wheel OPEL ASTRA K 2020 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: ASTRA K, Model: OPEL ASTRA K 2020Pages: 305, PDF Size: 27.84 MB

Page 223 of 305

Driving and operating221

Stow the coupling ball bar in the bag

and secure by fixing the strap through the rear right lashing eye. Wrap

around twice and tighten the strap to

secure the bag.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is selectively braked until the snaking

ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 174.

Page 224 of 305

222Vehicle careVehicle careGeneral Information...................222

Accessories and vehicle modifications .......................... 222

Vehicle storage ........................223

End-of-life vehicle recovery .....223

Vehicle checks ........................... 224

Performing work ......................224

Bonnet ..................................... 224

Engine oil ................................. 225

Engine coolant ......................... 226

Washer fluid ............................ 227

Brakes ..................................... 227

Brake fluid ............................... 227

Vehicle battery ......................... 228

Diesel fuel system bleeding .....229

Wiper blade replacement ........230

Bulb replacement .......................230

Halogen headlights ..................230

Front fog lights ......................... 232

Tail lights ................................. 233

Side turn lights ......................... 239

Number plate light ...................240

Interior lights ............................ 240

Electrical system ........................241

Fuses ....................................... 241Engine compartment fuse box . 242

Instrument panel fuse box .......244

Load compartment fuse box ....245

Vehicle tools .............................. 247

Tools ........................................ 247

Wheels and tyres .......................249

Winter tyres ............................. 249

Tyre designations ....................249

Tyre pressure .......................... 249

Tyre pressure monitoring system .................................... 251

Tread depth ............................. 253

Changing tyre and wheel size . 254

Wheel covers ........................... 254

Tyre chains .............................. 255

Tyre repair kit .......................... 255

Wheel changing .......................258

Spare wheel ............................ 259

Jump starting ............................. 263

Towing ....................................... 265

Towing the vehicle ...................265

Towing another vehicle ...........266

Appearance care .......................267

Exterior care ............................ 267

Interior care ............................. 269

Floor mats ............................... 269General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, fuel consumption, CO 2

emissions and other emissions of the

vehicle. They may also invalidate the

vehicle operating permit.

Page 246 of 305

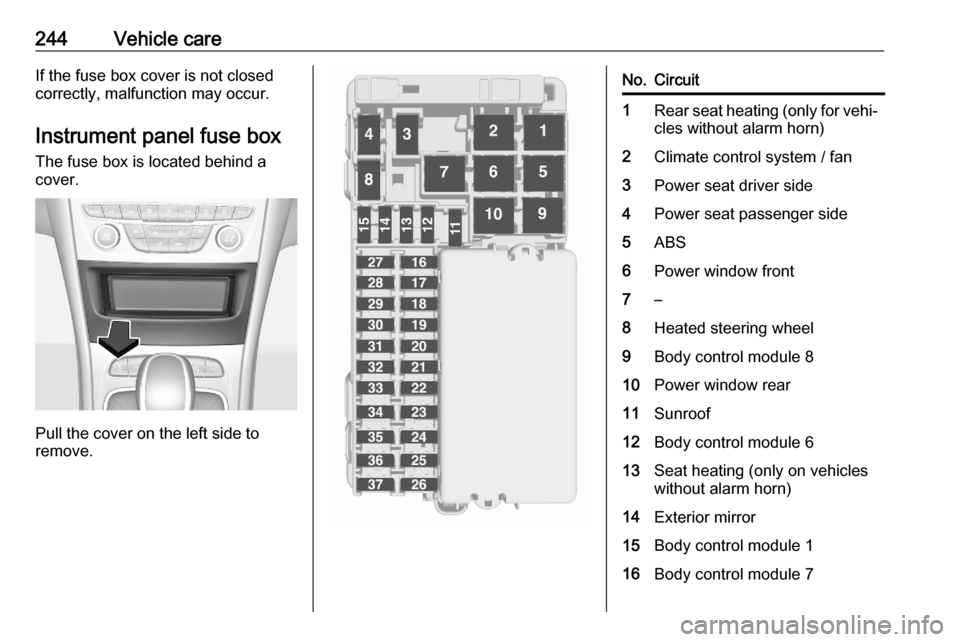

244Vehicle careIf the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse box The fuse box is located behind a

cover.

Pull the cover on the left side to

remove.

No.Circuit1Rear seat heating (only for vehi‐ cles without alarm horn)2Climate control system / fan3Power seat driver side4Power seat passenger side5ABS6Power window front7–8Heated steering wheel9Body control module 810Power window rear11Sunroof12Body control module 613Seat heating (only on vehicles

without alarm horn)14Exterior mirror15Body control module 116Body control module 7

Page 247 of 305

Vehicle care245No.Circuit17Body control module 418Body control module 319Data link connector20Airbag system21Climate control system22Central locking system / tailgate23Electronic key system24Power seat memory function25Airbag system steering wheel26Ignition switch / Steering

column lock27Body control module 228USB socket29Cigarette lighter / Power outlet

front30Selector lever31Rear window wiper32Transmission control moduleNo.Circuit33Anti-theft alarm system / Power

sounder34Parking assist / Side blind spot

alert / Infotainment system /

USB socket35SOS36Info Display / Instrument cluster37Infotainment system / radio

After having changed defective fuses,

close the fuse box cover:

1. Apply the cover on the right side.

2. Fold the left side of the cover forwards. Take care that thesecuring clamp is guided as

shown in the illustration.

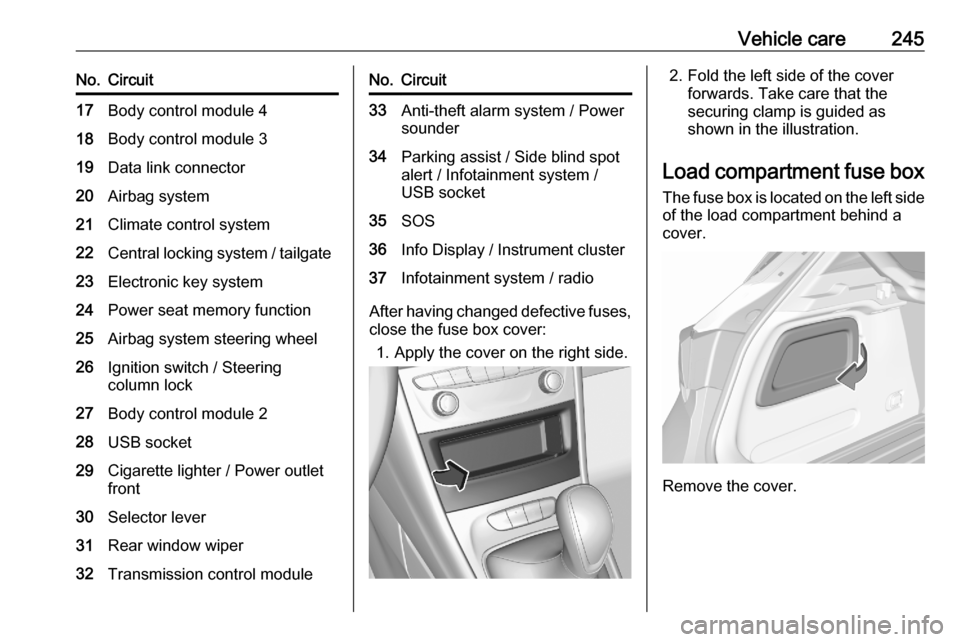

Load compartment fuse box The fuse box is located on the left side

of the load compartment behind a

cover.

Remove the cover.

Page 249 of 305

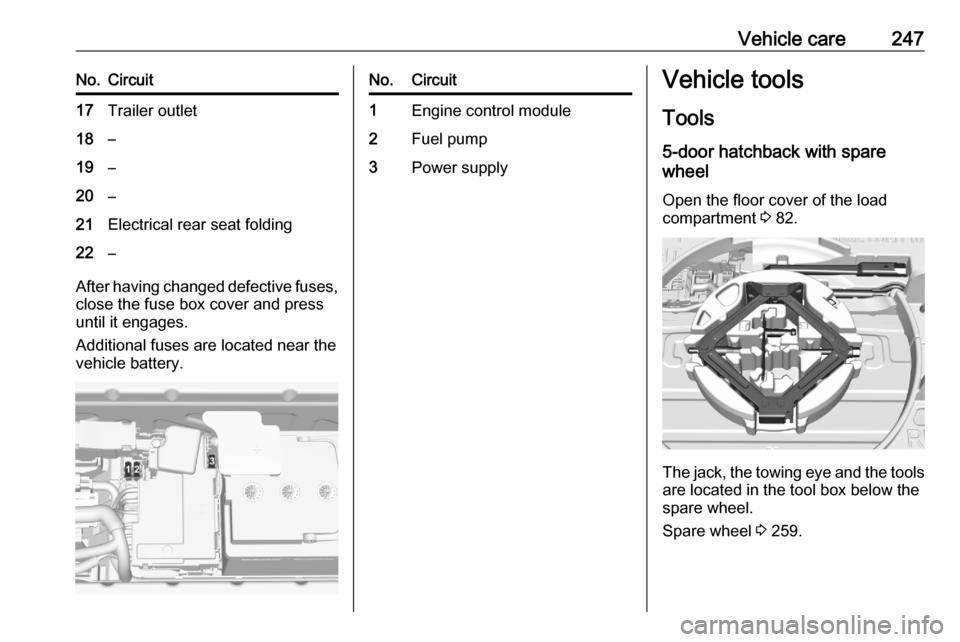

Vehicle care247No.Circuit17Trailer outlet18–19–20–21Electrical rear seat folding22–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

Additional fuses are located near the

vehicle battery.

No.Circuit1Engine control module2Fuel pump3Power supplyVehicle tools

Tools

5-door hatchback with spare

wheel

Open the floor cover of the load

compartment 3 82.

The jack, the towing eye and the tools

are located in the tool box below the

spare wheel.

Spare wheel 3 259.

Page 250 of 305

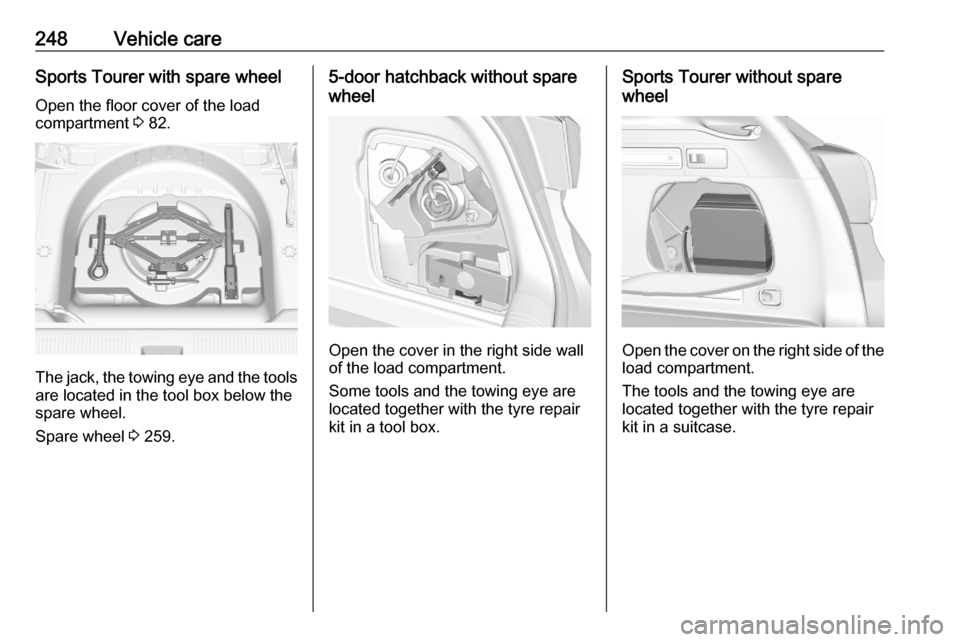

248Vehicle careSports Tourer with spare wheel

Open the floor cover of the load

compartment 3 82.

The jack, the towing eye and the tools

are located in the tool box below the

spare wheel.

Spare wheel 3 259.

5-door hatchback without spare

wheel

Open the cover in the right side wall

of the load compartment.

Some tools and the towing eye are

located together with the tyre repair

kit in a tool box.

Sports Tourer without spare

wheel

Open the cover on the right side of the load compartment.

The tools and the towing eye are

located together with the tyre repair

kit in a suitcase.

Page 251 of 305

Vehicle care249Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

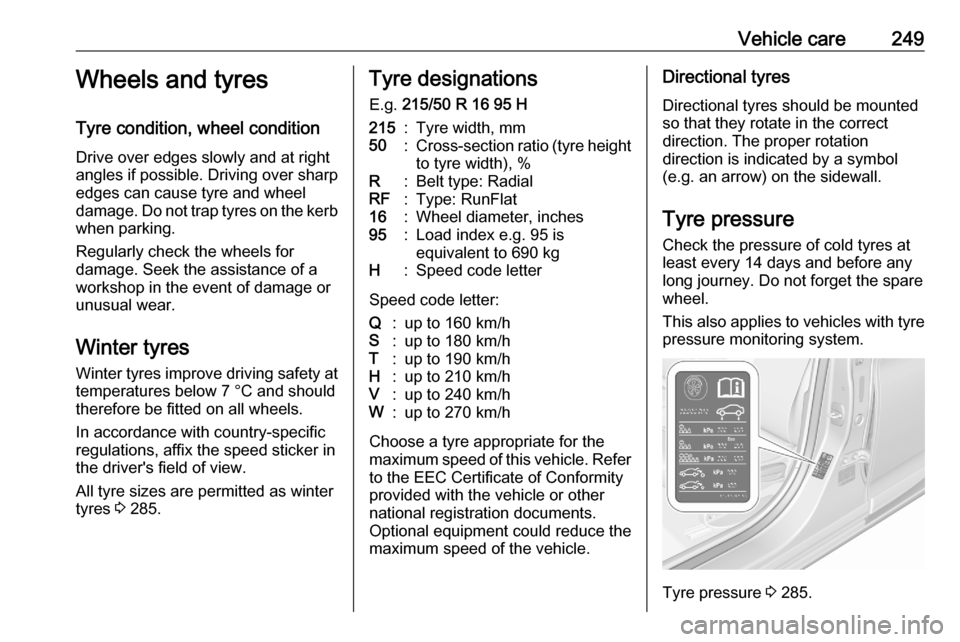

tyres 3 285.Tyre designations

E.g. 215/50 R 16 95 H215:Tyre width, mm50:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat16:Wheel diameter, inches95:Load index e.g. 95 is

equivalent to 690 kgH:Speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer to the EEC Certificate of Conformity

provided with the vehicle or other national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mountedso that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre

pressure monitoring system.

Tyre pressure 3 285.

Page 253 of 305

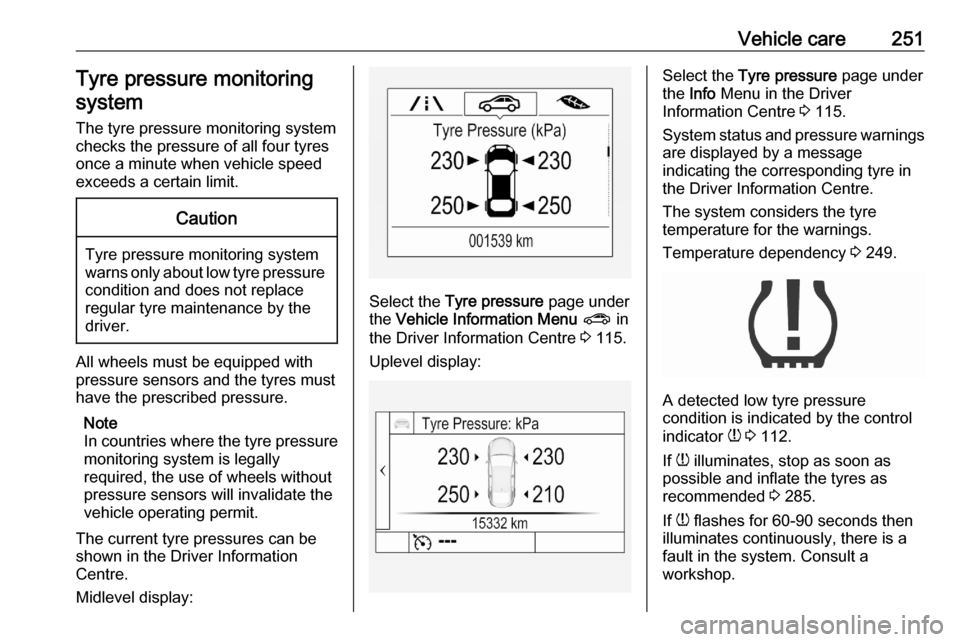

Vehicle care251Tyre pressure monitoringsystem

The tyre pressure monitoring system checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Driver Information

Centre.

Midlevel display:

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 115.

Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 115.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 249.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 112.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 285.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

Page 254 of 305

252Vehicle careAfter inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching

a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 122.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre

pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor, replace

valve core and sealing ring. For the

clipped sensor, replace complete

valve stem.

Use only original plastic valve caps to protect valve on any damage.Caution

Do not use metal valve caps as

they lead to valve oxidation and

damage.

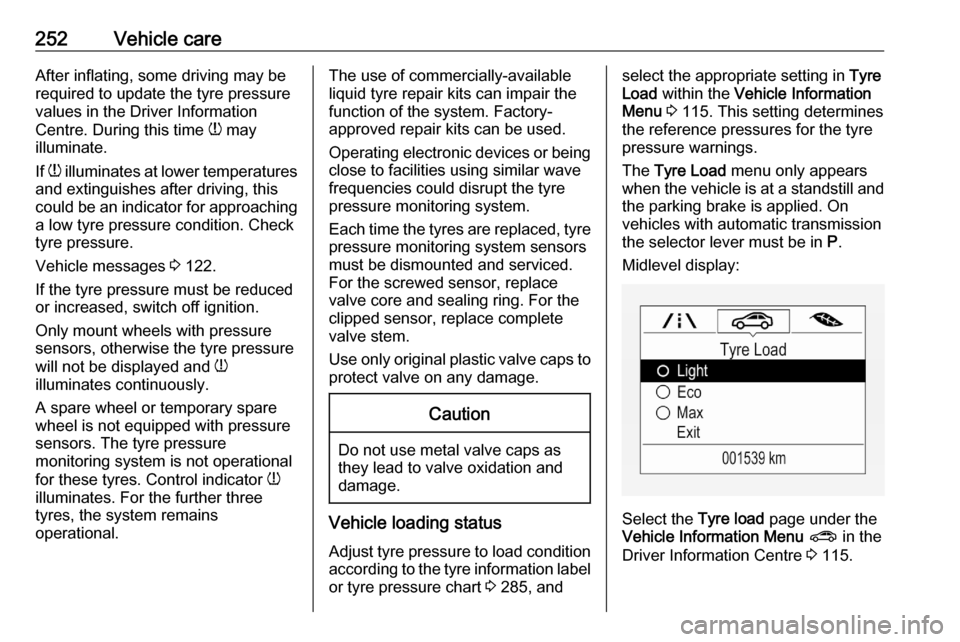

Vehicle loading status

Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 285, and

select the appropriate setting in Tyre

Load within the Vehicle Information

Menu 3 115. This setting determines

the reference pressures for the tyre

pressure warnings.

The Tyre Load menu only appears

when the vehicle is at a standstill and the parking brake is applied. On

vehicles with automatic transmission

the selector lever must be in P.

Midlevel display:

Select the Tyre load page under the

Vehicle Information Menu ? in the

Driver Information Centre 3 115.

Page 255 of 305

Vehicle care253Select● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 115.

Select

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Auto learn function After changing wheels or wheel

positions the vehicle must be

stationary for approx. 20 minutes,

before the system recalculates. The

following relearn process takes up to

10 minutes of driving in a speed range

of 40 to 100 km/h. Avoid to drive

outside of this range for a longer time.

If possible, use a country road or

similar which allows continuous

driving. During relearn process $

can be displayed or pressure values

can swap in the Driver Information Centre.

Ensure the tyre loading status is set

according to the selected pressure

3 115.If problems occur during the relearn

process, a failure message is

displayed in the Driver Information

Centre. w will flash for 60 seconds

and then illuminate continuously.

If this happens, repeat learning

process. Keep your vehicle stationary for approx. 20 minutes and then drive

again for 10 minutes as described

above.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.