tyre pressure OPEL CORSA E 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: CORSA E, Model: OPEL CORSA E 2017.5Pages: 269, PDF Size: 7.97 MB

Page 149 of 269

Driving and operating147Starting offDepress the brake pedal and move

the selector lever to D/M or R. If D is

selected, transmission is in automatic mode and first gear is engaged. If R

is selected, reverse gear is engaged.

The vehicle starts to move when the

brake pedal is released.

To start-off without depressing the

brake pedal, accelerate immediately

after engaging a gear as long as D or

R flashes.

If neither the accelerator nor the

brake pedal are depressed, no gear

is engaged and D or R flashes for a

brief time in the display.

Stopping the vehicle

In D, first gear is engaged and the

clutch is released when the vehicle is

stopped. In R, reverse gear remains

engaged.Engine braking

Automatic mode

When driving downhill, the manual

transmission automated does not shift into higher gears until a fairly

high engine speed has been reached. It shifts down in good time when

braking.

Manual mode

To utilise the engine braking effect,

select a lower gear in good time when

driving downhill. Changing into

manual mode is only possible while the engine is running or during an

Autostop.

Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud or snow. Move the selector

lever between R and D in a repeat

pattern. Do not race the engine and

avoid sudden acceleration.Parking

The most recently engaged gear (see transmission display) remains

engaged when switching off ignition.

With N, no gear is engaged.

Therefore always apply the parking

brake when switching off ignition. If

parking brake is not applied, P flashes

in the transmission display and the

key cannot be removed from the

ignition switch. P stops flashing in the

transmission display as soon as the

parking brake is slightly applied.

When the ignition is switched off, the

transmission no longer responds to

movement of the selector lever.

Tyre pressure monitoring system To start the sensor matching process

of the tyre pressure monitoring

system, the selector lever must be

moved and held in position N for

five seconds. P illuminates in the

transmission display to indicate that

the sensor matching process can be

started.

Tyre pressure monitoring system

3 215.

Page 187 of 269

Driving and operating185Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for trailer brake light cannot detect a

partial bulb outage, e.g. in case of four

times five watt bulbs, the function only detects lamp outage when only a

single five Watt lamp remains or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle when

not in use.Driving characteristics and

towing tips

Before attaching a trailer, lubricatethe coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1000 kg a speed of 80 km/h must not

be exceeded; the use of a stabiliser is

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 253.Trailer towing

Trailer loadsThe permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%

The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).

Page 192 of 269

190Vehicle careVehicle careGeneral Information...................191

Accessories and vehicle modifications .......................... 191

Vehicle storage ........................191

End-of-life vehicle recovery .....192

Vehicle checks ........................... 192

Performing work ......................192

Bonnet ..................................... 192

Engine oil ................................. 193

Engine coolant ......................... 194

Washer fluid ............................ 195

Brakes ..................................... 196

Brake fluid ............................... 196

Vehicle battery ......................... 196

Diesel fuel system bleeding .....198

Wiper blade replacement ........198

Bulb replacement .......................199

Halogen headlights ..................199

Xenon headlights .....................201

Fog lights ................................. 202

Front turn signal lights .............203

Tail lights ................................. 203

Side turn signal lights ..............205

Centre high-mounted brake light ......................................... 206Number plate light...................206

Interior lights ............................ 206

Instrument panel illumination ...206

Electrical system ........................207

Fuses ....................................... 207

Engine compartment fuse box . 208

Instrument panel fuse box .......210

Vehicle tools .............................. 212

Tools ........................................ 212

Wheels and tyres .......................213

Winter tyres ............................. 213

Tyre designations ....................213

Tyre pressure .......................... 213

Tyre pressure monitoring system .................................... 215

Tread depth ............................. 219

Changing tyre and wheel size . 219

Wheel covers ........................... 219

Tyre chains .............................. 220

Tyre repair kit .......................... 220

Wheel changing .......................225

Spare wheel ............................ 228

Jump starting ............................. 230

Towing ....................................... 231

Towing the vehicle ...................231

Towing another vehicle ...........232Appearance care .......................233

Exterior care ............................ 233

Interior care ............................. 236

Page 193 of 269

Vehicle care191General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps may be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

Page 215 of 269

Vehicle care213Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 253.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.Tyre designations

E.g. 195/55 R 16 95 H195:tyre width, mm55:cross-section ratio (tyre height

to tyre width), percentageR:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgH:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 247.

Directional tyres

Directional tyres must be mounted so

that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.

Page 216 of 269

214Vehicle careTyre pressure 3 253.

The tyre pressure information label on the right door frame indicates theoriginal equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code. Engine data 3 245.

● Identify the respective tyre. ● The tyre pressure tables show all

possible tyre combinations

3 253.For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting on the page Tyre load in the Driver

Information Centre 3 97.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,

which does not indicate an air leak.

Page 217 of 269

Vehicle care215Tyre pressure monitoringsystem

The tyre pressure monitoring system checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu ? in the Driver Information

Centre.

The menu can be selected by

pressing the buttons on the turn

signal lever.

Press MENU to select the Vehicle

Information Menu ? .

Turn the adjuster wheel to select the

tyre pressure monitoring system.

Midlevel display:

The tyre pressure for each tyre is

displayed on its own page.

Uplevel display:

Page 218 of 269

216Vehicle careThe tyre pressures for all tyres are

displayed on one page.

System status and pressure warnings are displayed by a message

indicating the corresponding tyre in the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 213.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 95.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 253.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 103.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information label

or tyre pressure chart 3 253, and

select the appropriate setting in the

menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 97 . This setting is

the reference for the tyre pressure warnings.

Page 219 of 269

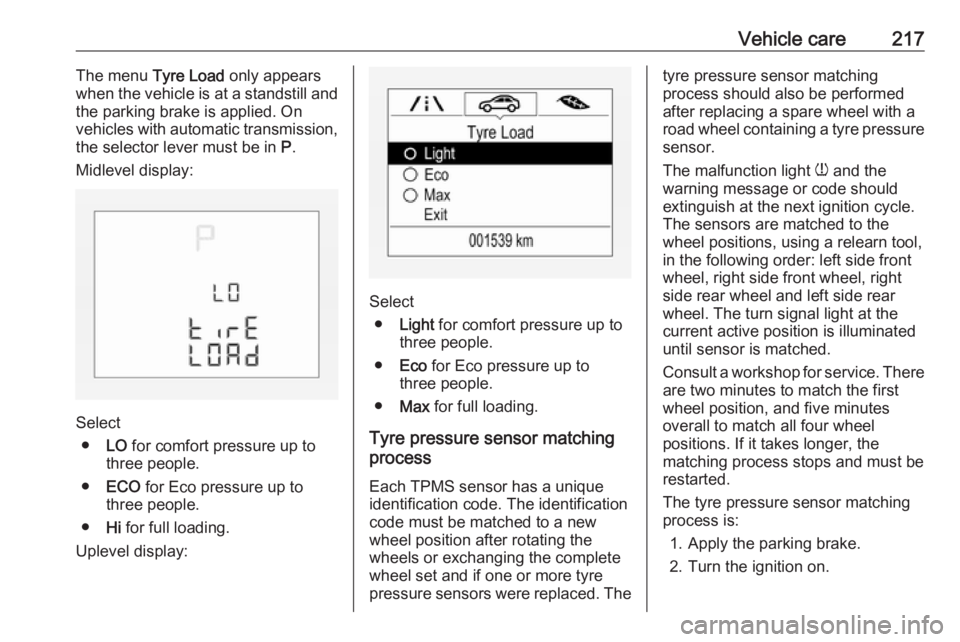

Vehicle care217The menu Tyre Load only appears

when the vehicle is at a standstill and

the parking brake is applied. On

vehicles with automatic transmission, the selector lever must be in P.

Midlevel display:

Select ● LO for comfort pressure up to

three people.

● ECO for Eco pressure up to

three people.

● Hi for full loading.

Uplevel display:

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Tyre pressure sensor matching process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more tyre

pressure sensors were replaced. The

tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

Page 220 of 269

218Vehicle care3. On vehicles with automatictransmission: set the selector

lever to P.

On vehicles with manual

transmission automated: Keep

brake pedal depressed. Move and hold the selector lever for five

seconds to position N until P is

displayed in the Driver

Information Centre. P indicates

that the tyre pressure sensor

matching process can be started.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the

Driver Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate that the sensor

identification code has been