front OPEL CORSA E 2017.5 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: CORSA E, Model: OPEL CORSA E 2017.5Pages: 269, PDF Size: 7.97 MB

Page 213 of 269

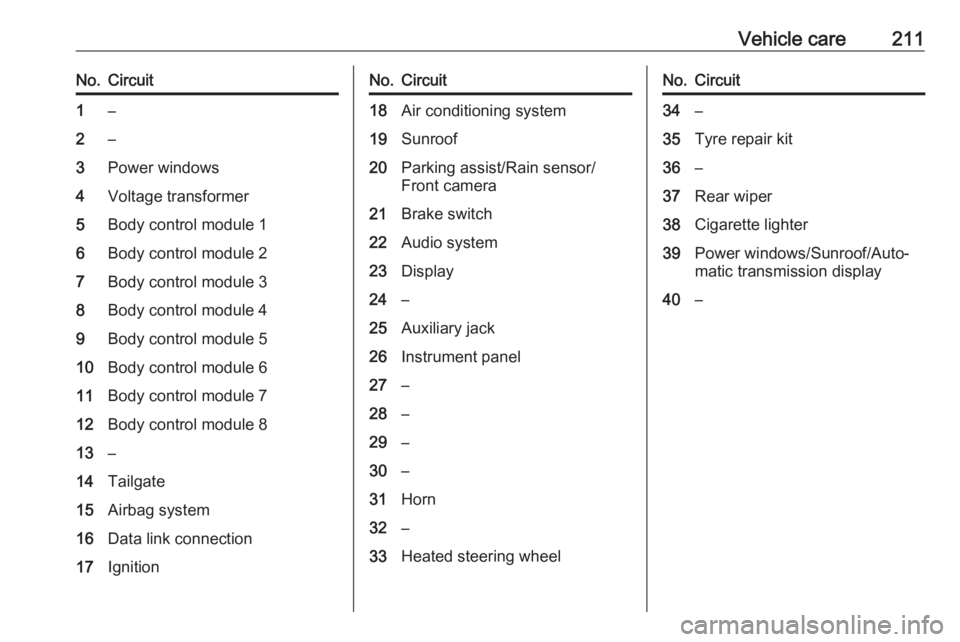

Vehicle care211No.Circuit1–2–3Power windows4Voltage transformer5Body control module 16Body control module 27Body control module 38Body control module 49Body control module 510Body control module 611Body control module 712Body control module 813–14Tailgate15Airbag system16Data link connection17IgnitionNo.Circuit18Air conditioning system19Sunroof20Parking assist/Rain sensor/

Front camera21Brake switch22Audio system23Display24–25Auxiliary jack26Instrument panel27–28–29–30–31Horn32–33Heated steering wheelNo.Circuit34–35Tyre repair kit36–37Rear wiper38Cigarette lighter39Power windows/Sunroof/Auto‐

matic transmission display40–

Page 215 of 269

Vehicle care213Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 253.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.Tyre designations

E.g. 195/55 R 16 95 H195:tyre width, mm55:cross-section ratio (tyre height

to tyre width), percentageR:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgH:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 247.

Directional tyres

Directional tyres must be mounted so

that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.

Page 219 of 269

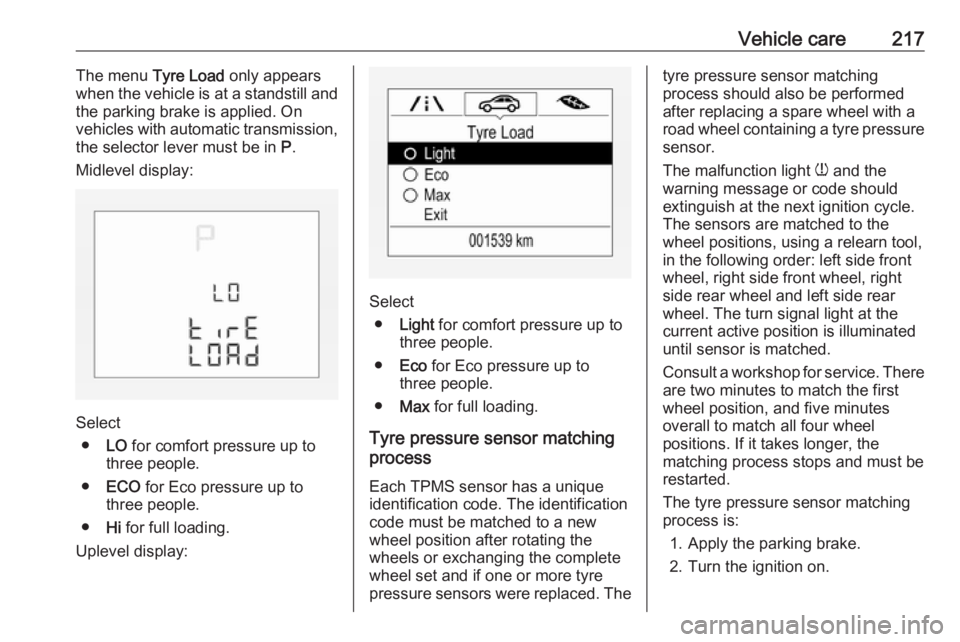

Vehicle care217The menu Tyre Load only appears

when the vehicle is at a standstill and

the parking brake is applied. On

vehicles with automatic transmission, the selector lever must be in P.

Midlevel display:

Select ● LO for comfort pressure up to

three people.

● ECO for Eco pressure up to

three people.

● Hi for full loading.

Uplevel display:

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Tyre pressure sensor matching process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more tyre

pressure sensors were replaced. The

tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

Page 220 of 269

218Vehicle care3. On vehicles with automatictransmission: set the selector

lever to P.

On vehicles with manual

transmission automated: Keep

brake pedal depressed. Move and hold the selector lever for five

seconds to position N until P is

displayed in the Driver

Information Centre. P indicates

that the tyre pressure sensor

matching process can be started.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the

Driver Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate that the sensor

identification code has been

Page 222 of 269

220Vehicle careIf the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts, do not attach wheel

covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

Page 227 of 269

Vehicle care225This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

13. Remove any excess sealant using a cloth.

14. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

15. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

16. Stow away tyre repair kit in load compartment.General information

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

Page 230 of 269

228Vehicle careRear arm position of the lifting

platform located centrally under the

recess of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

3-door/5-door hatchback

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Fitting a double load-bay floor in this

case in the upper position 3 70.

To remove, unscrew wing nut, lift

spare wheel, move to a vertical

position and remove from above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always secure

with the wing nut.Delivery van

Remove load floor.

The spare wheel is screwed down

together with the floor cover.

Unscrew wing nut and lift load cover.

Page 231 of 269

Vehicle care229

Remove spacer above the spare

wheel, lift the wheel, move to a

vertical position and remove from

above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always insert

the adapter and secure the load cover with the wing nut.

Depending on the defective replaced

wheel, the spacer can be omitted if

necessary, or the wheel can be bolted down without the floor cover.

Temporary spare wheelCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full size tyre in the

rear.

Tyre chains 3 220.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 234 of 269

232Vehicle care

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: the vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Vehicles with manual transmission

automated: the vehicle must only be

towed facing forwards with the front axle raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap at the top and engage

downwards.

Towing another vehicle

Insert a screwdriver in the slot at the

lower bend of the cap. Release the

cap by carefully moving the

screwdriver downwards.

The towing eye is stowed with the

vehicle tools 3 212.

Page 243 of 269

Technical data241Identification plate

The identification plate is located on

the left or right door frame.

Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weight rating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg8:vehicle-specific or country-

specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables use the

engine identifier code. The engine

data table additionally shows the

engineering code. Engine data

3 245.

To identify the respective engine,

refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The Certificate of Conformity shows

the engine identifier code, other

national publications may show the

engineering code. Check piston

displacement and engine power to

identify the respective engine.