service OPEL CALIBRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: CALIBRA, Model: OPEL CALIBRA 1988Pages: 525, PDF Size: 58.26 MB

Page 16 of 525

1General information and

precautions

The electrical system is of 12-volt negative

earth type. Power for the lights and all

electrical accessories is supplied by a

lead/acid type battery, which is charged by

the alternator.

This Chapter covers repair and service

procedures for the various electrical

components not associated with engine.

Information on the battery, alternator and

starter motor can be found in Chapter 5.

It should be noted that, before working on

any component in the electrical system, the

battery negative terminal should first be

disconnected, to prevent the possibility of

electrical short-circuits and/or fires.

Whenever the occasion arises, carefully

check the routing of the wiring harness,

ensuring that it is correctly secured by the

clips or ties provided so that it cannot chafe

against other components. Carefully check

points such as the clutch cable bracket,

clutch housing and harness support bracket,

the inlet manifold, the horn mounting bracket,

the starter motor terminals, and the rear

bumper and number plate lamp.

If evidence is found of the harness having

chafed against other components, repair the

damage and ensure that the harness is

secured or protected so that the problem

cannot occur again.

2Electrical fault-finding -

general information

Note:Refer to the precautions given in “Safety

first!” (at the beginning of this manual) and to

Section 1 of this Chapter before starting work.

The following tests relate to testing of the main

electrical circuits, and should not be used to

test delicate electronic circuits (such as anti-

lock braking systems), particularly where an

electronic control module is used.

A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links or circuit breakers

related to that component, and the wiring and

connectors that link the component to boththe battery and the chassis. To help to

pinpoint a problem in an electrical circuit,

wiring diagrams are included at the end of this

Chapter.

Before attempting to diagnose an electrical

fault, first study the appropriate wiring

diagram, to obtain a complete understanding

of the components included in the particular

circuit concerned. The possible sources of a

fault can be narrowed down by noting

whether other components related to the

circuit are operating properly. If several

components or circuits fail at one time, the

problem is likely to be related to a shared fuse

or earth connection.

Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a faulty earth connection, a

blown fuse, a melted fusible link, or a faulty

relay (refer to Section 3 for details of testing

relays). Visually inspect the condition of all

fuses, wires and connections in a problem

circuit before testing the components. Use

the wiring diagrams to determine which

terminal connections will need to be checked,

to pinpoint the trouble-spot.

The basic tools required for electrical fault-

finding include the following:

a)a circuit tester or voltmeter (a 12-volt bulb

with a set of test leads can also be used

for certain tests).

b)a self-powered test light (sometimes

known as a continuity tester).

c)an ohmmeter (to measure resistance).

d)a battery.

e)a set of test leads.

f)a jumper wire, preferably with a circuit

breaker or fuse incorporated, which can

be used to bypass suspect wires or

electrical components.

Before attempting to locate a problem with

test instruments, use the wiring diagram to

determine where to make the connections.

To find the source of an intermittent wiring

fault (usually due to a poor or dirty

connection, or damaged wiring insulation), a

“wiggle” test can be performed on the wiring.

This involves wiggling the wiring by hand, to

see if the fault occurs as the wiring is moved.

It should be possible to narrow down the

source of the fault to a particular section of

wiring. This method of testing can be used in

conjunction with any of the tests described in

the following sub-Sections.

Apart from problems due to poor

connections, two basic types of fault can

occur in an electrical circuit - open-circuit, or

short-circuit.

Open-circuit faults are caused by a break

somewhere in the circuit, which prevents

current from flowing. An open-circuit fault will

prevent a component from working, but will

not cause the relevant circuit fuse to blow.

Short-circuit faults are caused by a “short”

somewhere in the circuit, which allows the

current flowing in the circuit to “escape” along

an alternative route, usually to earth. Short-

circuit faults are normally caused by abreakdown in wiring insulation, which allows a

feed wire to touch either another wire, or an

earthed component such as the bodyshell. A

short-circuit fault will normally cause the

relevant circuit fuse to blow.

Finding an open-circuit

To check for an open-circuit, connect one

lead of a circuit tester or voltmeter to either

the negative battery terminal or a known good

earth.

Connect the other lead to a connector in

the circuit being tested, preferably nearest to

the battery or fuse.

Switch on the circuit, remembering that

some circuits are live only when the ignition

switch is moved to a particular position.

If voltage is present (indicated either by the

tester bulb lighting or a voltmeter reading, as

applicable), this means that the section of the

circuit between the relevant connector and

the battery is problem-free.

Continue to check the remainder of the

circuit in the same fashion.

When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

To check for a short-circuit, first disconnect

the load(s) from the circuit (loads are the

components that draw current from a circuit,

such as bulbs, motors, heating elements, etc.).

Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.

Switch on the circuit, remembering that

some circuits are live only when the ignition

switch is moved to a particular position.

If voltage is present (indicated either by the

tester bulb lighting or a voltmeter reading, as

applicable), this means that there is a short-

circuit.

If no voltage is present, but the fuse still

blows with the load(s) connected, this indicates

an internal fault in the load(s).

Finding an earth fault

The battery negative terminal is connected

to “earth” (the metal of the

engine/transmission and the car body), and

most systems are wired so that they only

receive a positive feed. The current returning

through the metal of the car body. This means

that the component mounting and the body

form part of that circuit. Loose or corroded

mountings can therefore cause a range of

electrical faults, ranging from total failure of a

circuit, to a puzzling partial fault. In particular,

lights may shine dimly (especially when

another circuit sharing the same earth point is

in operation). Motors (e.g. wiper motors or the

radiator cooling fan motor) may run slowly,

and the operation of one circuit may have an

affect on another. Note that on many vehicles,

earth straps are used between certain

components, such as the engine/transmission

and the body, usually where there is no metal-

12•2Body electrical systems

Warning: Before carrying out

any work on the electrical

system, read through the

precautions given in “Safety

first!” at the beginning of this manual, and

in Chapter 5.

Caution:If the radio/cassette player fitted

to the vehicle is one with an anti-theft

security code, as the standard unit is, refer

to “Radio/cassette player anti-theft system

- precaution”in the Reference Section of

this manual before disconnecting the

battery.

Page 93 of 525

8Alternator drivebelt -

removal, refitting and adjusting

2

V-belt type (not-ribbed)

Removal

1Disconnect the air inlet trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

2Correct tensioning of the drivebelt will

ensure that it has a long life. Beware,

however, of overtightening, as this can cause

excessive wear in the alternator.

3The belt should be inspected regularly, and

if it is found to be worn, frayed or cracked, it

should be renewed as a precaution against

breakage in service. It is advisable to carry a

spare drivebelt of the correct type in the

vehicle always.

4On models with power steering, the

alternator drivebelt also drives the power

steering pump.

5To remove the belt, on 1.8 and 2.0 litre

models first remove the power steering pump

drivebelt, as described in Chapter 10.

6Loosen the two alternator mounting nuts

and bolts sufficiently to allow the alternator to

be pivoted in towards the engine.

7Slide the belt from the pulleys.

Refitting

8Ensure that the correct type of belt is used,

if it is being renewed. Fit the belt around the

pulleys. Take up the slack in the belt byswinging the alternator away from the engine

and lightly tightening the mounting nuts and

bolts.

Adjusting

9Although special tools are available for

measuring the belt tension, a good

approximation can be achieved if the belt is

tensioned so that there is approximately 13.0

mm (0.5 in) of free movement under firm

thumb pressure at the mid-point of the

longest run between pulleys.

10With the mounting bolts just holding the

unit, lever the alternator away from the engine

using a wooden lever at the mounting bracket

end until the correct tension is achieved. Then

tighten the mounting nuts and bolts. On no

account lever at the free end of the alternator,

as serious internal damage could be caused.11Where applicable, refit and tension the

power steering pump drivebelt, as described

in Chapter 10.

12Refit the air inlet trunking.

13When a new belt has been fitted, it will

probably stretch slightly when it is first run,

and the tension should be rechecked and if

necessary adjusted after approximately 250

miles (400 km).

Ribbed V-belt type

General

14Later models equipped with power

steering are fitted with a ribbed V-belt type

drivebelt in conjunction with an automatic

tensioning roller. Once the belt is installed, no

further adjustment is necessary as the correct

tension is maintained by the automatic

tensioning roller. Removal and refitting

procedures are as follows.

Removal

15For improved access, remove the air

cleaner assembly and air inlet trunking.

16If the original drivebelt is to be refitted, mark

the rotational direction on the belt with chalk.

17Using a spanner or socket on the

automatic tensioning roller hexagon, turn the

tensioning roller clockwise (as viewed from the

right-hand side of the car) and hold it in this

position. With the drivebelt tension released,

slip the drivebelt off the pulleys, then allow the

tensioner to return to its original position.

18Support the engine under the sump with a

jack and interposed block of wood.

19From under the car, unbolt the right-hand

engine mounting block from the body.

20Lower the engine support jack just

sufficiently to allow the drivebelt to be

withdrawn from between the mounting block

and the body.

Refitting

21Slip the new drivebelt between the

mounting block and body then raise the

engine, by means of the jack, to its original

position.

22Clean the threads of the mounting block

retaining bolts, apply locking fluid, and refit

the bolts. Tighten the bolts to the specified

torque (see Chapter 2A).

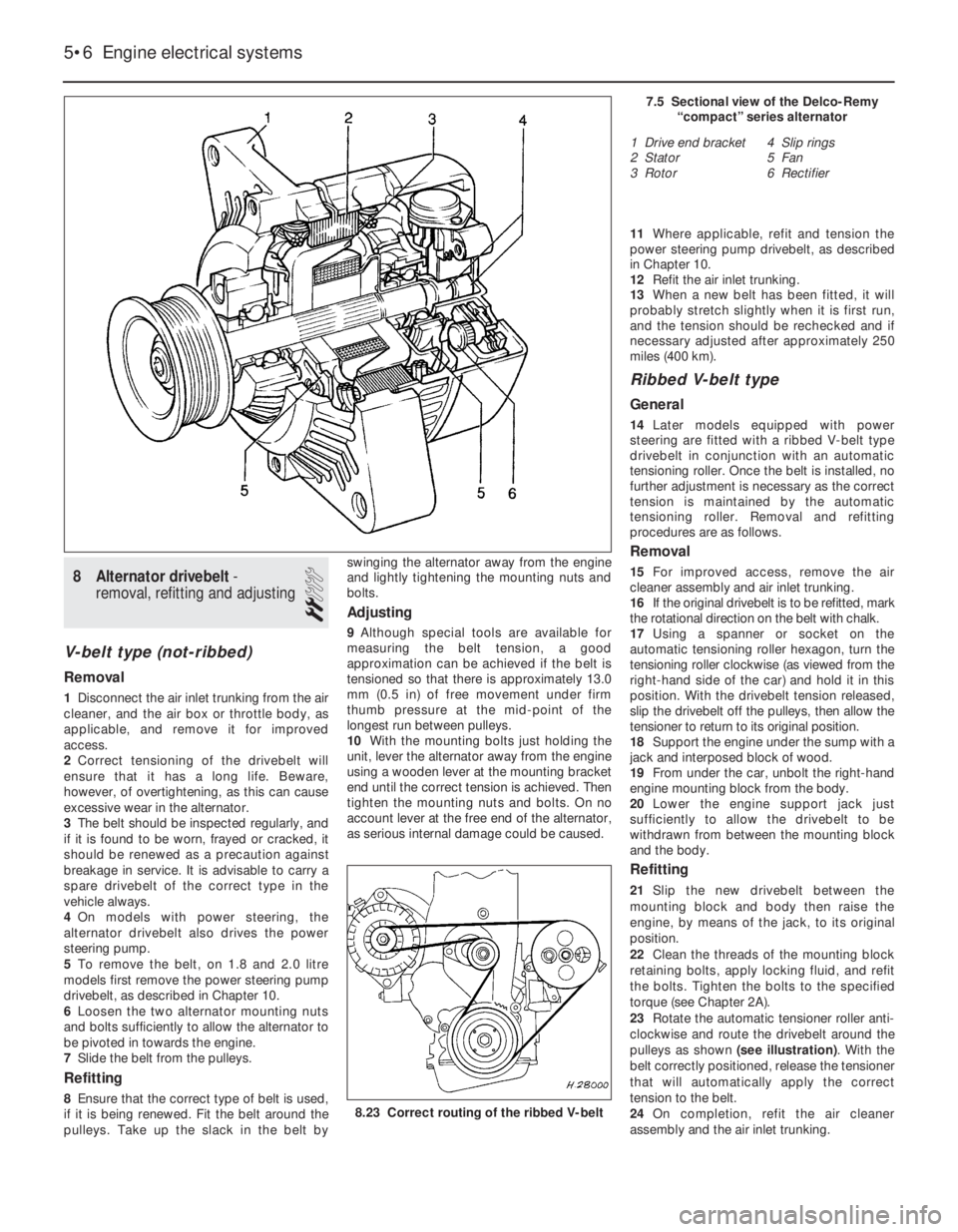

23Rotate the automatic tensioner roller anti-

clockwise and route the drivebelt around the

pulleys as shown (see illustration). With the

belt correctly positioned, release the tensioner

that will automatically apply the correct

tension to the belt.

24On completion, refit the air cleaner

assembly and the air inlet trunking.

5•6Engine electrical systems

7.5 Sectional view of the Delco-Remy

“compact” series alternator

1 Drive end bracket

2 Stator

3 Rotor4 Slip rings

5 Fan

6 Rectifier

8.23 Correct routing of the ribbed V-belt

Page 94 of 525

9Alternator-removal and

refitting

3

Note: Refer to Section 3 before proceeding

Except ‘compact’ series

alternators

Removal

1Disconnect the battery leads.

2Disconnect the air trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

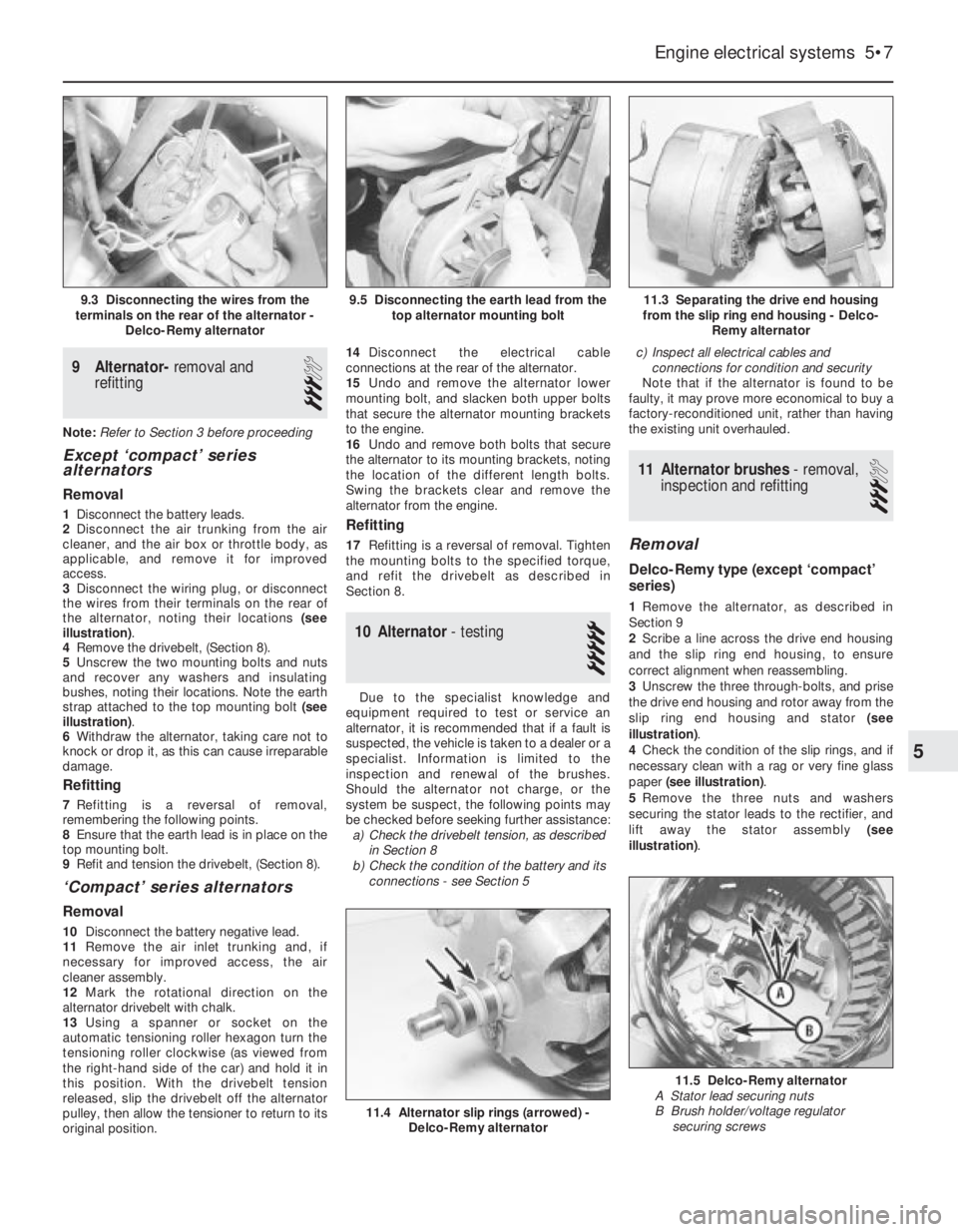

3Disconnect the wiring plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (see

illustration).

4Remove the drivebelt, (Section 8).

5Unscrew the two mounting bolts and nuts

and recover any washers and insulating

bushes, noting their locations. Note the earth

strap attached to the top mounting bolt (see

illustration).

6Withdraw the alternator, taking care not to

knock or drop it, as this can cause irreparable

damage.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Ensure that the earth lead is in place on the

top mounting bolt.

9Refit and tension the drivebelt, (Section 8).

‘Compact’ series alternators

Removal

10Disconnect the battery negative lead.

11Remove the air inlet trunking and, if

necessary for improved access, the air

cleaner assembly.

12Mark the rotational direction on the

alternator drivebelt with chalk.

13Using a spanner or socket on the

automatic tensioning roller hexagon turn the

tensioning roller clockwise (as viewed from

the right-hand side of the car) and hold it in

this position. With the drivebelt tension

released, slip the drivebelt off the alternator

pulley, then allow the tensioner to return to its

original position.14Disconnect the electrical cable

connections at the rear of the alternator.

15Undo and remove the alternator lower

mounting bolt, and slacken both upper bolts

that secure the alternator mounting brackets

to the engine.

16Undo and remove both bolts that secure

the alternator to its mounting brackets, noting

the location of the different length bolts.

Swing the brackets clear and remove the

alternator from the engine.

Refitting

17Refitting is a reversal of removal. Tighten

the mounting bolts to the specified torque,

and refit the drivebelt as described in

Section 8.

10Alternator -testing

5

Due to the specialist knowledge and

equipment required to test or service an

alternator, it is recommended that if a fault is

suspected, the vehicle is taken to a dealer or a

specialist. Information is limited to the

inspection and renewal of the brushes.

Should the alternator not charge, or the

system be suspect, the following points may

be checked before seeking further assistance:

a)Check the drivebelt tension, as described

in Section 8

b)Check the condition of the battery and its

connections -see Section 5c)Inspect all electrical cables and

connections for condition and security

Note that if the alternator is found to be

faulty, it may prove more economical to buy a

factory-reconditioned unit, rather than having

the existing unit overhauled.

11Alternator brushes -removal,

inspection and refitting

3

Removal

Delco-Remy type (except ‘compact’

series)

1Remove the alternator, as described in

Section 9

2Scribe a line across the drive end housing

and the slip ring end housing, to ensure

correct alignment when reassembling.

3Unscrew the three through-bolts, and prise

the drive end housing and rotor away from the

slip ring end housing and stator (see

illustration).

4Check the condition of the slip rings, and if

necessary clean with a rag or very fine glass

paper (see illustration).

5Remove the three nuts and washers

securing the stator leads to the rectifier, and

lift away the stator assembly (see

illustration).

Engine electrical systems 5•7

11.3 Separating the drive end housing

from the slip ring end housing - Delco-

Remy alternator

11.4 Alternator slip rings (arrowed) -

Delco-Remy alternator

11.5 Delco-Remy alternator

A Stator lead securing nuts

B Brush holder/voltage regulator

securing screws

9.5 Disconnecting the earth lead from the

top alternator mounting bolt9.3 Disconnecting the wires from the

terminals on the rear of the alternator -

Delco-Remy alternator

5

Page 107 of 525

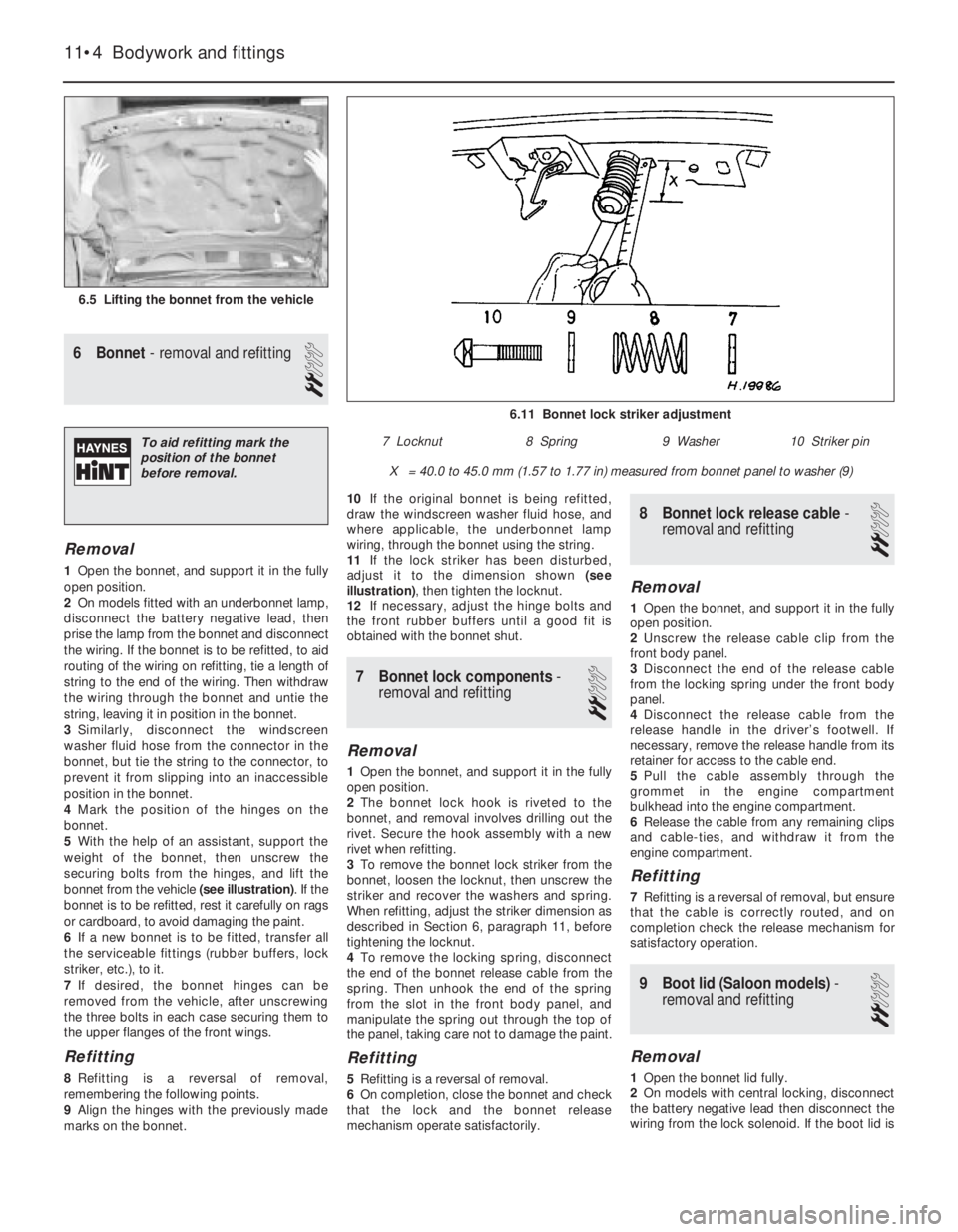

6Bonnet - removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2On models fitted with an underbonnet lamp,

disconnect the battery negative lead, then

prise the lamp from the bonnet and disconnect

the wiring. If the bonnet is to be refitted, to aid

routing of the wiring on refitting, tie a length of

string to the end of the wiring. Then withdraw

the wiring through the bonnet and untie the

string, leaving it in position in the bonnet.

3Similarly, disconnect the windscreen

washer fluid hose from the connector in the

bonnet, but tie the string to the connector, to

prevent it from slipping into an inaccessible

position in the bonnet.

4Mark the position of the hinges on the

bonnet.

5With the help of an assistant, support the

weight of the bonnet, then unscrew the

securing bolts from the hinges, and lift the

bonnet from the vehicle (see illustration). If the

bonnet is to be refitted, rest it carefully on rags

or cardboard, to avoid damaging the paint.

6If a new bonnet is to be fitted, transfer all

the serviceable fittings (rubber buffers, lock

striker, etc.), to it.

7If desired, the bonnet hinges can be

removed from the vehicle, after unscrewing

the three bolts in each case securing them to

the upper flanges of the front wings.

Refitting

8Refitting is a reversal of removal,

remembering the following points.

9Align the hinges with the previously made

marks on the bonnet.10If the original bonnet is being refitted,

draw the windscreen washer fluid hose, and

where applicable, the underbonnet lamp

wiring, through the bonnet using the string.

11If the lock striker has been disturbed,

adjust it to the dimension shown (see

illustration), then tighten the locknut.

12If necessary, adjust the hinge bolts and

the front rubber buffers until a good fit is

obtained with the bonnet shut.

7Bonnet lock components -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2The bonnet lock hook is riveted to the

bonnet, and removal involves drilling out the

rivet. Secure the hook assembly with a new

rivet when refitting.

3To remove the bonnet lock striker from the

bonnet, loosen the locknut, then unscrew the

striker and recover the washers and spring.

When refitting, adjust the striker dimension as

described in Section 6, paragraph 11, before

tightening the locknut.

4To remove the locking spring, disconnect

the end of the bonnet release cable from the

spring. Then unhook the end of the spring

from the slot in the front body panel, and

manipulate the spring out through the top of

the panel, taking care not to damage the paint.

Refitting

5Refitting is a reversal of removal.

6On completion, close the bonnet and check

that the lock and the bonnet release

mechanism operate satisfactorily.

8Bonnet lock release cable -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2Unscrew the release cable clip from the

front body panel.

3Disconnect the end of the release cable

from the locking spring under the front body

panel.

4Disconnect the release cable from the

release handle in the driver’s footwell. If

necessary, remove the release handle from its

retainer for access to the cable end.

5Pull the cable assembly through the

grommet in the engine compartment

bulkhead into the engine compartment.

6Release the cable from any remaining clips

and cable-ties, and withdraw it from the

engine compartment.

Refitting

7Refitting is a reversal of removal, but ensure

that the cable is correctly routed, and on

completion check the release mechanism for

satisfactory operation.

9Boot lid (Saloon models) -

removal and refitting

2

Removal

1Open the bonnet lid fully.

2On models with central locking, disconnect

the battery negative lead then disconnect the

wiring from the lock solenoid. If the boot lid is

11•4Bodywork and fittings

6.5 Lifting the bonnet from the vehicle

6.11 Bonnet lock striker adjustment

X = 40.0 to 45.0 mm (1.57 to 1.77 in) measured from bonnet panel to washer (9)

7 Locknut8 Spring9 Washer10 Striker pinTo aid refitting mark the

position of the bonnet

before removal.

Page 108 of 525

to be refitted, tie a length of string to the end

of the wiring. Then feed the wiring through the

boot lid and untie the string, leaving it in

position in the boot lid to assist refitting.

3Mark the position of the hinges on the boot

lid.

4With the help of an assistant, support the

weight of the boot lid, then unscrew the

securing bolts from the hinges, and lift the

boot lid from the vehicle. If the boot lid is to be

refitted, rest it carefully on rags or cardboard,

to avoid damaging the paint.

5If a new boot lid is to be fitted, transfer all

the serviceable fittings (rubber buffers, lock

mechanism, etc.), to it.

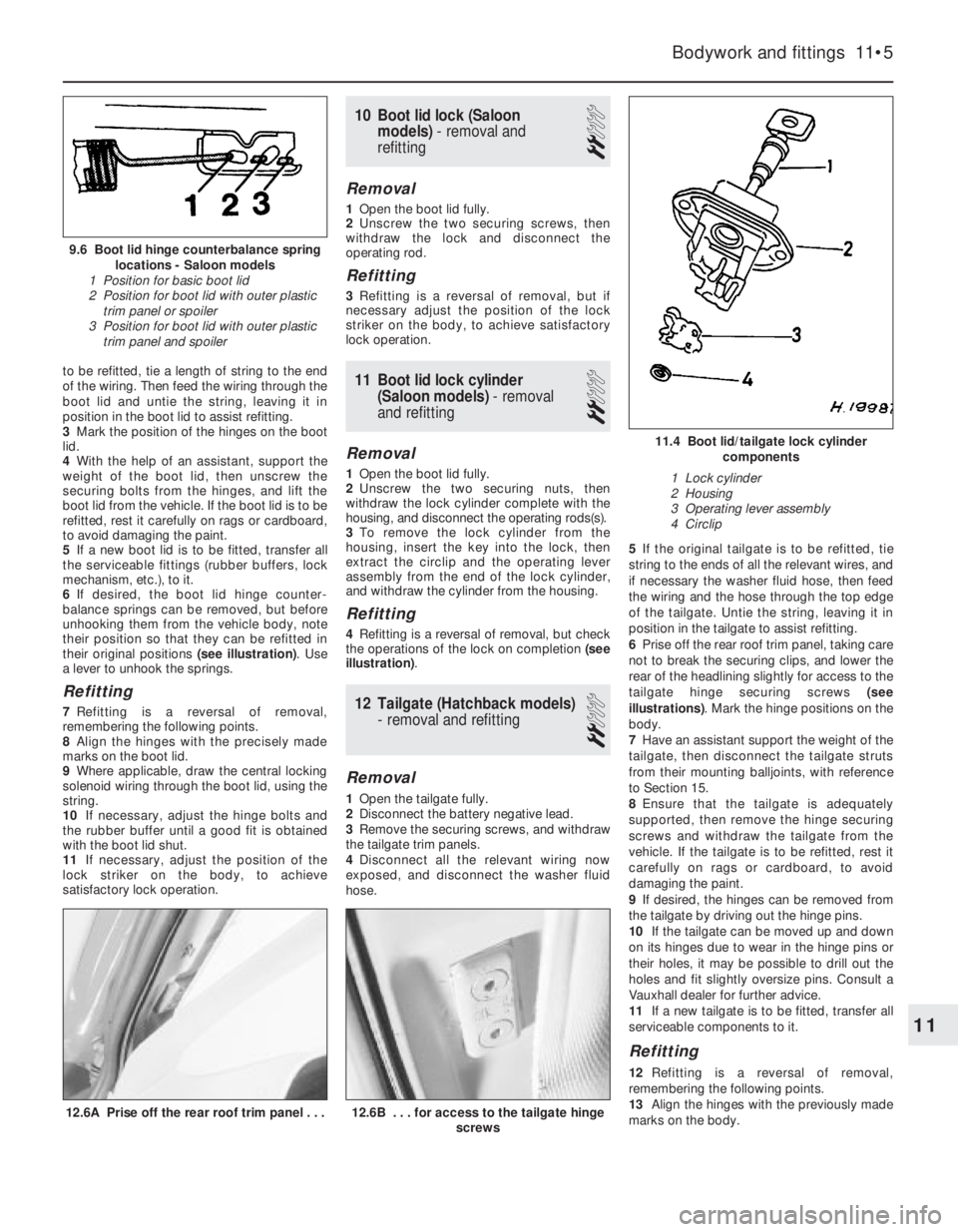

6If desired, the boot lid hinge counter-

balance springs can be removed, but before

unhooking them from the vehicle body, note

their position so that they can be refitted in

their original positions (see illustration). Use

a lever to unhook the springs.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Align the hinges with the precisely made

marks on the boot lid.

9Where applicable, draw the central locking

solenoid wiring through the boot lid, using the

string.

10If necessary, adjust the hinge bolts and

the rubber buffer until a good fit is obtained

with the boot lid shut.

11If necessary, adjust the position of the

lock striker on the body, to achieve

satisfactory lock operation.

10Boot lid lock (Saloon

models) - removal and

refitting

2

Removal

1Open the boot lid fully.

2Unscrew the two securing screws, then

withdraw the lock and disconnect the

operating rod.

Refitting

3Refitting is a reversal of removal, but if

necessary adjust the position of the lock

striker on the body, to achieve satisfactory

lock operation.

11Boot lid lock cylinder

(Saloon models) - removal

and refitting

2

Removal

1Open the boot lid fully.

2Unscrew the two securing nuts, then

withdraw the lock cylinder complete with the

housing, and disconnect the operating rods(s).

3To remove the lock cylinder from the

housing, insert the key into the lock, then

extract the circlip and the operating lever

assembly from the end of the lock cylinder,

and withdraw the cylinder from the housing.

Refitting

4Refitting is a reversal of removal, but check

the operations of the lock on completion (see

illustration).

12Tailgate (Hatchback models)

-removal and refitting

2

Removal

1Open the tailgate fully.

2Disconnect the battery negative lead.

3Remove the securing screws, and withdraw

the tailgate trim panels.

4Disconnect all the relevant wiring now

exposed, and disconnect the washer fluid

hose.5If the original tailgate is to be refitted, tie

string to the ends of all the relevant wires, and

if necessary the washer fluid hose, then feed

the wiring and the hose through the top edge

of the tailgate. Untie the string, leaving it in

position in the tailgate to assist refitting.

6Prise off the rear roof trim panel, taking care

not to break the securing clips, and lower the

rear of the headlining slightly for access to the

tailgate hinge securing screws (see

illustrations). Mark the hinge positions on the

body.

7Have an assistant support the weight of the

tailgate, then disconnect the tailgate struts

from their mounting balljoints, with reference

to Section 15.

8Ensure that the tailgate is adequately

supported, then remove the hinge securing

screws and withdraw the tailgate from the

vehicle. If the tailgate is to be refitted, rest it

carefully on rags or cardboard, to avoid

damaging the paint.

9If desired, the hinges can be removed from

the tailgate by driving out the hinge pins.

10If the tailgate can be moved up and down

on its hinges due to wear in the hinge pins or

their holes, it may be possible to drill out the

holes and fit slightly oversize pins. Consult a

Vauxhall dealer for further advice.

11If a new tailgate is to be fitted, transfer all

serviceable components to it.

Refitting

12Refitting is a reversal of removal,

remembering the following points.

13Align the hinges with the previously made

marks on the body.

Bodywork and fittings 11•5

12.6B . . . for access to the tailgate hinge

screws12.6A Prise off the rear roof trim panel . . .

11.4 Boot lid/tailgate lock cylinder

components

1 Lock cylinder

2 Housing

3 Operating lever assembly

4 Circlip

9.6 Boot lid hinge counterbalance spring

locations - Saloon models

1 Position for basic boot lid

2 Position for boot lid with outer plastic

trim panel or spoiler

3 Position for boot lid with outer plastic

trim panel and spoiler

11

Page 128 of 525

4The cut-off valve can now be removed from

the bracket.

Testing

5To test the cut-off valve a vacuum hand

pump with gauge will be required. If available,

connect to the cut-off valve and ensure that

air through-flow aperture is fully open.

Refitting

6Refitting is a reversal of removal. Ensure

valve is fitted in the correct direction.

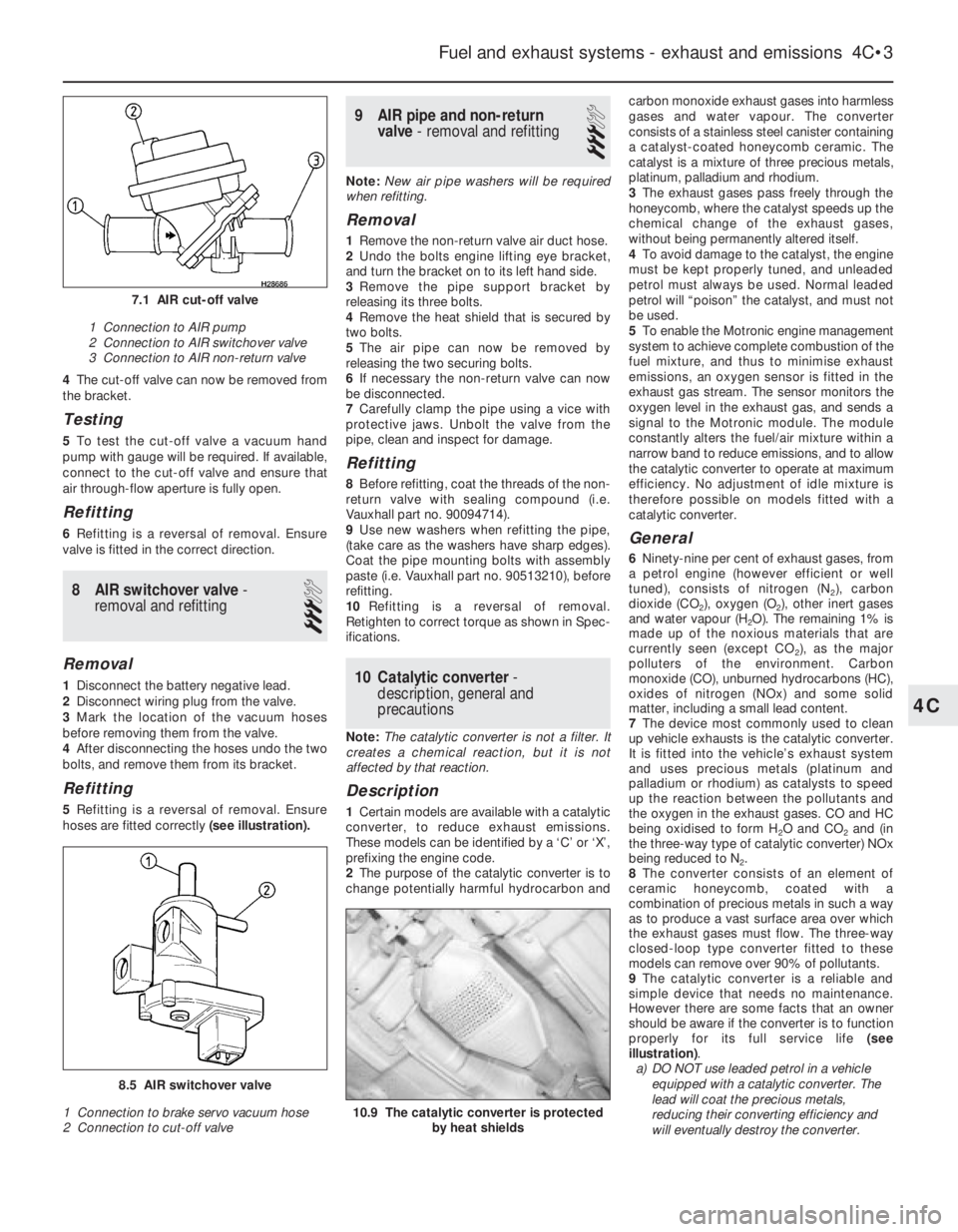

8AIR switchover valve -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect wiring plug from the valve.

3Mark the location of the vacuum hoses

before removing them from the valve.

4After disconnecting the hoses undo the two

bolts, and remove them from its bracket.

Refitting

5Refitting is a reversal of removal. Ensure

hoses are fitted correctly (see illustration).

9AIR pipe and non-return

valve - removal and refitting

3

Note:New air pipe washers will be required

when refitting.

Removal

1Remove the non-return valve air duct hose.

2Undo the bolts engine lifting eye bracket,

and turn the bracket on to its left hand side.

3Remove the pipe support bracket by

releasing its three bolts.

4Remove the heat shield that is secured by

two bolts.

5The air pipe can now be removed by

releasing the two securing bolts.

6If necessary the non-return valve can now

be disconnected.

7Carefully clamp the pipe using a vice with

protective jaws. Unbolt the valve from the

pipe, clean and inspect for damage.

Refitting

8Before refitting, coat the threads of the non-

return valve with sealing compound (i.e.

Vauxhall part no. 90094714).

9Use new washers when refitting the pipe,

(take care as the washers have sharp edges).

Coat the pipe mounting bolts with assembly

paste (i.e. Vauxhall part no. 90513210), before

refitting.

10Refitting is a reversal of removal.

Retighten to correct torque as shown in Spec-

ifications.

10Catalytic converter -

description, general and

precautions

Note: The catalytic converter is not a filter. It

creates a chemical reaction, but it is not

affected by that reaction.

Description

1Certain models are available with a catalytic

converter, to reduce exhaust emissions.

These models can be identified by a ‘C’ or ‘X’,

prefixing the engine code.

2The purpose of the catalytic converter is to

change potentially harmful hydrocarbon andcarbon monoxide exhaust gases into harmless

gases and water vapour. The converter

consists of a stainless steel canister containing

a catalyst-coated honeycomb ceramic. The

catalyst is a mixture of three precious metals,

platinum, palladium and rhodium.

3The exhaust gases pass freely through the

honeycomb, where the catalyst speeds up the

chemical change of the exhaust gases,

without being permanently altered itself.

4To avoid damage to the catalyst, the engine

must be kept properly tuned, and unleaded

petrol must always be used. Normal leaded

petrol will “poison” the catalyst, and must not

be used.

5To enable the Motronic engine management

system to achieve complete combustion of the

fuel mixture, and thus to minimise exhaust

emissions, an oxygen sensor is fitted in the

exhaust gas stream. The sensor monitors the

oxygen level in the exhaust gas, and sends a

signal to the Motronic module. The module

constantly alters the fuel/air mixture within a

narrow band to reduce emissions, and to allow

the catalytic converter to operate at maximum

efficiency. No adjustment of idle mixture is

therefore possible on models fitted with a

catalytic converter.

General

6Ninety-nine per cent of exhaust gases, from

a petrol engine (however efficient or well

tuned), consists of nitrogen (N

2), carbon

dioxide (CO

2), oxygen (O2), other inert gases

and water vapour (H

2O). The remaining 1% is

made up of the noxious materials that are

currently seen (except CO

2), as the major

polluters of the environment. Carbon

monoxide (CO), unburned hydrocarbons (HC),

oxides of nitrogen (NOx) and some solid

matter, including a small lead content.

7The device most commonly used to clean

up vehicle exhausts is the catalytic converter.

It is fitted into the vehicle’s exhaust system

and uses precious metals (platinum and

palladium or rhodium) as catalysts to speed

up the reaction between the pollutants and

the oxygen in the exhaust gases. CO and HC

being oxidised to form H

2O and CO2and (in

the three-way type of catalytic converter) NOx

being reduced to N

2.

8The converter consists of an element of

ceramic honeycomb, coated with a

combination of precious metals in such a way

as to produce a vast surface area over which

the exhaust gases must flow. The three-way

closed-loop type converter fitted to these

models can remove over 90% of pollutants.

9The catalytic converter is a reliable and

simple device that needs no maintenance.

However there are some facts that an owner

should be aware if the converter is to function

properly for its full service life (see

illustration).

a)DO NOT use leaded petrol in a vehicle

equipped with a catalytic converter. The

lead will coat the precious metals,

reducing their converting efficiency and

will eventually destroy the converter.

Fuel and exhaust systems - exhaust and emissions 4C•3

10.9 The catalytic converter is protected

by heat shields

8.5 AIR switchover valve

1 Connection to brake servo vacuum hose

2 Connection to cut-off valve

7.1 AIR cut-off valve

1 Connection to AIR pump

2 Connection to AIR switchover valve

3 Connection to AIR non-return valve

4C

Page 129 of 525

b)Always keep the ignition and fuel systems

well maintained according to the

manufacturers schedule (see “Routine

maintenance” and the relevant Chapter).

In particular, ensure that the air cleaner

filter element, the fuel filter and the spark

plugs are renewed at the correct intervals.

If the inlet air/fuel mixture is allowed to

become too rich due to neglect, the

unburned surplus will enter and burn in

the catalytic converter, overheating the

element and eventually destroying the

converter.

c)If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured. The

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

d)The engine control indicator (the outline

of an engine with a lightning symbol

superimposed), will light when the ignition

is switched on and the engine is started,

then it will go out. While it may light briefly

while the engine is running, it should go

out again immediately and stays unlit. If it

lights and stays on while the engine is

running, seek the advice of a Vauxhall

dealer as soon as possible. A fault has

occurred in the fuel injection/ignition

system that, apart from increasing fuel

consumption and impairing the engine’s

performance, may damage the catalytic

converter.

e)DO NOT push or tow-start the vehicle.

This will soak the catalytic converter in

unburned fuel causing it to overheat when

the engine does start see (b) above.

f)DO NOT switch off the ignition at high

engine speeds. If the ignition is switched

off at anything above idle speed,

unburned fuel will enter the (very hot)

catalytic converter, with the possible risk

of its igniting on the element and

damaging the converter.

g)DO NOT use fuel or engine oil additives.

These may contain substances harmful to

the catalytic converter.

h)DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke. The unburned

carbon deposits will clog the converter

passages and reduce its efficiency; in

severe cases the element will overheat.

i)Remember that the catalytic converter

operates at very high temperatures hence

the heat shields on the vehicle’s under-

body and the casing will become hot

enough to ignite combustible materials

that brush against it. DO NOT, therefore,

park the vehicle in dry undergrowth, over

long grass or over piles of dead leaves.

j)Remember that the catalytic converter is

FRAGlLE. Do not strike it with tools during

servicing work. Take great care when

working on the exhaust system. Ensure

that the converter is well clear of any

jacks or other lifting gear used to raise thevehicle. Do not drive the vehicle over

rough ground, road humps, etc., in such a

way as to ground the exhaust system.

k)In some cases, particularly when the

vehicle is new and/or is used for

stop/start driving, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles and

seems to be due to the small amount of

sulphur found in some petrol’s reacting

with hydrogen in the exhaust to produce

hydrogen sulphide (CS) gas. While this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the

vehicle has covered a few thousand miles

the problem should disappear. In the

meanwhile a change of driving style or of

the brand of petrol may effect a solution.

l)The catalytic converter, used on a

well-maintained and well-driven vehicle,

should last for between 50 000 and 100

000 miles. From this point on, careful

checks should be made at all specified

service intervals of the CO level to ensure

that the converter is still operating

efficiently. If the converter is no longer

effective it must be renewed.

11Carbon canister - removal

and refitting

3

Removal

1Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members

(see “Jacking and Vehicle Support”).

2Remove the front right hand wheel and

wheel arch liner.

3Note the hose and pipe connections to the

canister, or label them, to ensure that they are

reconnected to their original unions, then

disconnect them (see illustration). Unscrew

the two nuts securing the canister mounting

bracket to the vehicle body.

Refitting

4Refitting is a reversal of removal, however

ensure correct fitment of hose and pipes.

12Oxygen sensor (catalytic

converter models) - removal

and refitting

3

Note: This sensor is also known as a Lambda

sensor.

Removal

1Disconnect the battery negative lead.

2Disconnect the oxygen sensor wiring plug,

which is located behind the coolant expansion

tank.

3Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members.

4On DOHC models, remove the engine

undershield, as described in Chapter 11.

5On models fitted with Multec injection

system, the sensor is screwed into the

exhaust manifold. Trace the wiring from the

sensor itself to the connector (either clipped

to the radiator cooling fan shroud or behind

the coolant expansion tank). Release it from

any clips or ties; disconnect the wiring before

unscrewing the sensor.

6On other models, unscrew the oxygen

sensor from the front section of the exhaust

system (see illustration). It is advisable to

wear gloves, as the exhaust system will be

extremely hot.

7Withdraw the oxygen sensor and its wiring,

taking care not to burn the wiring on the

exhaust system. If the sensor is to be re-used,

take care that the sealing ring is not lost, and

that the sensor is not dropped.

Refitting

8If a new sensor is being fitted, it will be

supplied with the threads coated in a special

grease to prevent it seizing in the exhaust

system.

9If the original sensor is being refitted,

ensure that the screw thread is clean. Coat

the thread with a lithium based copper grease

(i.e. Vauxhall Part No. 90295397).

10Refitting is a reversal of removal. Check

the exhaust system for leakage when the

engine is re-started.

4C•4Fuel and exhaust systems - exhaust and emissions

12.6 Oxygen sensor location in front

section of exhaust system - DOHC models

11.3 Charcoal canister

A Vent to atmosphere

B Vapour feed hose from filler pipe

C Vapour exhaust hose to inlet tract

D Control valve vacuum pipe from

throttle body

Page 138 of 525

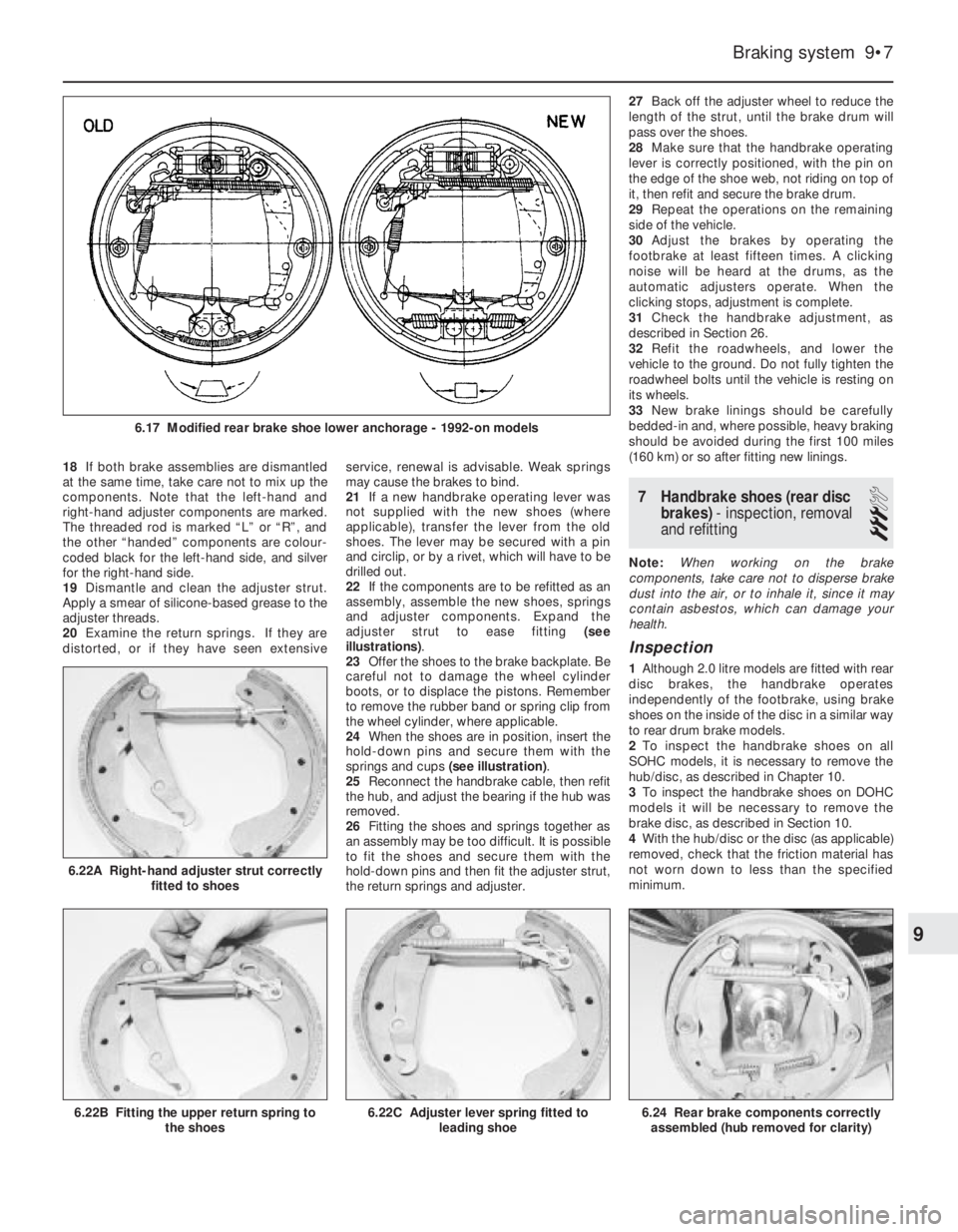

18If both brake assemblies are dismantled

at the same time, take care not to mix up the

components. Note that the left-hand and

right-hand adjuster components are marked.

The threaded rod is marked “L” or “R”, and

the other “handed” components are colour-

coded black for the left-hand side, and silver

for the right-hand side.

19Dismantle and clean the adjuster strut.

Apply a smear of silicone-based grease to the

adjuster threads.

20Examine the return springs. If they are

distorted, or if they have seen extensiveservice, renewal is advisable. Weak springs

may cause the brakes to bind.

21If a new handbrake operating lever was

not supplied with the new shoes (where

applicable), transfer the lever from the old

shoes. The lever may be secured with a pin

and circlip, or by a rivet, which will have to be

drilled out.

22If the components are to be refitted as an

assembly, assemble the new shoes, springs

and adjuster components. Expand the

adjuster strut to ease fitting (see

illustrations).

23Offer the shoes to the brake backplate. Be

careful not to damage the wheel cylinder

boots, or to displace the pistons. Remember

to remove the rubber band or spring clip from

the wheel cylinder, where applicable.

24When the shoes are in position, insert the

hold-down pins and secure them with the

springs and cups (see illustration).

25Reconnect the handbrake cable, then refit

the hub, and adjust the bearing if the hub was

removed.

26Fitting the shoes and springs together as

an assembly may be too difficult. It is possible

to fit the shoes and secure them with the

hold-down pins and then fit the adjuster strut,

the return springs and adjuster.27Back off the adjuster wheel to reduce the

length of the strut, until the brake drum will

pass over the shoes.

28Make sure that the handbrake operating

lever is correctly positioned, with the pin on

the edge of the shoe web, not riding on top of

it, then refit and secure the brake drum.

29Repeat the operations on the remaining

side of the vehicle.

30Adjust the brakes by operating the

footbrake at least fifteen times. A clicking

noise will be heard at the drums, as the

automatic adjusters operate. When the

clicking stops, adjustment is complete.

31Check the handbrake adjustment, as

described in Section 26.

32Refit the roadwheels, and lower the

vehicle to the ground. Do not fully tighten the

roadwheel bolts until the vehicle is resting on

its wheels.

33New brake linings should be carefully

bedded-in and, where possible, heavy braking

should be avoided during the first 100 miles

(160 km) or so after fitting new linings.

7Handbrake shoes (rear disc

brakes) - inspection, removal

and refitting

3

Note: When working on the brake

components, take care not to disperse brake

dust into the air, or to inhale it, since it may

contain asbestos, which can damage your

health.

Inspection

1Although 2.0 litre models are fitted with rear

disc brakes, the handbrake operates

independently of the footbrake, using brake

shoes on the inside of the disc in a similar way

to rear drum brake models.

2To inspect the handbrake shoes on all

SOHC models, it is necessary to remove the

hub/disc, as described in Chapter 10.

3To inspect the handbrake shoes on DOHC

models it will be necessary to remove the

brake disc, as described in Section 10.

4With the hub/disc or the disc (as applicable)

removed, check that the friction material has

not worn down to less than the specified

minimum.

Braking system 9•7

6.22A Right-hand adjuster strut correctly

fitted to shoes

6.24 Rear brake components correctly

assembled (hub removed for clarity)6.22C Adjuster lever spring fitted to

leading shoe6.22B Fitting the upper return spring to

the shoes

6.17 Modified rear brake shoe lower anchorage - 1992-on models

9

Page 174 of 525

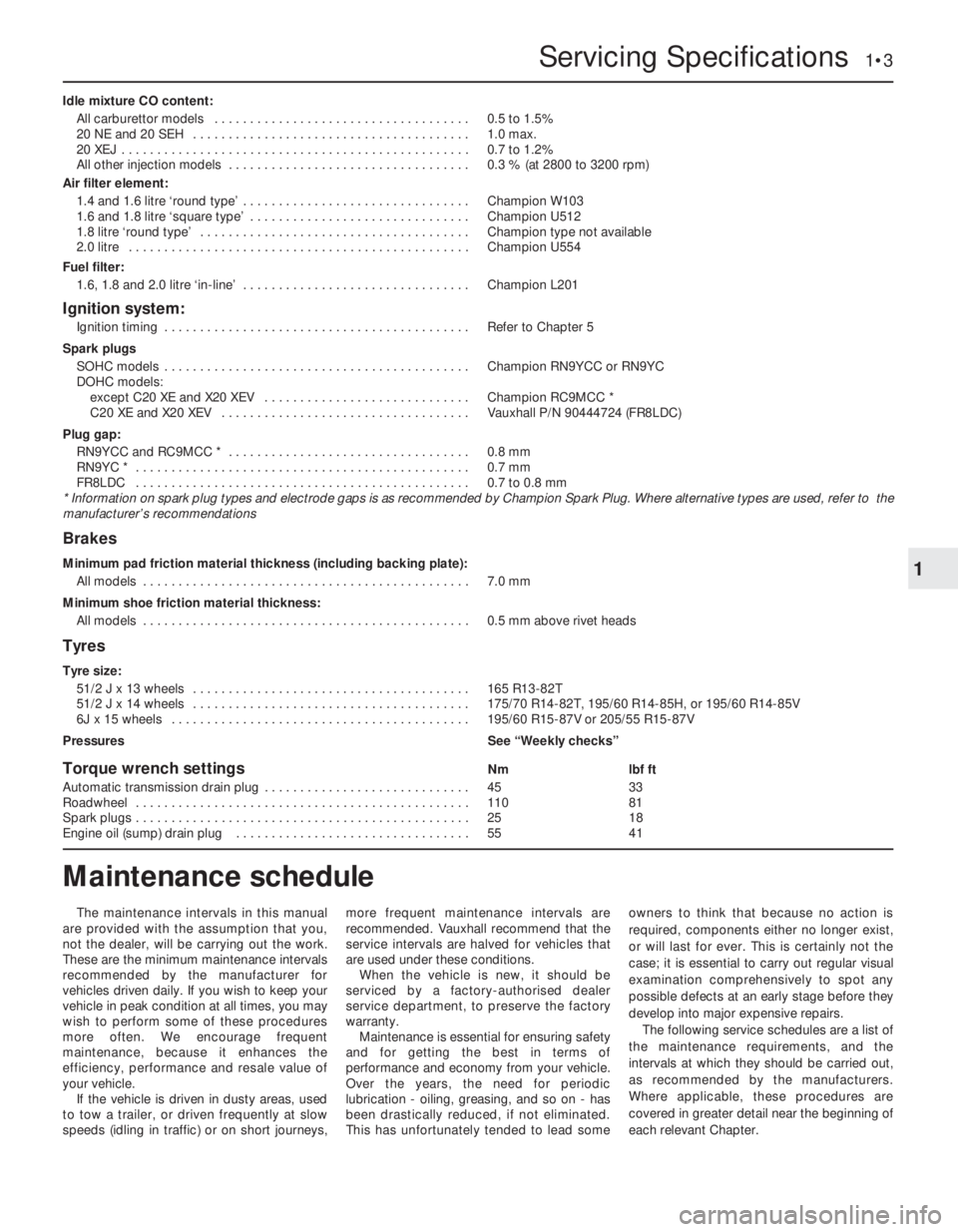

Idle mixture CO content:

All carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5 to 1.5%

20 NE and 20 SEH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0 max.

20 XEJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 to 1.2%

All other injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.3 % (at 2800 to 3200 rpm)

Air filter element:

1.4 and 1.6 litre ‘round type’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W103

1.6 and 1.8 litre ‘square type’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion U512

1.8 litre ‘round type’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion type not available

2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion U554

Fuel filter:

1.6, 1.8 and 2.0 litre ‘in-line’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion L201

Ignition system:

Ignition timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Refer to Chapter 5

Spark plugs

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RN9YCC or RN9YC

DOHC models:

except C20 XE and X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC9MCC *

C20 XE and X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Vauxhall P/N 90444724 (FR8LDC)

Plug gap:

RN9YCC and RC9MCC * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm

RN9YC * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm

FR8LDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 to 0.8 mm

* Information on spark plug types and electrode gaps is as recommended by Champion Spark Plug. Where alternative types are used, refer to the

manufacturer’s recommendations

Brakes

Minimum pad friction material thickness (including backing plate):

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.0 mm

Minimum shoe friction material thickness:

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5 mm above rivet heads

Tyres

Tyre size:

51/2 J x 13 wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165 R13-82T

51/2 J x 14 wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175/70 R14-82T, 195/60 R14-85H, or 195/60 R14-85V

6J x 15 wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195/60 R15-87V or 205/55 R15-87V

PressuresSee “Weekly checks”

Torque wrench settingsNmlbf ft

Automatic transmission drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Roadwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11081

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Engine oil (sump) drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Servicing Specifications 1•3

1

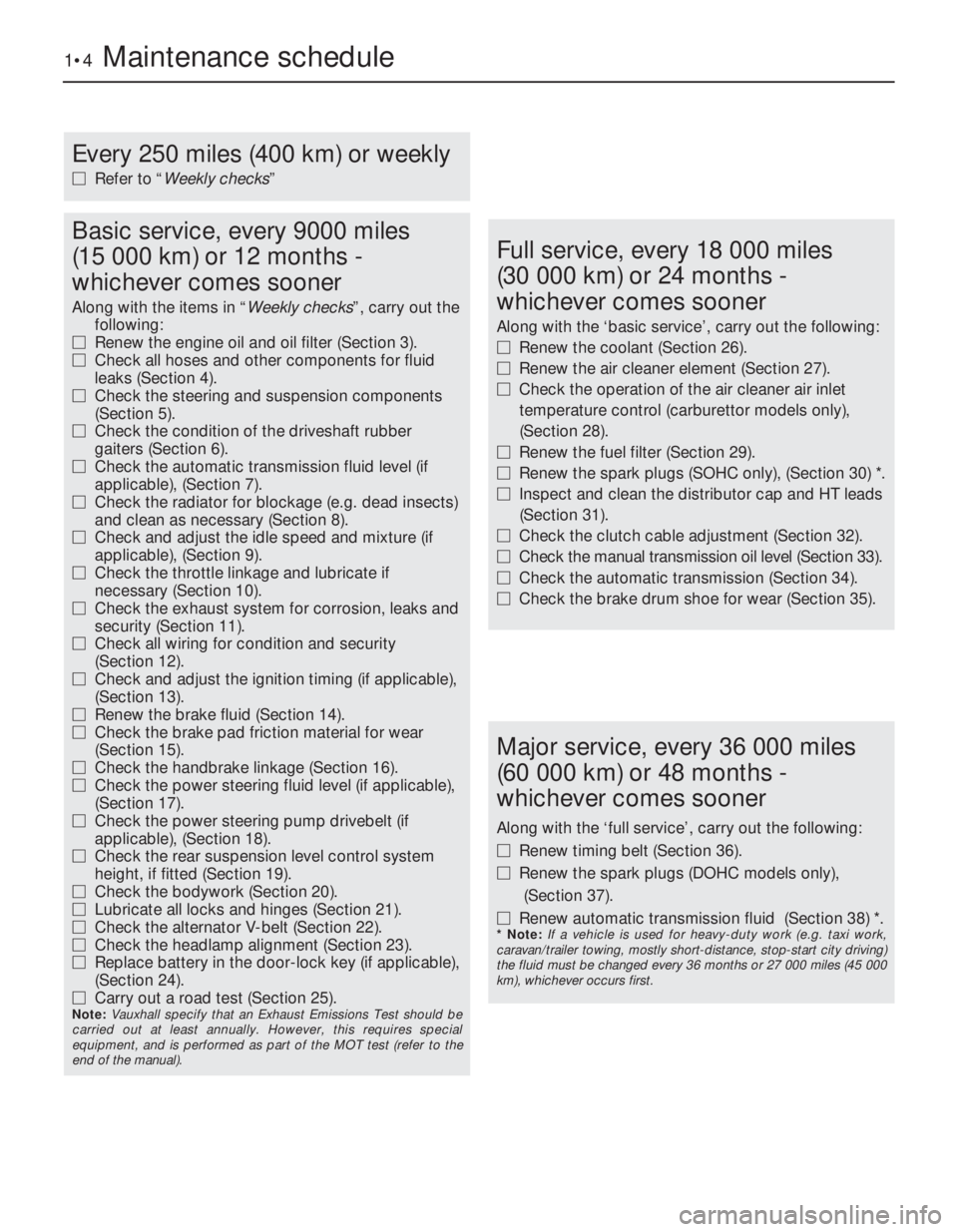

The maintenance intervals in this manual

are provided with the assumption that you,

not the dealer, will be carrying out the work.

These are the minimum maintenance intervals

recommended by the manufacturer for

vehicles driven daily. If you wish to keep your

vehicle in peak condition at all times, you may

wish to perform some of these procedures

more often. We encourage frequent

maintenance, because it enhances the

efficiency, performance and resale value of

your vehicle.

If the vehicle is driven in dusty areas, used

to tow a trailer, or driven frequently at slow

speeds (idling in traffic) or on short journeys,more frequent maintenance intervals are

recommended. Vauxhall recommend that the

service intervals are halved for vehicles that

are used under these conditions.

When the vehicle is new, it should be

serviced by a factory-authorised dealer

service department, to preserve the factory

warranty.

Maintenance is essential for ensuring safety

and for getting the best in terms of

performance and economy from your vehicle.

Over the years, the need for periodic

lubrication -oiling, greasing, and so on -has

been drastically reduced, if not eliminated.

This has unfortunately tended to lead someowners to think that because no action is

required, components either no longer exist,

or will last for ever. This is certainly not the

case; it is essential to carry out regular visual

examination comprehensively to spot any

possible defects at an early stage before they

develop into major expensive repairs.

The following service schedules are a list of

the maintenance requirements, and the

intervals at which they should be carried out,

as recommended by the manufacturers.

Where applicable, these procedures are

covered in greater detail near the beginning of

each relevant Chapter.

Maintenance schedule

Page 175 of 525

1•4Maintenance schedule

Every 250 miles (400 km) or weekly

MRefer to “Weekly checks”

Basic service, every 9000 miles

(15 000 km) or 12 months -

whichever comes sooner

Along with the items in “Weekly checks”, carry out the

following:

MRenew the engine oil and oil filter (Section 3).

MCheck all hoses and other components for fluid

leaks (Section 4).

MCheck the steering and suspension components

(Section 5).

MCheck the condition of the driveshaft rubber

gaiters (Section 6).

MCheck the automatic transmission fluid level (if

applicable), (Section 7).

MCheck the radiator for blockage (e.g. dead insects)

and clean as necessary (Section 8).

MCheck and adjust the idle speed and mixture (if

applicable), (Section 9).

MCheck the throttle linkage and lubricate if

necessary (Section 10).

MCheck the exhaust system for corrosion, leaks and

security (Section 11).

MCheck all wiring for condition and security

(Section 12).

MCheck and adjust the ignition timing (if applicable),

(Section 13).

MRenew the brake fluid (Section 14).

MCheck the brake pad friction material for wear

(Section 15).

MCheck the handbrake linkage (Section 16).

MCheck the power steering fluid level (if applicable),

(Section 17).

MCheck the power steering pump drivebelt (if

applicable), (Section 18).

MCheck the rear suspension level control system

height, if fitted (Section 19).

MCheck the bodywork (Section 20).

MLubricate all locks and hinges (Section 21).

MCheck the alternator V-belt (Section 22).

MCheck the headlamp alignment (Section 23).

MReplace battery in the door-lock key (if applicable),

(Section 24).

MCarry out a road test (Section 25).

Note: Vauxhall specify that an Exhaust Emissions Test should be

carried out at least annually. However, this requires special

equipment, and is performed as part of the MOT test (refer to the

end of the manual).

Full service, every 18 000 miles

(30 000 km) or 24 months -

whichever comes sooner

Along with the ‘basic service’, carry out the following:

MRenew the coolant (Section 26).

MRenew the air cleaner element (Section 27).

MCheck the operation of the air cleaner air inlet

temperature control (carburettor models only),

(Section 28).

MRenew the fuel filter (Section 29).

MRenew the spark plugs (SOHC only), (Section 30) *.

MInspect and clean the distributor cap and HT leads

(Section 31).

MCheck the clutch cable adjustment (Section 32).

MCheck the manual transmission oil level (Section 33).

MCheck the automatic transmission (Section 34).

MCheck the brake drum shoe for wear (Section 35).

Major service, every 36 000 miles

(60 000 km) or 48 months -

whichever comes sooner

Along with the ‘full service’, carry out the following:

MRenew timing belt (Section 36).

MRenew the spark plugs (DOHC models only),

(Section 37).

MRenew automatic transmission fluid (Section 38) *.

* Note: If a vehicle is used for heavy-duty work (e.g. taxi work,

caravan/trailer towing, mostly short-distance, stop-start city driving)

the fluid must be changed every 36 months or 27 000 miles (45 000

km), whichever occurs first.