tyre pressure OPEL CASCADA 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: CASCADA, Model: OPEL CASCADA 2018Pages: 267, PDF Size: 8 MB

Page 222 of 267

220Vehicle care14. Detach the tyre repair kit. Pushcatch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away the tyre repair kit in the

load compartment.

Note

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 217.

Page 224 of 267

222Vehicle care2. Install the wheel wrench ensuringthat it locates securely and loosen

each wheel nut by half a turn.

The wheels may be protected by

locking wheel nuts. To loosen

these specific nuts, first attach the adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate

wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 223.

7. Screw on the wheel nuts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Stow the replaced wheel 3 223,

the vehicle tools 3 210 and the

adapter for the locking wheel nuts

3 70.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Page 233 of 267

Vehicle care231Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Caution

After washing or cleaning, the softtop must be completely dried

before opening. If a wet soft top

remains opened for a longer time,

it would be damaged by water

spotting and mould growth.

When cleaning with a high-pressure

jet cleaner ensure a minimum

distance of 30 cm to the rear brand

emblem to prevent unintended

unlocking.

Thoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on the windows will impair vision.

Have the door hinges of all doors

greased by a workshop.

Do not use hard objects to remove

spots of tar. Use tar removal spray on

painted surfaces.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them dry.

Polishing and waxing Wax painted parts of the vehicle

regularly (at the latest when water no

longer beads). Otherwise, the

paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Soft top as well as plastic body parts

must not be treated with wax or

polishing agents.Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois leather together with window cleaner and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Remove dirt residues from smearing wiper blades by using a soft cloth and window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous wiping on dry windows will damage or

even destroy the wiper blades.

Wheels and tyres Do not use high-pressure jet

cleaners.

Page 239 of 267

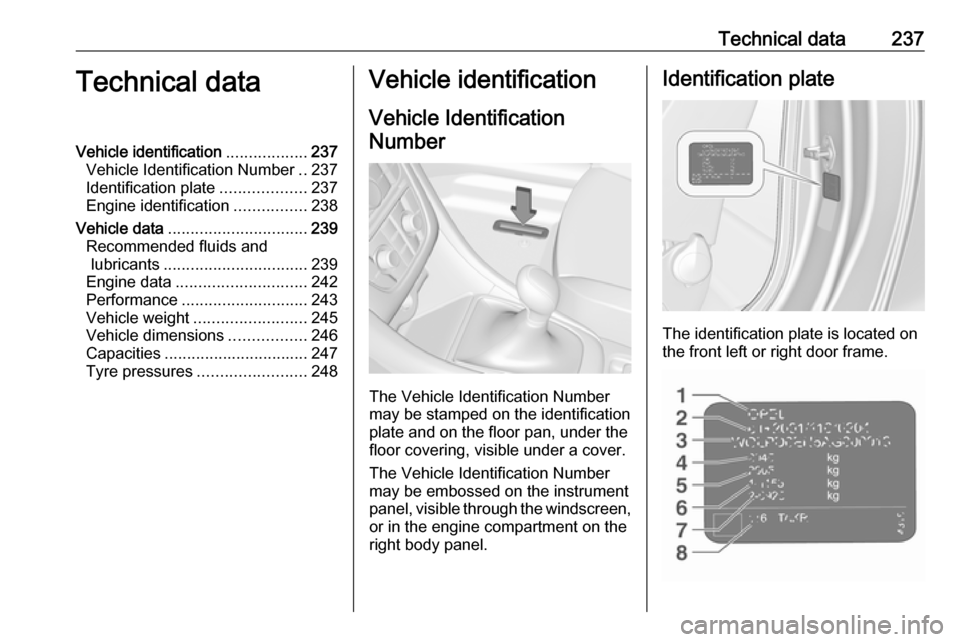

Technical data237Technical dataVehicle identification..................237

Vehicle Identification Number ..237

Identification plate ...................237

Engine identification ................238

Vehicle data ............................... 239

Recommended fluids and lubricants ................................ 239

Engine data ............................. 242

Performance ............................ 243

Vehicle weight ......................... 245

Vehicle dimensions .................246

Capacities ................................ 247

Tyre pressures ........................ 248Vehicle identification

Vehicle IdentificationNumber

The Vehicle Identification Number

may be stamped on the identification plate and on the floor pan, under thefloor covering, visible under a cover.

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen,

or in the engine compartment on the

right body panel.

Identification plate

The identification plate is located on

the front left or right door frame.

Page 250 of 267

![OPEL CASCADA 2018 Manual user 248Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi] OPEL CASCADA 2018 Manual user 248Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi]](/img/37/18799/w960_18799-249.png)

248Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])B14NEL,

B14NET,

A16XHT,

B16SHT,

B16SHL235/55 R17,230/2.3 (34)230/2.3 (34)280/2.8 (41)280/2.8 (41)240/2.4

(35)280/2.8

(41)235/50 R18,245/45 R18,235/45 R19,245/40 R20,225/55 R17

Page 253 of 267

Customer information251Antenna Kathrain

Kathrein Automotive GmbH

Roemerring 1, 31137 Hildesheim, Germany

Operation frequency: N/A

Maximum output: N/A

OnStar module

LGE

LG Electronics European Shared

Service Center B.V., Krijgsman 1,

1186 DM Amstelveen, The

NetherlandsOperation

frequency (MHz)Maximum output

(dBm)2402 - 248042412 - 246218880 - 915331710 - 1785241850 - 1910241920 - 1980242500 - 257023Immobiliser

Continental Automotive GmbH

Siemensstrasse 12, 93055

Regensburg, Germany

Operation frequency: 125 kHz

Maximum output:

5.1 dBuA/m @ 10m

Radio remote control receiver

Continental Automotive GmbH

Siemensstrasse 12, 93055

Regensburg, Germany

Operation frequency: 433.92 MHz

Maximum output: N/A

Radio remote control transmitter

Continental Automotive GmbH

Siemensstrasse 12, 93055

Regensburg, Germany

Operation frequency: 433.92 MHz

Maximum output: -5,7 dBm

Tyre pressure sensors

Schrader Electronics Ltd.

11 Technology Park, Belfast Road,

Antrim BT41 1QS, Northern Ireland,

United KingdomOperation frequency: 433.92 MHz

Maximum output: 10 dBm

Radar systems

Country-specific Declarations of

Conformity for radar systems are

shown on the following page:

Page 260 of 267

258Customer informationRadio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in Opel

vehicles does not use or record

personal information or link with any

other Opel system containing

personal information.

Page 265 of 267

263QQuickheat ................................... 132

R

Radio Frequency Identification (RFID) ..................................... 258

Radio remote control ...................22

REACH ....................................... 254

Reading lights ............................ 122

Rear floor storage cover ..............75

Rear fog light ............................... 94

Rear fog lights ........................... 120

Rear storage ................................. 75

Rear view camera ...................... 172

Recommended fluids and lubricants ........................ 234, 239

Refuelling ................................... 180

Registered trademarks ...............256

Retained power off .....................137

Reversing lights .........................121

Ride control systems ..................153

Rollover protection system ...........45

S Seat adjustment ............................. 7

Seat belt ........................................ 8

Seat belt reminder .......................89

Seat belts ..................................... 56

Seat folding .................................. 52

Seat heating ................................. 55

Seat position ................................ 49Seat ventilation............................. 55

Selective catalytic reduction .......143

Selector lever ............................. 147

Service ............................... 134, 233

Service display ............................ 87

Service information ....................233

Side airbag system ......................63

Side blind spot alert ....................170

Sidelights .................................... 112

Side turn signal lights ................202

Soft top ........................................ 36

Software acknowledgement .......254

Spare wheel ............................... 223

Speed limiter............................... 159

Speedometer ............................... 85

Starting and operating ................137

Starting off ................................... 18

Starting the engine ....................137

Steering ...................................... 136

Steering wheel adjustment ......9, 79

Steering wheel controls ...............79

Stop-start system........................ 138

Storage ......................................... 70

Storage compartments .................70

Sunvisor lights ........................... 122

Sun visors .................................... 35

Symbols ......................................... 4T

Tachometer ................................. 86

Tail lights ................................... 201

Three-point seat belt .................... 57

Tools .......................................... 210

Tow bar....................................... 183

Towing ................................ 183, 228

Towing another vehicle .............229

Towing equipment .....................184

Towing the vehicle .....................228

Traction Control system ............. 153

Traction Control system off........... 92

Traffic sign assistant ...................174

Trailer coupling ........................... 183

Trailer towing ............................. 183

Transmission ............................... 17

Transmission display .................146

Tread depth ............................... 216

Trip odometer .............................. 85

Turn and lane-change signals ...120

Turn signal ................................... 89

Tyre chains ................................ 217

Tyre designations ......................211

Tyre pressure ............................ 215

Tyre pressure monitoring system ............................... 93, 211

Tyre pressures ........................... 248

Tyre repair kit ............................. 217