Spec OPEL ASTRA K 2020 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: ASTRA K, Model: OPEL ASTRA K 2020Pages: 305, PDF Size: 27.84 MB

Page 219 of 305

Driving and operating217Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 285.Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 276.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by 40 kg. If the permissible rear axle load

is exceeded, a maximum speed of

100 km/h applies.

Page 224 of 305

222Vehicle careVehicle careGeneral Information...................222

Accessories and vehicle modifications .......................... 222

Vehicle storage ........................223

End-of-life vehicle recovery .....223

Vehicle checks ........................... 224

Performing work ......................224

Bonnet ..................................... 224

Engine oil ................................. 225

Engine coolant ......................... 226

Washer fluid ............................ 227

Brakes ..................................... 227

Brake fluid ............................... 227

Vehicle battery ......................... 228

Diesel fuel system bleeding .....229

Wiper blade replacement ........230

Bulb replacement .......................230

Halogen headlights ..................230

Front fog lights ......................... 232

Tail lights ................................. 233

Side turn lights ......................... 239

Number plate light ...................240

Interior lights ............................ 240

Electrical system ........................241

Fuses ....................................... 241Engine compartment fuse box . 242

Instrument panel fuse box .......244

Load compartment fuse box ....245

Vehicle tools .............................. 247

Tools ........................................ 247

Wheels and tyres .......................249

Winter tyres ............................. 249

Tyre designations ....................249

Tyre pressure .......................... 249

Tyre pressure monitoring system .................................... 251

Tread depth ............................. 253

Changing tyre and wheel size . 254

Wheel covers ........................... 254

Tyre chains .............................. 255

Tyre repair kit .......................... 255

Wheel changing .......................258

Spare wheel ............................ 259

Jump starting ............................. 263

Towing ....................................... 265

Towing the vehicle ...................265

Towing another vehicle ...........266

Appearance care .......................267

Exterior care ............................ 267

Interior care ............................. 269

Floor mats ............................... 269General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, fuel consumption, CO 2

emissions and other emissions of the

vehicle. They may also invalidate the

vehicle operating permit.

Page 225 of 305

Vehicle care223Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Number plate mounting

To ensure a proper functionality of the

radar system, do not use a number

plate support on the front bumper.

Vehicle storage Storage for a long period of timeIf the vehicle is to be stored for several

months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Note that all systems are

not functional, e.g. anti-theft

alarm system.Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Initialize the power

windows 3 43.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

Number plate mounting 3 222.

End-of-life vehicle recovery Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 227 of 305

Vehicle care225If the bonnet is opened during an

Autostop, the engine will be restarted

automatically for safety reasons.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and let it fall into the

latch from a low height (20-25 cm).

Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch to avoid dents.

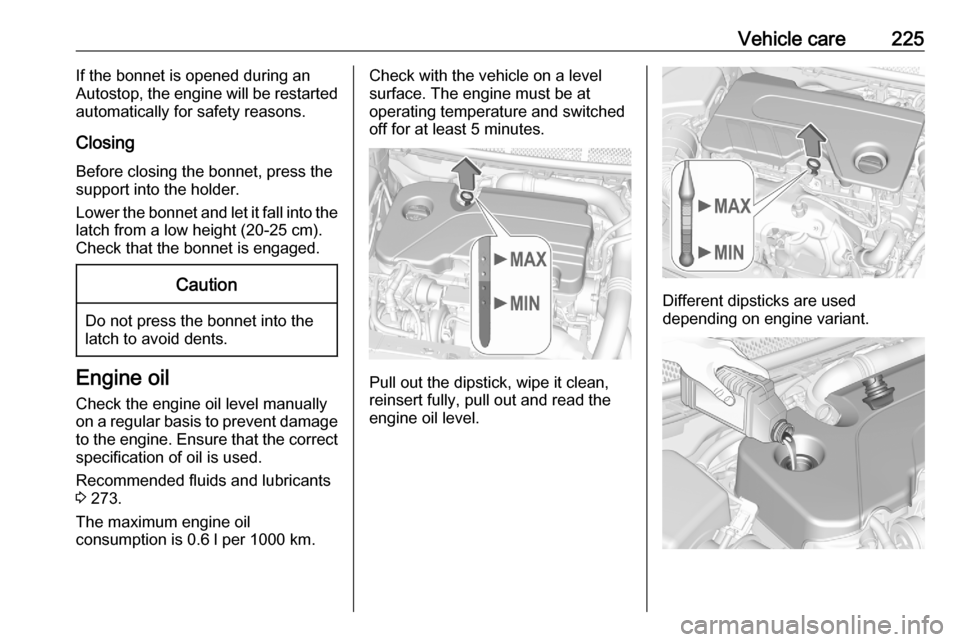

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct

specification of oil is used.

Recommended fluids and lubricants

3 273.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Pull out the dipstick, wipe it clean,

reinsert fully, pull out and read the

engine oil level.

Different dipsticks are used

depending on engine variant.

Page 235 of 305

Vehicle care233

2. Disengage the plug connector bypressing the retaining lug.

3. Remove and replace the bulb unit

and attach the plug connector.

Note that the bulb and the socket

are one unit and have to be

changed together.

4. Insert the bulb socket into the light

assembly by turning clockwise

and engage.

5. Mount the light assembly by tightening the screws.

6. Attach the faceplate and tighten the screw.

Tail lights

5-door Hatchback

1. Release the cover on the respective side and remove it.

2. Vehicles with tyre repair kit: To replace bulbs on the right side,

first unscrew the plastic nut and

take out the insert with the sealant

bottle.

3. Unscrew the plastic securing nut from the inside by hand.

Page 238 of 305

236Vehicle careOn version with LED tail lights, theposition of the retaining lugs is

slightly different.

6. Remove and replace the bulb:

Tail light ( 1)

Rear fog light ( 2) (left side)

Reverse light ( 2) (right side)

On version with LED tail lights

only reverse light bulb ( 1) can be

removed and replaced.

7. Insert the bulb carrier into the tail light assembly. Attach plug to the

light assembly. Fit light assembly

on the tailgate and tighten the

screw from the inside. Attach

cover.

Depending on the version, tail lights are designed as LEDs. In case of failure, have LEDs replaced by aworkshop.

Sports Tourer

1. Release and open the cover on the respective side.

Page 243 of 305

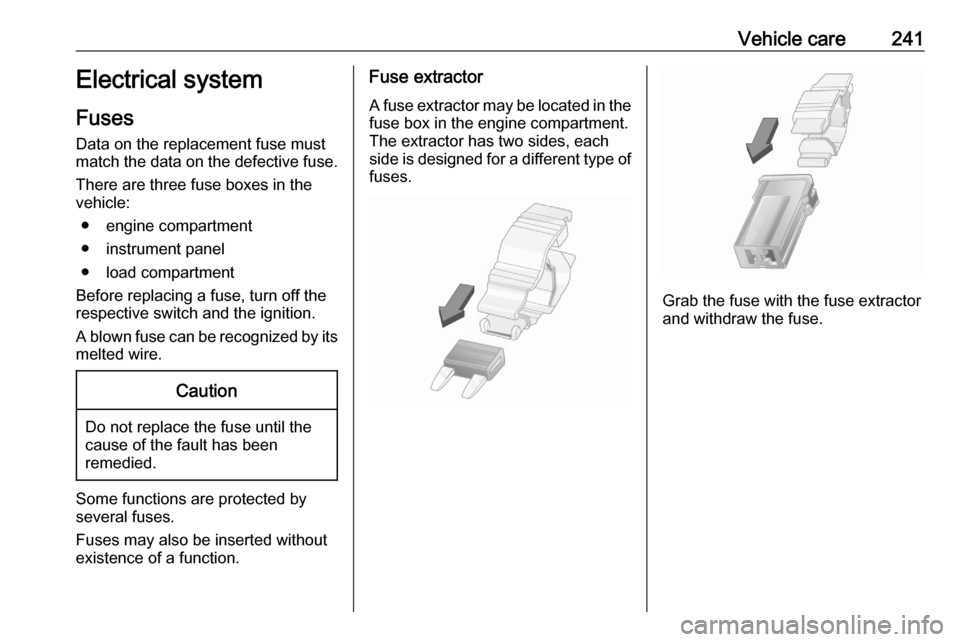

Vehicle care241Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

● load compartment

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

The extractor has two sides, each

side is designed for a different type of fuses.

Grab the fuse with the fuse extractor

and withdraw the fuse.

Page 251 of 305

Vehicle care249Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 285.Tyre designations

E.g. 215/50 R 16 95 H215:Tyre width, mm50:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat16:Wheel diameter, inches95:Load index e.g. 95 is

equivalent to 690 kgH:Speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer to the EEC Certificate of Conformity

provided with the vehicle or other national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mountedso that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

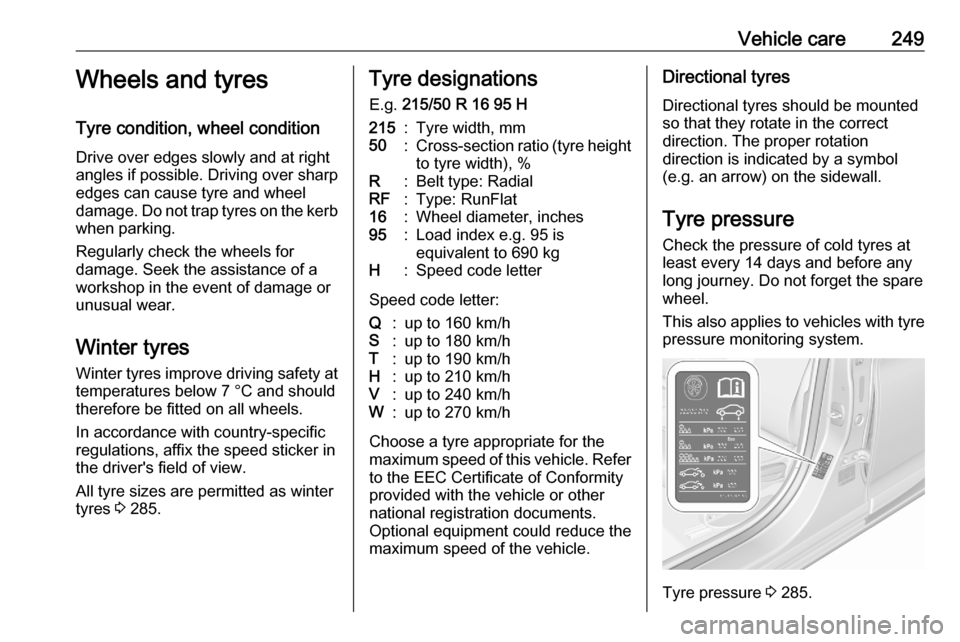

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre

pressure monitoring system.

Tyre pressure 3 285.

Page 252 of 305

250Vehicle careThe tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 251.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code.Engine data 3 280.

● Identify the respective tyre. ● The tyre pressure tables show all

possible tyre combinations

3 285.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,which does not indicate an air leak.

Page 256 of 305

254Vehicle care

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced and the tyre

pressure monitoring system

reinitialised 3 251.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.