brake sensor OPEL CORSA E 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CORSA E, Model: OPEL CORSA E 2019Pages: 231, PDF Size: 6.87 MB

Page 64 of 231

62Storage●Use the hook at the right sidewall

of the load compartment for

hanging up carrier bags.

Maximum load: 5 kg.

● Do not allow the load to protrude above the upper edge of the

backrests.

● Do not place any objects on the load compartment cover or theinstrument panel.

● Do not cover the sensor on top of

the instrument panel.

● The load must not obstruct the operation of the pedals, parking

brake and gear selector lever, or

hinder the freedom of movement of the driver. Do not place any

unsecured objects in the interior.

● Do not drive with an open load compartment.9Warning

Always make sure that the load in

the vehicle is securely stowed.

Otherwise objects can be thrown

around inside the vehicle and

cause personal injury or damage

to the load or vehicle.

● The payload is the difference between the permitted gross

vehicle weight (see identification

plate 3 206) and the EC kerb

weight.

To calculate the payload, enter

the data for your vehicle in the

weights table at the front of this

manual.

The EC kerb weight includes

weights for the driver (68 kg),

luggage (7 kg) and all fluids (fuel

tank 90% full).

Optional equipment and

accessories increase the kerb

weight.

● Driving with a roof load increases

the sensitivity of the vehicle to

cross-winds and has a

detrimental effect on vehicle

handling due to the vehicle's

higher centre of gravity.

Distribute the load evenly and secure it properly with retaining

straps. Adjust the tyre pressure

and vehicle speed according to

the load conditions. Check and

retighten the straps frequently.

Do not drive faster than

120 km/h.

The permissible roof load is

75 kg. The roof load is the

combined weight of the roof rack and the load.

Page 83 of 231

Instruments and controls81or

Fault due to sensors that are dirty or

covered by ice or snow

or

Interference due to external sources of ultrasound. Once the source ofinterference is removed, the system

will operate normally.

Have the cause of the fault in the

system remedied by a workshop.

Parking assist 3 141.

Electronic Stability Control and Traction Control system

b flashes or illuminates yellow.

Flashes

The system is actively engaged.

Engine output may be reduced and

the vehicle may be braked

automatically to a small degree.

Illuminates

A fault in the system is present. A

warning message or warning code

appears in the Driver Information

Centre. Continued driving is possible.The system is not operational. Driving stability, however, may deteriorate

depending on road surface

conditions.

Have the cause of the fault remedied

by a workshop.

Electronic Stability Control 3 133.

Traction Control system 3 133.

Exhaust filter

% illuminates or flashes yellow.

The exhaust filter requires cleaning.

Continue driving until %

extinguishes. If possible, do not allow engine speed to drop below

2000 rpm.

Illuminates

The exhaust filter is full. Start cleaning

process as soon as possible.

Flashes

The maximum filling level of the filter

is reached. Start cleaning process

immediately to avoid damage to the

engine.

Exhaust filter 3 125.Stop-start system 3 122.

Tyre pressure monitoring system

w illuminates or flashes yellow.

Illuminates

Tyre pressure loss. Stop immediately

and check tyre pressure.

Flashes

Fault in system or tyre without

pressure sensor mounted ( e.g. spare

wheel). After 60-90 seconds the

control indicator illuminates

continuously. Consult a workshop.

Tyre pressure monitoring system

3 180.

Engine oil pressure

I illuminates red.

Illuminates when the ignition is

switched on and extinguishes shortly

after the engine starts.

Page 92 of 231

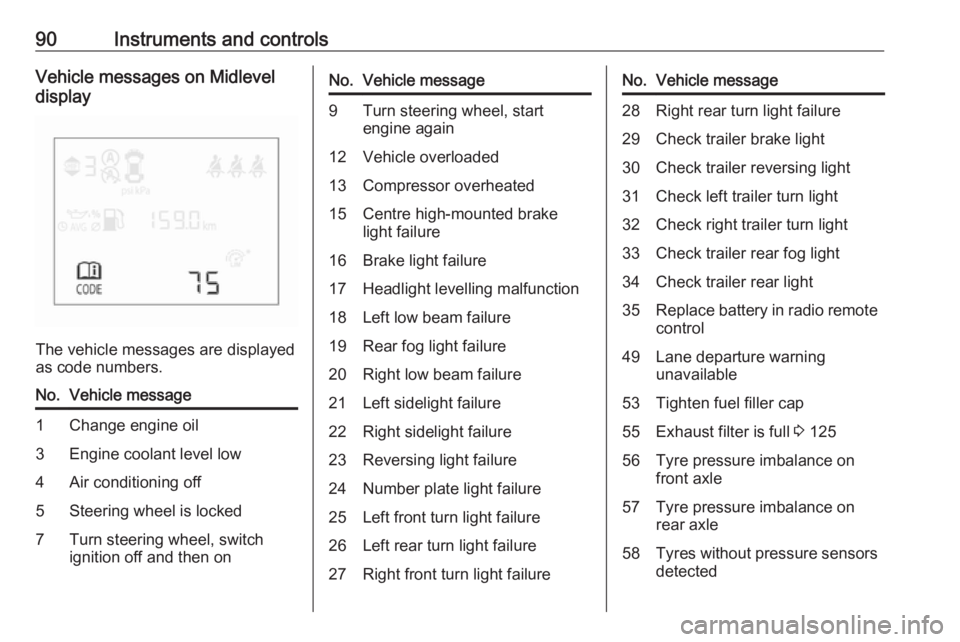

90Instruments and controlsVehicle messages on Midlevel

display

The vehicle messages are displayed

as code numbers.

No.Vehicle message1Change engine oil3Engine coolant level low4Air conditioning off5Steering wheel is locked7Turn steering wheel, switch

ignition off and then onNo.Vehicle message9Turn steering wheel, start

engine again12Vehicle overloaded13Compressor overheated15Centre high-mounted brake

light failure16Brake light failure17Headlight levelling malfunction18Left low beam failure19Rear fog light failure20Right low beam failure21Left sidelight failure22Right sidelight failure23Reversing light failure24Number plate light failure25Left front turn light failure26Left rear turn light failure27Right front turn light failureNo.Vehicle message28Right rear turn light failure29Check trailer brake light30Check trailer reversing light31Check left trailer turn light32Check right trailer turn light33Check trailer rear fog light34Check trailer rear light35Replace battery in radio remote

control49Lane departure warning

unavailable53Tighten fuel filler cap55Exhaust filter is full 3 12556Tyre pressure imbalance on

front axle57Tyre pressure imbalance on

rear axle58Tyres without pressure sensors

detected

Page 142 of 231

140Driving and operatingGeneral information9Warning

Forward collision alert is just a

warning system and does not

apply the brakes. When

approaching a vehicle ahead too

rapidly, it may not provide you

enough time to avoid a collision.

The driver accepts full

responsibility for the appropriate

following distance based on traffic, weather and visibility conditions.

The complete attention of the

driver is always required while

driving. The driver must always be

ready to take action and apply the

brakes.

System limitations

The system is designed to warn of vehicles only, but may react also to

other objects.

In the following cases, forward

collision alert may not detect a vehicle ahead or sensor performance is

limited:

● on winding roads

● when weather limits visibility, e.g.

fog, rain, or snow

● when the sensor is blocked by snow, ice, slush, mud, dirt,

windscreen damage or affected

by foreign items, e.g. stickers

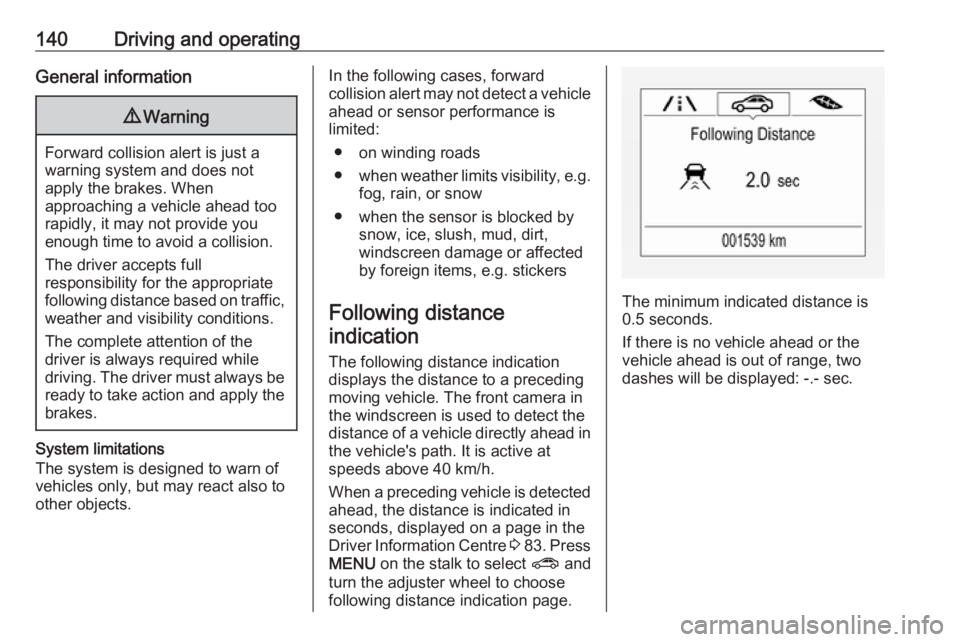

Following distance indication

The following distance indication

displays the distance to a preceding

moving vehicle. The front camera in

the windscreen is used to detect the

distance of a vehicle directly ahead in

the vehicle's path. It is active at

speeds above 40 km/h.

When a preceding vehicle is detected

ahead, the distance is indicated in

seconds, displayed on a page in the

Driver Information Centre 3 83 . Press

MENU on the stalk to select ? and

turn the adjuster wheel to choose following distance indication page.

The minimum indicated distance is 0.5 seconds.

If there is no vehicle ahead or the

vehicle ahead is out of range, two

dashes will be displayed: -.- sec.

Page 176 of 231

174Vehicle careNo.Circuit1-2-3Battery sensor4Chassis control module, fuel

pump5ABS6Low beam and daytime running

light left, Xenon high beam7–8LPG control module9Body control module10Headlamp levelling11Rear wiper12Heated rear window13Low beam and daytime running

light right14Heated exterior mirror15–No.Circuit16Brake booster kit17Ignition signal, waterpump18Engine control module19Fuel pump20–21Engine solenoids, engine

sensors22–23Ignition coils, injectors24Washer system25–26Engine sensors27Engine management28Engine control module29Engine control module30Engine control module31High beam left, Xenon low

beam leftNo.Circuit32High beam right, Xenon low

beam right33Engine control module34Horn35Air condition compressor clutch36Front fog lights

Page 178 of 231

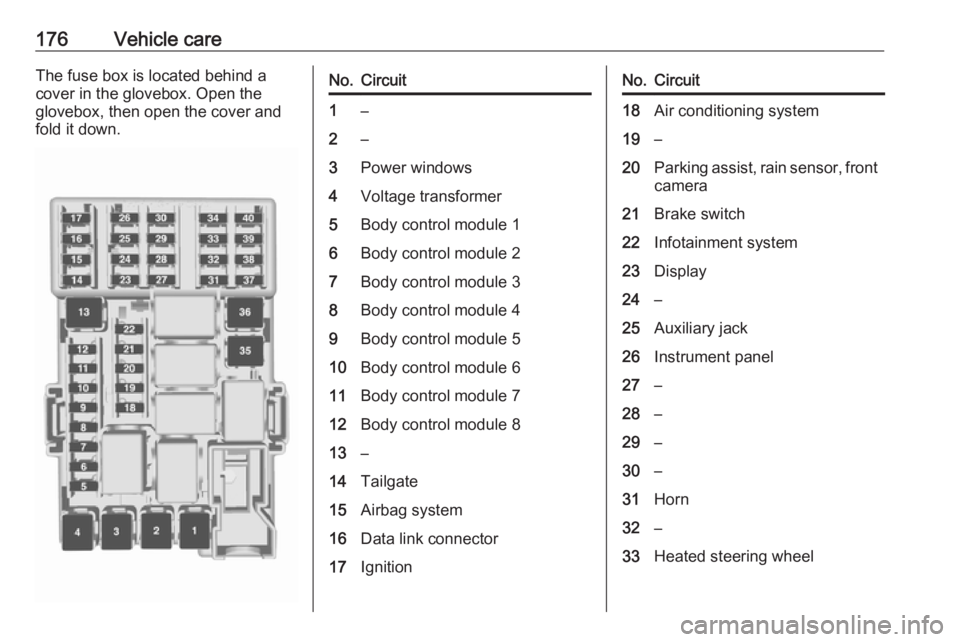

176Vehicle careThe fuse box is located behind a

cover in the glovebox. Open the

glovebox, then open the cover and

fold it down.No.Circuit1–2–3Power windows4Voltage transformer5Body control module 16Body control module 27Body control module 38Body control module 49Body control module 510Body control module 611Body control module 712Body control module 813–14Tailgate15Airbag system16Data link connector17IgnitionNo.Circuit18Air conditioning system19–20Parking assist, rain sensor, front camera21Brake switch22Infotainment system23Display24–25Auxiliary jack26Instrument panel27–28–29–30–31Horn32–33Heated steering wheel

Page 184 of 231

182Vehicle careThe use of commercially-availableliquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre

pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

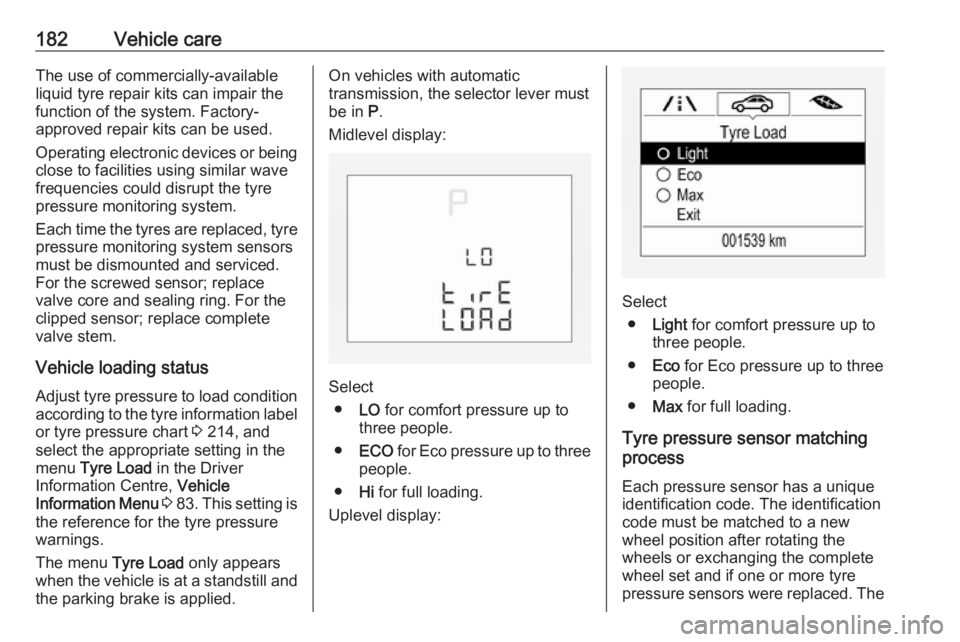

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 214, and

select the appropriate setting in the menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 83 . This setting is

the reference for the tyre pressure

warnings.

The menu Tyre Load only appears

when the vehicle is at a standstill and

the parking brake is applied.On vehicles with automatic

transmission, the selector lever must

be in P.

Midlevel display:

Select ● LO for comfort pressure up to

three people.

● ECO for Eco pressure up to three

people.

● Hi for full loading.

Uplevel display:

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Tyre pressure sensor matching

process

Each pressure sensor has a unique identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more tyre

pressure sensors were replaced. The

Page 185 of 231

Vehicle care183tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle. The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn light at the current

active position is illuminated until

sensor is matched.

Consult a workshop for service. There

are 2 minutes to match the first wheel position, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

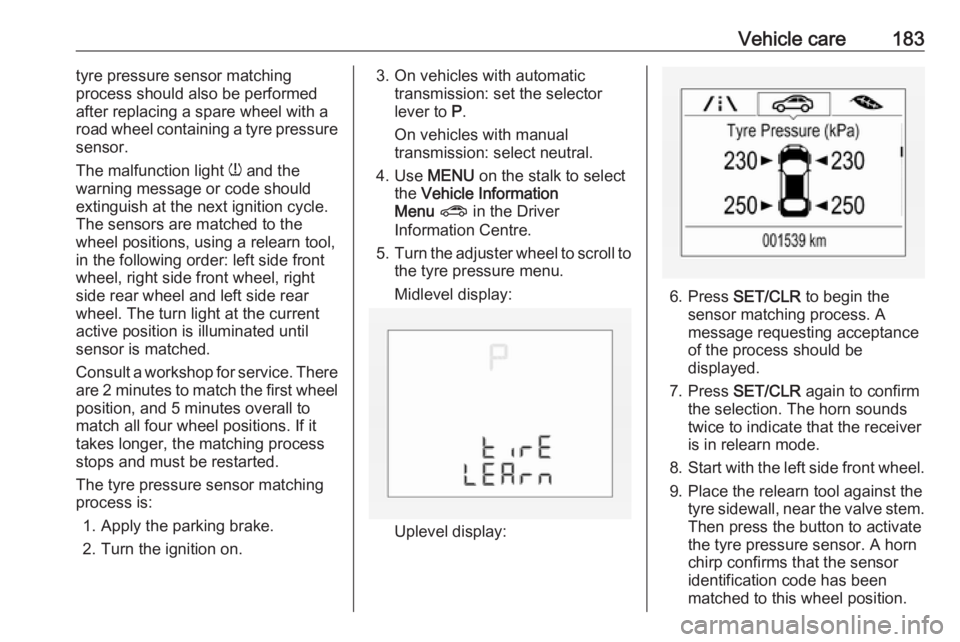

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the stalk to select

the Vehicle Information

Menu ? in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

Page 223 of 231

Customer information221Operating data in the vehicleControl units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate,

"seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board

the vehicle itself. Control units often

include data storage (including the

vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.Depending on technical equipment

levels, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,brakes)

● system reactions in special driving situations (e.g. triggering

of an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating datawhich is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.