light OPEL COMBO E 2019 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: COMBO E, Model: OPEL COMBO E 2019Pages: 279, PDF Size: 10.43 MB

Page 204 of 279

202Driving and operatingdriver, the system triggers the first

level of alert. The driver is notified by

a message and an audible signal is

given.

After three first level alerts, the

system triggers a new alert with a message, accompanied by a more

pronounced audible signal.

In certain driving conditions (poor

road surface or strong winds), the

system may give alerts independent of the driver's level of vigilance.

The driver drowsiness detection is

reinitialised when the ignition has

been switched off for a few minutes or the speed remains below 65 km/h for

a few minutes.

System limitationsIn the following situations, the system

may not operate properly or even not

operate at all:

● poor visibility caused by inadequate lighting of the

roadway, falling snow, heavy

rain, dense fog etc.● dazzle caused by headlamps of oncoming vehicles, low sun,

reflections on damp roads,

leaving a tunnel, alternating

shade and light etc.

● windscreen area in front of the camera covered by dirt, snow,

stickers etc.

● no lane markings detected or multiple lane markings due to

roadworks

● close vehicles ahead

● winding roads or narrow roadsFuel

Fuel for petrol engines The petrol engines are compatible

with bio-fuels that conform to current

and future European standards and

and can be obtained from filling

stations:

Petrol that meets the EN228

standard, mixed with a biofuel

meeting the EN15376 standard.

Fuel for diesel engines The Diesel engines are compatible

with bio-fuels that conform to current and future European standards and

and can be obtained from filling

stations:

Page 206 of 279

204Driving and operatingRefuelling9Danger

Before refuelling, switch off

ignition and any external heaters

with combustion chambers.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

A label with symbols at the fuel filler

flap is indicating the allowed fuel

types. In Europe the pump nozzles of the filling stations are marked with

these symbols. Refuel only the

allowed fuel type.

Caution

In case of misfuelling, do not

switch on ignition.

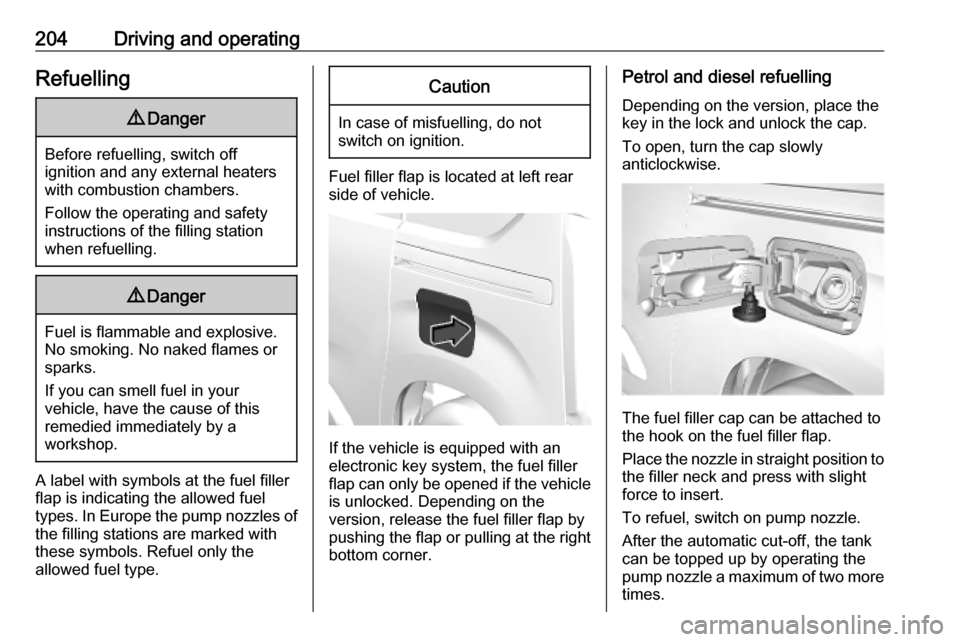

Fuel filler flap is located at left rear

side of vehicle.

If the vehicle is equipped with an

electronic key system, the fuel filler

flap can only be opened if the vehicle

is unlocked. Depending on the

version, release the fuel filler flap by

pushing the flap or pulling at the right bottom corner.

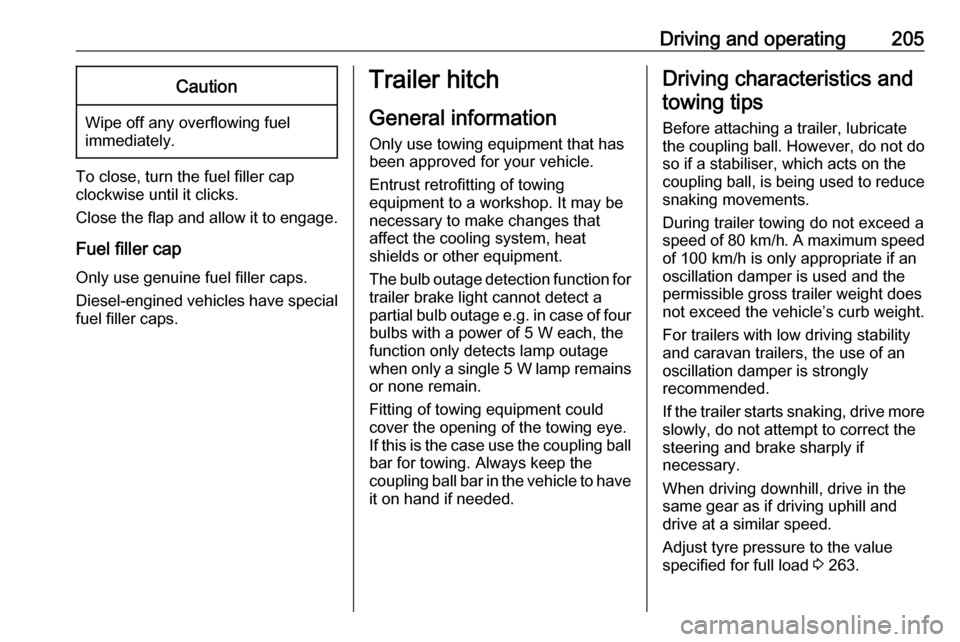

Petrol and diesel refuelling

Depending on the version, place the

key in the lock and unlock the cap.

To open, turn the cap slowly

anticlockwise.

The fuel filler cap can be attached to

the hook on the fuel filler flap.

Place the nozzle in straight position to the filler neck and press with slight

force to insert.

To refuel, switch on pump nozzle.

After the automatic cut-off, the tank can be topped up by operating the

pump nozzle a maximum of two more

times.

Page 207 of 279

Driving and operating205Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and allow it to engage.

Fuel filler cap

Only use genuine fuel filler caps.

Diesel-engined vehicles have special fuel filler caps.

Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage e.g. in case of four

bulbs with a power of 5 W each, the

function only detects lamp outage

when only a single 5 W lamp remains

or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle to have

it on hand if needed.Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 263.

Page 208 of 279

206Driving and operatingTrailer towingTrailer loadsThe permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross train weight also decreases by 10%

for every 1000 metres of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 254.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents.

Always aim for the maximum vertical

coupling load, especially in the case

of heavy trailers. The vertical coupling load should never fall below 25 kg.

Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

60 kg , the gross vehicle weight rating

must not be exceeded. If thepermissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

Towing equipment Depending on version the vehicle canbe fitted with a detachable or a fixed

coupling ball bar.

Type ACaution

When operating without a trailer,

remove the coupling ball bar.

Fitting the coupling ball bar

Page 212 of 279

210Vehicle careVehicle careGeneral Information...................210

Accessories and vehicle modifications .......................... 210

Vehicle storage ........................211

End-of-life vehicle recovery .....212

Vehicle checks ........................... 212

Performing work ......................212

Bonnet ..................................... 212

Engine oil ................................. 213

Engine coolant ......................... 214

Washer fluid ............................ 215

Brakes ..................................... 215

Brake fluid ............................... 215

Vehicle battery ......................... 215

Diesel fuel system bleeding .....217

Wiper blade replacement ........217

Bulb replacement .......................218

Halogen headlights ..................218

LED headlights ........................ 220

Front fog lights ......................... 220

Front turn lights .......................221

Tail lights ................................. 222

Side turn lights ......................... 224

Number plate light ...................225

Interior lights ............................ 225Electrical system........................225

Fuses ....................................... 225

Engine compartment fuse box . 226

Instrument panel fuse box .......227

Vehicle tools .............................. 228

Tools ........................................ 228

Wheels and tyres .......................229

Winter tyres ............................. 229

Tyre designations ....................230

Tyre pressure .......................... 230

Tyre deflation detection system .................................... 231

Tread depth ............................. 232

Changing tyre and wheel size . 233

Wheel covers ........................... 233

Tyre chains .............................. 233

Tyre repair kit .......................... 234

Wheel changing .......................237

Spare wheel ............................ 238

Jump starting ............................. 242

Towing ....................................... 243

Towing the vehicle ...................243

Towing another vehicle ...........244

Appearance care .......................245

Exterior care ............................ 245

Interior care ............................. 247General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 219 of 279

Vehicle care217● See the Owner's Manual forfurther information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.Wiper blade replacement

Windscreen

Switch off the ignition.

Within one minute after switching off

the ignition, operate the wiper lever to positon the wiper blades vertically on

the windscreen.

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade to the wiper

arm and push until it engages.

Lower the wiper arm carefully.

Rear window

Lift the wiper arm. Disengage the

wiper blade as shown in the

illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower the wiper arm carefully.

Page 220 of 279

218Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.

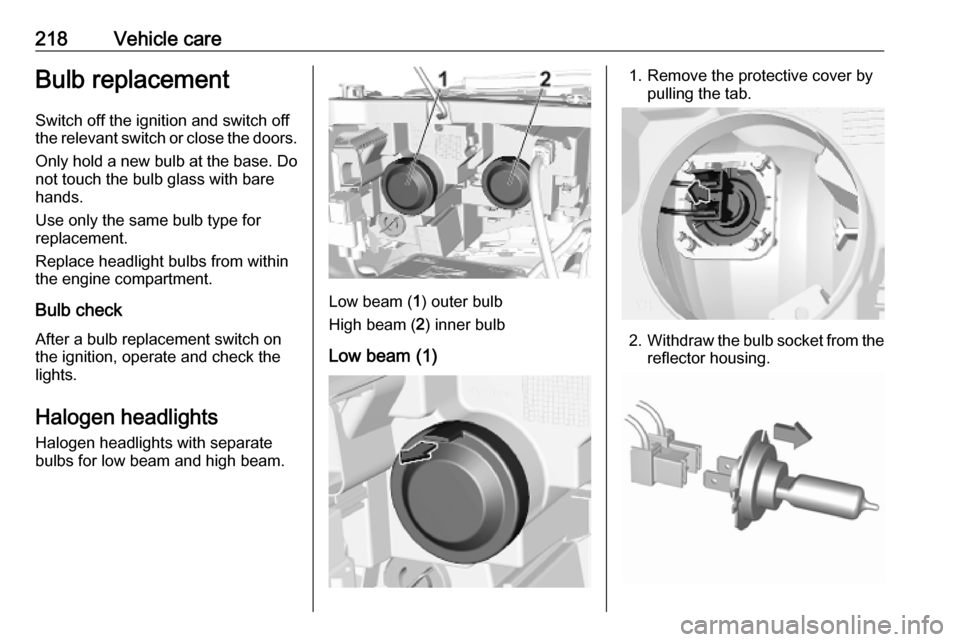

Halogen headlights

Halogen headlights with separate

bulbs for low beam and high beam.

Low beam ( 1) outer bulb

High beam ( 2) inner bulb

Low beam (1)

1. Remove the protective cover by pulling the tab.

2.Withdraw the bulb socket from the

reflector housing.

Page 222 of 279

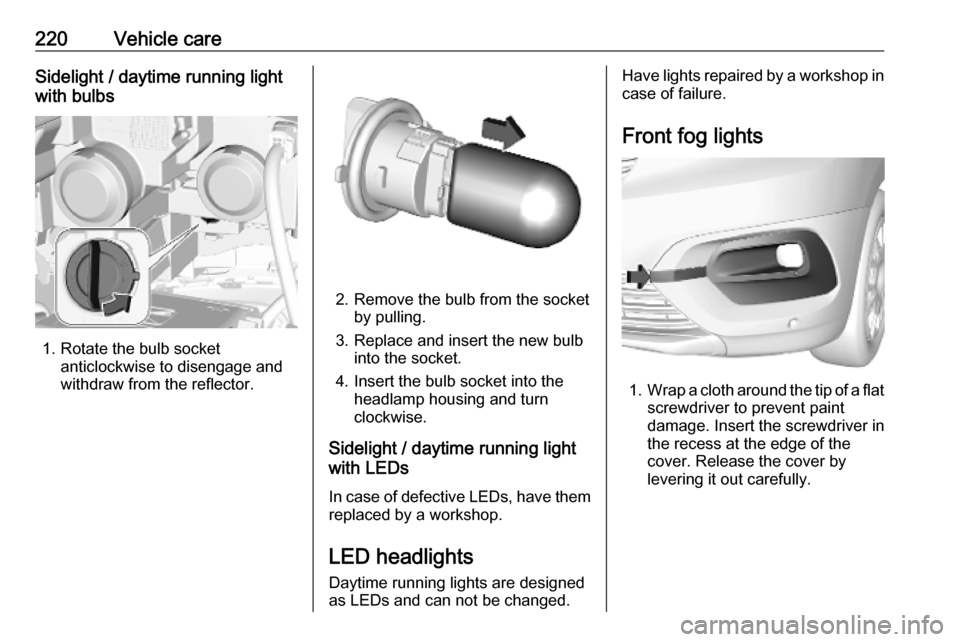

220Vehicle careSidelight / daytime running light

with bulbs

1. Rotate the bulb socket anticlockwise to disengage and

withdraw from the reflector.

2. Remove the bulb from the socket by pulling.

3. Replace and insert the new bulb into the socket.

4. Insert the bulb socket into the headlamp housing and turn

clockwise.

Sidelight / daytime running light

with LEDs

In case of defective LEDs, have them replaced by a workshop.

LED headlights Daytime running lights are designedas LEDs and can not be changed.

Have lights repaired by a workshop in

case of failure.

Front fog lights

1. Wrap a cloth around the tip of a flat

screwdriver to prevent paint

damage. Insert the screwdriver in

the recess at the edge of the

cover. Release the cover by

levering it out carefully.

Page 223 of 279

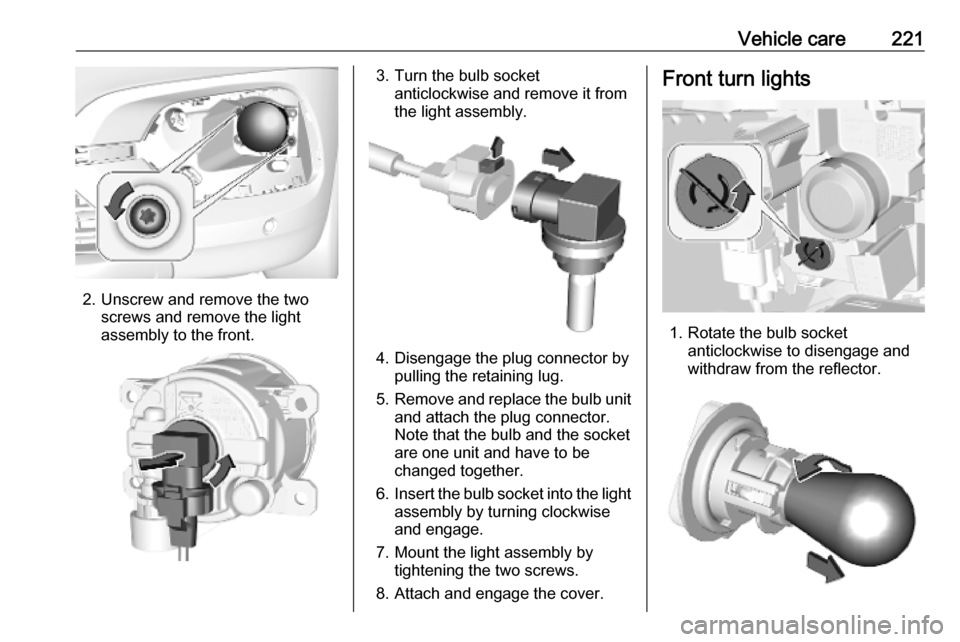

Vehicle care221

2. Unscrew and remove the twoscrews and remove the lightassembly to the front.

3. Turn the bulb socket anticlockwise and remove it from

the light assembly.

4. Disengage the plug connector by pulling the retaining lug.

5. Remove and replace the bulb unit

and attach the plug connector.

Note that the bulb and the socket

are one unit and have to be

changed together.

6. Insert the bulb socket into the light

assembly by turning clockwise

and engage.

7. Mount the light assembly by tightening the two screws.

8. Attach and engage the cover.

Front turn lights

1. Rotate the bulb socket anticlockwise to disengage and

withdraw from the reflector.

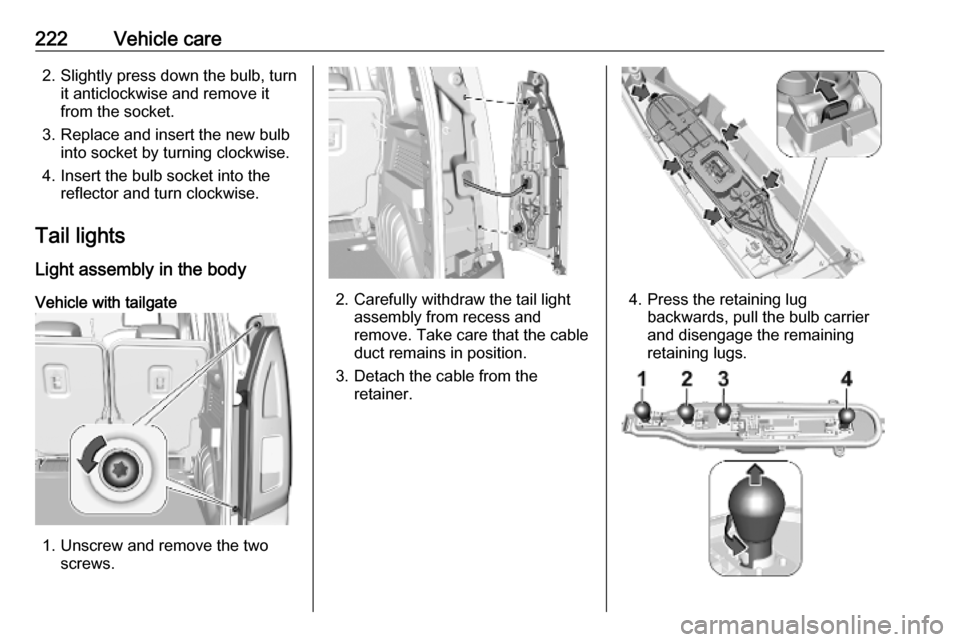

Page 224 of 279

222Vehicle care2. Slightly press down the bulb, turnit anticlockwise and remove it

from the socket.

3. Replace and insert the new bulb into socket by turning clockwise.

4. Insert the bulb socket into the reflector and turn clockwise.

Tail lights Light assembly in the body

Vehicle with tailgate

1. Unscrew and remove the two screws.

2. Carefully withdraw the tail lightassembly from recess and

remove. Take care that the cable

duct remains in position.

3. Detach the cable from the retainer.4. Press the retaining lug backwards, pull the bulb carrier

and disengage the remaining

retaining lugs.