torque OPEL COMBO E 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: COMBO E, Model: OPEL COMBO E 2020Pages: 283, PDF Size: 29.4 MB

Page 152 of 283

150Driving and operatingStarting the vehicle at low

temperatures

Starting the engine without additional

heaters is possible down to -25 °С for diesel engines and -30 °C for petrol

engines. Required is an engine oil

with the correct viscosity, the correct

fuel, performed services and a

sufficiently charged vehicle battery.

With temperatures below -30 °C the

automatic transmission requires a

warming phase of approx.

five minutes. The selector lever must

be in position P.

Heating functionalities Note

Individual heating functionalities,

such as heated seats or heated

steering wheel, may be temporarily

unavailable in the event of electrical

loading constraints. Functions will

be resumed after some minutes.Turbo engine warm-up

Upon start-up, engine available

torque may be limited for a short time, especially when the engine

temperature is cold. The limitation is

to allow the lubrication system to fully

protect the engine.

Overrun cut-off

The fuel supply is automatically cut off

during overrun, i.e. when the vehicle

is driven with a gear engaged but accelerator pedal is released.

Depending on driving conditions, the

overrun cut-off may be deactivated.

Stop-start system The stop-start system helps to save

fuel and to reduce the exhaust

emissions. When conditions allow, it

switches off the engine as soon as the

vehicle is at a low speed or at a

standstill, e.g. at a traffic light or in a

traffic jam.Activation

The stop-start system is available as

soon as the engine is started, the

vehicle starts-off and the conditions

as stated below in this section are

fulfilled.

The system is ready to operate when

the LED in the button Ò is not

illuminated. To activate the system

when the system is deactivated,

press Ó.

If the stop-start system is temporarily

not available and the button Ò is

pressed, the LED in the button

flashes.

Page 171 of 283

Driving and operating169A LED illuminates and a status

message appears in the Driver

Information Centre to confirm the

chosen mode.

ESC off mode 9

The ESC and Traction Control are

deactivated in this mode.

An LED in the button a illuminates.

ESC and Traction Control are

reactivated automatically from

50 km/h or everytime the ignition is

switched on.

Standard mode 2

This mode is calibrated for a low level

of wheel spin, based on the different

types of grip generally encountered in normal day to day driving.

Everytime the ignition is switched off,

the system is automatically reset to

this mode.

Snow mode 3

This mode adapts to the grip

conditions encountered by each

wheel when starting.When advancing, the system

optimises wheel spin to guarantee the

best acceleration based on the

available traction. Recommended in

cases of deep snow and steep

inclines.

This mode is active up to a speed of 50 km/h.

Mud mode 4

This mode allows considerable wheel

spin at start-up for the wheel with the

least grip, this removes mud and re-

establishes traction.

Simultaneously, the wheel with the

most grip is provided with the most

torque possible.

This mode is active up to a speed of

80 km/h.

Sand mode 1

This mode allows a small amount of simultaneous wheel spin on the two

drive wheels, enabling the vehicle to

advance and reduce the risk of

sinking.

This mode is active up to a speed of

120 km/h.Caution

Do not use the other modes on

sand as the vehicle may become

stuck.

Page 207 of 283

Driving and operating205driver, the system triggers the first

level of alert. The driver is notified by

a message and an audible signal is

given.

After three first level alerts, the

system triggers a new alert with a

message, accompanied by a more

pronounced audible signal.

In certain driving conditions (poor

road surface or strong winds), the

system may give alerts independent of the driver's level of vigilance.

The driver drowsiness detection is reinitialised when the ignition hasbeen switched off for a few minutes or

the speed remains below 65 km/h for a few minutes.

System limitations

In the following situations, the system

may not operate properly or even not operate at all:

● poor visibility caused by inadequate lighting of the

roadway, falling snow, heavy

rain, dense fog etc.● dazzle caused by headlights of oncoming vehicles, low sun,

reflections on damp roads,

leaving a tunnel, alternating

shade and light etc.

● windscreen area in front of the camera covered by dirt, snow,

stickers etc.

● no lane markings detected or multiple lane markings due to

roadworks

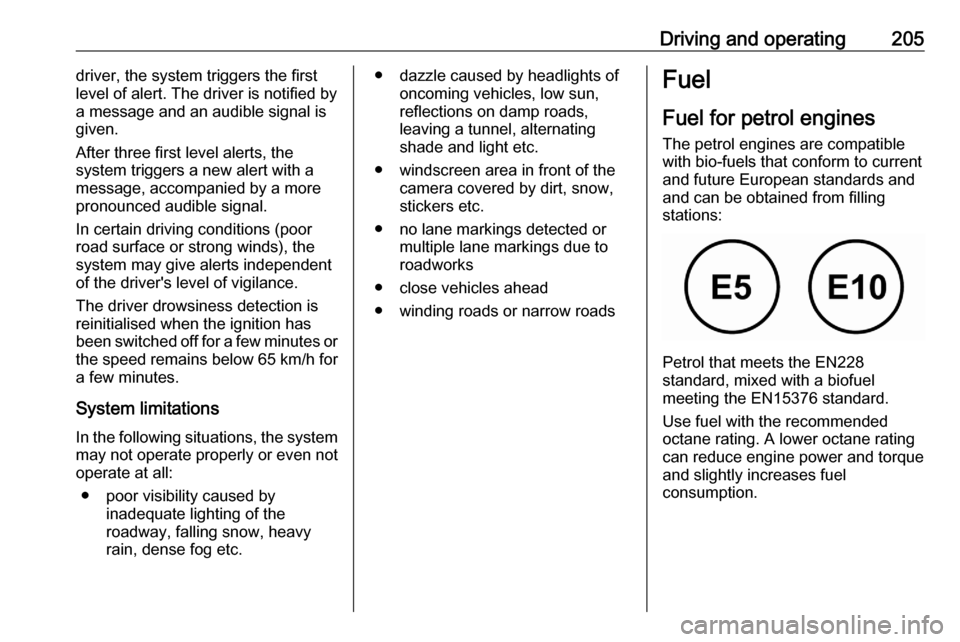

● close vehicles ahead ● winding roads or narrow roadsFuel

Fuel for petrol engines The petrol engines are compatible

with bio-fuels that conform to current

and future European standards and

and can be obtained from filling

stations:

Petrol that meets the EN228

standard, mixed with a biofuel

meeting the EN15376 standard.

Use fuel with the recommended

octane rating. A lower octane rating

can reduce engine power and torque

and slightly increases fuel

consumption.

Page 243 of 283

Vehicle care241Repeat the checking procedure

once more after driving further

10 km but no more than ten

minutes to check that there is no

more loss of pressure.

If the tyre pressure has fallen

below 150 kPa (1.5 bar), the

vehicle must not be used. Seek

the assistance of a workshop.

17. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of 700 kPa (7 bar).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Wheel changing Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

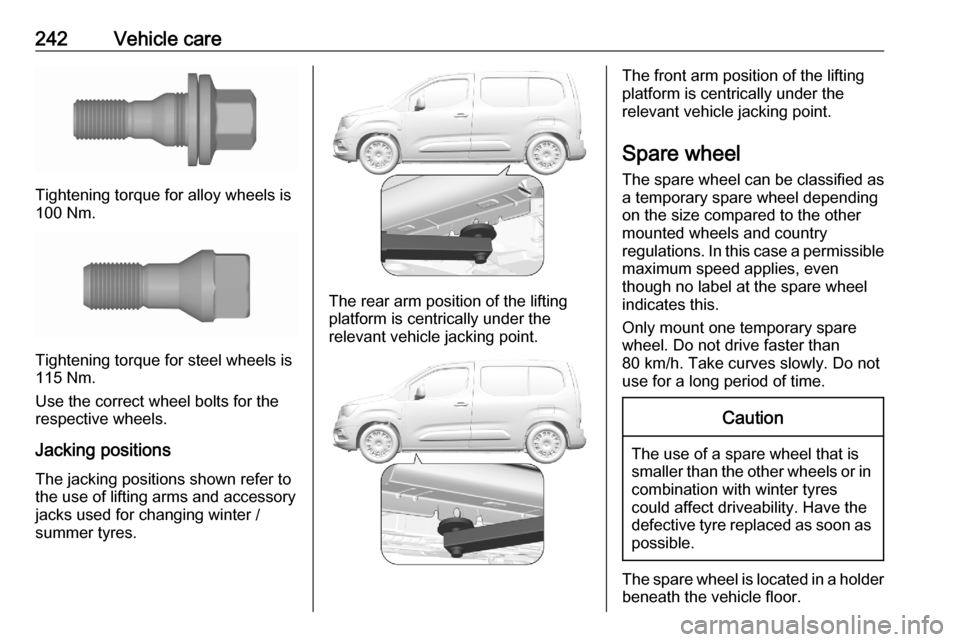

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

There are two different types of

wheels with two different bolts and tightening torques.

Page 244 of 283

242Vehicle care

Tightening torque for alloy wheels is

100 Nm.

Tightening torque for steel wheels is

115 Nm.

Use the correct wheel bolts for the respective wheels.

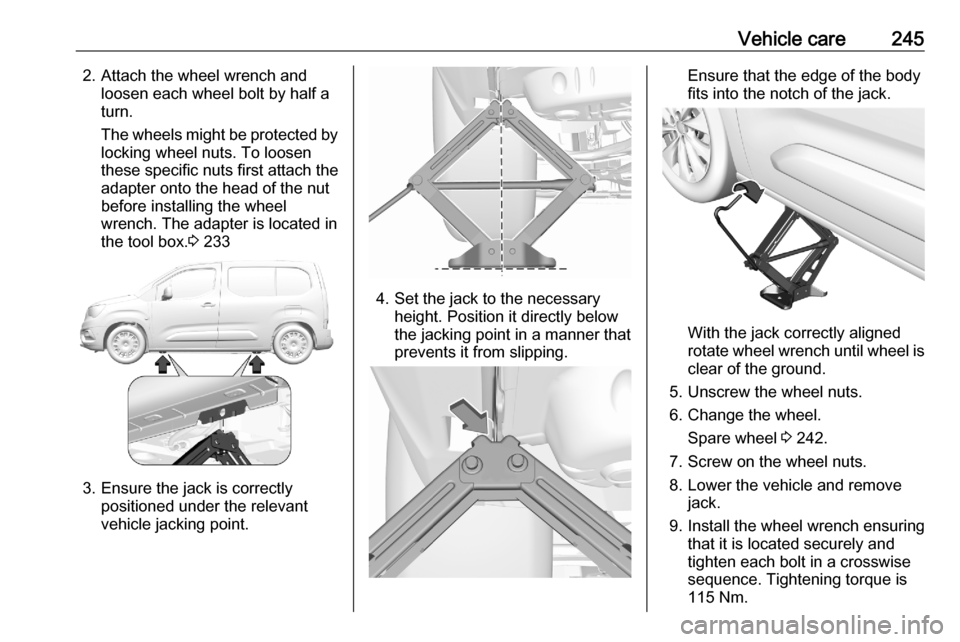

Jacking positions The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

The rear arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

The front arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

Page 247 of 283

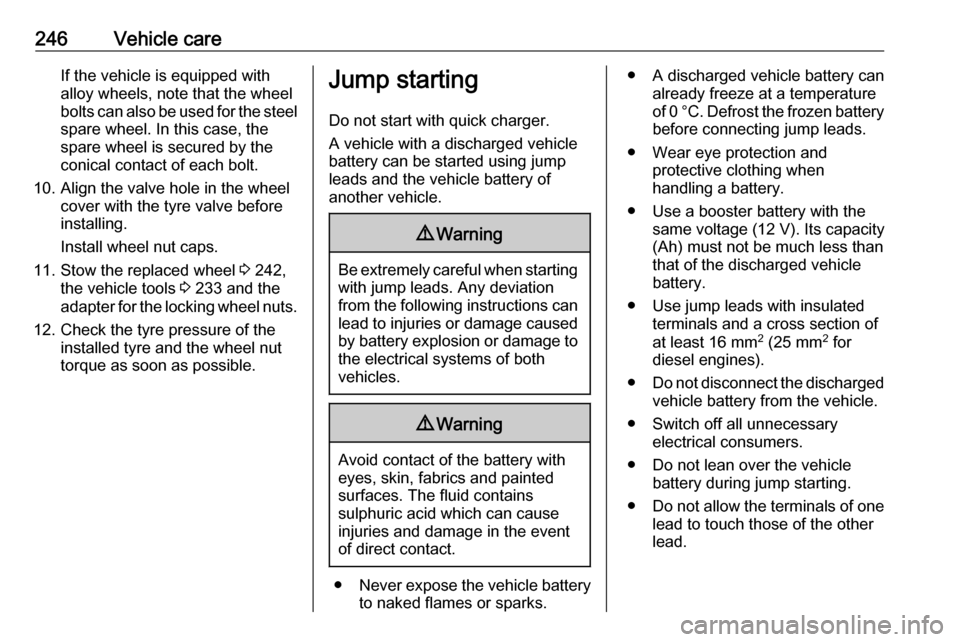

Vehicle care2452. Attach the wheel wrench andloosen each wheel bolt by half a

turn.

The wheels might be protected by locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the tool box. 3 233

3. Ensure the jack is correctly

positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.

With the jack correctly aligned

rotate wheel wrench until wheel is

clear of the ground.

5. Unscrew the wheel nuts.

6. Change the wheel. Spare wheel 3 242.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

115 Nm.

Page 248 of 283

246Vehicle careIf the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 242,

the vehicle tools 3 233 and the

adapter for the locking wheel nuts.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

Page 265 of 283

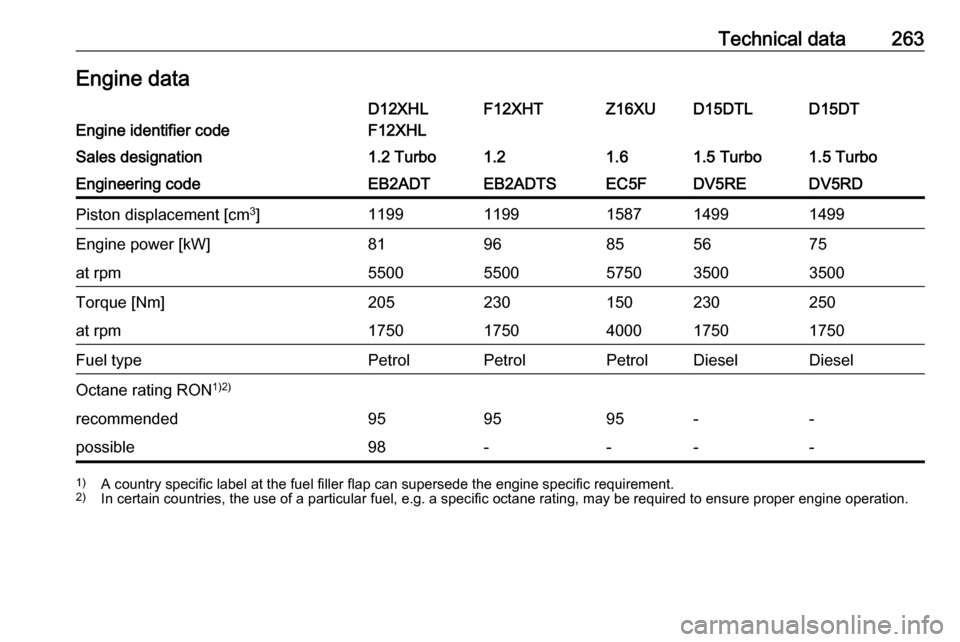

Technical data263Engine dataEngine identifier code

D12XHL

F12XHLF12XHTZ16XUD15DTLD15DTSales designation1.2 Turbo1.21.61.5 Turbo1.5 TurboEngineering codeEB2ADTEB2ADTSEC5FDV5REDV5RDPiston displacement [cm 3

]11991199158714991499Engine power [kW]8196855675at rpm55005500575035003500Torque [Nm]205230150230250at rpm17501750400017501750Fuel typePetrolPetrolPetrolDieselDieselOctane rating RON 1)2)recommended959595--possible98----1)

A country specific label at the fuel filler flap can supersede the engine specific requirement.

2) In certain countries, the use of a particular fuel, e.g. a specific octane rating, may be required to ensure proper engine operation.

Page 266 of 283

![OPEL COMBO E 2020 Manual user 264Technical dataEngine identifier codeD15DTHA16DTB16DTLB16DTSales designation1.5 Turbo1.6 Turbo1.6 Turbo1.6 TurboEngineering codeDV5RCDV6DDV6FEDV6FDPiston displacement [cm3

]1499156015601560Engine po OPEL COMBO E 2020 Manual user 264Technical dataEngine identifier codeD15DTHA16DTB16DTLB16DTSales designation1.5 Turbo1.6 Turbo1.6 Turbo1.6 TurboEngineering codeDV5RCDV6DDV6FEDV6FDPiston displacement [cm3

]1499156015601560Engine po](/img/37/18815/w960_18815-265.png)

264Technical dataEngine identifier codeD15DTHA16DTB16DTLB16DTSales designation1.5 Turbo1.6 Turbo1.6 Turbo1.6 TurboEngineering codeDV5RCDV6DDV6FEDV6FDPiston displacement [cm3

]1499156015601560Engine power [kW]96685574at rpm3750400035003750Torque [Nm]300230210255at rpm1750175017501750Fuel typeDieselDieselDieselDiesel