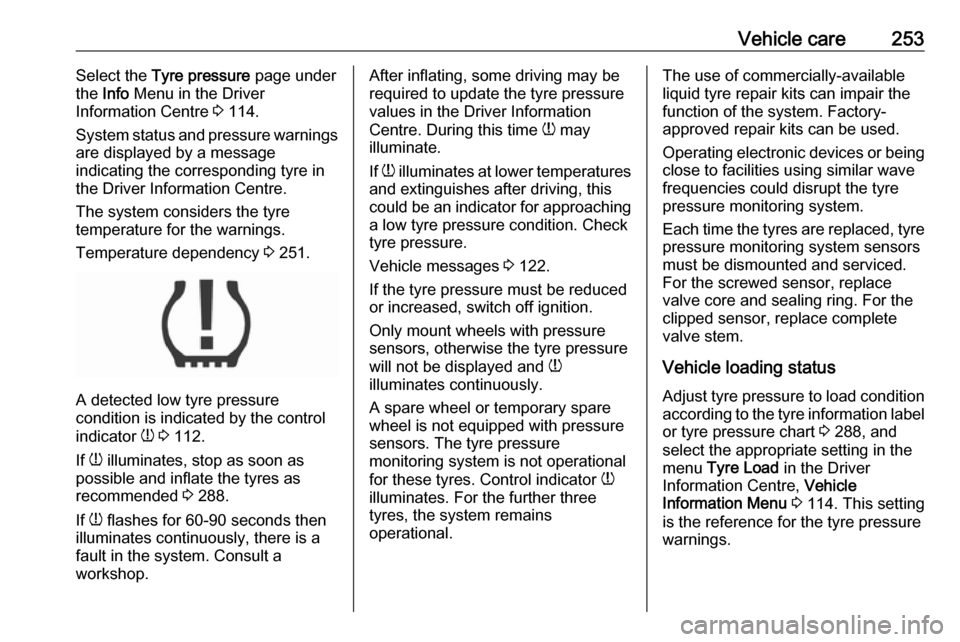

Vehicle care251Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 288.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code. Engine data 3 280.

● Identify the respective tyre. ● The tyre pressure tables show all

possible tyre combinations

3 288.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Page 255 of 305

Vehicle care253Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 114.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 251.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 112.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 288.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 122.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For the

clipped sensor, replace complete

valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information label

or tyre pressure chart 3 288, and

select the appropriate setting in the

menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 114. This setting

is the reference for the tyre pressure

warnings.

Page 256 of 305

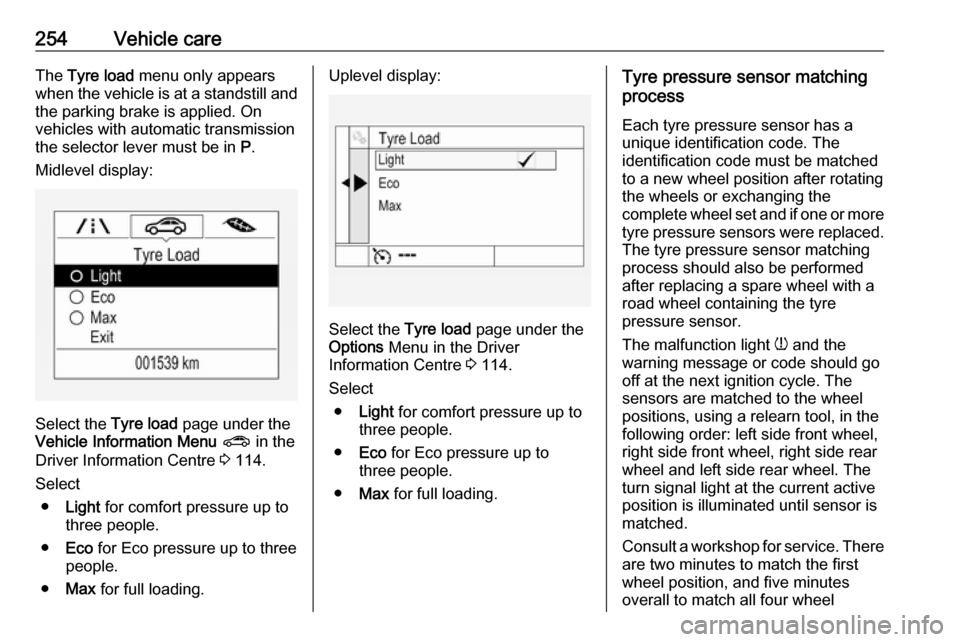

254Vehicle careThe Tyre load menu only appears

when the vehicle is at a standstill and the parking brake is applied. On

vehicles with automatic transmission

the selector lever must be in P.

Midlevel display:

Select the Tyre load page under the

Vehicle Information Menu ? in the

Driver Information Centre 3 114.

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 114.

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.

The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn signal light at the current active

position is illuminated until sensor is

matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

Page 258 of 305

256Vehicle careto indicate that the sensor

identification code has been

matched to the left side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

14. Ensure the tyre loading status is set according to the selected

pressure 3 114.

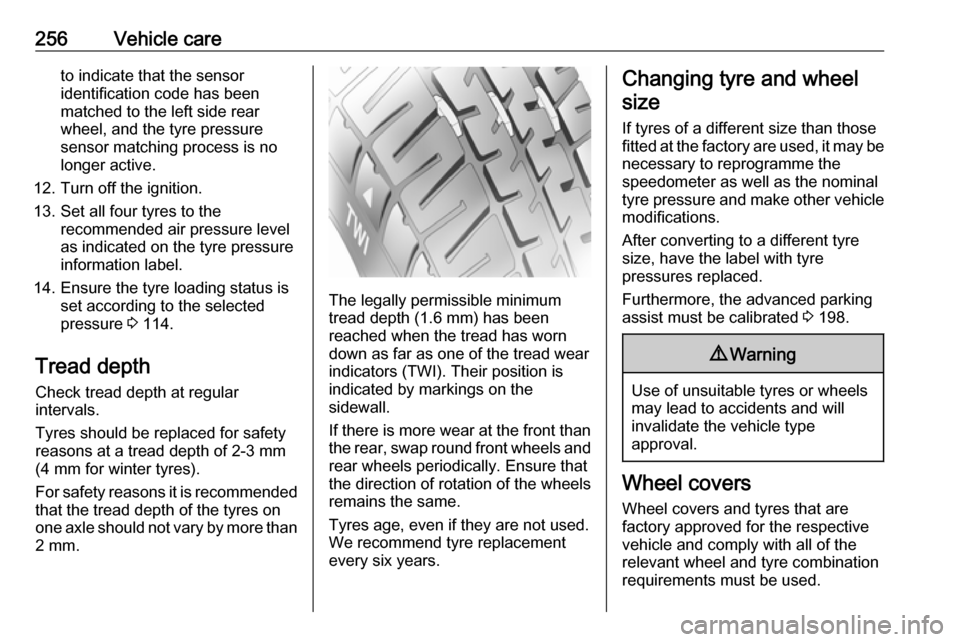

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimumtread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Furthermore, the advanced parking

assist must be calibrated 3 198.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 259 of 305

Vehicle care257If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 195/65 R15, 205/55 R16 and

215/55 R16.

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

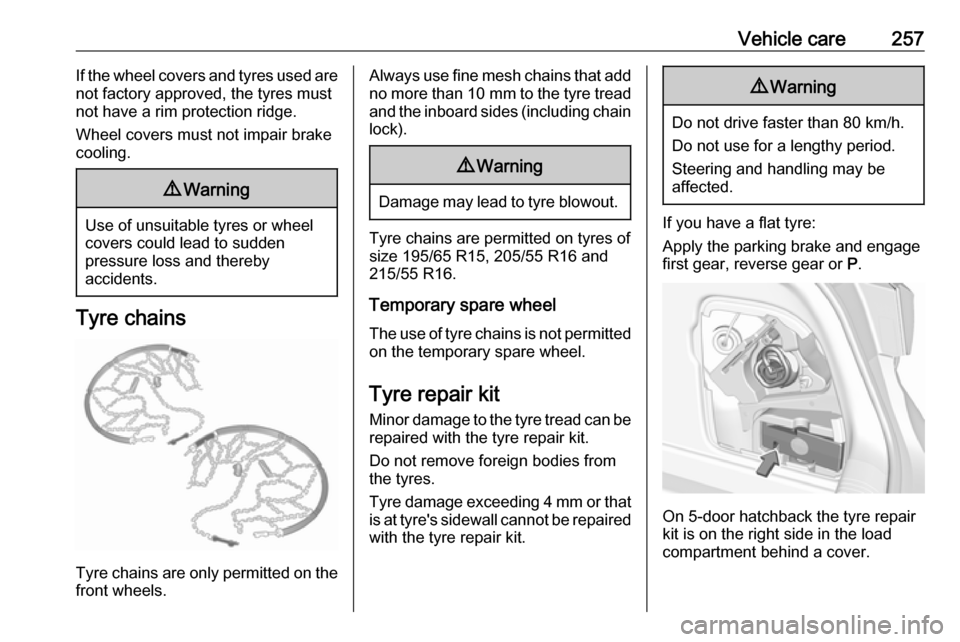

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at tyre's sidewall cannot be repairedwith the tyre repair kit.

9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

On 5-door hatchback the tyre repair

kit is on the right side in the load

compartment behind a cover.

Page 263 of 305

Vehicle care261●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. For alloy

wheels, place a soft cloth

underneath the screwdriver. Pull

off the wheel cover. Vehicle tools

3 249.

2. Fold out the wheel wrench and

install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.