check engine OPEL COMBO D 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: COMBO D, Model: OPEL COMBO D 2018Pages: 203, PDF Size: 4.97 MB

Page 120 of 203

118Driving and operatingDeactivation

Deactivate the stop-start system

manually by pressing ^ in the centre

console. LED in the button illuminates

to confirm deactivation.

Depending on version, a

corresponding message, e.g.

Start&Stop disconnected , may also

be displayed in the Driver Information

Centre 3 91.

Autostop

If the vehicle is at a low speed or at a standstill, activate an Autostop as

follows:

● depress the clutch pedal

● set the lever to neutral

● release the clutch pedal

The engine will be switched off while the ignition stays on.

An Autostop is indicated when control

indicator ^ flashes in the Driver

Information Centre 3 91.

During an Autostop, the heating,

power steering and brake

performance will be maintained.

Caution

The power steering assist may be

reduced during an Autostop.

Conditions for an Autostop

The stop-start system checks if each

of the following conditions is fulfilled.

Otherwise an Autostop will be

inhibited.

● the stop-start system is not manually deactivated

● the bonnet is fully closed

● the driver's door is closed and the

driver's seat belt is fastened

● the vehicle battery is sufficiently charged and in good condition

● the engine is warmed up

● the engine coolant temperature is

not too high

● the engine exhaust temperature is not too high, e.g. after driving

with high engine load

● the ambient temperature is not too low

● the climate control system allows

an Autostop

Page 143 of 203

Vehicle care141Vehicle careGeneral Information...................141

Accessories and vehicle modifications .......................... 141

Vehicle storage ........................142

End-of-life vehicle recovery .....142

Vehicle checks ........................... 143

Performing work ......................143

Bonnet ..................................... 143

Engine oil ................................. 144

Engine coolant ......................... 145

Power steering fluid .................145

Washer fluid ............................ 146

Brakes ..................................... 146

Brake fluid ............................... 146

Vehicle battery ......................... 147

Wiper blade replacement ........148

Bulb replacement .......................149

Halogen headlights ..................149

Fog lights ................................. 151

Tail lights ................................. 151

Side turn signal lights ..............152

Centre high-mounted brake light ......................................... 152

Number plate light ...................153Interior lights ............................ 154

Instrument panel illumination ...155

Electrical system ........................155

Fuses ....................................... 155

Engine compartment fuse box . 156

Instrument panel fuse box .......157

Vehicle tools .............................. 159

Tools ........................................ 159

Wheels and tyres .......................160

Winter tyres ............................. 160

Tyre designations ....................160

Tyre pressure .......................... 160

Tyre pressure monitoring

system .................................... 161

Tread depth ............................. 163

Changing tyre and wheel size . 163 Wheel covers ........................... 163

Tyre chains .............................. 164

Tyre repair kit .......................... 164

Wheel changing .......................166

Spare wheel ............................ 168

Jump starting ............................. 170

Towing ....................................... 172

Towing the vehicle ...................172

Towing another vehicle ...........173

Appearance care .......................173

Exterior care ............................ 173

Interior care ............................. 176General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warrantyoffered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 144 of 203

142Vehicle careCaution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear to prevent the

vehicle from rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

locking system.

Putting back into operation

When the vehicle is to be put back into operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plates if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website. Only entrust this work to an

authorised recycling centre.

Natural gas vehicles must be recycled by a service centre authorised for

natural gas vehicles.

Page 145 of 203

Vehicle care143Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

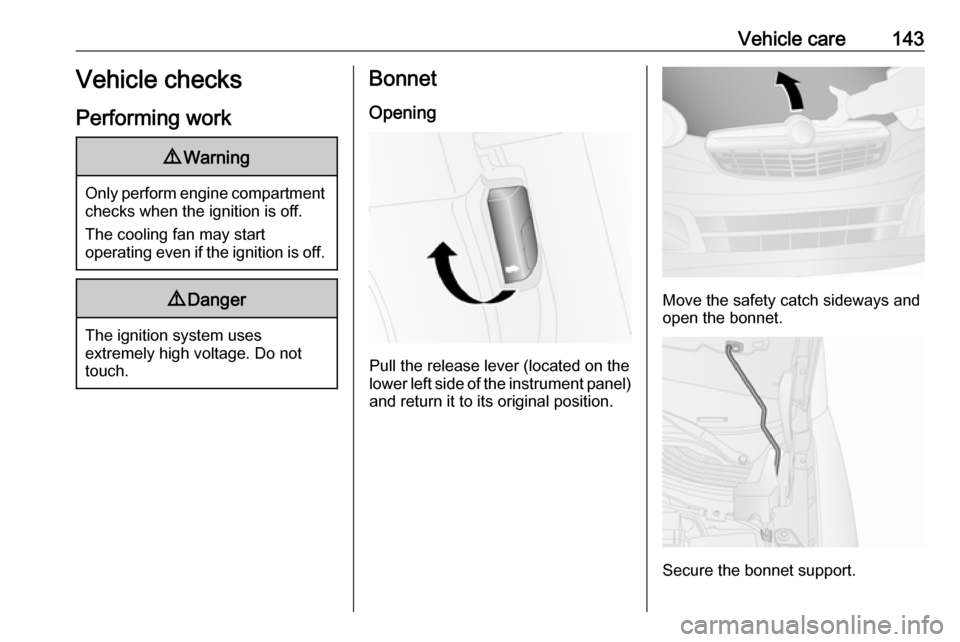

Bonnet

Opening

Pull the release lever (located on the

lower left side of the instrument panel) and return it to its original position.

Move the safety catch sideways and

open the bonnet.

Secure the bonnet support.

Page 146 of 203

144Vehicle careIf the bonnet is opened during anAutostop, the engine will be restarted automatically for safety reasons.

Stop-start system 3 117.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is

engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 178.

Low engine oil level control indicator

S 3 89.

The maximum engine oil

consumption is 0.6 litres per

1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

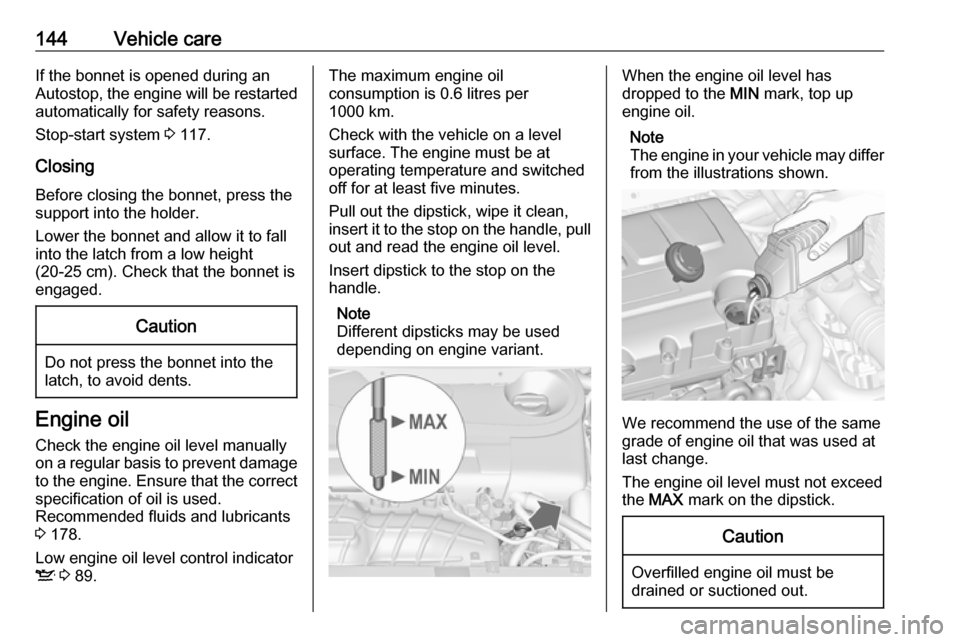

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle.

Note

Different dipsticks may be used

depending on engine variant.When the engine oil level has

dropped to the MIN mark, top up

engine oil.

Note

The engine in your vehicle may differ from the illustrations shown.

We recommend the use of the same

grade of engine oil that was used at

last change.

The engine oil level must not exceed

the MAX mark on the dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

Page 147 of 203

Vehicle care145Capacities 3 190.

Fit the cap on straight and tighten it.

Engine coolant

The coolant provides freeze

protection down to approx. -28 °C. In

cold regions with very low

temperatures, the factory filled

coolant provides frost protection

down to approx. -37 °C.Caution

Only use approved antifreeze.

Coolant and antifreeze 3 178.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be between the

MIN and MAX mark. Top up if the

level is low.

9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up, use a 1:1 mixture of

approved coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have

the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Coolant and antifreeze 3 178.

Power steering fluidCaution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not

work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap/dipstick or

from entering the reservoir.

Page 151 of 203

Vehicle care149Wiper blade on tailgate

Lift wiper arm, press retaining clips to

detach wiper blade.

Attach the wiper blade to the wiper

arm and push until it engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement, switch on

the ignition, operate and check the

lights.Halogen headlights

Headlights have separate systems for low beam/sidelight 1 (outer bulb),

high beam/daytime running light 2

(inner bulb).

To access bulbs, pull off protective

covers.

Low beam 1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove bulb from reflector.

Page 163 of 203

Vehicle care161Tyre pressures differ depending on

various options. For the correct tyre pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 183.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 191.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressures.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa (0.1 bar) for a 10 °C

temperature increase. This must be

considered when warm tyres are

checked.

Tyre pressure monitoring

system

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

The tyre pressure monitoring system sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Tyre pressure chart 3 191.

Page 167 of 203

Vehicle care165

5. Screw the flexible filler hose ontothe tyre valve.

6. The switch on the compressor must be set to J.

7. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.8. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

9. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Tyre pressure 3 191. When the

correct pressure is obtained,

switch off the compressor.

10. If a pressure of 1.5 bar is not obtained within five minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for five minutes. If a pressure of

1.8 bar is still not obtained within

five minutes, the tyre is too badly

damaged. Seek the assistance of

a workshop.

Do not run the compressor longer

than 20 minutes.

11. Detach the tyre repair kit.

12. Remove any excess sealant using a cloth.

13. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

14. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than

ten minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

Page 177 of 203

Vehicle care175For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and

window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous wiping on dry windows will damage or

even destroy the wiper blades.

Glass panel

Never clean with solvents or abrasive agents, fuels, aggressive media (e.g.

paint cleaner, acetone-containing

solutions etc.), acidic or highly

alkaline media or abrasive pads. Do

not apply wax or polishing agents to

the glass panel.Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.

Underbody

Some areas of the vehicle underbody

have a PVC undercoating while other critical areas have a durable

protective wax coating.

After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen/rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.Before and after winter, wash the

underbody and have the protective

wax coating checked.

Natural gas system

Do not direct the steam jet or high-

pressure jet towards natural gas

system components. It is particularly

important to protect the natural gas tank and the pressure valves on the

vehicle underbody and the bulkhead

in the engine compartment.

These components must not be

treated using chemical cleaners or

preservatives.

Have components of the natural gas

system cleaned by a workshop

authorised to carry out maintenance

of natural gas vehicles.

Towing equipment

Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.