Speed OPEL ASTRA K 2020 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: ASTRA K, Model: OPEL ASTRA K 2020Pages: 305, PDF Size: 27.84 MB

Page 212 of 305

210Driving and operatingSystem limitations

Traffic sign assistant may not operate properly when:

● Vehicle speed is faster than 200 km/h.

● Driving on winding or hilly roads. ● During nighttime driving.

● The area of the windscreen, where the front camera is

located, is not clean or affected

by foreign items, e.g. stickers.

● Weather limits visibility, such as fog, rain, or snow.

● The sun is shining directly into the camera lens.

● Traffic signs are completely or partially covered or difficult to

discern.

● Traffic signs are incorrectly mounted or damaged.

● Traffic signs do not comply with the Vienna Convention on traffic

signs.

● The navigation map data is outdated.Caution

The system is intended to help thedriver within a defined speed

range to discern certain traffic

signs. Do not ignore traffic signs

which are not displayed by the

system.

The system does not discern any other than the conventional traffic

signs that might give or end a

speed limit.

Do not let this special feature

tempt you into taking risks when

driving.

Always adapt speed to the road

conditions.

The driver assistance systems do not relieve the driver from full

responsibility for vehicle

operation.

Lane keep assist

Lane keep assist supports the driver

to avoid unintentional crossing of lane markings. The front camera observes

the lane markings between which the

vehicle is driving. If the vehicle

approaches a lane marking without

activated turn signal, the steering

wheel is gently turned to position the

vehicle back into the lane. Turn

steering wheel in same direction, if

system steers not sufficient. Turn

steering wheel gently into opposite

direction, if lane change is intended.

The Lane Keep Assist informs the

driver with an optical warning during

the trajectory correction. If the system is not able to avoid the lane crossing

an additional acoustic warning is

issued.

Unintended lane departure is

assumed:

● without using the turn lights

● using the turn lights in the opposite direction of the lane

departure

● without braking

● without acceleration

● without active steering

Note

The system might be inactive when

the detected lane markings are ambiguous or insufficient, e.g. in

construction areas.

Page 213 of 305

Driving and operating211Note

The system may be switched off if it

detects lanes which are too narrow,

too wide or too curved.

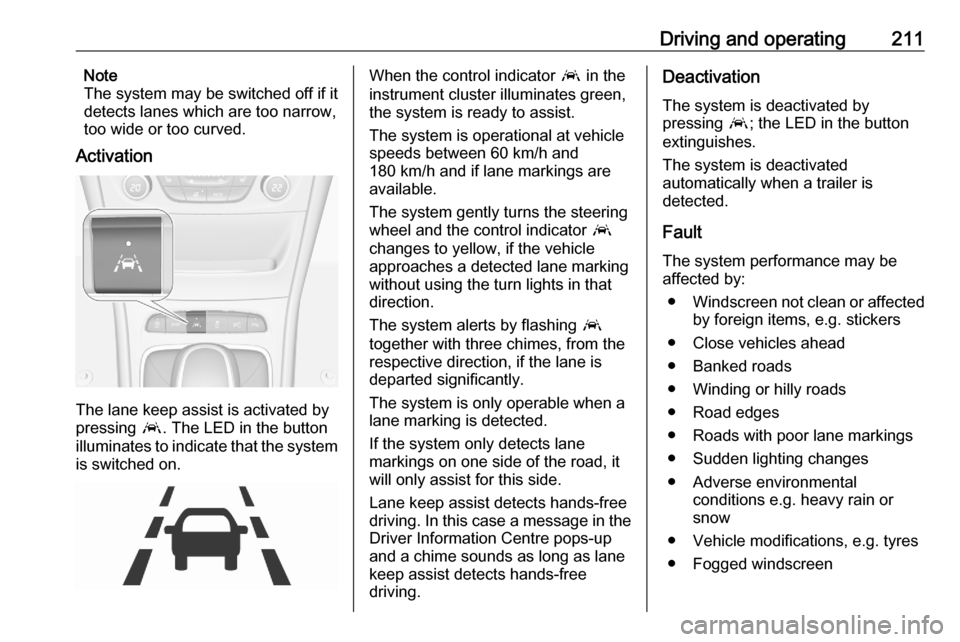

Activation

The lane keep assist is activated by

pressing a. The LED in the button

illuminates to indicate that the system

is switched on.

When the control indicator a in the

instrument cluster illuminates green,

the system is ready to assist.

The system is operational at vehicle

speeds between 60 km/h and

180 km/h and if lane markings are

available.

The system gently turns the steering

wheel and the control indicator a

changes to yellow, if the vehicle

approaches a detected lane marking

without using the turn lights in that

direction.

The system alerts by flashing a

together with three chimes, from the

respective direction, if the lane is

departed significantly.

The system is only operable when a

lane marking is detected.

If the system only detects lane

markings on one side of the road, it

will only assist for this side.

Lane keep assist detects hands-free

driving. In this case a message in the

Driver Information Centre pops-up

and a chime sounds as long as lane

keep assist detects hands-free

driving.Deactivation

The system is deactivated by

pressing a; the LED in the button

extinguishes.

The system is deactivated

automatically when a trailer is

detected.

Fault

The system performance may be affected by:

● Windscreen not clean or affected

by foreign items, e.g. stickers

● Close vehicles ahead

● Banked roads

● Winding or hilly roads

● Road edges

● Roads with poor lane markings

● Sudden lighting changes

● Adverse environmental conditions e.g. heavy rain or

snow

● Vehicle modifications, e.g. tyres ● Fogged windscreen

Page 219 of 305

Driving and operating217Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 285.Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 276.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by 40 kg. If the permissible rear axle load

is exceeded, a maximum speed of

100 km/h applies.

Page 251 of 305

Vehicle care249Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 285.Tyre designations

E.g. 215/50 R 16 95 H215:Tyre width, mm50:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat16:Wheel diameter, inches95:Load index e.g. 95 is

equivalent to 690 kgH:Speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer to the EEC Certificate of Conformity

provided with the vehicle or other national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mountedso that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre

pressure monitoring system.

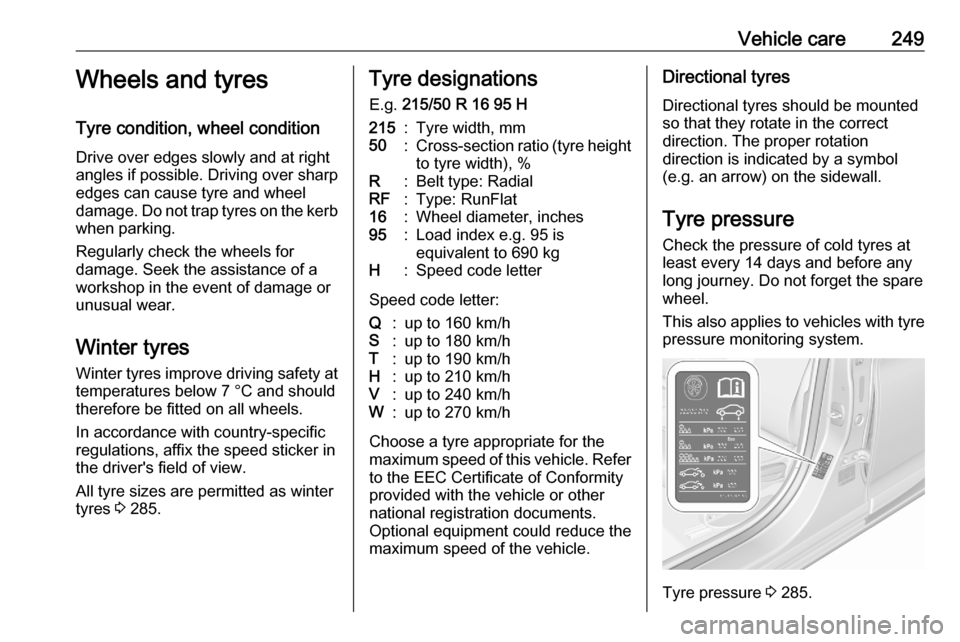

Tyre pressure 3 285.

Page 252 of 305

250Vehicle careThe tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 251.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code.Engine data 3 280.

● Identify the respective tyre. ● The tyre pressure tables show all

possible tyre combinations

3 285.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,which does not indicate an air leak.

Page 253 of 305

Vehicle care251Tyre pressure monitoringsystem

The tyre pressure monitoring system checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Driver Information

Centre.

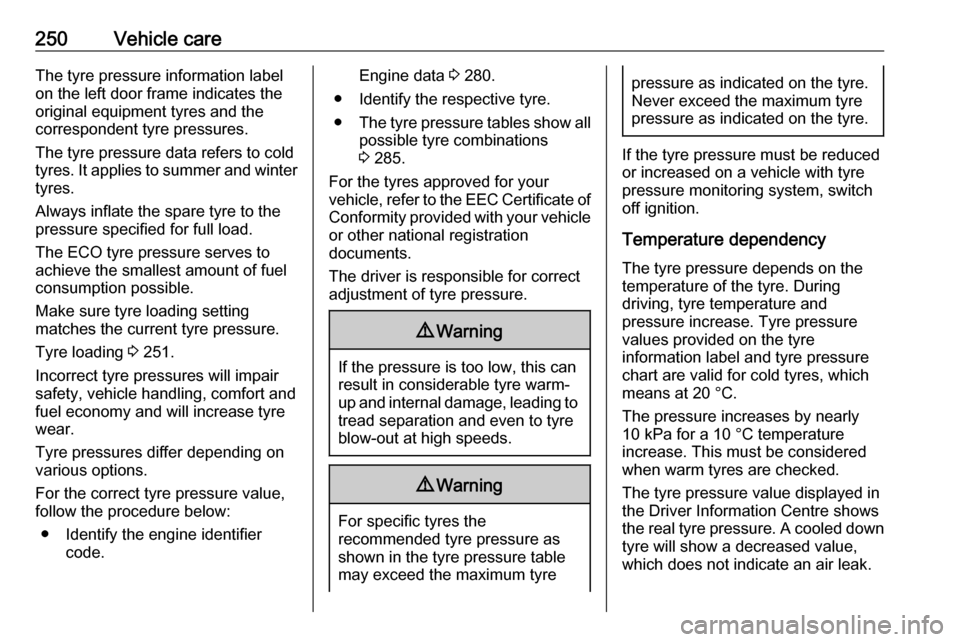

Midlevel display:

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 115.

Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 115.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 249.

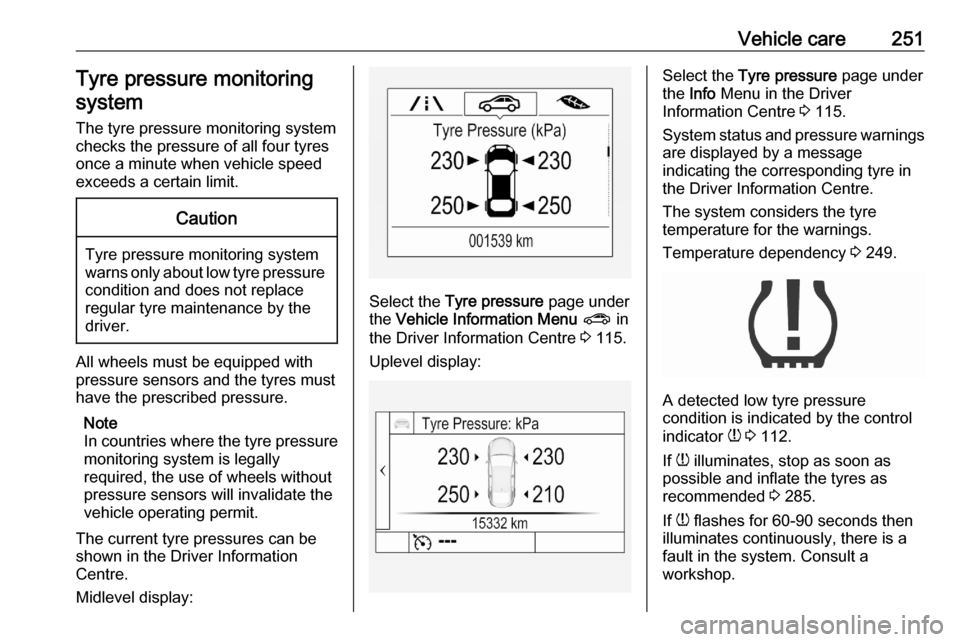

A detected low tyre pressure

condition is indicated by the control

indicator w 3 112.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 285.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

Page 255 of 305

Vehicle care253Select● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 115.

Select

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Auto learn function After changing wheels or wheel

positions the vehicle must be

stationary for approx. 20 minutes,

before the system recalculates. The

following relearn process takes up to

10 minutes of driving in a speed range

of 40 to 100 km/h. Avoid to drive

outside of this range for a longer time.

If possible, use a country road or

similar which allows continuous

driving. During relearn process $

can be displayed or pressure values

can swap in the Driver Information Centre.

Ensure the tyre loading status is set

according to the selected pressure

3 115.If problems occur during the relearn

process, a failure message is

displayed in the Driver Information

Centre. w will flash for 60 seconds

and then illuminate continuously.

If this happens, repeat learning

process. Keep your vehicle stationary for approx. 20 minutes and then drive

again for 10 minutes as described

above.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

Page 260 of 305

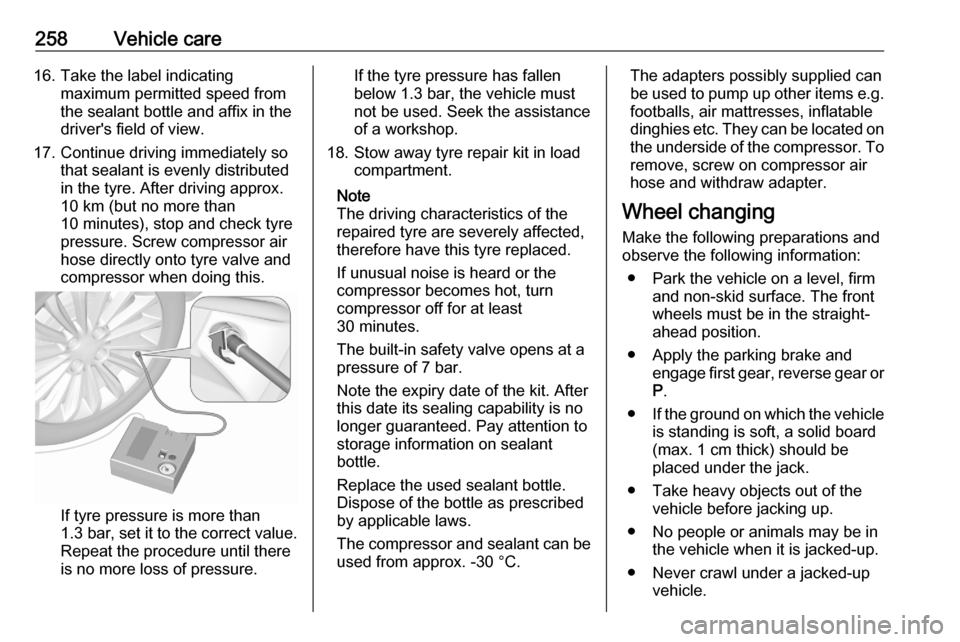

258Vehicle care16. Take the label indicatingmaximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.The adapters possibly supplied can

be used to pump up other items e.g. footballs, air mattresses, inflatable

dinghies etc. They can be located on

the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

Page 261 of 305

Vehicle care259●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

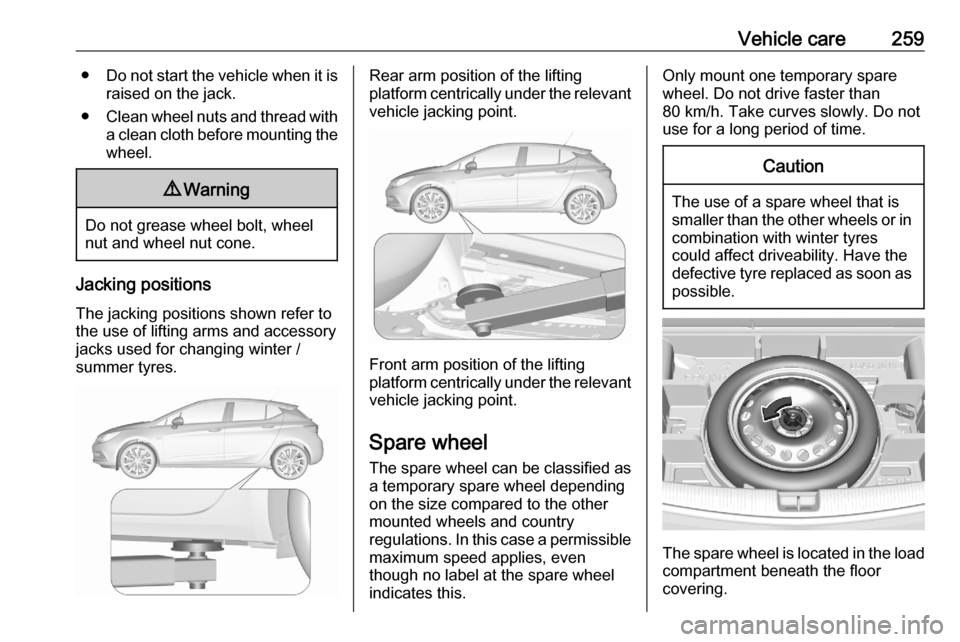

Jacking positions

The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Front arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.Caution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering.

Page 262 of 305

260Vehicle careTo remove:1. Open the floor cover 3 82.

2. The spare wheel is secured with a

wing nut. Unscrew the wing nut

and take out the spare wheel.

Under the spare wheel there is the

box with vehicle tools.

3. When, after a wheel change, no wheel is placed in the spare wheelwell, secure the tool box by

tightening the wing nut as far as it

will go and close floor cover.

4. After wheel change back to full size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.● Never crawl under a jacked-upvehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels with cover: Pull off the wheel cover.

Alloy wheels: Disengage wheel

nut caps with a slot screwdriver

and remove. To protect the wheel paint and the cap, wrap a cloth

around the screwdriver tip 3 247.