ESP OPEL COMBO E 2019 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: COMBO E, Model: OPEL COMBO E 2019Pages: 279, PDF Size: 10.43 MB

Page 233 of 279

Vehicle care231The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Tyre deflation detectionsystem

The tyre deflation detection system

continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values and further

signals.

If a tyre loses pressure the control

indicator w illuminates, a warning

chime is given and a warning

message is displayed in the Driver

Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 109.After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.Caution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used. Once the road tyre has

been refitted, check the tyre pressure with cold tyres and initialise the

system.

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

Page 235 of 279

Vehicle care233Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel

size

If tyres of a different size than thosefitted at the factory are used, it may be

necessary to reprogramme the tyre

deflation detection system and make

other vehicle modifications.

Tyre deflation detection system

3 231.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on all tyres

sizes allowed for the vehicle.

Page 239 of 279

Vehicle care237Replace the used sealant bottle.

Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Wheel changing Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.● Never crawl under a jacked-upvehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

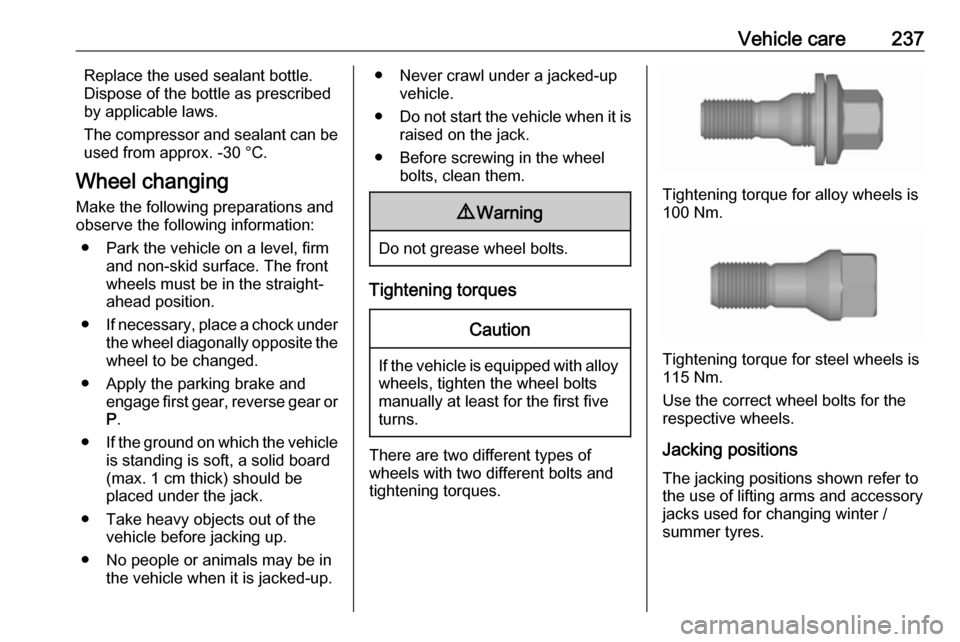

There are two different types of

wheels with two different bolts and tightening torques.

Tightening torque for alloy wheels is

100 Nm.

Tightening torque for steel wheels is

115 Nm.

Use the correct wheel bolts for the respective wheels.

Jacking positions The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Page 250 of 279

248Vehicle careClean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light-

coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could

damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Page 257 of 279

Technical data255Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weightrating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg8:vehicle-specific or country-

specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables show the

engine identifier code.

Engine data 3 259.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.