lock OPEL COMBO D 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: COMBO D, Model: OPEL COMBO D 2017.5Pages: 201, PDF Size: 4.76 MB

Page 152 of 201

150Vehicle care

2. Withdraw bulb holder fromreflector by turning anticlockwise.

3. Remove bulb from socket, insert new bulb.

4. Insert bulb holder in reflector. 5. Rotate clockwise to engage.

6. Install protective cover.

Front turn signal light 1. Remove protective cover.2. Withdraw bulb holder from reflector by turning anticlockwise.

3. Push bulb into holder slightly, rotate anticlockwise, remove and

renew bulb.

4. Insert bulb holder in reflector.

5. Rotate clockwise to engage.

6. Install protective cover.

Fog lights

Have bulbs replaced by a workshop.

Tail lights

1. Remove the three retaining screws.

2. Remove lamp assembly from vehicle.

3. Disengage connector plug from bulb holder.

Page 153 of 201

Vehicle care151

4.Unscrew the four retaining screws

using a screwdriver. Turn bulb

holder for reverse light

anticlockwise and replace bulb.

5. Remove bulb holder and seal from lamp assembly.

6. Push bulb into socket slightly, rotate anticlockwise, remove and

renew bulb.Brake light ( 1)

Turn signal light ( 2)

Tail light ( 3)

Tail light/fog light ( 4)

7. Install seal on bulb holder ensuring it is fitted correctly.

Install bulb holder in lamp

assembly ensuring that it

engages correctly. Tighten the

four retaining screws using a

screwdriver.

8. Install reverse light bulb holder and turn clockwise to tighten.

9. Engage connector plug.

10. Insert lamp assembly in body, ensuring correct positioning.

Tighten the three retaining

screws.

11. Switch on ignition, operate and check all lights.

Side turn signal lights

Have bulbs replaced by a workshop.

Centre high-mounted brakelight

Have bulbs replaced by a workshop.

Page 154 of 201

152Vehicle careNumber plate lightTailgate

1. Insert screwdriver as indicated by

the arrows, press to the side and

release the bulb housing.

2. Turn the bulb holder anticlockwise

to remove from the bulb housing.

Remove the bulb by pulling.

3. Replace the bulb.

4. Insert bulb holder in bulb housing and rotate clockwise

5. Install the bulb housing ensuring it

engages correctly.

Rear doors

1. Insert screwdriver as indicated by

the arrows, press to the left and

release the bulb housing.

2. Press bulb slightly towards spring

clip and remove.

3. Replace the bulb.

4. Install the bulb housing ensuring it

engages correctly.

Page 159 of 201

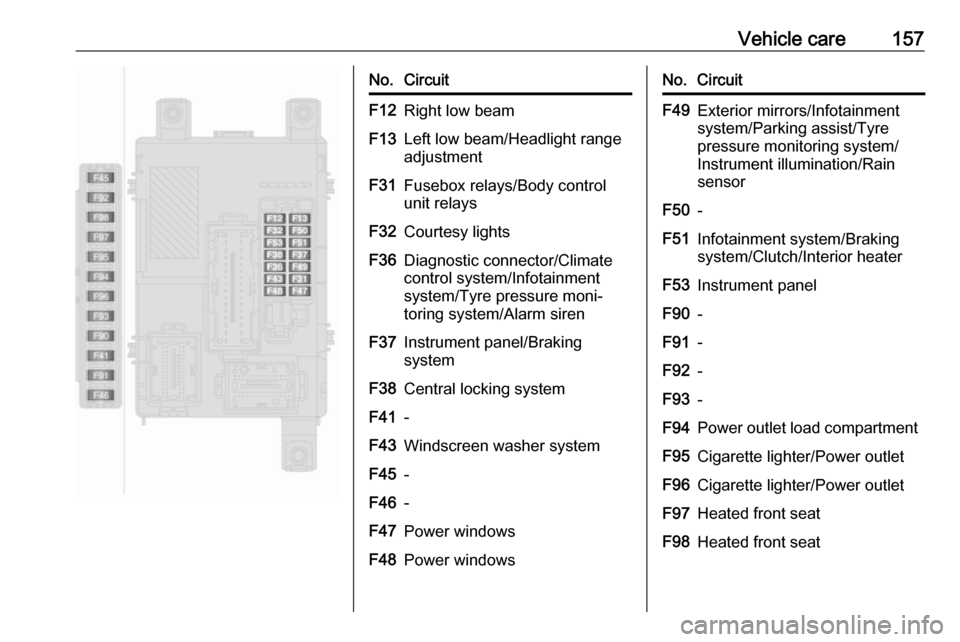

Vehicle care157No.CircuitF12Right low beamF13Left low beam/Headlight range

adjustmentF31Fusebox relays/Body control

unit relaysF32Courtesy lightsF36Diagnostic connector/Climate

control system/Infotainment

system/Tyre pressure moni‐

toring system/Alarm sirenF37Instrument panel/Braking

systemF38Central locking systemF41-F43Windscreen washer systemF45-F46-F47Power windowsF48Power windowsNo.CircuitF49Exterior mirrors/Infotainment

system/Parking assist/Tyre

pressure monitoring system/

Instrument illumination/Rain

sensorF50-F51Infotainment system/Braking

system/Clutch/Interior heaterF53Instrument panelF90-F91-F92-F93-F94Power outlet load compartmentF95Cigarette lighter/Power outletF96Cigarette lighter/Power outletF97Heated front seatF98Heated front seat

Page 165 of 201

Vehicle care163Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

Do not exceed 50 km/h when tyre

chains are fitted.9 Warning

Damage may lead to tyre blowout.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at tyre's sidewall cannot be repairedwith the tyre repair kit.

9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first or reverse gear.

The tyre repair kit may be located

under the front seat, in the glovebox,

or on the right side of the load

compartment behind a cover.

1. Take the tyre repair kit from the vehicle.

2. Remove the compressor.

3. Set the compressor upright near the tyre.

4. Unscrew valve cap from defective

tyre.

Page 167 of 201

Vehicle care165

If tyre pressure is more than

1.8 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.8 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

15. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off and allow to cool.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle.

Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -20 °C.

Replacing the sealant canister

To replace the sealant canister: 1. Disconnect the compressor air hose.2. Turn the canister anticlockwise to lift it out.

3. Insert the new canister and turn it clockwise.

4. Connect the compressor air hose to the canister and fit the flexible

filler tube into its allocated space.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 163.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first or reverse gear.

● Remove the spare wheel 3 167.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

Page 172 of 201

170Vehicle care● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a vehicle battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much

less than that of the discharged

vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

one minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

Page 173 of 201

Vehicle care1714. Switch on electrical consumers(e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Release the cap by carefully lifting

with a screwdriver. To prevent

damage, it is recommended to place

a cloth between the screwdriver and

the frame.

The towing eye is stowed with the vehicle tools 3 158.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

Caution

The towing eye must only be used for towing and not for recovering

the vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Note

If neutral cannot be selected on

vehicles with manual transmission

automated (MTA), the vehicle must

only be towed with the drive wheels

raised off the ground.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

Page 174 of 201

172Vehicle careTo prevent the entry of exhaust gasesfrom the towing vehicle, switch on the

air recirculation 3 107 and close the

windows.

Seek the assistance of a workshop. After towing, unscrew the towing eye

and replace the cap.

Towing another vehicle

Insert a screwdriver in the slot at the

side of the cap. Release the cap by

carefully levering the screwdriver. To

prevent damage it is recommended to place a cloth between the screwdriver

and the frame.

The towing eye is stowed with the vehicle tools 3 158.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or even better a tow bar – to the towing eye.

The towing eye must only be used for

towing and not for recovering a

vehicle.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

After towing, unscrew the towing eye.

Insert cap.

Appearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has a

degreasing effect and impairs lock

function. After using a de-icing agent,

have the locks regreased by a

workshop.

WashingThe paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly.

When using automatic vehicle

washes, select a programme that

includes waxing. Restrictions for

filmed or matt painted body parts or

decor tapes, see "Polishing and

waxing".

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

Page 182 of 201

180Technical dataIdentification plate

The identification plate is located in

the engine compartment, attached to

the bulkhead.

Information on identification label:1:type approval number2:vehicle Identification Number3:vehicle type identification

code4:permissible gross vehicle

weight rating in kg5:permissible gross train weight

in kg6:maximum permissible front

axle load in kg7:maximum permissible rear

axle load in kg8:engine type9-11:vehicle-specific or country-

specific data

Note

The identification plate on your

vehicle may differ from the

illustration shown.

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the

front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The engine number is stamped on the engine block.

The technical data tables show the

engine identifier code. Engine data

3 182.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.