dead battery OPEL CALIBRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 91 of 525

28The system also incorporates a separate

ignition amplifier module that transmits

amplified signals from the main system

module to trigger the HT pulse from the

ignition coil. The module is mounted on the

ignition coil’s bracket/baseplate.

29Additionally, the Motronic module

receives information from a cylinder

block-mounted knock sensor, which senses

“knocking” (or pre-ignition) just as it begins to

occur, enabling the module to retard the

ignition timing, thus preventing engine

damage.

Simtec 56.1

30This system uses increased amount of

electronic components instead of mechanical

parts as sensors and actuators with the

Simtec engine management system. This

provides more precise operating data as well

as greater problem free motoring.

31The control unit is equipped with

electronic ignition control. Called ‘Micropro-

cessor Spark Timing System, inductive

triggered’, (or MSTS-i), and means that the

mechanical high voltage distributor is no

longer needed. It is located behind the trim

panel, on the right-hand side footwell (door

pillar).

32The ignition coil is replaced by a dual

spark ignition coil, which is switched directly

by the output stages in the control unit.

33A camshaft sensor will maintain

emergency operation, should the crankshaft

inductive pulse pick-up, malfunction. These

sense TDC (‘Top Dead Centre’), crankshaft

angle and engine speed. The signals are used

by the control unit to calculate ignition point

and for fuel injection.

34The ‘hot film airflow meter’ determines the

mass of air taken in by the engine. The system

uses this information to calculate the correct

amount of fuel needed for injection in the

engine.

35The air inlet temperature sensor (NTC), is

fitted in the air inlet duct between the air

cleaner and the hot mass air flow meter.

36A controlled canister purge valve is

actuated by the system. The tank ventilation is

monitored closely with the Lambda control (or

oxygen sensor) and adaptation by the

computer within the control unit.

37A knock control system is also fitted. This

eliminates the need for octane number

adjustment, as it is performed automatically

through the control unit.

3Electrical system -

precautions

1It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

2Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

3Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

4If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

5Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

6The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

7Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

8Engine management modules are very

sensitive components, and certain

precautions must be taken, to avoid damage

to the module when working on a vehicle

equipped with an engine management

system, as follows.

9When carrying out welding operations on

the vehicle using electric welding equipment,

the battery and alternator should be

disconnected.

10Although underbonnet-mounted modules

will tolerate normal underbonnet conditions,

they can be adversely affected by excess heat

or moisture. If using welding equipment or

pressure washing equipment near the

module, take care not to direct heat, or jets of

water or steam, at the module. If this cannot

be avoided, remove the module from the

vehicle, and protect its wiring plug with a

plastic bag.

11Before disconnecting any wiring, or

removing components, always ensure that the

ignition is switched off.

12Do not attempt to improvise fault

diagnosis procedures using a test lamp or

multimeter, as irreparable damage could be

caused to the module.13After working on ignition/engine

management system components, ensure

that all wiring is correctly reconnected before

reconnecting the battery or switching on the

ignition.

14Any ignition system that uses a

“Hall-effect” generator in the distributor,

cannot be tested. Test equipment that uses

its own power source (e.g. an ohmmeter),

when connected to the distributor or the

“Hall-effect” generator, will be damaged.

4Ignition system testing -

general

3

Note: Refer to Section 3 before proceeding.

Always switch off the ignition before

disconnecting or connecting any component

and when using a multi-meter to check

resistances. Any voltmeter or multi-meter

used to test ignition system components must

have an impedance of 10 meg ohms or

greater

1Electronic ignition system components are

normally very reliable. Most faults are far more

likely to be due to loose or dirty connections,

or to “tracking” of HT voltage due to dirt,

dampness or damaged insulation than to

component failure. Always check all wiring

thoroughly before condemning an electrical

component and work methodically to

eliminate all other possibilities before deciding

that a particular component is faulty.

2The old practice of checking for a spark by

holding the live end of a HT lead a short

distance away from the engine is not

recommended. Not only is there a high risk of

a powerful electric shock, but the ignition coil

or amplifier module will be damaged.

Similarly, never try to “diagnose” misfires by

pulling off one HT lead at a time. Note also

that the ECU is at risk if the system is

triggered with an open (i.e., not properly

earthed) HT circuit; ECU’s are very expensive

to replace, so take care!

3If you are in any doubt as to your skill and

ability to test an ignition system component or

if you do not have the required equipment,

take the vehicle to a suitably equipped

Vauxhall dealer. It is better to pay the labour

charges involved in having the vehicle

checked by an expert than to risk damage to

the system or to yourself.

4If the engine either will not turn over at all,

or only turns very slowly, check the battery

and starter motor. Connect a voltmeter across

the battery terminals (meter positive probe to

battery positive terminal) and disconnect the

ignition coil HT lead from the distributor cap

and earth. Note the voltage reading obtained

while turning over the engine on the starter for

(no more than) ten seconds. If the reading

obtained is less than approximately 9.5 volts,

check the battery, battery connections, starter

motor and charging system.

5•4Engine electrical systems

Warning: The HT voltage

generated by an electronic

ignition system is extremely

high and, in certain

circumstances, could prove fatal. Take

care to avoid receiving electric shocks

from the HT side of the ignition system.

Do not handle HT leads, or touch the

distributor or coil, when the engine is

running. If tracing faults in the HT circuit,

use well-insulated tools to manipulate live

leads

Page 129 of 525

b)Always keep the ignition and fuel systems

well maintained according to the

manufacturers schedule (see “Routine

maintenance” and the relevant Chapter).

In particular, ensure that the air cleaner

filter element, the fuel filter and the spark

plugs are renewed at the correct intervals.

If the inlet air/fuel mixture is allowed to

become too rich due to neglect, the

unburned surplus will enter and burn in

the catalytic converter, overheating the

element and eventually destroying the

converter.

c)If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured. The

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

d)The engine control indicator (the outline

of an engine with a lightning symbol

superimposed), will light when the ignition

is switched on and the engine is started,

then it will go out. While it may light briefly

while the engine is running, it should go

out again immediately and stays unlit. If it

lights and stays on while the engine is

running, seek the advice of a Vauxhall

dealer as soon as possible. A fault has

occurred in the fuel injection/ignition

system that, apart from increasing fuel

consumption and impairing the engine’s

performance, may damage the catalytic

converter.

e)DO NOT push or tow-start the vehicle.

This will soak the catalytic converter in

unburned fuel causing it to overheat when

the engine does start see (b) above.

f)DO NOT switch off the ignition at high

engine speeds. If the ignition is switched

off at anything above idle speed,

unburned fuel will enter the (very hot)

catalytic converter, with the possible risk

of its igniting on the element and

damaging the converter.

g)DO NOT use fuel or engine oil additives.

These may contain substances harmful to

the catalytic converter.

h)DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke. The unburned

carbon deposits will clog the converter

passages and reduce its efficiency; in

severe cases the element will overheat.

i)Remember that the catalytic converter

operates at very high temperatures hence

the heat shields on the vehicle’s under-

body and the casing will become hot

enough to ignite combustible materials

that brush against it. DO NOT, therefore,

park the vehicle in dry undergrowth, over

long grass or over piles of dead leaves.

j)Remember that the catalytic converter is

FRAGlLE. Do not strike it with tools during

servicing work. Take great care when

working on the exhaust system. Ensure

that the converter is well clear of any

jacks or other lifting gear used to raise thevehicle. Do not drive the vehicle over

rough ground, road humps, etc., in such a

way as to ground the exhaust system.

k)In some cases, particularly when the

vehicle is new and/or is used for

stop/start driving, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles and

seems to be due to the small amount of

sulphur found in some petrol’s reacting

with hydrogen in the exhaust to produce

hydrogen sulphide (CS) gas. While this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the

vehicle has covered a few thousand miles

the problem should disappear. In the

meanwhile a change of driving style or of

the brand of petrol may effect a solution.

l)The catalytic converter, used on a

well-maintained and well-driven vehicle,

should last for between 50 000 and 100

000 miles. From this point on, careful

checks should be made at all specified

service intervals of the CO level to ensure

that the converter is still operating

efficiently. If the converter is no longer

effective it must be renewed.

11Carbon canister - removal

and refitting

3

Removal

1Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members

(see “Jacking and Vehicle Support”).

2Remove the front right hand wheel and

wheel arch liner.

3Note the hose and pipe connections to the

canister, or label them, to ensure that they are

reconnected to their original unions, then

disconnect them (see illustration). Unscrew

the two nuts securing the canister mounting

bracket to the vehicle body.

Refitting

4Refitting is a reversal of removal, however

ensure correct fitment of hose and pipes.

12Oxygen sensor (catalytic

converter models) - removal

and refitting

3

Note: This sensor is also known as a Lambda

sensor.

Removal

1Disconnect the battery negative lead.

2Disconnect the oxygen sensor wiring plug,

which is located behind the coolant expansion

tank.

3Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members.

4On DOHC models, remove the engine

undershield, as described in Chapter 11.

5On models fitted with Multec injection

system, the sensor is screwed into the

exhaust manifold. Trace the wiring from the

sensor itself to the connector (either clipped

to the radiator cooling fan shroud or behind

the coolant expansion tank). Release it from

any clips or ties; disconnect the wiring before

unscrewing the sensor.

6On other models, unscrew the oxygen

sensor from the front section of the exhaust

system (see illustration). It is advisable to

wear gloves, as the exhaust system will be

extremely hot.

7Withdraw the oxygen sensor and its wiring,

taking care not to burn the wiring on the

exhaust system. If the sensor is to be re-used,

take care that the sealing ring is not lost, and

that the sensor is not dropped.

Refitting

8If a new sensor is being fitted, it will be

supplied with the threads coated in a special

grease to prevent it seizing in the exhaust

system.

9If the original sensor is being refitted,

ensure that the screw thread is clean. Coat

the thread with a lithium based copper grease

(i.e. Vauxhall Part No. 90295397).

10Refitting is a reversal of removal. Check

the exhaust system for leakage when the

engine is re-started.

4C•4Fuel and exhaust systems - exhaust and emissions

12.6 Oxygen sensor location in front

section of exhaust system - DOHC models

11.3 Charcoal canister

A Vent to atmosphere

B Vapour feed hose from filler pipe

C Vapour exhaust hose to inlet tract

D Control valve vacuum pipe from

throttle body

Page 156 of 525

4B

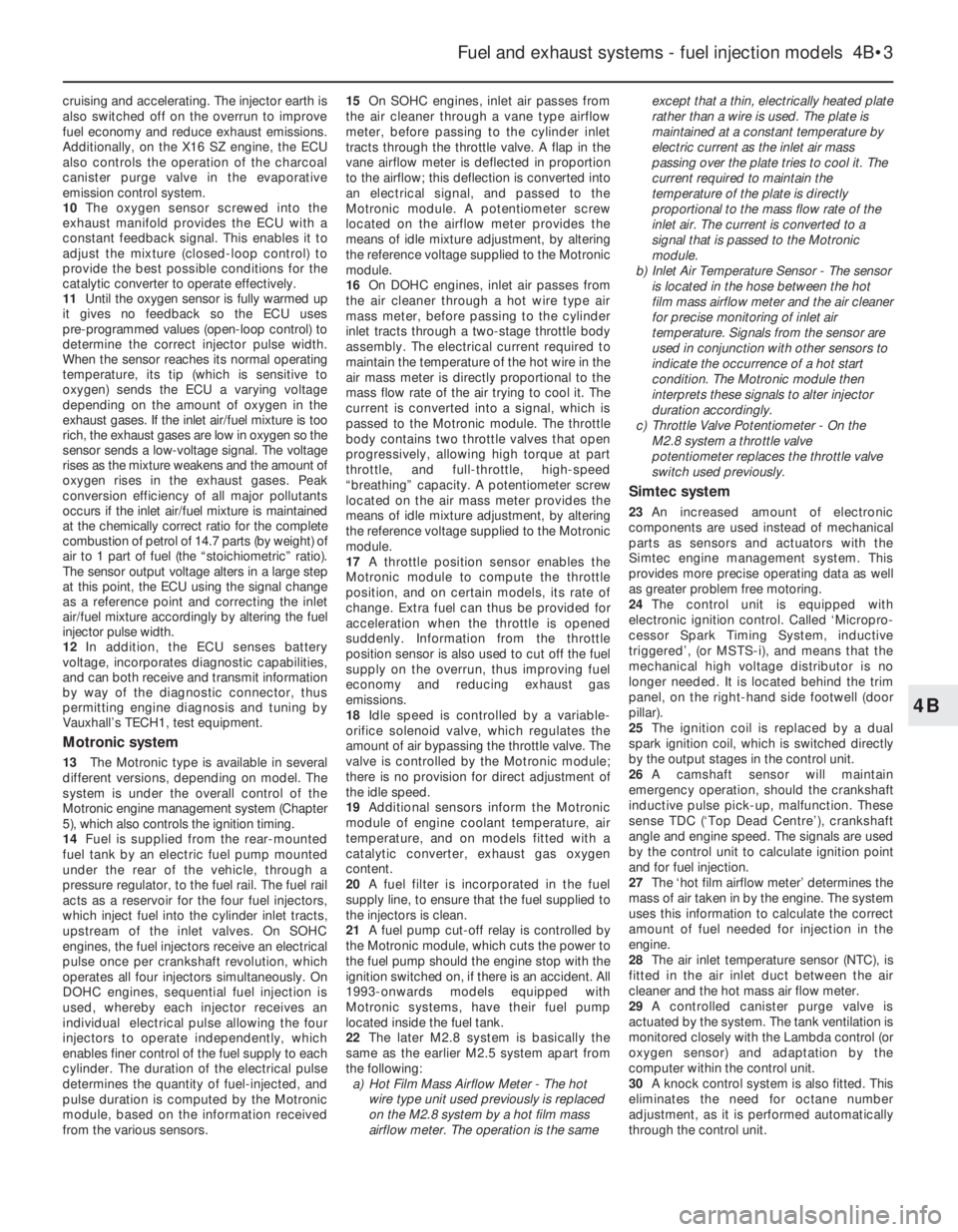

cruising and accelerating. The injector earth is

also switched off on the overrun to improve

fuel economy and reduce exhaust emissions.

Additionally, on the X16 SZ engine, the ECU

also controls the operation of the charcoal

canister purge valve in the evaporative

emission control system.

10The oxygen sensor screwed into the

exhaust manifold provides the ECU with a

constant feedback signal. This enables it to

adjust the mixture (closed-loop control) to

provide the best possible conditions for the

catalytic converter to operate effectively.

11Until the oxygen sensor is fully warmed up

it gives no feedback so the ECU uses

pre-programmed values (open-loop control) to

determine the correct injector pulse width.

When the sensor reaches its normal operating

temperature, its tip (which is sensitive to

oxygen) sends the ECU a varying voltage

depending on the amount of oxygen in the

exhaust gases. If the inlet air/fuel mixture is too

rich, the exhaust gases are low in oxygen so the

sensor sends a low-voltage signal. The voltage

rises as the mixture weakens and the amount of

oxygen rises in the exhaust gases. Peak

conversion efficiency of all major pollutants

occurs if the inlet air/fuel mixture is maintained

at the chemically correct ratio for the complete

combustion of petrol of 14.7 parts (by weight) of

air to 1 part of fuel (the “stoichiometric” ratio).

The sensor output voltage alters in a large step

at this point, the ECU using the signal change

as a reference point and correcting the inlet

air/fuel mixture accordingly by altering the fuel

injector pulse width.

12In addition, the ECU senses battery

voltage, incorporates diagnostic capabilities,

and can both receive and transmit information

by way of the diagnostic connector, thus

permitting engine diagnosis and tuning by

Vauxhall’s TECH1, test equipment.

Motronic system

13The Motronic type is available in several

different versions, depending on model. The

system is under the overall control of the

Motronic engine management system (Chapter

5), which also controls the ignition timing.

14Fuel is supplied from the rear-mounted

fuel tank by an electric fuel pump mounted

under the rear of the vehicle, through a

pressure regulator, to the fuel rail. The fuel rail

acts as a reservoir for the four fuel injectors,

which inject fuel into the cylinder inlet tracts,

upstream of the inlet valves. On SOHC

engines, the fuel injectors receive an electrical

pulse once per crankshaft revolution, which

operates all four injectors simultaneously. On

DOHC engines, sequential fuel injection is

used, whereby each injector receives an

individual electrical pulse allowing the four

injectors to operate independently, which

enables finer control of the fuel supply to each

cylinder. The duration of the electrical pulse

determines the quantity of fuel-injected, and

pulse duration is computed by the Motronic

module, based on the information received

from the various sensors.15On SOHC engines, inlet air passes from

the air cleaner through a vane type airflow

meter, before passing to the cylinder inlet

tracts through the throttle valve. A flap in the

vane airflow meter is deflected in proportion

to the airflow; this deflection is converted into

an electrical signal, and passed to the

Motronic module. A potentiometer screw

located on the airflow meter provides the

means of idle mixture adjustment, by altering

the reference voltage supplied to the Motronic

module.

16On DOHC engines, inlet air passes from

the air cleaner through a hot wire type air

mass meter, before passing to the cylinder

inlet tracts through a two-stage throttle body

assembly. The electrical current required to

maintain the temperature of the hot wire in the

air mass meter is directly proportional to the

mass flow rate of the air trying to cool it. The

current is converted into a signal, which is

passed to the Motronic module. The throttle

body contains two throttle valves that open

progressively, allowing high torque at part

throttle, and full-throttle, high-speed

“breathing” capacity. A potentiometer screw

located on the air mass meter provides the

means of idle mixture adjustment, by altering

the reference voltage supplied to the Motronic

module.

17A throttle position sensor enables the

Motronic module to compute the throttle

position, and on certain models, its rate of

change. Extra fuel can thus be provided for

acceleration when the throttle is opened

suddenly. Information from the throttle

position sensor is also used to cut off the fuel

supply on the overrun, thus improving fuel

economy and reducing exhaust gas

emissions.

18Idle speed is controlled by a variable-

orifice solenoid valve, which regulates the

amount of air bypassing the throttle valve. The

valve is controlled by the Motronic module;

there is no provision for direct adjustment of

the idle speed.

19Additional sensors inform the Motronic

module of engine coolant temperature, air

temperature, and on models fitted with a

catalytic converter, exhaust gas oxygen

content.

20A fuel filter is incorporated in the fuel

supply line, to ensure that the fuel supplied to

the injectors is clean.

21A fuel pump cut-off relay is controlled by

the Motronic module, which cuts the power to

the fuel pump should the engine stop with the

ignition switched on, if there is an accident. All

1993-onwards models equipped with

Motronic systems, have their fuel pump

located inside the fuel tank.

22The later M2.8 system is basically the

same as the earlier M2.5 system apart from

the following:

a)Hot Film Mass Airflow Meter - The hot

wire type unit used previously is replaced

on the M2.8 system by a hot film mass

airflow meter. The operation is the sameexcept that a thin, electrically heated plate

rather than a wire is used. The plate is

maintained at a constant temperature by

electric current as the inlet air mass

passing over the plate tries to cool it. The

current required to maintain the

temperature of the plate is directly

proportional to the mass flow rate of the

inlet air. The current is converted to a

signal that is passed to the Motronic

module.

b)Inlet Air Temperature Sensor -The sensor

is located in the hose between the hot

film mass airflow meter and the air cleaner

for precise monitoring of inlet air

temperature. Signals from the sensor are

used in conjunction with other sensors to

indicate the occurrence of a hot start

condition. The Motronic module then

interprets these signals to alter injector

duration accordingly.

c)Throttle Valve Potentiometer -On the

M2.8 system a throttle valve

potentiometer replaces the throttle valve

switch used previously.

Simtec system

23An increased amount of electronic

components are used instead of mechanical

parts as sensors and actuators with the

Simtec engine management system. This

provides more precise operating data as well

as greater problem free motoring.

24The control unit is equipped with

electronic ignition control. Called ‘Micropro-

cessor Spark Timing System, inductive

triggered’, (or MSTS-i), and means that the

mechanical high voltage distributor is no

longer needed. It is located behind the trim

panel, on the right-hand side footwell (door

pillar).

25The ignition coil is replaced by a dual

spark ignition coil, which is switched directly

by the output stages in the control unit.

26A camshaft sensor will maintain

emergency operation, should the crankshaft

inductive pulse pick-up, malfunction. These

sense TDC (‘Top Dead Centre’), crankshaft

angle and engine speed. The signals are used

by the control unit to calculate ignition point

and for fuel injection.

27The ‘hot film airflow meter’ determines the

mass of air taken in by the engine. The system

uses this information to calculate the correct

amount of fuel needed for injection in the

engine.

28The air inlet temperature sensor (NTC), is

fitted in the air inlet duct between the air

cleaner and the hot mass air flow meter.

29A controlled canister purge valve is

actuated by the system. The tank ventilation is

monitored closely with the Lambda control (or

oxygen sensor) and adaptation by the

computer within the control unit.

30A knock control system is also fitted. This

eliminates the need for octane number

adjustment, as it is performed automatically

through the control unit.

Fuel and exhaust systems - fuel injection models 4B•3

Page 175 of 525

1•4Maintenance schedule

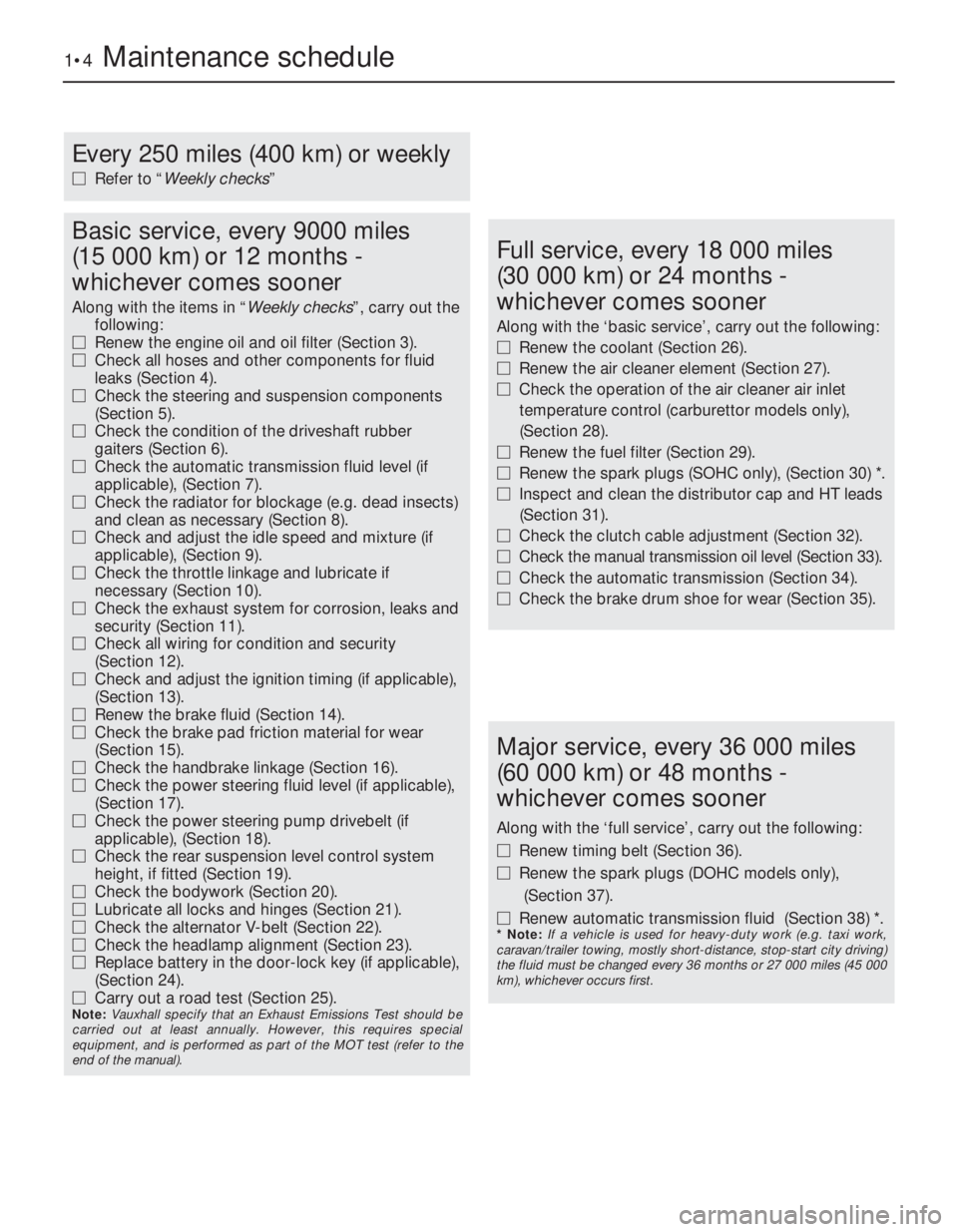

Every 250 miles (400 km) or weekly

MRefer to “Weekly checks”

Basic service, every 9000 miles

(15 000 km) or 12 months -

whichever comes sooner

Along with the items in “Weekly checks”, carry out the

following:

MRenew the engine oil and oil filter (Section 3).

MCheck all hoses and other components for fluid

leaks (Section 4).

MCheck the steering and suspension components

(Section 5).

MCheck the condition of the driveshaft rubber

gaiters (Section 6).

MCheck the automatic transmission fluid level (if

applicable), (Section 7).

MCheck the radiator for blockage (e.g. dead insects)

and clean as necessary (Section 8).

MCheck and adjust the idle speed and mixture (if

applicable), (Section 9).

MCheck the throttle linkage and lubricate if

necessary (Section 10).

MCheck the exhaust system for corrosion, leaks and

security (Section 11).

MCheck all wiring for condition and security

(Section 12).

MCheck and adjust the ignition timing (if applicable),

(Section 13).

MRenew the brake fluid (Section 14).

MCheck the brake pad friction material for wear

(Section 15).

MCheck the handbrake linkage (Section 16).

MCheck the power steering fluid level (if applicable),

(Section 17).

MCheck the power steering pump drivebelt (if

applicable), (Section 18).

MCheck the rear suspension level control system

height, if fitted (Section 19).

MCheck the bodywork (Section 20).

MLubricate all locks and hinges (Section 21).

MCheck the alternator V-belt (Section 22).

MCheck the headlamp alignment (Section 23).

MReplace battery in the door-lock key (if applicable),

(Section 24).

MCarry out a road test (Section 25).

Note: Vauxhall specify that an Exhaust Emissions Test should be

carried out at least annually. However, this requires special

equipment, and is performed as part of the MOT test (refer to the

end of the manual).

Full service, every 18 000 miles

(30 000 km) or 24 months -

whichever comes sooner

Along with the ‘basic service’, carry out the following:

MRenew the coolant (Section 26).

MRenew the air cleaner element (Section 27).

MCheck the operation of the air cleaner air inlet

temperature control (carburettor models only),

(Section 28).

MRenew the fuel filter (Section 29).

MRenew the spark plugs (SOHC only), (Section 30) *.

MInspect and clean the distributor cap and HT leads

(Section 31).

MCheck the clutch cable adjustment (Section 32).

MCheck the manual transmission oil level (Section 33).

MCheck the automatic transmission (Section 34).

MCheck the brake drum shoe for wear (Section 35).

Major service, every 36 000 miles

(60 000 km) or 48 months -

whichever comes sooner

Along with the ‘full service’, carry out the following:

MRenew timing belt (Section 36).

MRenew the spark plugs (DOHC models only),

(Section 37).

MRenew automatic transmission fluid (Section 38) *.

* Note: If a vehicle is used for heavy-duty work (e.g. taxi work,

caravan/trailer towing, mostly short-distance, stop-start city driving)

the fluid must be changed every 36 months or 27 000 miles (45 000

km), whichever occurs first.