sensor OPEL ASTRA K 2019.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019.5, Model line: ASTRA K, Model: OPEL ASTRA K 2019.5Pages: 311, PDF Size: 9.52 MB

Page 208 of 311

206Driving and operatingexternal noise sources may causethe system to fail to detect

obstacles.

Special attention must be paid to

low obstacles which can damage

the lower part of the bumper.Caution

Performance of the system can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Note

It is possible that the sensor detects a non-existing object caused by

echo disturbance from external

acoustic noise or mechanical

misalignments (sporadic false

warnings may occur).

Make sure that the front number

plate is properly mounted (not bent

and no gaps to the bumper on the left

or right side) and the sensors are

firmly in place.

Advanced parking assist system

may not respond to changes in the

available parking space after

initiating a parking manoeuvre. The

system may recognize an entry, a

gateway, a courtyard or even a crossing as a parking slot. After

selecting reverse gear the system

will start a parking manoeuvre. Take care regarding the availability of the

suggested parking slot.

Low curbs and surface irregularities,

e.g. on construction zones, are not

detected by the system. The driver

accepts responsibility.

Note

After production, the system

requires a calibration. For optimal

parking guidance, a driving distance

of at least 10 km, including a number of bends, is required.

Side blind spot alert The Side blind spot alert system

detects and reports objects on either

side of the vehicle, within a specified

"blind spot" zone. The system

displays a visual alert in each exterior

mirror, when detecting objects that

may not be visible in the interior and exterior mirrors.

Side blind spot alert uses some of the advanced parking assist sensors

which are located in the front and rear

bumper on both sides of the vehicle.

Page 210 of 311

208Driving and operatingFault

Occasional missed alerts can occur

under normal circumstances and will

increase in wet conditions.

Side blind spot alert does not operate when the left or right corners of the

rear bumper are covered with mud,

dirt, snow, ice, slush, or in heavy

rainstorms.

Cleaning instructions 3 273.

In the event of a fault in the system or

if the system does not work due to

temporary conditions, the symbols in

the mirrors will be permanently

illuminated and a message is

displayed in the Driver Information

Centre. Seek the assistance of a

workshop.

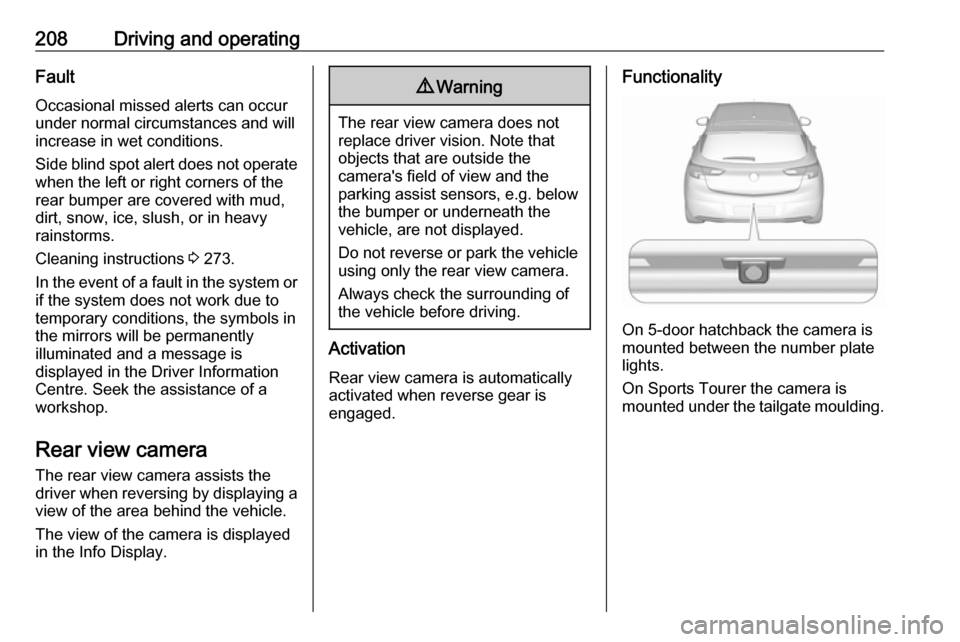

Rear view camera

The rear view camera assists the

driver when reversing by displaying a

view of the area behind the vehicle.

The view of the camera is displayed

in the Info Display.9 Warning

The rear view camera does not

replace driver vision. Note that

objects that are outside the

camera's field of view and the

parking assist sensors, e.g. below

the bumper or underneath the

vehicle, are not displayed.

Do not reverse or park the vehicle

using only the rear view camera.

Always check the surrounding of

the vehicle before driving.

Activation

Rear view camera is automatically

activated when reverse gear is

engaged.

Functionality

On 5-door hatchback the camera is

mounted between the number plate

lights.

On Sports Tourer the camera is

mounted under the tailgate moulding.

Page 211 of 311

Driving and operating209

The area displayed by the camera is

limited. The distance of the image that

appears on the display differs from

the actual distance.

Guiding lines

Dynamic guiding lines are horizontal

lines at one metre intervals projected

onto the picture to define the distance

to displayed objects.Trajectory lane of the vehicle is

shown in accordance with the

steering angle.

Warning symbols

Warning symbols are indicated as

triangles 9 on the picture, which show

obstacles detected by the rear

sensors of the advanced parking

assist.

Additionally, 9 appears on the top

line of the Info Display with the

warning to check the vehicle

surrounding.

Deactivation

The camera is switched off when a

certain forward speed is exceeded or if reverse gear is not engaged for

approx. 15 seconds.

Deactivation of guiding lines and

warning symbols

7'' Colour Info Display: Activation or

deactivation of the visual guiding lines and the warning symbols can be

changed via touch buttons in the

lower zone of the display.

8'' Colour Info Display: Activation or

deactivation of the visual guiding lines

and the warning symbols can be

Page 249 of 311

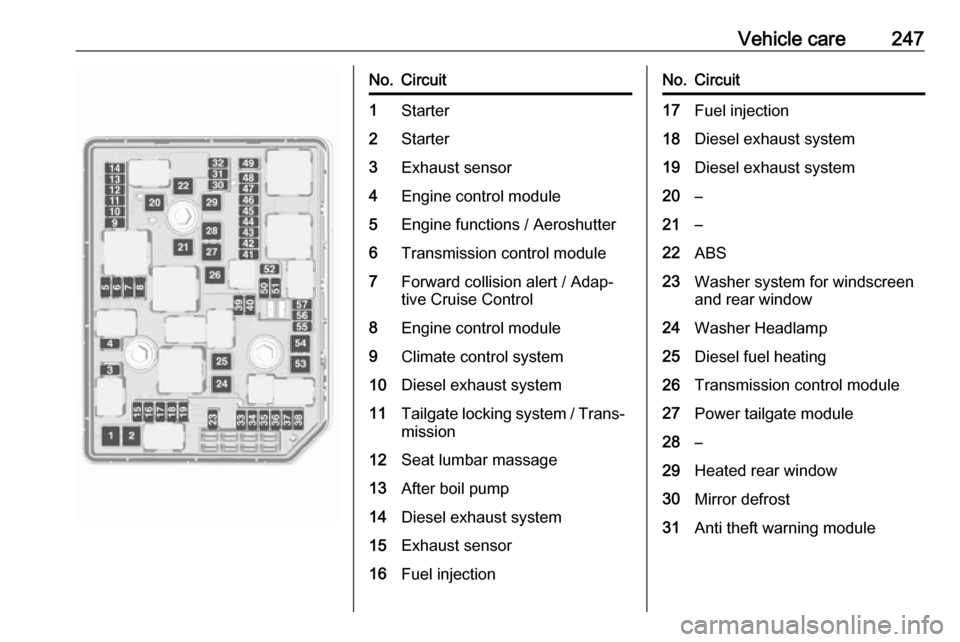

Vehicle care247No.Circuit1Starter2Starter3Exhaust sensor4Engine control module5Engine functions / Aeroshutter6Transmission control module7Forward collision alert / Adap‐

tive Cruise Control8Engine control module9Climate control system10Diesel exhaust system11Tailgate locking system / Trans‐ mission12Seat lumbar massage13After boil pump14Diesel exhaust system15Exhaust sensor16Fuel injectionNo.Circuit17Fuel injection18Diesel exhaust system19Diesel exhaust system20–21–22ABS23Washer system for windscreen

and rear window24Washer Headlamp25Diesel fuel heating26Transmission control module27Power tailgate module28–29Heated rear window30Mirror defrost31Anti theft warning module

Page 250 of 311

248Vehicle careNo.Circuit32DC transformer / LED display /

Electrical heater / Climate

control / Glow plug controller33Anti theft warning horn34Horn35Power outlet load compartment36Right high beam (Halogen) /

Right low beam (LED)37Left high beam (Halogen)38LED headlight / Automatic

headlight range adjustment39Front fog light40Central Gateway Module41Water in fuel sensor / Water

pump42Manual headlight range adjust‐

ment43Fuel pump44Rear view camera / Inside rear

view mirror / Trailer moduleNo.Circuit45LED headlight left / Automatic

headlight range adjustment left46Instrument cluster47Steering column lock48Rear wiper49Outside rearview mirror50LED headlight right / Automatic

headlight range adjustment

right51Left low beam (LED)52Engine control module / Trans‐

mission control module53Diesel exhaust system54Windscreen wiper55Electrical rear seat folding56–57–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

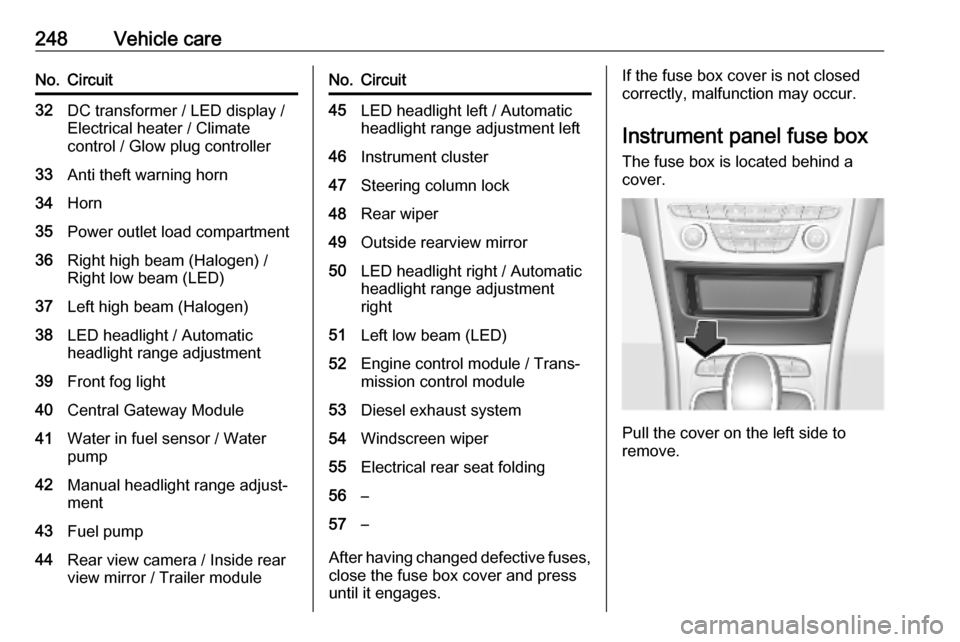

Instrument panel fuse boxThe fuse box is located behind a

cover.

Pull the cover on the left side to

remove.

Page 257 of 311

Vehicle care255Engine data 3 284.

● Identify the respective tyre.

● The tyre pressure tables show all

possible tyre combinations

3 290.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,which does not indicate an air leak.

Tyre pressure monitoring

system

The tyre pressure monitoring system

checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

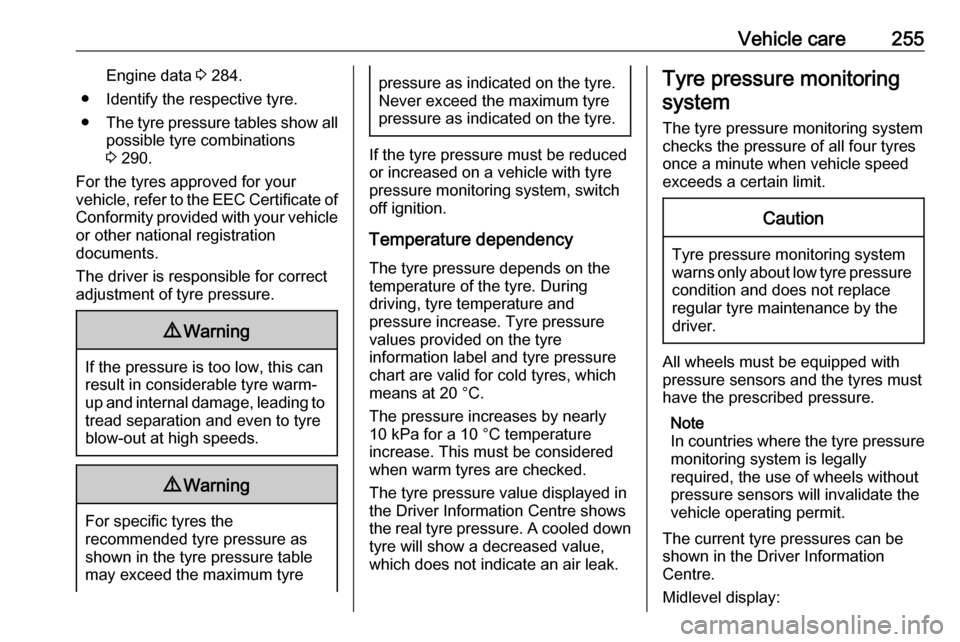

The current tyre pressures can be

shown in the Driver Information

Centre.

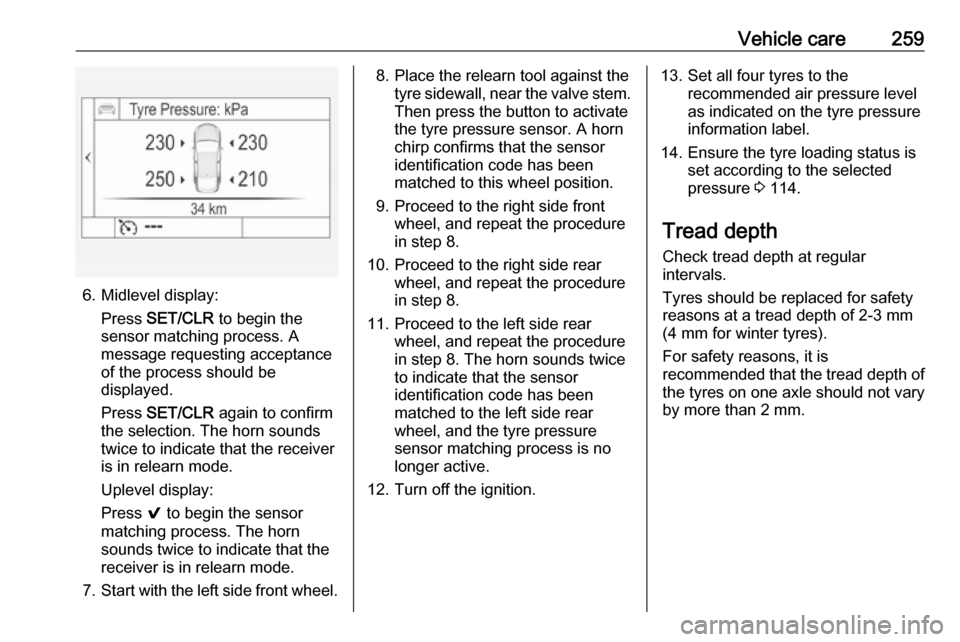

Midlevel display:

Page 258 of 311

256Vehicle care

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 114.

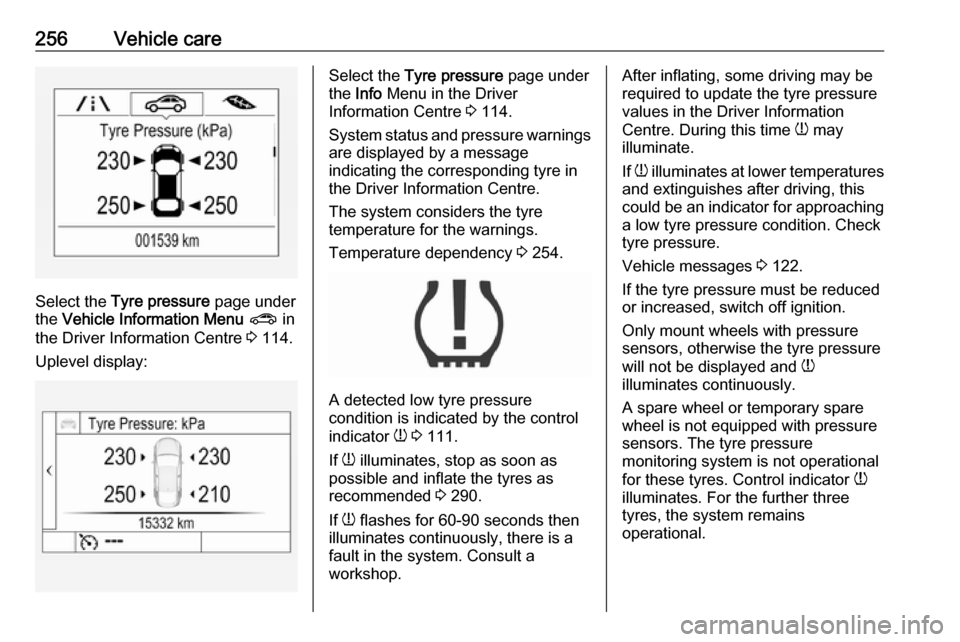

Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 114.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 254.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 111.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 290.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 122.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.

Page 259 of 311

Vehicle care257The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For the

clipped sensor, replace complete

valve stem.

Use only original plastic valve caps to

protect valve on any damage.Caution

Do not use metal valve caps as

they lead to valve oxidation and

damage.

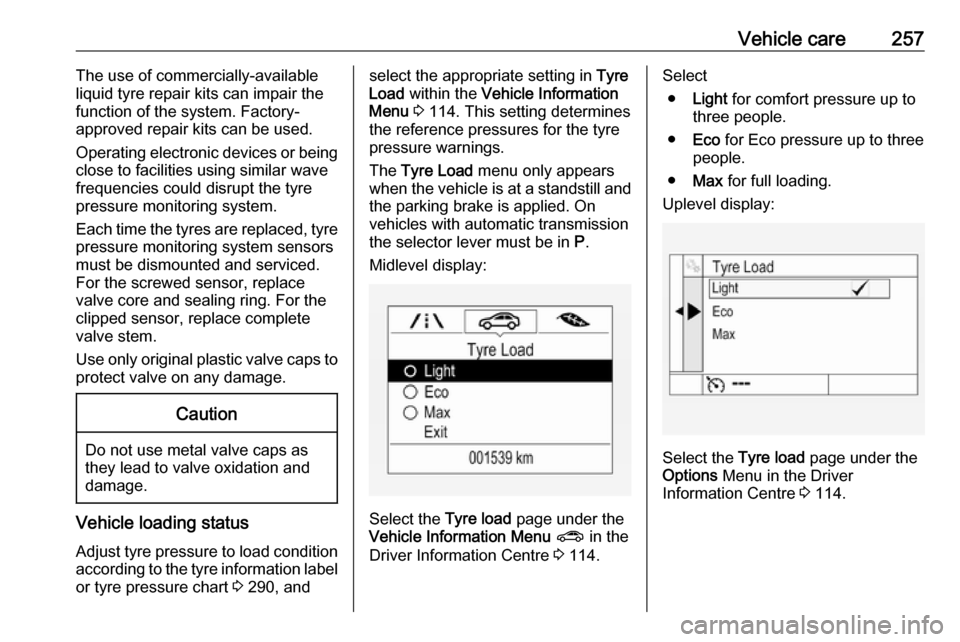

Vehicle loading status

Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 290, and

select the appropriate setting in Tyre

Load within the Vehicle Information

Menu 3 114. This setting determines

the reference pressures for the tyre

pressure warnings.

The Tyre Load menu only appears

when the vehicle is at a standstill and the parking brake is applied. On

vehicles with automatic transmission

the selector lever must be in P.

Midlevel display:

Select the Tyre load page under the

Vehicle Information Menu ? in the

Driver Information Centre 3 114.

Select

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

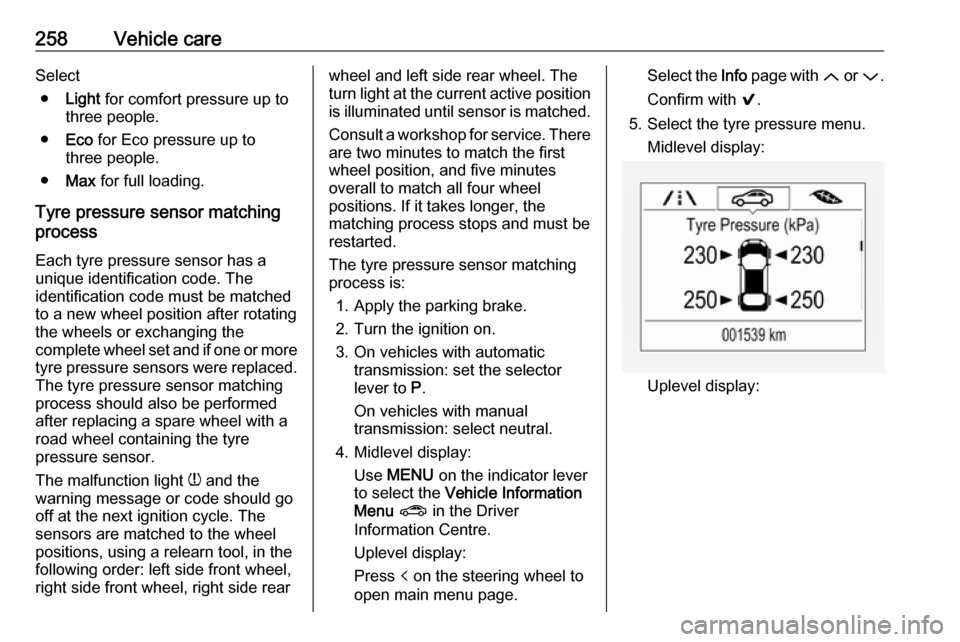

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 114.

Page 260 of 311

258Vehicle careSelect● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the

following order: left side front wheel,

right side front wheel, right side rearwheel and left side rear wheel. The

turn light at the current active position

is illuminated until sensor is matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Midlevel display: Use MENU on the indicator lever

to select the Vehicle Information

Menu ? in the Driver

Information Centre.

Uplevel display:

Press p on the steering wheel to

open main menu page.Select the Info page with Q or P.

Confirm with 9.

5. Select the tyre pressure menu. Midlevel display:

Uplevel display:

Page 261 of 311

Vehicle care259

6. Midlevel display:Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

Uplevel display:

Press 9 to begin the sensor

matching process. The horn

sounds twice to indicate that the receiver is in relearn mode.

7. Start with the left side front wheel.

8. Place the relearn tool against the

tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

9. Proceed to the right side front wheel, and repeat the procedure

in step 8.

10. Proceed to the right side rear wheel, and repeat the procedure

in step 8.

11. Proceed to the left side rear wheel, and repeat the procedure

in step 8. The horn sounds twice

to indicate that the sensor

identification code has been

matched to the left side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

12. Turn off the ignition.13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

14. Ensure the tyre loading status is set according to the selected

pressure 3 114.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.