battery OPEL CROSSLAND X 2017.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.75, Model line: CROSSLAND X, Model: OPEL CROSSLAND X 2017.75Pages: 245, PDF Size: 7.6 MB

Page 177 of 245

Vehicle care175Vehicle careGeneral Information...................175

Accessories and vehicle modifications .......................... 175

Vehicle storage ........................176

End-of-life vehicle recovery .....176

Vehicle checks ........................... 177

Performing work ......................177

Bonnet ..................................... 177

Engine oil ................................. 178

Engine coolant ......................... 179

Washer fluid ............................ 179

Brakes ..................................... 180

Brake fluid ............................... 180

Vehicle battery ......................... 180

Diesel fuel system bleeding .....182

Wiper blade replacement ........182

Bulb replacement .......................183

Halogen headlights ..................183

LED headlights ........................ 185

Fog lights ................................. 185

Tail lights ................................. 186

Side turn signal lights ..............189

Number plate light ...................190

Interior lights ............................ 190

Instrument panel illumination ...190Electrical system ........................190

Fuses ....................................... 190

Engine compartment fuse box . 191

Instrument panel fuse box .......193

Vehicle tools .............................. 195

Tools ........................................ 195

Wheels and tyres .......................196

Winter tyres ............................. 196

Tyre designations ....................196

Tyre pressure .......................... 197

Tyre deflation detection system .................................... 198

Tread depth ............................. 199

Changing tyre and wheel size . 199

Wheel covers ........................... 200

Tyre chains .............................. 200

Tyre repair kit .......................... 200

Wheel changing .......................203

Spare wheel ............................ 206

Jump starting ............................. 207

Towing ....................................... 209

Towing the vehicle ...................209

Towing another vehicle ...........210

Appearance care .......................211

Exterior care ............................ 211

Interior care ............................. 213General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.

Page 178 of 245

176Vehicle careCaution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 182 of 245

180Vehicle careBrakesIn the event of minimum thickness of

the brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

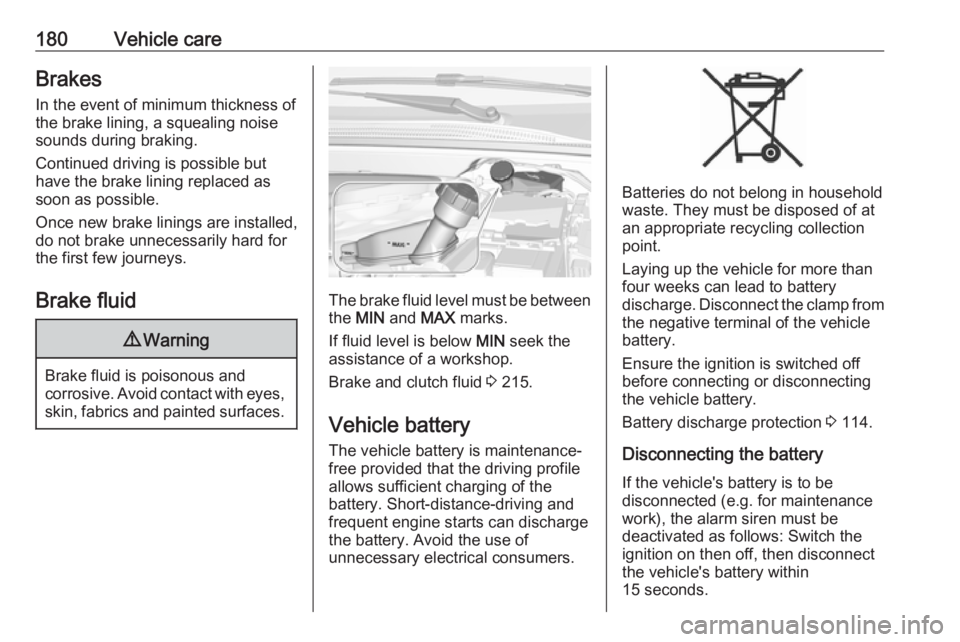

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below MIN seek the

assistance of a workshop.

Brake and clutch fluid 3 215.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Battery discharge protection 3 114.

Disconnecting the battery

If the vehicle's battery is to be

disconnected (e.g. for maintenance

work), the alarm siren must be

deactivated as follows: Switch the

ignition on then off, then disconnect

the vehicle's battery within

15 seconds.

Page 183 of 245

Vehicle care181Replacing the vehicle batteryNote

Any deviation from the instructions

given in this section may lead to

temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap,

and the ventilation in the vicinity of the negative terminal must be opened.

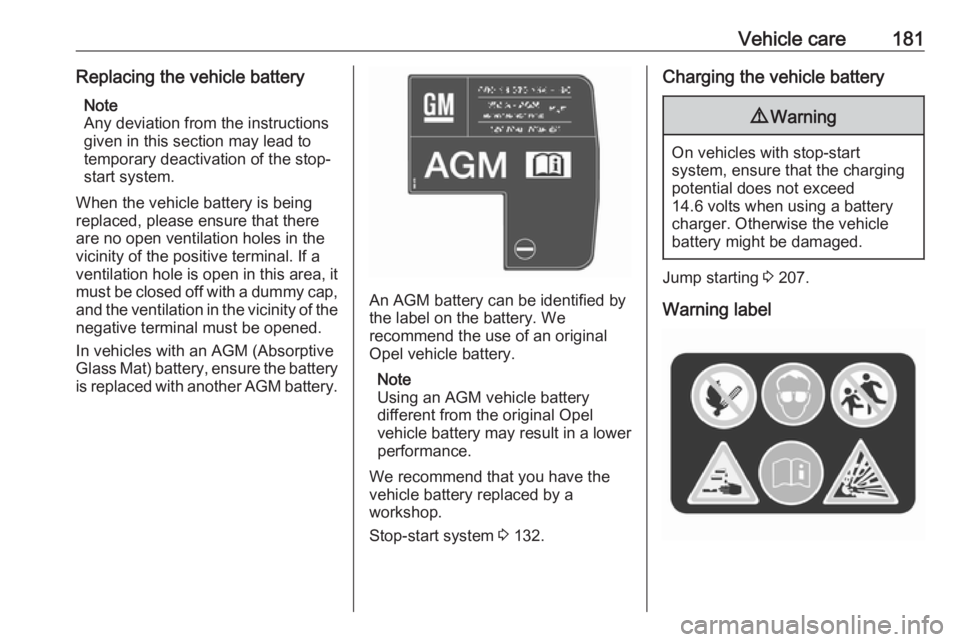

In vehicles with an AGM (Absorptive

Glass Mat) battery, ensure the battery

is replaced with another AGM battery.

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Opel vehicle battery.

Note

Using an AGM vehicle battery

different from the original Opel

vehicle battery may result in a lower performance.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 132.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 207.

Warning label

Page 184 of 245

182Vehicle careMeaning of symbols:● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding

If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

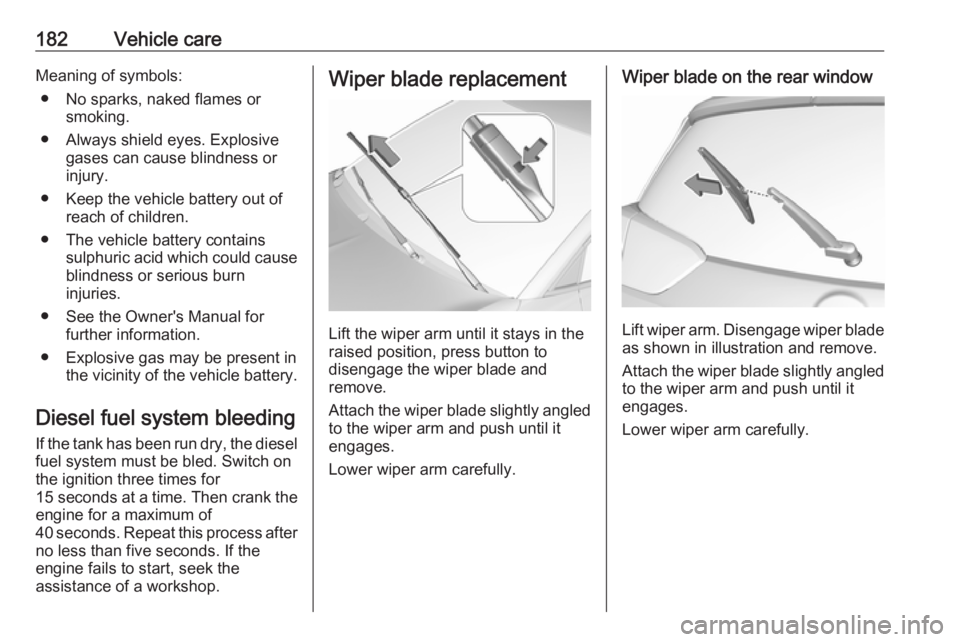

assistance of a workshop.Wiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 194 of 245

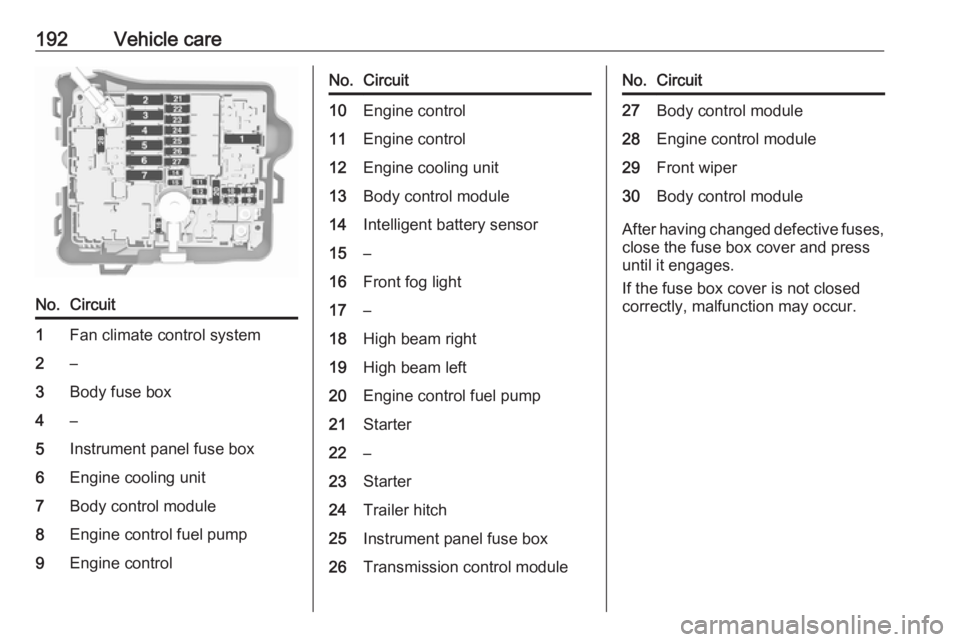

192Vehicle careNo.Circuit1Fan climate control system2–3Body fuse box4–5Instrument panel fuse box6Engine cooling unit7Body control module8Engine control fuel pump9Engine controlNo.Circuit10Engine control11Engine control12Engine cooling unit13Body control module14Intelligent battery sensor15–16Front fog light17–18High beam right19High beam left20Engine control fuel pump21Starter22–23Starter24Trailer hitch25Instrument panel fuse box26Transmission control moduleNo.Circuit27Body control module28Engine control module29Front wiper30Body control module

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 204 of 245

202Vehicle care9. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is being

inflated.

13. The prescribed tyre pressure should be obtained within ten

minutes.

Tyre pressure 3 229.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button on the air hose.

Do not run the compressor longer

than ten minutes.

14. Detach the tyre repair kit. Remove

sealant bottle from bracket. Screw the filler hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

Page 209 of 245

Vehicle care207

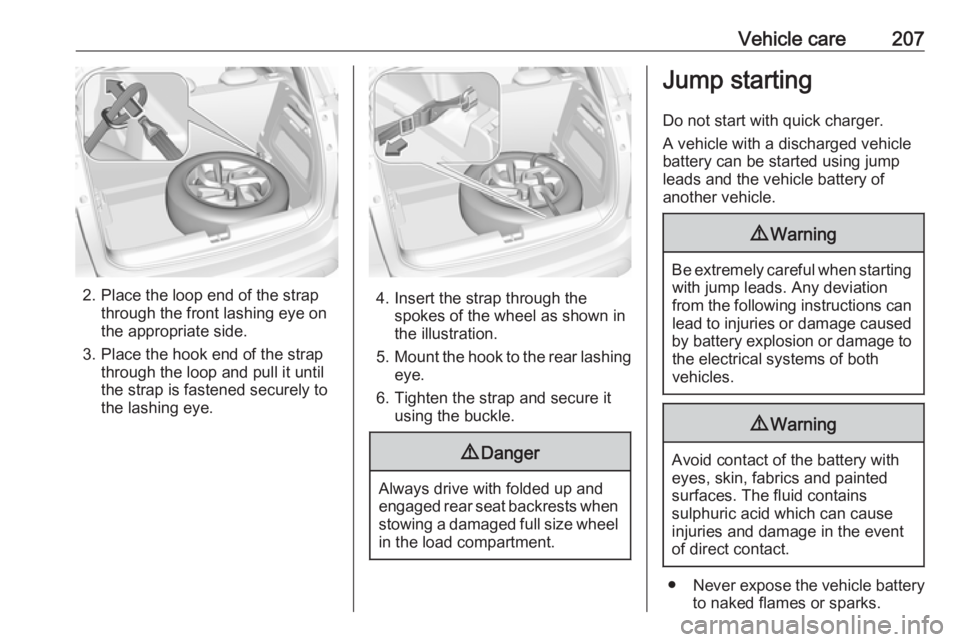

2. Place the loop end of the strapthrough the front lashing eye on

the appropriate side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear lashing

eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

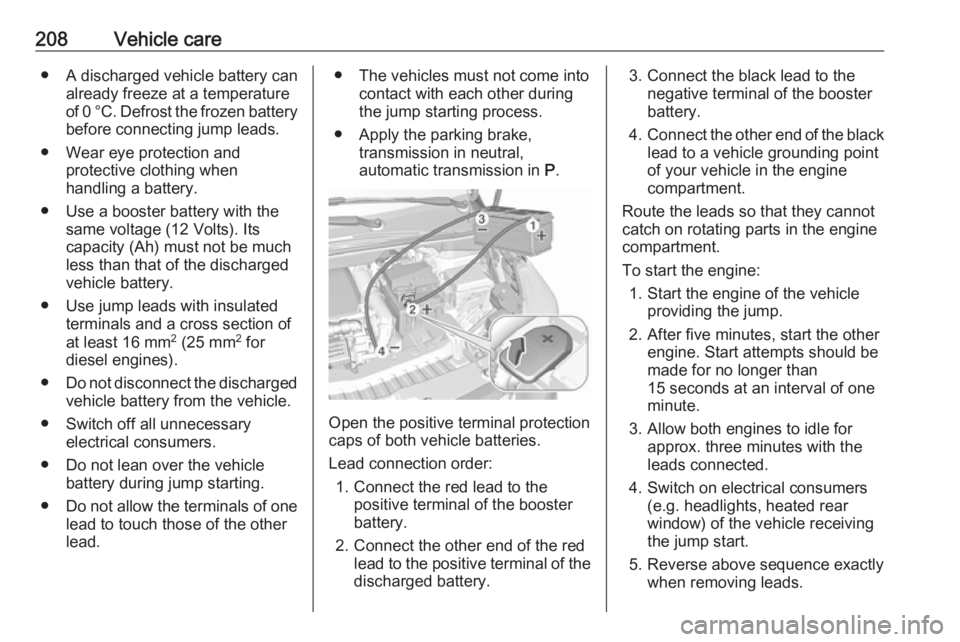

Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

Page 210 of 245

208Vehicle care● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 240 of 245

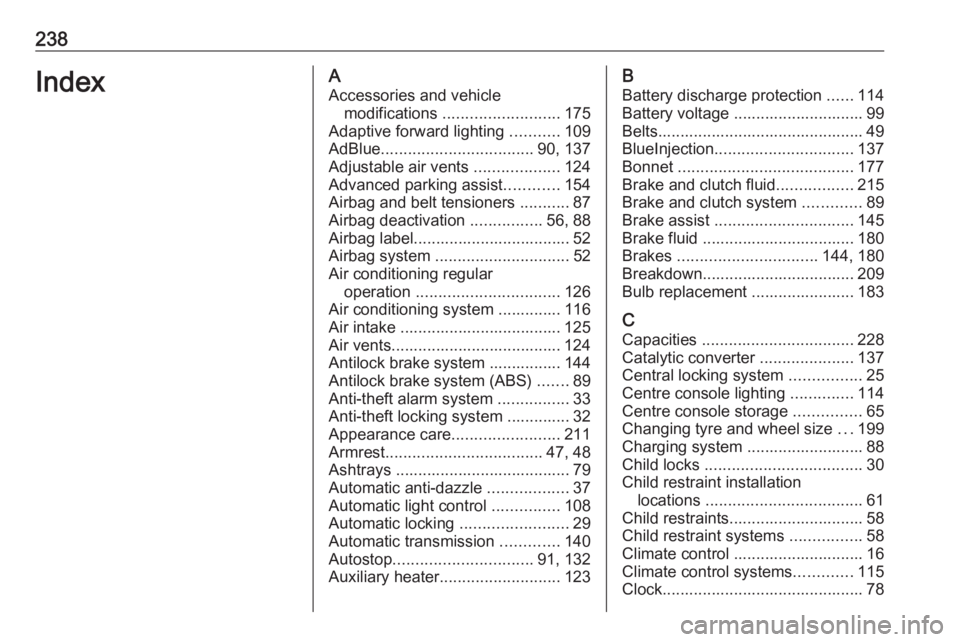

238IndexAAccessories and vehicle modifications .......................... 175

Adaptive forward lighting ...........109

AdBlue .................................. 90, 137

Adjustable air vents ...................124

Advanced parking assist ............154

Airbag and belt tensioners ...........87

Airbag deactivation ................56, 88

Airbag label................................... 52 Airbag system .............................. 52

Air conditioning regular operation ................................ 126

Air conditioning system .............. 116

Air intake .................................... 125

Air vents...................................... 124

Antilock brake system ................ 144

Antilock brake system (ABS) .......89

Anti-theft alarm system ................33

Anti-theft locking system .............. 32

Appearance care ........................211

Armrest ................................... 47, 48

Ashtrays ....................................... 79

Automatic anti-dazzle ..................37

Automatic light control ...............108

Automatic locking ........................29

Automatic transmission .............140

Autostop ............................... 91, 132

Auxiliary heater ........................... 123B

Battery discharge protection ......114

Battery voltage ............................. 99

Belts.............................................. 49

BlueInjection ............................... 137

Bonnet ....................................... 177

Brake and clutch fluid .................215

Brake and clutch system .............89

Brake assist ............................... 145

Brake fluid .................................. 180

Brakes ............................... 144, 180

Breakdown.................................. 209

Bulb replacement ....................... 183

C Capacities .................................. 228

Catalytic converter .....................137

Central locking system ................25

Centre console lighting ..............114

Centre console storage ...............65

Changing tyre and wheel size ...199

Charging system .......................... 88

Child locks ................................... 30

Child restraint installation locations ................................... 61

Child restraints.............................. 58

Child restraint systems ................58

Climate control ............................. 16

Climate control systems .............115

Clock............................................. 78