tow OPEL ASTRA K 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: ASTRA K, Model: OPEL ASTRA K 2020Pages: 305, PDF Size: 27.84 MB

Page 258 of 305

256Vehicle careOn Sports Tourer the tyre repair kit isin a suitcase on the right side of the

load compartment behind a cover.

The suitcase is secured with a strap.

1. Remove the sealant bottle.

2. Insert thumb into the opening and

pull out the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery, we recommend running the

engine.

Page 259 of 305

Vehicle care257

10. Set the rocker switch on thecompressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes.

Tyre pressure 3 285.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Depending on version the button

can be located on the air hose.

Do not run the compressor longer

than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

Page 260 of 305

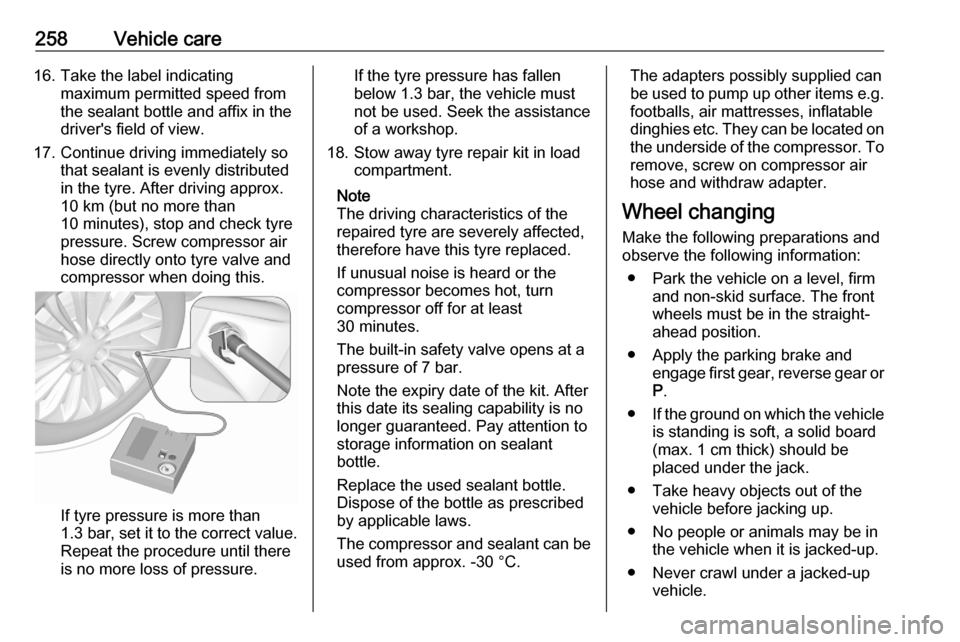

258Vehicle care16. Take the label indicatingmaximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.The adapters possibly supplied can

be used to pump up other items e.g. footballs, air mattresses, inflatable

dinghies etc. They can be located on

the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

Page 264 of 305

262Vehicle careAttach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow and secure the replaced wheel, the vehicle tools 3 247 and

the adapter for the locking wheel

nuts 3 73.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or repaired as soon as possible.Stowing a damaged full size

wheel in the load compartment, 5-

door hatchback

The spare wheel well is not designed

for other tyre sizes than the spare

wheel. A damaged full size wheel

must be stowed in the load

compartment.

Vehicle tools 3 247.

Make sure to store the wheel securely in the load compartment 3 90.9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured with the strap.

Stowing a damaged full size

wheel in the load compartment,

Sports Tourer

All permitted wheel sizes can be

stowed in the spare wheel well. To

secure the wheel:

Page 267 of 305

Vehicle care265Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

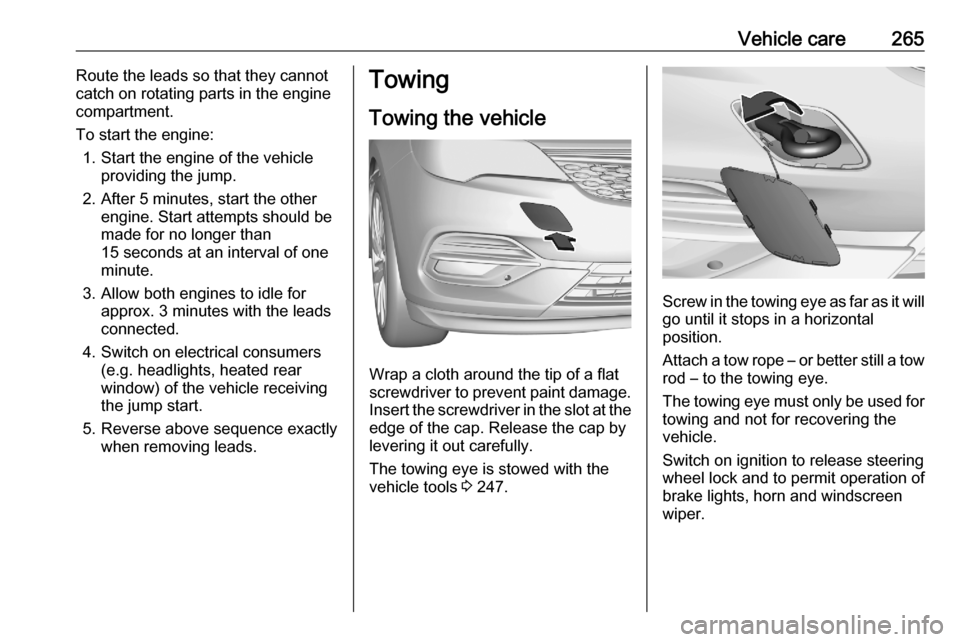

Towing the vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

edge of the cap. Release the cap by

levering it out carefully.

The towing eye is stowed with the

vehicle tools 3 247.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Page 268 of 305

266Vehicle careCaution

Deactivate the driver assistance

systems like active emergency

braking 3 190, otherwise the

vehicle may automatically brake during towing.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap at the top and engage

downwards.

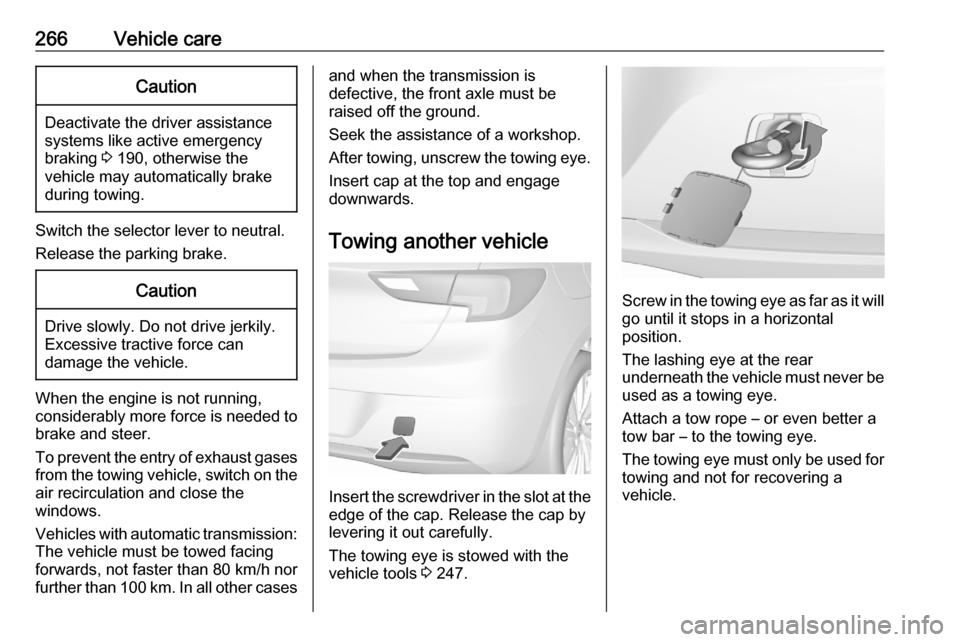

Towing another vehicle

Insert the screwdriver in the slot at the edge of the cap. Release the cap by

levering it out carefully.

The towing eye is stowed with the

vehicle tools 3 247.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

The lashing eye at the rear

underneath the vehicle must never be used as a towing eye.

Attach a tow rope – or even better a

tow bar – to the towing eye.

The towing eye must only be used for

towing and not for recovering a

vehicle.

Page 269 of 305

Vehicle care267Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

After towing, unscrew the towing eye.

Insert cap at the top and engage

downwards.

Appearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has a

degreasing effect and impairs lock function. After using a de-icing agent,

have the locks regreased by a

workshop.

WashingThe paintwork of your vehicle is

exposed to environmental influences.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wiper and rear window wiper must beswitched off. Remove antenna and

external accessories such as roof

racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Do not clean the engine compartmentwith a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Page 271 of 305

Vehicle care269Before and after winter, wash the

underbody and have the protective

wax coating checked.

Towing equipment

Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.

Air shutterClean the shutter system in the front

bumper to maintain correct

functionality.

Interior care

Interior and upholstery Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light- coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could

damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Floor mats9 Warning

If a floor mat has the wrong size or

is not properly installed, it can

interfere with the accelerator pedal

and/or brake pedal, what can

cause unintended acceleration

and/or increased stopping

distance which can cause a crash and injury.

Use the following guidelines for

proper floor mat usage.

● The original equipment floor mats

were designed for your vehicle. If the floor mats need replacing, it

is recommended that certified

Page 273 of 305

Vehicle care2713. Turn retainers clockwise for aquarter turn.Removing1. Move the driver's seat backwards

as far as possible.

2. Turn retainers a quarter turn towards the opposite direction

than during installation.

3. Remove the mat.

Page 301 of 305

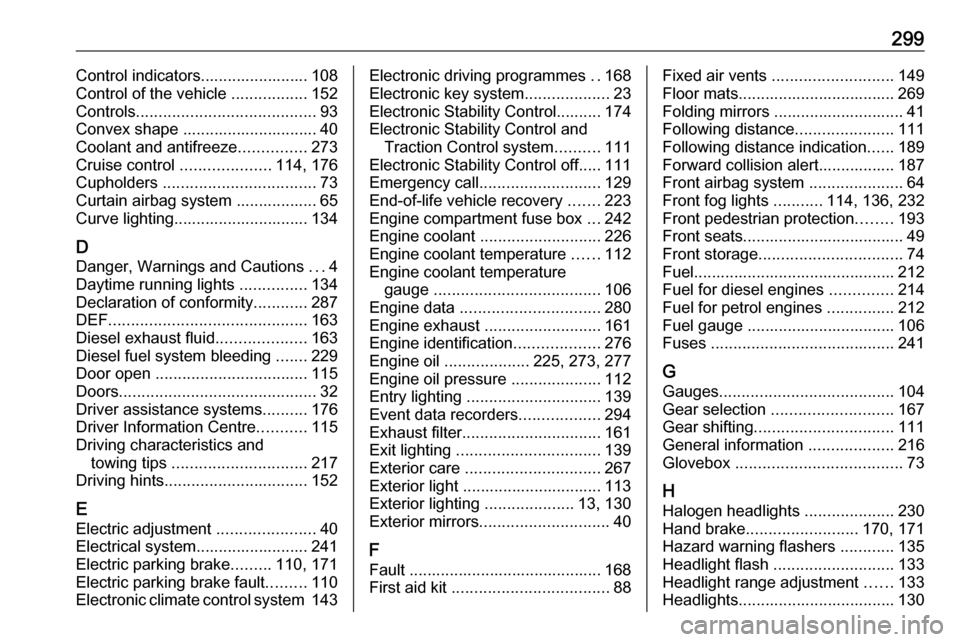

299Control indicators........................ 108

Control of the vehicle .................152

Controls ........................................ 93

Convex shape .............................. 40

Coolant and antifreeze ...............273

Cruise control ....................114, 176

Cupholders .................................. 73

Curtain airbag system .................. 65

Curve lighting.............................. 134

D

Danger, Warnings and Cautions ...4

Daytime running lights ...............134

Declaration of conformity ............287

DEF ............................................ 163

Diesel exhaust fluid ....................163

Diesel fuel system bleeding .......229

Door open .................................. 115

Doors ............................................ 32

Driver assistance systems ..........176

Driver Information Centre ...........115

Driving characteristics and towing tips .............................. 217

Driving hints ................................ 152

E Electric adjustment ......................40

Electrical system......................... 241

Electric parking brake .........110, 171

Electric parking brake fault .........110

Electronic climate control system 143Electronic driving programmes ..168

Electronic key system ...................23

Electronic Stability Control.......... 174

Electronic Stability Control and Traction Control system ..........111

Electronic Stability Control off..... 111

Emergency call ........................... 129

End-of-life vehicle recovery .......223

Engine compartment fuse box ...242

Engine coolant ........................... 226

Engine coolant temperature ......112

Engine coolant temperature gauge ..................................... 106

Engine data ............................... 280

Engine exhaust .......................... 161

Engine identification ...................276

Engine oil ................... 225, 273, 277

Engine oil pressure ....................112

Entry lighting .............................. 139

Event data recorders ..................294

Exhaust filter ............................... 161

Exit lighting ................................ 139

Exterior care .............................. 267

Exterior light ............................... 113

Exterior lighting ....................13, 130

Exterior mirrors ............................. 40

F

Fault ........................................... 168

First aid kit ................................... 88Fixed air vents ........................... 149

Floor mats................................... 269

Folding mirrors ............................. 41

Following distance ......................111

Following distance indication ......189

Forward collision alert................. 187

Front airbag system .....................64

Front fog lights ...........114, 136, 232

Front pedestrian protection ........193

Front seats.................................... 49

Front storage ................................ 74

Fuel............................................. 212

Fuel for diesel engines ..............214

Fuel for petrol engines ...............212

Fuel gauge ................................. 106

Fuses ......................................... 241

G Gauges ....................................... 104

Gear selection ........................... 167

Gear shifting ............................... 111

General information ...................216

Glovebox ..................................... 73

H Halogen headlights ....................230

Hand brake ......................... 170, 171

Hazard warning flashers ............135

Headlight flash ........................... 133

Headlight range adjustment ......133

Headlights................................... 130