ESP OPEL ASTRA K 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: ASTRA K, Model: OPEL ASTRA K 2020Pages: 305, PDF Size: 27.84 MB

Page 214 of 305

212Driving and operatingManual switch off the lane keep assist

if the system is disturbed by tar

marks, shadows, road cracks,

temporary or construction lane

markings, or other road

imperfections.9 Warning

Always keep your attention on the

road and maintain proper vehicle

position within the lane, otherwise

vehicle damage, injury or death

could occur.

Lane keep assist does not

continuously steer the vehicle.

The system may not keep the

vehicle in the lane or give an alert,

even if a lane marking is detected.

The steering of the lane keep

assist may not be sufficient to

avoid a lane departure.

The system may not detect hands-

off driving due to external

influences like road condition and

surface and weather. The driver has full responsibility to control the

vehicle and is always required to

keep the hands on the steering

wheel while driving.

Using the system while towing a

trailer or on slippery roads could

cause loss of control of the vehicle

and a crash. Switch the system off.Fuel

Fuel for petrol engines

Only use unleaded fuel that complies

with European standard EN 228 or

equivalent.

The engine is capable of running with

fuel that contains up to 10% ethanol

(e.g. named E10).

Use fuel with the recommended

octane rating. A lower octane rating can reduce engine power and torque

and slightly increases fuel

consumption.

Page 219 of 305

Driving and operating217Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 285.Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 276.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by 40 kg. If the permissible rear axle load

is exceeded, a maximum speed of

100 km/h applies.

Page 235 of 305

Vehicle care233

2. Disengage the plug connector bypressing the retaining lug.

3. Remove and replace the bulb unit

and attach the plug connector.

Note that the bulb and the socket

are one unit and have to be

changed together.

4. Insert the bulb socket into the light

assembly by turning clockwise

and engage.

5. Mount the light assembly by tightening the screws.

6. Attach the faceplate and tighten the screw.

Tail lights

5-door Hatchback

1. Release the cover on the respective side and remove it.

2. Vehicles with tyre repair kit: To replace bulbs on the right side,

first unscrew the plastic nut and

take out the insert with the sealant

bottle.

3. Unscrew the plastic securing nut from the inside by hand.

Page 238 of 305

236Vehicle careOn version with LED tail lights, theposition of the retaining lugs is

slightly different.

6. Remove and replace the bulb:

Tail light ( 1)

Rear fog light ( 2) (left side)

Reverse light ( 2) (right side)

On version with LED tail lights

only reverse light bulb ( 1) can be

removed and replaced.

7. Insert the bulb carrier into the tail light assembly. Attach plug to the

light assembly. Fit light assembly

on the tailgate and tighten the

screw from the inside. Attach

cover.

Depending on the version, tail lights are designed as LEDs. In case of failure, have LEDs replaced by aworkshop.

Sports Tourer

1. Release and open the cover on the respective side.

Page 243 of 305

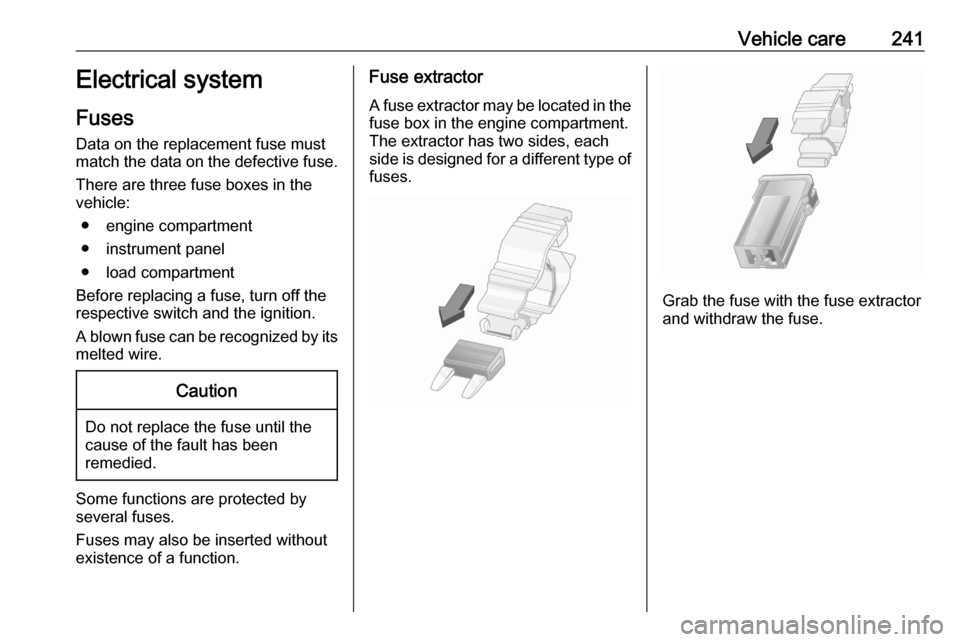

Vehicle care241Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

● load compartment

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

The extractor has two sides, each

side is designed for a different type of fuses.

Grab the fuse with the fuse extractor

and withdraw the fuse.

Page 250 of 305

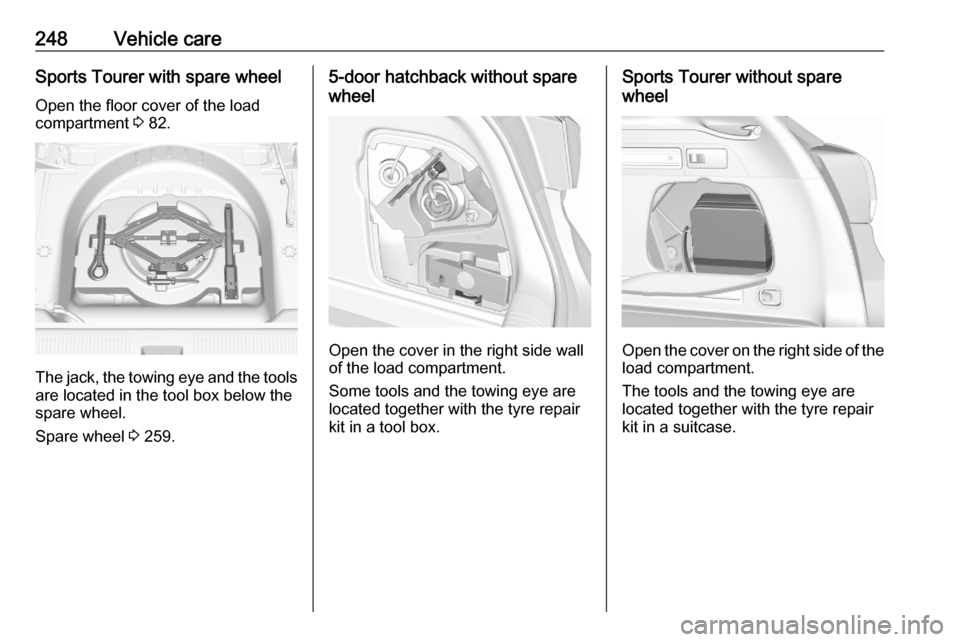

248Vehicle careSports Tourer with spare wheel

Open the floor cover of the load

compartment 3 82.

The jack, the towing eye and the tools

are located in the tool box below the

spare wheel.

Spare wheel 3 259.

5-door hatchback without spare

wheel

Open the cover in the right side wall

of the load compartment.

Some tools and the towing eye are

located together with the tyre repair

kit in a tool box.

Sports Tourer without spare

wheel

Open the cover on the right side of the load compartment.

The tools and the towing eye are

located together with the tyre repair

kit in a suitcase.

Page 252 of 305

250Vehicle careThe tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 251.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code.Engine data 3 280.

● Identify the respective tyre. ● The tyre pressure tables show all

possible tyre combinations

3 285.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,which does not indicate an air leak.

Page 253 of 305

Vehicle care251Tyre pressure monitoringsystem

The tyre pressure monitoring system checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Driver Information

Centre.

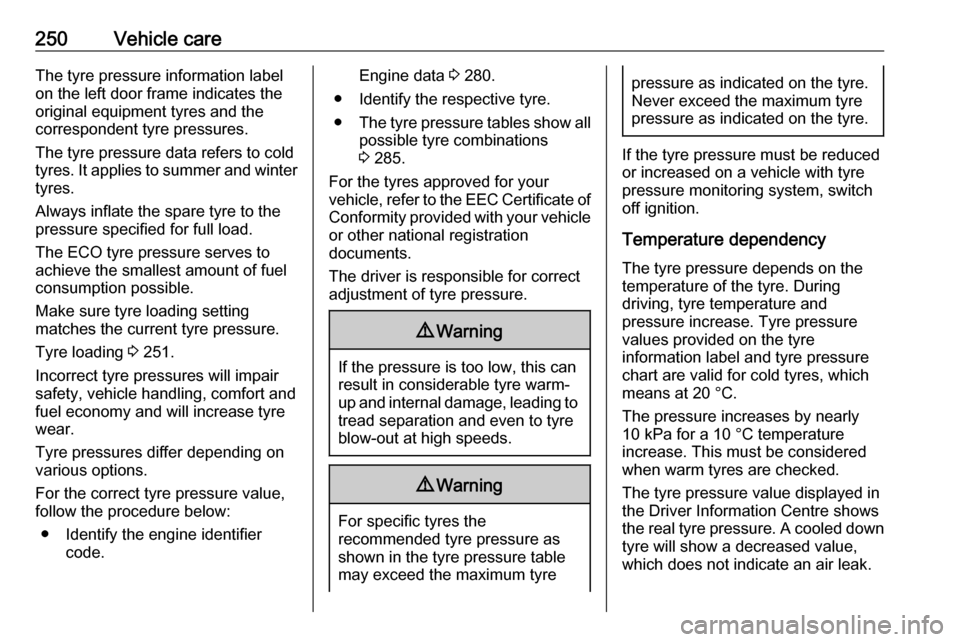

Midlevel display:

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 115.

Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 115.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 249.

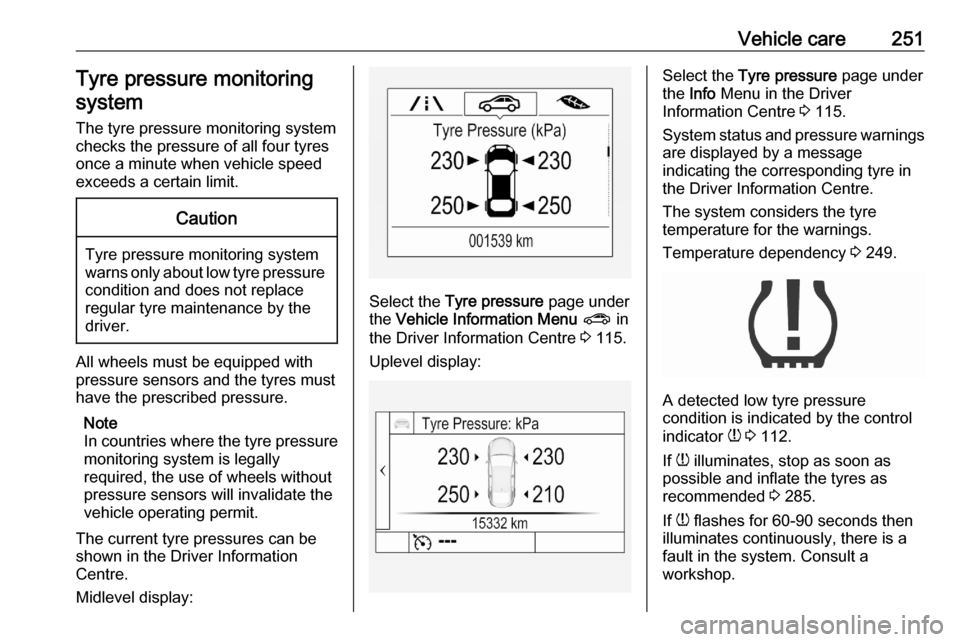

A detected low tyre pressure

condition is indicated by the control

indicator w 3 112.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 285.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

Page 256 of 305

254Vehicle care

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced and the tyre

pressure monitoring system

reinitialised 3 251.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Page 264 of 305

262Vehicle careAttach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow and secure the replaced wheel, the vehicle tools 3 247 and

the adapter for the locking wheel

nuts 3 73.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or repaired as soon as possible.Stowing a damaged full size

wheel in the load compartment, 5-

door hatchback

The spare wheel well is not designed

for other tyre sizes than the spare

wheel. A damaged full size wheel

must be stowed in the load

compartment.

Vehicle tools 3 247.

Make sure to store the wheel securely in the load compartment 3 90.9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured with the strap.

Stowing a damaged full size

wheel in the load compartment,

Sports Tourer

All permitted wheel sizes can be

stowed in the spare wheel well. To

secure the wheel: