battery OPEL CORSA E 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: CORSA E, Model: OPEL CORSA E 2017.5Pages: 269, PDF Size: 7.97 MB

Page 200 of 269

198Vehicle careMeaning of symbols:● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of the reach of children.

● The vehicle battery contains sulfuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's manual for further information.

● Explosive gas may be present in the vicinity of the battery.

Diesel fuel system bleeding

If the tank has been run dry, the diesel fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.Wiper blade replacement

Lift the wiper arm until it stays in the

raised position. Press the catches on

both sides, tilt wiper blade at a 90°

angle to the wiper arm and remove

upwards.

Insert in reverse order.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 210 of 269

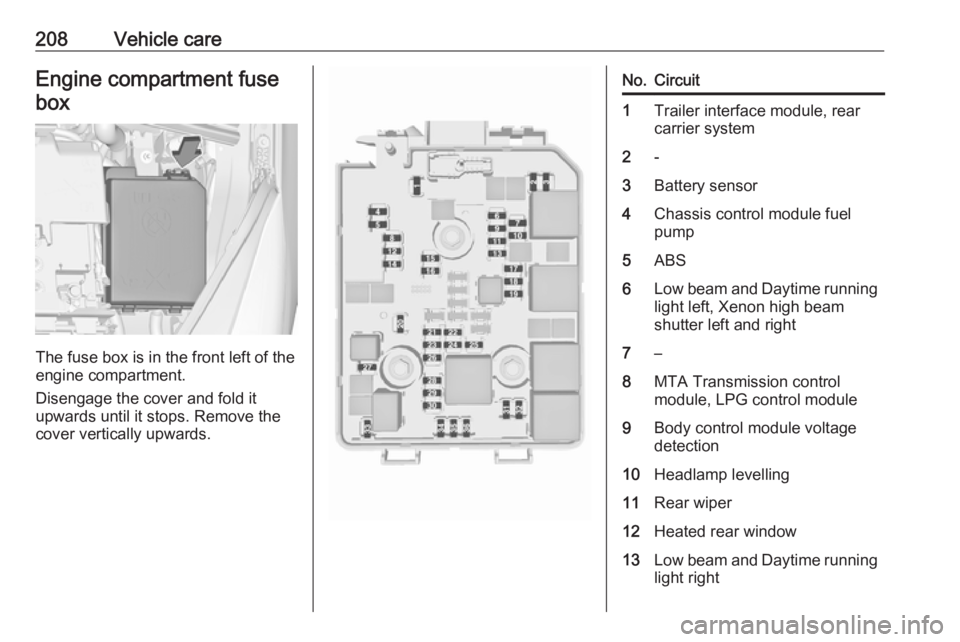

208Vehicle careEngine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and fold it

upwards until it stops. Remove the

cover vertically upwards.

No.Circuit1Trailer interface module, rear

carrier system2-3Battery sensor4Chassis control module fuel

pump5ABS6Low beam and Daytime running

light left, Xenon high beam

shutter left and right7–8MTA Transmission control

module, LPG control module9Body control module voltage

detection10Headlamp levelling11Rear wiper12Heated rear window13Low beam and Daytime running

light right

Page 224 of 269

222Vehicle care9. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressureshould be obtained within ten

minutes.

Tyre pressure 3 253.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor for

longer than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

Page 226 of 269

224Vehicle care

3. Position the sealant bottle on thebracket. Make sure that the bottle

does not fall.

4. Unscrew valve cap from defective

tyre.

5. Screw tyre inflation hose to valve.

6. Screw air hose onto compressor connection.

7. Switch on ignition. To avoid discharging the battery,

we recommend running the

engine.

8. Press on/off switch on the compressor. The tyre is filled withsealant.

9. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

10. All of the sealant is pumped into the tyre. Then the tyre is inflated.

11. The prescribed tyre pressure should be obtained within ten

minutes.

Tyre pressure 3 253.

When the correct pressure is

obtained, switch off the

compressor by pressing the on/off

switch again.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for ten minutes. If the prescribed tyre pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Release excess tyre pressure

using ].

Do not run the compressor for

longer than ten minutes.

12. Push catch on bracket to remove sealant bottle from bracket. Screw

the tyre inflation hose to the free

connection of the sealant bottle.

Page 232 of 269

230Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.

Page 233 of 269

Vehicle care2313. Connect the black lead to thenegative terminal of the booster

vehicle battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Insert a screwdriver in the slot at the

lower part of the cap. Release the cap

by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 212.

Page 264 of 269

262IndexAAccessories and vehicle modifications .......................... 191

Adjustable air vents ...................131

Airbag and belt tensioners ...........91

Airbag deactivation ................49, 92

Airbag label................................... 44 Airbag system .............................. 44

Air conditioning regular operation ................................ 132

Air conditioning system .............. 124

Air intake .................................... 131

Air vents...................................... 131

Antilock brake system ................ 149

Antilock brake system (ABS) .......93

Anti-theft alarm system ................28

Anti-theft locking system .............. 28

Appearance care ........................233

Ashtrays ....................................... 83

Automatic anti-dazzle ..................31

Automatic light control ...............114

Automatic locking ........................26

Automatic transmission .............141

Autostop ............................... 96, 136

B Battery discharge protection ......122

Battery voltage ........................... 105

Belts.............................................. 41

Bicycle rack .................................. 59Bonnet ....................................... 192

Brake and clutch fluid .................238

Brake and clutch system .............93

Brake assist ............................... 150

Brake fluid .................................. 196

Brakes ............................... 149, 196

Breakdown.................................. 231

Bulb replacement ....................... 199

C Capacities .................................. 252

Car Pass ...................................... 23

Catalytic converter .....................141

Central locking system ................24

Centre high-mounted brake light 206

Changing tyre and wheel size ...219

Charging system .......................... 92

Child locks ................................... 26

Child restraint installation locations ................................... 52

Child restraints.............................. 50

Child restraint systems ................50

Cigarette lighter ........................... 83

City mode ................................... 153

Climate control ............................. 17

Climate control systems .............123

Clock ............................................ 80

Code ........................................... 103

Collision damage repair ..............257

Colour-Info-Display .....................101

Page 268 of 269

266Upholstery.................................. 236

Using this manual ..........................3

V Vehicle battery ........................... 196

Vehicle checks............................ 192 Vehicle data ................................ 242

Vehicle data recording and privacy ..................................... 259

Vehicle detected ahead ................96

Vehicle dimensions .................... 251

Vehicle Identification Number ....240

Vehicle jack ................................ 212

Vehicle messages .....................103

Vehicle personalisation .............106

Vehicle security ............................ 28

Vehicle specific data ......................3

Vehicle storage ........................... 191

Vehicle tools ............................... 212

Vehicle unlocking ........................... 6

Vehicle weight ........................... 249

Ventilation ................................... 123

W

Warning chimes .........................105

Warning lights ............................... 83

Warning triangle .......................... 72

Washer and wiper systems .........16

Washer fluid ............................... 195

Wheel changing .........................225

Wheel covers ............................. 219Wheels and tyres .......................213

Windows ....................................... 32

Windscreen................................... 32 Windscreen wiper/washer ...........77

Winter tyres ............................... 213

Wiper blade replacement ..........198

X Xenon headlights .......................201

Xenon lighting system ................116