tyre pressure OPEL CORSA F 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: CORSA F, Model: OPEL CORSA F 2020Pages: 229, PDF Size: 21.14 MB

Page 186 of 229

184Vehicle care4.Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the bracket on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

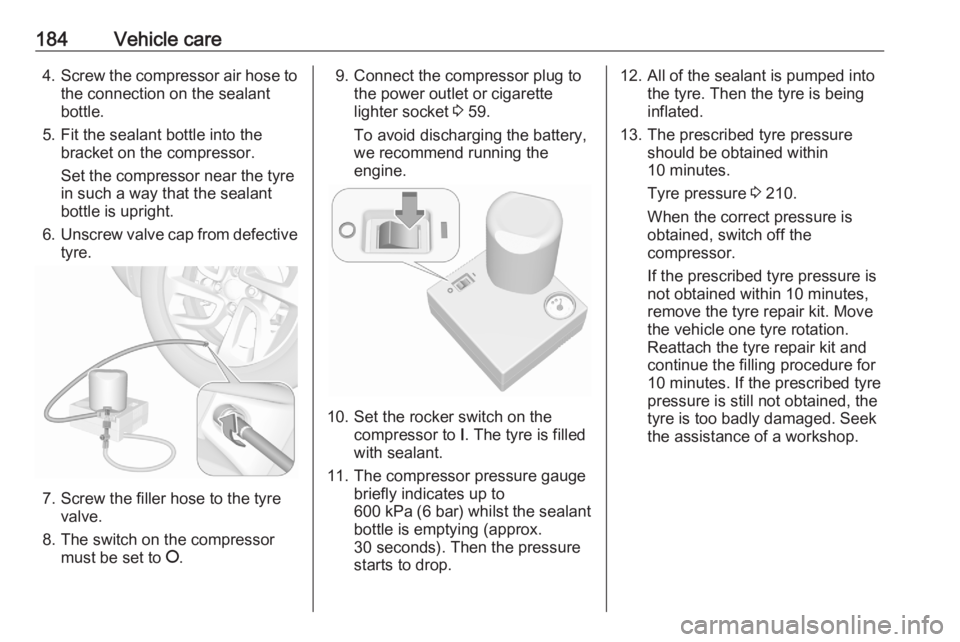

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket 3 59.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to

600 kPa (6 bar) whilst the sealant

bottle is emptying (approx.

30 seconds). Then the pressure

starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is being

inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes.

Tyre pressure 3 210.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for 10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Page 187 of 229

Vehicle care185

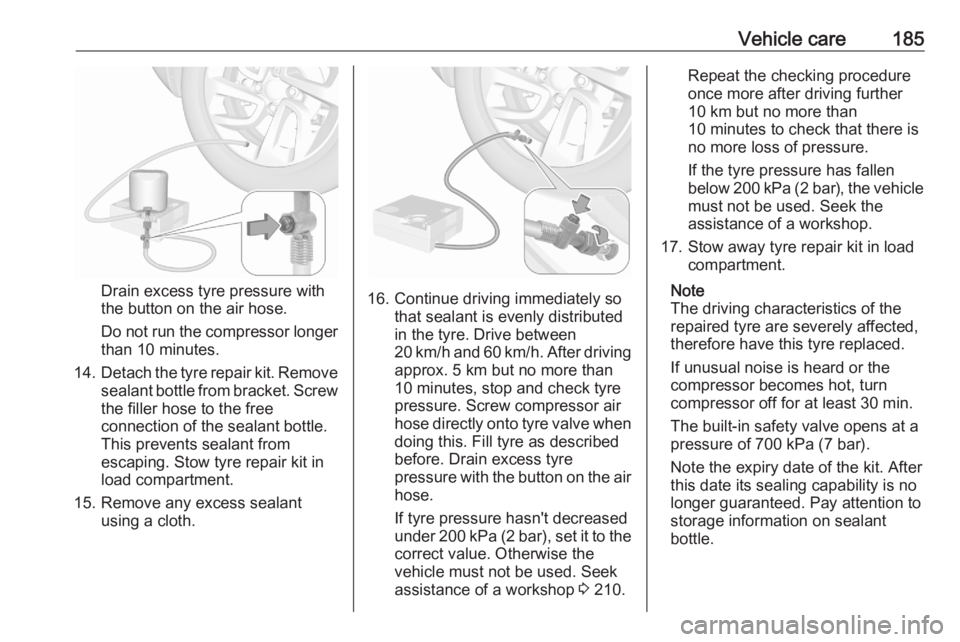

Drain excess tyre pressure with

the button on the air hose.

Do not run the compressor longer

than 10 minutes.

14. Detach the tyre repair kit. Remove

sealant bottle from bracket. Screw

the filler hose to the free connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.16. Continue driving immediately sothat sealant is evenly distributed

in the tyre. Drive between

20 km/h and 60 km/h. After driving approx. 5 km but no more than

10 minutes, stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve when

doing this. Fill tyre as described

before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 200 kPa (2 bar), set it to the

correct value. Otherwise the vehicle must not be used. Seek

assistance of a workshop 3 210.

Repeat the checking procedure

once more after driving further

10 km but no more than

10 minutes to check that there is

no more loss of pressure.

If the tyre pressure has fallen

below 200 kPa (2 bar), the vehicle must not be used. Seek the

assistance of a workshop.

17. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of 700 kPa (7 bar).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Page 192 of 229

190Vehicle careWith the jack correctly aligned

rotate wheel wrench until wheel is

clear of the ground.

5. Unscrew the wheel nuts.

6. Change the wheel.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence.

Tightening torque for 15" is

100 Nm and for 16" is 115 Nm.

If the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Vehicles with wheel cover: Align the valve hole in the wheel cover

with the tyre valve before

installing.

Install wheel nut caps.11. Stow the replaced wheel, the vehicle tools and the adapter forthe locking wheel nuts 3 178.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

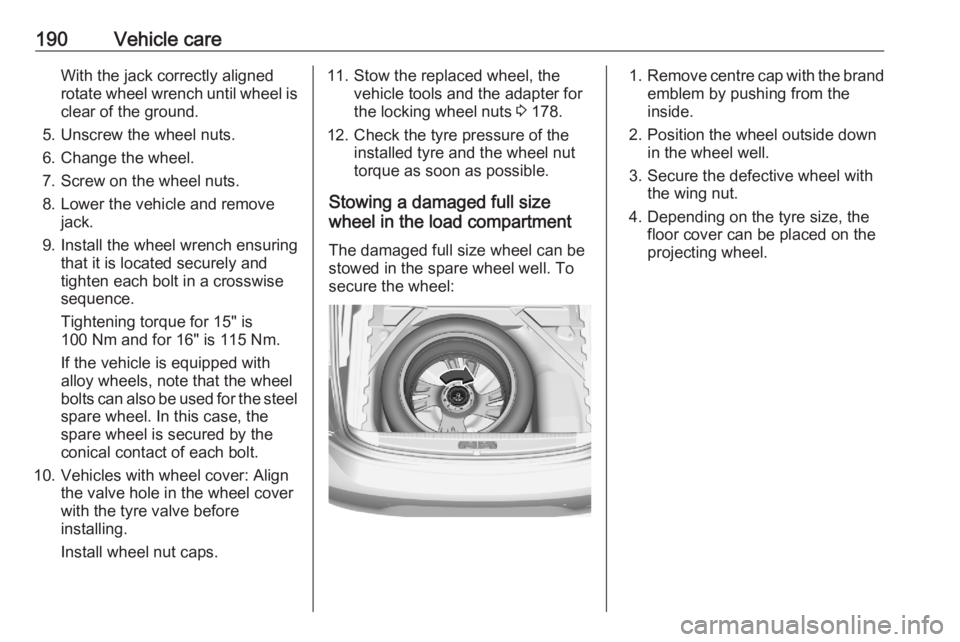

Stowing a damaged full size

wheel in the load compartment

The damaged full size wheel can be

stowed in the spare wheel well. To

secure the wheel:1. Remove centre cap with the brand

emblem by pushing from the

inside.

2. Position the wheel outside down in the wheel well.

3. Secure the defective wheel with the wing nut.

4. Depending on the tyre size, the floor cover can be placed on the

projecting wheel.

Page 197 of 229

Vehicle care195Have the door hinges of all doors

greased by a workshop.

Do not use hard objects to remove

spots of tar. Use tar removal spray on

painted surfaces.

Exterior lights Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Plastic body parts must not be treated with wax or polishing agents.

Windows and wiper blades Switch off wipers before handling in

their areas.

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner. Also

make sure to remove any residues

such as wax, insect residues and

similar from the window.

Ice residues, pollution and continuous

wiping on dry windows will damage or even destroy the wiper blades.

Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.Paintwork damage

Rectify minor paintwork damage witha touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check the underbody and have it waxed if

necessary.

Bitumen / rubber materials could damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Towing equipment

Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.

Page 205 of 229

Technical data203Technical dataVehicle identification..................203

Vehicle identification number ..203

Identification plate ...................203

Engine identification ................204

Vehicle data ............................... 205

Recommended fluids and lubricants ................................ 205

Engine data ............................. 207

Performance ............................ 208

Vehicle dimensions .................209

Capacities ................................ 210

Tyre pressures ........................ 211Vehicle identification

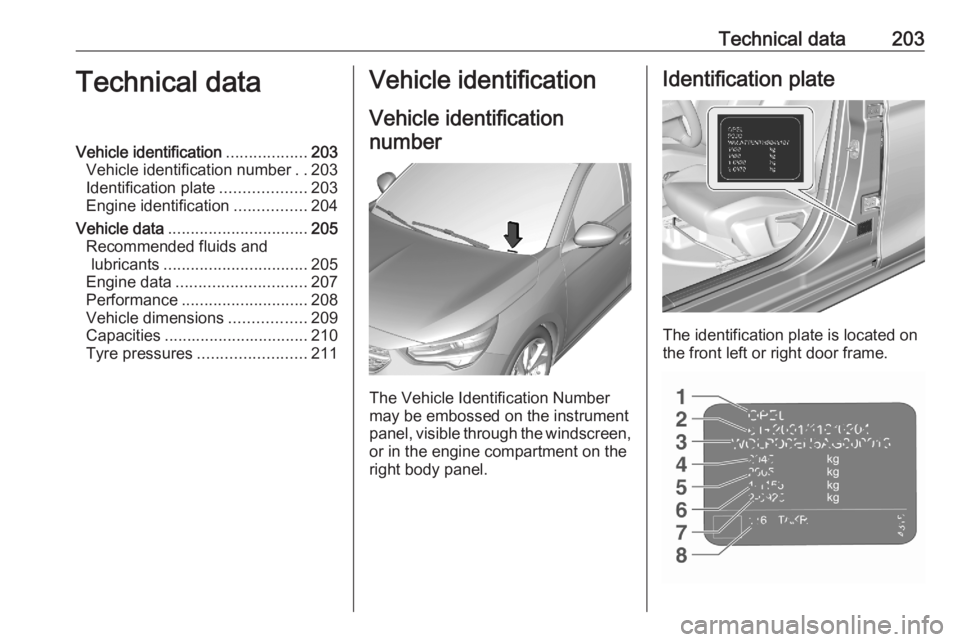

Vehicle identificationnumber

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen, or in the engine compartment on the

right body panel.

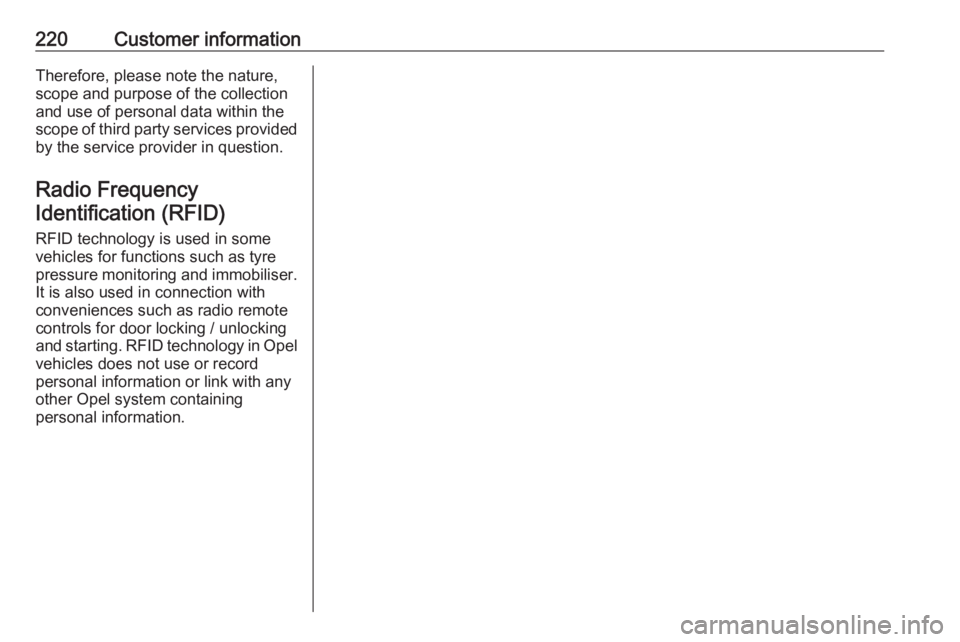

Identification plate

The identification plate is located on

the front left or right door frame.

Page 213 of 229

![OPEL CORSA F 2020 Manual user Technical data211Tyre pressuresVehicle with up to 3 peopleWith full loadEngineTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])EB2FA185/65 R15,

195/55 R16,

20 OPEL CORSA F 2020 Manual user Technical data211Tyre pressuresVehicle with up to 3 peopleWith full loadEngineTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])EB2FA185/65 R15,

195/55 R16,

20](/img/37/18833/w960_18833-212.png)

Technical data211Tyre pressuresVehicle with up to 3 peopleWith full loadEngineTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])EB2FA185/65 R15,

195/55 R16,

205/45 R17

195/55 R16220/2.2 (32)210/2.1 (30)270/2.7 (39)290/2.9 (42)EB2ADTD,

EB2ADTS

DV5RD195/55 R16,

205/45 R17220/2.2 (32)210/2.1 (30)270/2.7 (39)290/2.9 (42)AllTemporary spare wheel 115/70 R15420/4.2 (60)420/4.2 (60)420/4.2 (60)420/4.2 (60)

Page 219 of 229

Customer information217Vehicle data recording

and privacy

Event data recorders Electronic control units are installed in

your vehicle. Control units process

data which is received by vehicle

sensors, for example, or which they

generate themselves or exchange

amongst themselves. Some control

units are necessary for the safe

functioning of your vehicle, others

assist you while you drive (driver

assistance systems), while others

provide comfort or infotainment

functions.

The following contains general

information about data processing in

the vehicle. You will find additional

information as to which specific data

is uploaded, stored and passed on to third parties and for what purpose in

your vehicle under the key word Data Protection closely linked to the

references for the affected functional

characteristics in the relevant owner's

manual or in the general terms of

sale. These are also available online.Operating data in the vehicle

Control units process data for

operation of the vehicle.

This data includes, for example: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate,

"seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient and is not stored for longer than an

operational cycle, and only processed

on board the vehicle itself. Often

control units include data storage

(including the vehicle key). This is

used to allow information to be

documented temporarily or

permanently on vehicle condition,

component stress, maintenance

requirements and technical events

and errors.Depending on technical equipment

levels, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggeringof an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.

Page 222 of 229

220Customer informationTherefore, please note the nature,

scope and purpose of the collection

and use of personal data within the

scope of third party services provided by the service provider in question.

Radio Frequency Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and immobiliser.

It is also used in connection with

conveniences such as radio remote

controls for door locking / unlocking

and starting. RFID technology in Opel vehicles does not use or record

personal information or link with any other Opel system containing

personal information.

Page 227 of 229

225QQuickheat ..................................... 96

R

Radio Frequency Identification (RFID) ..................................... 220

Radio remote control ...................10

Rain sensor .................................. 72

REACH ....................................... 214

Reading lights .............................. 87

Rear floor storage cover ..............51

Rear fog light .................72, 86, 172

Rear view camera ...................... 150

Rear window wiper and washer ..58

Recommended fluids and lubricants ........................ 201, 205

Refuelling ................................... 157

Registered trademarks ...............216

Reversing lights ........................... 86

Ride control systems ..................118

Roadside assistance ....................78

Roller blinds ................................. 26

Roof .............................................. 26

Roof load ...................................... 52

Roof rack ..................................... 51

S

Seat belt reminder .......................66

Seat belts ..................................... 32

Seat heating ................................. 31

Seat position ................................ 28Selective catalytic reduction .......107

Selector lever.............................. 111

Service ................................. 97, 198

Service display ............................ 65

Service information ....................198

Service vehicle soon .................... 68

Side airbag system ......................38

Side blind spot alert ....................146

Sidelights ...................................... 80

Smart access ........................ 12, 100

Software acknowledgement .......214

Software update ......................... 216

SOS .............................................. 78

Spare wheel ............................... 187

Speed limiter............................... 122

Speedometer ............................... 63

Starting and operating ..................99

Starting the engine ....................101

Steering ........................................ 99

Steering wheel adjustment ..........55

Steering wheel controls ...............55

Stop engine .................................. 68

Stop-start system........................ 103

Storage ......................................... 47

Storage compartments .................47

Sunvisor lights ............................. 87

Sun visors .................................... 25

Symbols ......................................... 4

System check ............................... 68T

Tachometer ................................. 64

Tailgate ......................................... 18

Tail lights ................................... 172

Three-point seat belt .................... 33 Tools .......................................... 178

Tow bar....................................... 158

Towing ................................ 158, 192

Towing another vehicle .............193

Towing the vehicle .....................192

Traffic sign assistant ...................151

Trailer coupling ........................... 158

Trailer towing ............................. 159

Transmission display .................110

Tread depth ............................... 181

Trip odometer .............................. 63

Turn lights .............................. 66, 85

Tyre chains ................................ 182

Tyre deflation detection system . 180

Tyre designations ......................179

Tyre pressure ............................ 179

Tyre pressures ........................... 211

Tyre repair kit ............................. 183

U

Ultrasonic parking assist............. 138

Upholstery .................................. 196

USB port ....................................... 59

Using this manual ..........................3